Perfect silicon disks - BASF.com

Perfect silicon disks - BASF.com

Perfect silicon disks - BASF.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Science around us<br />

A news service provided by <strong>BASF</strong><br />

<strong>Perfect</strong> <strong>silicon</strong> <strong>disks</strong><br />

Microchip manufacturers rely on high purity <strong>BASF</strong> chemicals<br />

February 10, 2005<br />

P 104e<br />

contact<br />

Christian Böhme<br />

Corporate Media Relations<br />

phone +49(0)621 60-20130<br />

fax +49(0)621 60-92693<br />

christian.boehme@basf-ag.de<br />

Modern <strong>com</strong>puters have little room to spare, with as many as a billion transistors<br />

per square centimeter jostling for position on their processors and memory chips.<br />

Imagine the entire population of India holidaying in Washington DC and you’ll have<br />

some idea of the density. What makes it possible is that transistors are so small.<br />

And that, in fact, is the biggest problem in their production. Circuits this tiny can be<br />

paralyzed by a particle smaller than a flu virus. A single misplaced atom may render<br />

a chip useless.<br />

Microchip production is <strong>com</strong>plicated. More than 600 working steps are required to<br />

turn the raw material, quartz sand, into a modern processor. Most of these steps<br />

require the use of special chemicals, for example to clean and etch <strong>silicon</strong> chips.<br />

“<strong>BASF</strong> is a leading manufacturer of electronic chemicals,” says Claus Poppe,<br />

Director Global Business Management for Electronic Chemicals. “At least one<br />

<strong>BASF</strong> product was used in the production of any microchip manufactured today.”<br />

The Story<br />

A single particle of dust is one too many:<br />

<strong>BASF</strong> experts test chemicals for microchip<br />

manufacture in special clean room<br />

labs.<br />

The first step is to get <strong>silicon</strong> (the building material for most microchips) from simple<br />

quartz sand. To clean the “dirty” <strong>silicon</strong> produced, technicians convert it to trichlorosilane<br />

using hydrogen chloride. This clear liquid is easily purified by multiple distillations.<br />

The much cleaner <strong>silicon</strong> emerging from this process is ready for the next<br />

step, in which specialists use the Czochralski method (see info box) to grow<br />

impressive shiny silver crystals up to two meters tall with a perfect interior structure.<br />

Special saws cut these crystals into paper-thin wafers that form the basis of microchip<br />

production, but they need to be smoothed down first and polished to a shine.<br />

Again, a number of high-purity <strong>BASF</strong> chemicals such as nitric acid, sulfuric acid<br />

and hydrochloric acid are used for the polishing and cleaning process. The finished<br />

wafers are round <strong>disks</strong> measuring up to 30 centimeters across. Their surface has to<br />

be absolutely perfect with no irregularities larger than a couple of nanometers – if<br />

they were the size of a football pitch, this would mean no bumps larger than onetenth<br />

of a millimeter.<br />

Basis of each microchip: The paper-thin<br />

wafer is smoothed down and polished<br />

to a shine with high-purity chemicals.<br />

Text, photography and illustration are available at:<br />

www.basf.de/science_around_us<br />

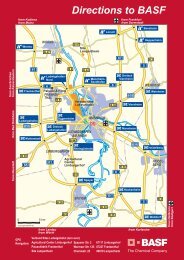

<strong>BASF</strong> Aktiengesellschaft<br />

67056 Ludwigshafen, Germany<br />

Telephone +49(0)621 60-0<br />

Telefax +49(0)621 60-20129<br />

http://www.basf.de<br />

E-Mail: presse.kontakt@basf-ag.de

Science around us<br />

A news service provided by <strong>BASF</strong><br />

<strong>Perfect</strong> <strong>silicon</strong> <strong>disks</strong><br />

Microchip manufacturers rely on high purity <strong>BASF</strong> chemicals<br />

Christian Böhme<br />

Corporate Media Relations<br />

phone +49(0)621 60-20130<br />

P 104e<br />

When <strong>com</strong>puters were first produced, technicians were able to solder transistors by hand.<br />

Today’s tiny circuits call for a different technique. The modern technology for etching transistors<br />

onto wafers is called photolithography. In this process, specialists first apply a barrier<br />

layer to the <strong>silicon</strong> which they illuminate using a mask. The layer dissolves at the sites<br />

exposed to light and the underlying <strong>silicon</strong> layer is etched. Chip manufacturers treat the<br />

etched locations with chemicals and repeat the process a number of times, building up<br />

transistors layer by layer, like building houses from layers of blocks.<br />

Finished transistors will not work if more than one atom out of a million is faulty. But dirt is<br />

everywhere. Metal devices invariably give off unwanted atoms. Humans transmit impurities<br />

by a mere touch or breath. That’s not counting the approximately half a billion particles of<br />

dust floating around a normal room. For this reason every step of chip manufacture takes<br />

place in pristine working areas where all the furnishings are plastic and filters are installed<br />

to remove the last particle of dust from the ambient air. Anyone entering these facilities<br />

must wear a full set of protective gear including gloves and a face mask.<br />

“Finished microchips must be absolutely free of contaminants, so the chemicals that are<br />

used in their manufacture have to be extremely pure,” explains Dr. Karl-Rudolf Kurtz, head<br />

of <strong>BASF</strong>’s Electronic Materials business unit. “<strong>BASF</strong> currently supplies around 30 chemicals<br />

of electronic grade purity.” <strong>BASF</strong> is equipped with cleanroom labs to check the chemicals’<br />

purity before they are delivered to chip manufacturers. “We have the technology to detect<br />

impurities in trace amounts of less than one microgram per tonne of product. That’s like a<br />

needle in 100,000 haystacks. Detecting tiny concentrations of these magnitudes is only<br />

possible with state of the art spectrometry.”

