Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

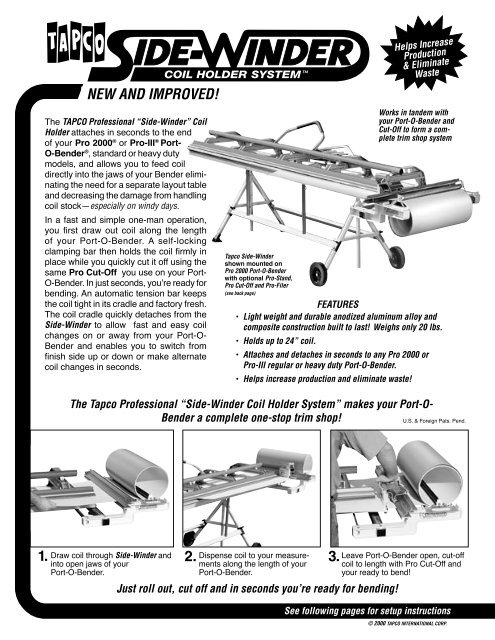

NEW AND IMPROVED!<br />

<strong>The</strong> <strong>TAPCO</strong> <strong>Professional</strong> <strong>“Side</strong>-<strong>Winder”</strong> Coil<br />

Holder attaches in seconds to the end<br />

of your Pro 2000 ® or Pro-III ® Port-<br />

O-Bender ® , standard or heavy duty<br />

models, and allows you to feed coil<br />

directly into the jaws of your Bender eliminating<br />

the need for a separate layout table<br />

and decreasing the damage from handling<br />

coil stock—especially on windy days.<br />

In a fast and simple one-man operation,<br />

you first draw out coil along the length<br />

of your Port-O-Bender. A self-locking<br />

clamping bar then holds the coil firmly in<br />

place while you quickly cut it off using the<br />

same Pro Cut-Off you use on your Port-<br />

O-Bender. In just seconds, you’re ready for<br />

bending. An automatic tension bar keeps<br />

the coil tight in its cradle and factory fresh.<br />

<strong>The</strong> coil cradle quickly detaches from the<br />

Side-Winder to allow fast and easy coil<br />

changes on or away from your Port-O-<br />

Bender and enables you to switch from<br />

finish side up or down or make alternate<br />

coil changes in seconds.<br />

Tapco Side-Winder<br />

shown mounted on<br />

Pro 2000 Port-O-Bender<br />

with optional Pro-Stand,<br />

Pro Cut-Off and Pro-Filer<br />

(see back page)<br />

FEATURES<br />

• Light weight and durable anodized aluminum alloy and<br />

composite construction built to last! Weighs only 20 lbs.<br />

• Holds up to 24” coil.<br />

• Attaches and detaches in seconds to any Pro 2000 or<br />

Pro-III regular or heavy duty Port-O-Bender.<br />

• Helps increase production and eliminate waste!<br />

Helps Increase<br />

Production<br />

& Eliminate<br />

Waste<br />

Works in tandem with<br />

your Port-O-Bender and<br />

Cut-Off to form a complete<br />

trim shop system<br />

<strong>The</strong> Tapco <strong>Professional</strong> <strong>“Side</strong>-Winder Coil Holder System” makes your Port-O-<br />

Bender a complete one-stop trim shop!<br />

U.S. & Foreign Pats. Pend.<br />

1. Draw coil through Side-Winder and<br />

into open jaws of your<br />

Port-O-Bender.<br />

2. Dispense coil to your measurements<br />

along the length of your coil to length with Pro Cut-Off and<br />

3. Leave Port-O-Bender open, cut-off<br />

Port-O-Bender.<br />

your ready to bend!<br />

Just roll out, cut off and in seconds you’re ready for bending!<br />

See following pages for setup instructions<br />

© 2000 <strong>TAPCO</strong> INTERNATIONAL CORP.

