Exterior painting of Enclave compound building, American Embassy

Exterior painting of Enclave compound building, American Embassy

Exterior painting of Enclave compound building, American Embassy

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

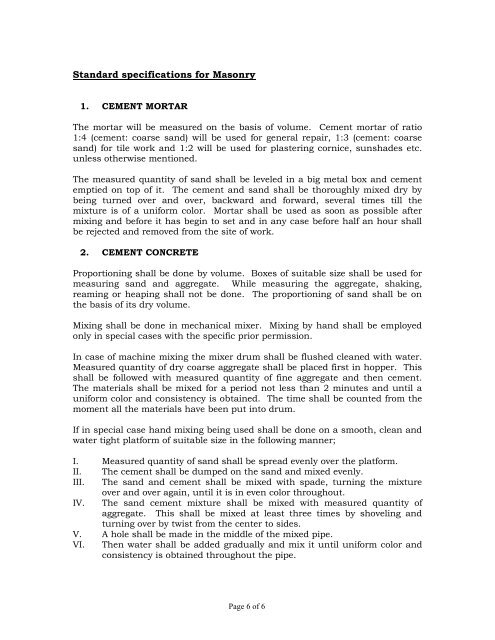

Standard specifications for Masonry<br />

1. CEMENT MORTAR<br />

The mortar will be measured on the basis <strong>of</strong> volume. Cement mortar <strong>of</strong> ratio<br />

1:4 (cement: coarse sand) will be used for general repair, 1:3 (cement: coarse<br />

sand) for tile work and 1:2 will be used for plastering cornice, sunshades etc.<br />

unless otherwise mentioned.<br />

The measured quantity <strong>of</strong> sand shall be leveled in a big metal box and cement<br />

emptied on top <strong>of</strong> it. The cement and sand shall be thoroughly mixed dry by<br />

being turned over and over, backward and forward, several times till the<br />

mixture is <strong>of</strong> a uniform color. Mortar shall be used as soon as possible after<br />

mixing and before it has begin to set and in any case before half an hour shall<br />

be rejected and removed from the site <strong>of</strong> work.<br />

2. CEMENT CONCRETE<br />

Proportioning shall be done by volume. Boxes <strong>of</strong> suitable size shall be used for<br />

measuring sand and aggregate. While measuring the aggregate, shaking,<br />

reaming or heaping shall not be done. The proportioning <strong>of</strong> sand shall be on<br />

the basis <strong>of</strong> its dry volume.<br />

Mixing shall be done in mechanical mixer. Mixing by hand shall be employed<br />

only in special cases with the specific prior permission.<br />

In case <strong>of</strong> machine mixing the mixer drum shall be flushed cleaned with water.<br />

Measured quantity <strong>of</strong> dry coarse aggregate shall be placed first in hopper. This<br />

shall be followed with measured quantity <strong>of</strong> fine aggregate and then cement.<br />

The materials shall be mixed for a period not less than 2 minutes and until a<br />

uniform color and consistency is obtained. The time shall be counted from the<br />

moment all the materials have been put into drum.<br />

If in special case hand mixing being used shall be done on a smooth, clean and<br />

water tight platform <strong>of</strong> suitable size in the following manner;<br />

I. Measured quantity <strong>of</strong> sand shall be spread evenly over the platform.<br />

II. The cement shall be dumped on the sand and mixed evenly.<br />

III. The sand and cement shall be mixed with spade, turning the mixture<br />

over and over again, until it is in even color throughout.<br />

IV. The sand cement mixture shall be mixed with measured quantity <strong>of</strong><br />

aggregate. This shall be mixed at least three times by shoveling and<br />

turning over by twist from the center to sides.<br />

V. A hole shall be made in the middle <strong>of</strong> the mixed pipe.<br />

VI. Then water shall be added gradually and mix it until uniform color and<br />

consistency is obtained throughout the pipe.<br />

Page 6 <strong>of</strong> 6