Science around us<br />

A news service provided by <strong>BASF</strong><br />

<strong>Perfect</strong> <strong>silicon</strong> <strong>disks</strong><br />

Microchip manufacturers rely on high purity <strong>BASF</strong> chemicals<br />

Christian Böhme<br />

Corporate Media Relations<br />

phone +49(0)621 60-20130<br />

P 104e<br />

Gordon Moore, co-founder of Intel, worked out a hypothesis in 1965 based on his observations<br />

of the market. He predicted that the number of transistors per unit of surface area<br />

would double every year as microchip technology progressed. Moore’s law basically still<br />

applies to this day, with transistors getting smaller and smaller all the time. For as long as<br />

the trend still holds, the quality of electronic chemicals must continue to rise.<br />

The Prospects<br />

<strong>BASF</strong> is a leading supplier of chemicals to the semiconductor industry. The global<br />

electronic chemical business acquired from Merck KGaA at the start of 2005 will significantly<br />

strengthen <strong>BASF</strong>’s market position. Electronic chemicals distribution is organized in a<br />

global business management system for easier ordering and shorter delivery times. <strong>BASF</strong><br />

was conferred the UK gas supplier BOC Edwards’ Supplier Quality Award for the reliability<br />

and quality of its electronic gases hydrogen chloride and ammonia. <strong>BASF</strong> is also the world’s<br />

only supplier of hydroxylamine free base, a highly active solvent for cleaning microchips.<br />

The Graphics

Science around us<br />

A news service provided by <strong>BASF</strong><br />

<strong>Perfect</strong> <strong>silicon</strong> <strong>disks</strong><br />

Microchip manufacturers rely on high purity <strong>BASF</strong> chemicals<br />

Christian Böhme<br />

Corporate Media Relations<br />

phone +49(0)621 60-20130<br />

P 104e<br />

From beach sand to <strong>com</strong>puter chip<br />

The Info Box<br />

Silicon (from the Latin silex meaning ‘flint’) is the second most abundant element in<br />

the earth’s crust after oxygen and is contained in most minerals. Elemental <strong>silicon</strong> is a<br />

semiconductor. Its electronic properties can be modified in a targeted fashion by<br />

introducing foreign atoms, a process called doping. Silicon is widely used in microelectronics<br />

and solar cell technology.<br />

The Czochralski method is the technology used to grow the large crystals required<br />

in the chip industry. A tiny but perfectly formed crystal is immersed in a melted purified<br />

<strong>silicon</strong> bath that is only slightly warmer than the melting point. If the crystal is removed<br />

from the molten <strong>silicon</strong> carefully enough, <strong>silicon</strong> atoms will remain attached. The attached<br />

atoms align themselves precisely to the structure of the little seed crystal. The<br />

process results in the growth of ideal monocrystals up to two meters tall. The method<br />

was named after the Polish scientist Jan Czochralski who discovered it by serendipity<br />

in 1916 after accidentally dipping his quill into a tub of molten metal instead of an inkpot.<br />

Hydroxylamine is a colorless crystalline <strong>com</strong>pound produced from nitrates and<br />

hydrogen. <strong>BASF</strong> is the world’s only supplier of pure hydroxylamine in the form of a<br />

50 percent aqueous solution. The 7,000 tonne production capacity in Ludwigshafen is<br />

enough to supply the entire global microchip industry, where the <strong>com</strong>pound is used to<br />

clean chips after etching.<br />

Transistors switch an electric current on or off between two connectors, depending<br />

on the voltage applied to a third connector attached to the respective transistor. They<br />

can also increase the flow of current. Silicon-based microchip transistors are very fast<br />

switchers, economical and tiny. Modern <strong>com</strong>puters could not have been developed<br />

without them.<br />

Further information can be found at:<br />

http://www.intel.<strong>com</strong>/pressroom/kits/manufacturing/making_a_chip_bkgrnd.htm<br />

http://www.siltronic.<strong>com</strong>/internet/webcache/de_DE/Products/Poster_2004.pdf<br />

http://en.wikipedia.org/wiki/Microprocessor<br />

Text, photography and illustration are available at:<br />

www.basf.de/science_around_us<br />

Links to third-party sites (“hyperlinks”)<br />

do not constitute an endorsement of<br />

such third-party sites by <strong>BASF</strong> and<br />

<strong>BASF</strong> is not responsible for the availability<br />

of these sites or their contents.<br />

The hyperlinking to these sites is at<br />

the user’s own risk.