Baymod A 52 e - LANXESS

Baymod A 52 e - LANXESS

Baymod A 52 e - LANXESS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Storage<br />

<strong>Baymod</strong> A <strong>52</strong> keeps for at least 2 years if<br />

stored in a cool, dry place and protected from<br />

light.<br />

Packaging<br />

Paper bag, capacity 15 kg<br />

Pallet size: 50 bags, 750 kg<br />

These raw material properties are typical properties and, unless specifically indicated<br />

otherwise, are not to be considered as delivery specification.<br />

1. Use of <strong>Baymod</strong> A <strong>52</strong> as an impact<br />

modifier in rigid PVC<br />

Processing and compound properties<br />

Blends of PVC and <strong>Baymod</strong> A <strong>52</strong> are prepared<br />

and processed by the usual methods employed<br />

for PVC. Processing aids are necessary, the<br />

usual combinations of stabilisers and lubricants<br />

being suitable.<br />

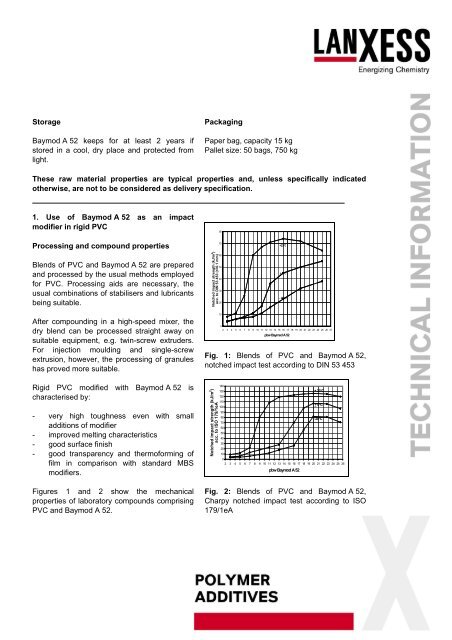

Notched impact strength (kJ/m 2 )<br />

acc. to DIN 53 453 (r=0.1 mm)<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

+23°C<br />

+ 0°C<br />

- 20°C<br />

After compounding in a high-speed mixer, the<br />

dry blend can be processed straight away on<br />

suitable equipment, e.g. twin-screw extruders.<br />

For injection moulding and single-screw<br />

extrusion, however, the processing of granules<br />

has proved more suitable.<br />

Rigid PVC modified with <strong>Baymod</strong> A <strong>52</strong> is<br />

characterised by:<br />

- very high toughness even with small<br />

additions of modifier<br />

- improved melting characteristics<br />

- good surface finish<br />

- good transparency and thermoforming of<br />

film in comparison with standard MBS<br />

modifiers.<br />

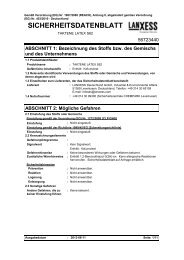

Figures 1 and 2 show the mechanical<br />

properties of laboratory compounds comprising<br />

PVC and <strong>Baymod</strong> A <strong>52</strong>.<br />

10<br />

0<br />

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27<br />

pbw <strong>Baymod</strong> A <strong>52</strong><br />

Fig. 1: Blends of PVC and <strong>Baymod</strong> A <strong>52</strong>,<br />

notched impact test according to DIN 53 453<br />

Notched impact strength (kJ/m 2 )<br />

acc. to ISO 179/1eA<br />

140<br />

130<br />

+ 23°C<br />

120<br />

110<br />

+ 0°C<br />

100<br />

90<br />

80<br />

-20°C<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26<br />

pbw <strong>Baymod</strong> A <strong>52</strong><br />

Fig. 2: Blends of PVC and <strong>Baymod</strong> A <strong>52</strong>,<br />

Charpy notched impact test according to ISO<br />

179/1eA<br />

Technical Information<br />

2008-05-26, Page 2 of 4