PARTS LIST<br />

10801 10802 10796<br />

10791<br />

10786<br />

10782<br />

10803<br />

10785<br />

10798<br />

10794<br />

10793<br />

10780<br />

10810<br />

10779<br />

10812<br />

10789<br />

10784<br />

10792<br />

10519<br />

10805<br />

10783<br />

10799<br />

10790<br />

10809<br />

10787<br />

10778<br />

10795<br />

10551<br />

Part No. Part Name Part No. Part Name<br />

10519 1/4-20 x 3/4” Hex Wash HD Screw<br />

10551 Back Rail Cap<br />

10777 Coil Carriage<br />

10778 Sidewinder Arm<br />

10779 Anvil Spring<br />

10780 Clamping Rail<br />

10783 Middle Support<br />

10784 Clamp Support<br />

10785 5/16-18 X 1 3/4” Shoulder Bolt<br />

10787 Front Support<br />

10789 10-24 X 3/4” Phil FL HD Type F Screw<br />

10790 Rail Clip<br />

10792 Tension Clip<br />

10795 T-Knob<br />

10799 1/4-20 X 1” Hex Wash HD Screw<br />

10805 Top Clamp/Support Vinyl<br />

10809 Nylon Spacer<br />

10810 Clamping Rail Bushing<br />

10812 Cut-Off Stop<br />

Coil Carriage Components<br />

10782 Cradle Handle<br />

10786 Cradle Roller<br />

10791 Cradle Rail<br />

10793 Roller Clip<br />

10794 Roller Spring<br />

10796 Roller Cover<br />

10798 10-24 X 3/4” Phil Pan HD Screw<br />

10801 Roller Tube Insert<br />

10802 5/16-18 X 2 1/4” Hex Bolt<br />

10803 5/16-18 Nylok Hex Nut

SIDE-WINDER® Coil Holder How<br />

to Setup and Change Coil<br />

Bender’s Back Rail<br />

Rail Clip<br />

Tension Clip<br />

Coil Cradle<br />

Rail Clip<br />

Bender’s<br />

Front Base<br />

Hinge<br />

PRO-III<br />

position<br />

PRO 2000<br />

position<br />

Locking<br />

Knob<br />

®<br />

Tension<br />

Clip<br />

2. Attach Side-Winder to your Port-O-Bender by<br />

inserting Back Rail Clip into Bender’s Back (Box)<br />

Rail and Tension Clip onto your Bender’s Front<br />

Base Hinge. Tighten Locking Knob (See fig. 1)<br />

Roller Tube<br />

1. Set up is fast and easy. First, install Tension Clip with<br />

Locking Knob onto middle support rail in correct hole position<br />

for your Bender. Do not tighten. See illustration above.<br />

Loading the Coil Cradle—<br />

U.S. & Foreign Pats. Pend.<br />

Coil Cradle<br />

Cradle Roller<br />

Roller Clip<br />

3. Remove Cradle<br />

Roller from Coil Cradle<br />

by grasping and<br />

unhooking Roller<br />

Clips at each end. To<br />

load coil finish side<br />

UP see steps 4a &<br />

4b. To<br />

load coil finish side<br />

DOWN see steps<br />

5a, 5b & 5c.<br />

Finish<br />

Side UP<br />

NOTE:<br />

Direction of<br />

Coil Material<br />

Coil<br />

Cradle<br />

4a. To load coil finish side UP, insert Coil<br />

Cradle into center of coil then attach Cradle<br />

Roller to Coil Cradle over TOP of coil.<br />

Feed coil<br />

through<br />

Clamping<br />

Rail<br />

Remove<br />

Cradle<br />

Roller<br />

Finish Side DOWN<br />

4b. Place entire assembly on Side-Winder.<br />

Feed coil through<br />

Clamping Rail<br />

5a. To load coil finish side DOWN,<br />

place Coil Cradle onto Side-Winder<br />

after removing Cradle Roller.<br />

5b. Place coil on top of Coil Cradle<br />

(Note direction of coil material).<br />

5c. Insert Cradle Roller through<br />

center of coil and attach to Roller<br />

Clips at each end of Cradle.

