civil & structural engineering - Institution of Engineers Singapore

civil & structural engineering - Institution of Engineers Singapore

civil & structural engineering - Institution of Engineers Singapore

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

NEWS<br />

Dyneema fibre<br />

Made from UHMWPE, Dyneema fi bre is said to <strong>of</strong>fer maximum<br />

strength combined with minimum weight. It is said to be up to<br />

15 times stronger than quality steel and up to 40% stronger than<br />

aramid fi bres, both on a weight for weight basis. Dyneema fi bre<br />

fl oats on water, is durable, and is resistant to moisture, UV light<br />

and chemicals.<br />

As a result <strong>of</strong> these properties, Dyneema is fast becoming a<br />

more effective alternative to traditional materials like steel wire<br />

and synthetic rope in a wide range <strong>of</strong> industries and applications.<br />

It is used to secure very large commercial vessels; safeguard the<br />

lives <strong>of</strong> police, soldiers, and emergency workers; reduce airline<br />

fuel consumption with stronger light-weight containers; extend<br />

the lifting and towing capabilities <strong>of</strong> ocean rescue and salvage<br />

vessels; improve fi sh farm yields with stronger netting; produce<br />

gloves to protect the hands <strong>of</strong> workers in the manufacturing<br />

sector; and develop new medical devices for surgeons. In the<br />

Asia Pacifi c region, Dyneema has the following applications:<br />

• Life and vehicle protection: Incorporated into personnel<br />

protection equipment such as bullet resistant vests,<br />

helmets, and inserts, Dyneema increases ballistic<br />

performance without increasing weight, making them<br />

comfortable and safe for wearing in extreme conditions<br />

and over long periods <strong>of</strong> time. Dyneema panels<br />

in military vehicles provide added protection at low<br />

additional weight.<br />

• Commercial marine: Mooring and tugging ropes made with<br />

Dyneema help reduce mooring times, improve safety and<br />

vessel effi ciency, and cut physical workload. Commercial<br />

fi shing nets and aquaculture cages made with Dyneema are<br />

tough and resistant to wear and tear, delivering signifi cant<br />

economic and handling benefi ts to fi sh farmers.<br />

• Industrial: Ropes and lifting slings made with Dyneema are<br />

stronger and lighter than those made with traditional steel<br />

wire or synthetic materials. This contributes to greater safety,<br />

effi ciency, precision and speed for any heavy lifting operations<br />

on land or at sea.<br />

• Protective textiles: Lightweight safety gloves and garments<br />

containing Dyneema <strong>of</strong>fer higher levels <strong>of</strong> cut-protection,<br />

fl exibility and comfort. Possessing high abrasion resistance,<br />

gloves and garments can be washed and re-used several times.<br />

• Sports: Dyneema gives yachting lines, sail cloth and rigging the<br />

same strength but with up to half the weight <strong>of</strong> traditional<br />

materials. Fishing lines are easier to cast and retain their<br />

original shape. Kite lines made with Dyneema have a higher<br />

stiffness combined with low elongation, make steering easier.<br />

DSM Dyneema Asia Pacific Technical Center<br />

The DSM Dyneema Asia Pacifi c Technical Center incorporates<br />

the following:<br />

• Two ballistics ranges capable <strong>of</strong> performing a wide range <strong>of</strong><br />

small to large calibre ballistics testing for both personnel and<br />

vehicle protection applications, in accordance with various<br />

international standards.<br />

• A ‘Stab Tower’ capable <strong>of</strong> testing concepts and applications for<br />

protection against knife or spike threats, in accordance with<br />

international standards.<br />

• An environmental chamber using low and high temperatures<br />

for conditioning articles before testing.<br />

• Two large hydraulic press machines capable <strong>of</strong> producing fl at<br />

and/or curved articles using Dyneema, for the development<br />

<strong>of</strong> current and new applications.<br />

The Asia Pacifi c Technical Center is also equipped with<br />

technology which allows customers to connect with DSM<br />

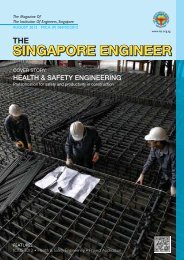

Dyneema fi bre is used in mooring ropes and lifting slings, replacing traditional<br />

materials. It ensures greater operational effi ciency and enhances safety.<br />

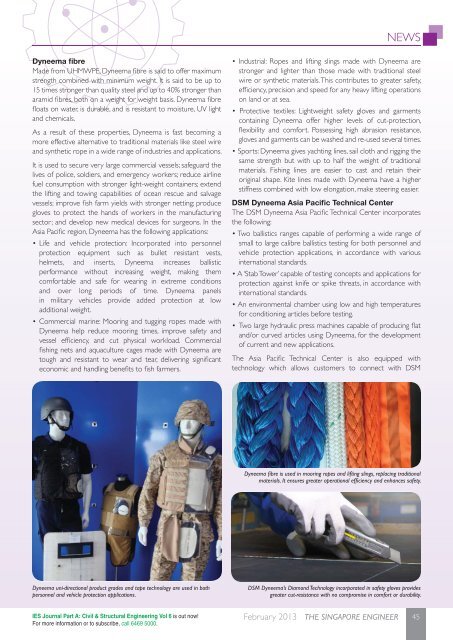

Dyneema uni-directional product grades and tape technology are used in both<br />

personnel and vehicle protection applications.<br />

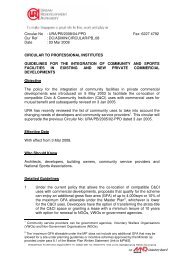

DSM Dyneema’s Diamond Technology incorporated in safety gloves provides<br />

greater cut-resistance with no compromise in comfort or durability.<br />

IES Journal Part A: Civil & Structural Engineering Vol 6 is out now!<br />

For more information or to subscribe, call 6469 5000.<br />

February 2013 THE SINGAPORE ENGINEER<br />

45