Chapter 2 Review of Forces and Moments - Brown University

Chapter 2 Review of Forces and Moments - Brown University

Chapter 2 Review of Forces and Moments - Brown University

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

When we do engineering calculations involving friction forces, we always want to calculate the forces<br />

that will cause the two contacting surfaces to slip. Sometimes (e.g. when we design moving machinery)<br />

we are trying to calculate the forces that are needed to overcome friction <strong>and</strong> keep the parts moving.<br />

Sometimes (e.g. when we design self-locking joints) we need to check whether the contact can safely<br />

support tangential force without sliding.<br />

2.5.1 Experimental measurement <strong>of</strong> friction forces<br />

To do both these calculations, we need to know how to determine the critical tangential forces that cause<br />

contacting surfaces to slip. The critical force must be determined experimentally. Leonardo da Vinci was<br />

apparently the first person to do this – his experiments were repeated by Amontons <strong>and</strong> Coulomb about<br />

100 years later. We now refer to the formulas that predict friction forces as Coulomb’s law or Amonton’s<br />

law (you can choose which you prefer!).<br />

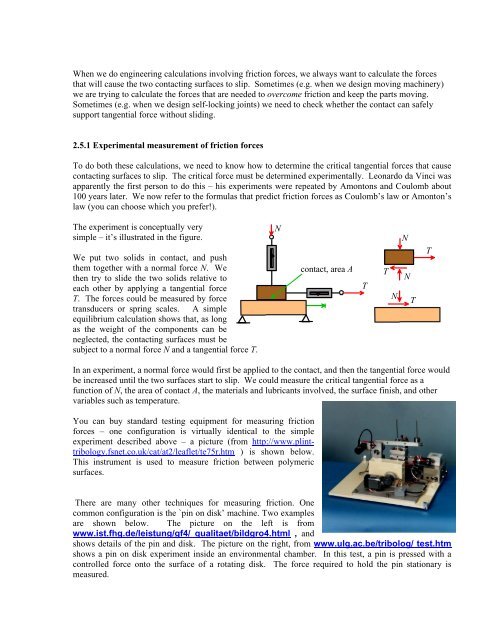

The experiment is conceptually very<br />

simple – it’s illustrated in the figure.<br />

We put two solids in contact, <strong>and</strong> push<br />

them together with a normal force N. We<br />

then try to slide the two solids relative to<br />

each other by applying a tangential force<br />

T. The forces could be measured by force<br />

transducers or spring scales. A simple<br />

equilibrium calculation shows that, as long<br />

as the weight <strong>of</strong> the components can be<br />

neglected, the contacting surfaces must be<br />

subject to a normal force N <strong>and</strong> a tangential force T.<br />

N<br />

contact, area A<br />

T<br />

N<br />

T<br />

N<br />

N<br />

T<br />

T<br />

In an experiment, a normal force would first be applied to the contact, <strong>and</strong> then the tangential force would<br />

be increased until the two surfaces start to slip. We could measure the critical tangential force as a<br />

function <strong>of</strong> N, the area <strong>of</strong> contact A, the materials <strong>and</strong> lubricants involved, the surface finish, <strong>and</strong> other<br />

variables such as temperature.<br />

You can buy st<strong>and</strong>ard testing equipment for measuring friction<br />

forces – one configuration is virtually identical to the simple<br />

experiment described above – a picture (from http://www.plinttribology.fsnet.co.uk/cat/at2/leaflet/te75r.htm<br />

) is shown below.<br />

This instrument is used to measure friction between polymeric<br />

surfaces.<br />

There are many other techniques for measuring friction. One<br />

common configuration is the `pin on disk’ machine. Two examples<br />

are shown below. The picture on the left is from<br />

www.ist.fhg.de/leistung/gf4/ qualitaet/bildgro4.html , <strong>and</strong><br />

shows details <strong>of</strong> the pin <strong>and</strong> disk. The picture on the right, from www.ulg.ac.be/tribolog/ test.htm<br />

shows a pin on disk experiment inside an environmental chamber. In this test, a pin is pressed with a<br />

controlled force onto the surface <strong>of</strong> a rotating disk. The force required to hold the pin stationary is<br />

measured.