Great tools for the professional from <strong>TAPCO</strong><br />

TM<br />

Tapco PRO 2000 shown with<br />

optional Tapco Side-Winder,<br />

Pro-Stand, Pro Cut-Off and<br />

Tapco Kwik Square.<br />

PRO CUT-OFF<br />

Quickly safely and easily makes factory quality<br />

cuts right on your Port-O-Bender<br />

and Tapco Side-Winder<br />

<strong>The</strong> most<br />

revolutionary tool<br />

since the portable<br />

bender!<br />

®<br />

NEW!<br />

35% More<br />

Throat<br />

Depth<br />

➤<br />

19”<br />

Bends up to .030 soft aluminum,<br />

28 ga. galvanized steel, 16 oz.<br />

copper sheet and coil.<br />

<strong>TAPCO</strong> PRO-STAND<br />

Heavy Duty Deluxe<br />

Transportable Support<br />

SOLID<br />

SUPPORT AND<br />

PORTABILITY<br />

TOO!<br />

➤<br />

<br />

Maximum throat depth for<br />

expanded capabilities<br />

• Extra Wide 19” Throat Depth,<br />

35% more than any other portable<br />

bender in the industry!<br />

• Patented “Moving Pivot Hinge”<br />

increases lifting power, while<br />

eliminating marring of material.<br />

• Specifically engineered for optimum<br />

use with all Tapco accessories<br />

enabling you to do your jobs faster,<br />

easier, better.<br />

Fits all PRO-III, PRO 2000<br />

Port-O-Benders and<br />

E-Z Angle Siding Table<br />

U.S. & Foreign<br />

Pats. Pend.<br />

U.S. & Foreign Pats. Pend.<br />

• Lightweight aluminum construction built to last, also<br />

for use with Tapco Side-Winder<br />

• Hardened and captured tool steel cutting knives<br />

for safety and durability.<br />

• Pays for itself by reducing scrap and eliminating<br />

knifing damage to costly bending hinges.<br />

• Saves time and labor in scoring and breaking off<br />

material. Cuts up to .030 alum., 28 ga. gal. steel.<br />

PORT-O-SLITTER<br />

Portable precision slitting and rib forming<br />

system for use in the shop or on the job site!<br />

Slitter CUT-OFF<br />

®<br />

Slitter Cut-Off<br />

24” model<br />

Port-O-Slitter<br />

• Fast and easy height adjustments<br />

from 28” to 37”.<br />

• Heavy duty wheels handle the roughest<br />

job site terrains then convert to support pads.<br />

• Added portability on the job site.<br />

• Legs fold and remove for easy transport.<br />

Pro Filer ® and Pro Filer ® 2000*<br />

Automatic Squaring and Profile<br />

Duplicating System<br />

• For the first time ever, a tool that automatically<br />

squares and measures material fed into your<br />

Port-O-Bender. Eliminates the need to mark<br />

and snip on your coil.<br />

• Automates your production. Saves up to 50%<br />

of your layout time—the largest block of time<br />

that slows you down the most.<br />

• Also functions as a template and profile<br />

maker taking the guesswork out of making<br />

perfect shapes every time.<br />

• Turns rookies into pros in hours instead<br />

of years; makes pros more efficient.<br />

12053-LS rev 12/00<br />

®<br />

<strong>TAPCO</strong> PRODUCTS COMPANY<br />

* Pro Filer for use with the PRO-III.<br />

Pro Filer 2000 works with the expanded<br />

capabilities of the PRO 2000<br />

and MAX-I-MUM II Port-O-Benders.<br />

U.S. & Foreign Pats. Pend.<br />

A <strong>TAPCO</strong> INTERNATIONAL COMPANY<br />

45657 Port Street • Plymouth, MI 48170-6010 USA<br />

Telephone: (734) 451-8272 • Fax: (734) 451-0702<br />

Web Site: http://www.tapcoint.com<br />

Makes factory quality<br />

cross cuts right on your<br />

Port-O-Slitter. Saves time,<br />

increases production.<br />

(optional)<br />

Saves<br />

3-4 hours<br />

on most<br />

jobs!<br />

U.S. & Foreign<br />

Pats. Pend.<br />

PRO-Coiler<br />

Coil Holder<br />

(optional)<br />

Port-O-Slitter Stand with PRO-Coiler<br />

• Feeds coil directly into your<br />

Port-O-Slitter, adjustable heights.<br />

• Pro-Coiler holds up to 24” x 100’ coil.<br />

Adjustable Port-O-Slitter<br />

Stand<br />

(optional)<br />

<strong>TAPCO</strong> PORT-O-SLITTER FEATURES<br />

• Slitters come with two sets of cutting knives to make single<br />

or multiple factory quality cuts in aluminum, steel, galvanized<br />

steel, stainless steel, vinyl, clad metals, paper and<br />

some textiles. (Ask your distributor for details.)<br />

• Forms strengthening ribs and perforates (optional)<br />

most materials.<br />

• Saves 3-4 hours on most jobs.<br />

• Motor kit available in 110v or 220v. Saves even more time!<br />

• 24” Port-O-Slitter weighs only 60 lbs.<br />

©2000