the profilers 01-2009 - Greiner Extrusions Technik

the profilers 01-2009 - Greiner Extrusions Technik

the profilers 01-2009 - Greiner Extrusions Technik

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Information oF <strong>Greiner</strong> Extrusion<br />

PRODUCTION<br />

COMPETENCE<br />

1/<strong>2009</strong><br />

Edition 3<br />

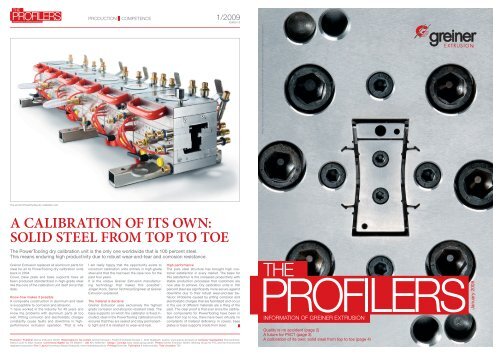

Photo: This product is <strong>the</strong> registered property of CHIALI PROFIPLAST with brand and patent registered or applied for.<br />

The six-fold PowerTooling dry calibration unit.<br />

A CALIBRATION OF ITS OWN:<br />

SOLID STEEL FROM TOP TO TOE<br />

The PowerTooling dry calibration unit is <strong>the</strong> only one worldwide that is 100 percent steel.<br />

This means enduring high productivity due to robust wear-and-tear and corrosion resistance.<br />

<strong>Greiner</strong> Extrusion replaced all aluminum parts for<br />

steel for all its PowerTooling dry calibration units<br />

back in 2004.<br />

Cover, base plate and base supports have all<br />

been produced standardized in high-grade steel<br />

like <strong>the</strong> core of <strong>the</strong> calibration unit itself since that<br />

date.<br />

Know-how makes it possible<br />

A composite construction in aluminum and steel<br />

is susceptible to corrosion and abrasion.<br />

“I have worked in <strong>the</strong> industry for 40 years and<br />

know <strong>the</strong> problems with aluminum parts all too<br />

well. Pitting corrosion and electrostatic charges<br />

constantly cause faults and downtime in highperformance<br />

extrusion operation. That is why<br />

I am really happy that <strong>the</strong> opportunity exists to<br />

construct calibration units entirely in high-grade<br />

steel and that this has been <strong>the</strong> case now for <strong>the</strong><br />

past four years.<br />

It is <strong>the</strong> unique <strong>Greiner</strong> Extrusion manufacturing<br />

technology that makes this possible”,<br />

Jürgen Kock, Senior Technical Engineer at <strong>Greiner</strong><br />

Extrusion explained.<br />

The material is decisive<br />

<strong>Greiner</strong> Extrusion uses exclusively <strong>the</strong> highest<br />

grade corrosion and abrasion resistant steel. The<br />

base supports on which <strong>the</strong> calibrator is fixed included;<br />

steel in <strong>the</strong> PowerTooling calibration units<br />

ensures that <strong>the</strong>y are sealed and stay permanently<br />

tight and it is resistant to wear-and-tear.<br />

High performance<br />

The pure steel structure has brought high customer<br />

satisfaction in every market. The basis for<br />

this satisfaction is <strong>the</strong> increased productivity with<br />

stable production processes that customers are<br />

now able to achieve. Dry calibration units in 100<br />

percent steel are significantly more secure against<br />

downtime due to <strong>the</strong>ir robust wear-and-tear behavior.<br />

Problems caused by pitting corrosion and<br />

electrostatic charges that are facilitated and occur<br />

in <strong>the</strong> use of different materials are a thing of <strong>the</strong><br />

past. The clear proof is that ever since <strong>the</strong> calibration<br />

components for PowerTooling have been in<br />

steel from top to toe, <strong>the</strong>re have been virtually no<br />

complaints of material deficiency in covers, base<br />

plates or base supports made from steel.<br />

Proprietor / Publisher <strong>Greiner</strong> Extrusion GmbH Responsible for <strong>the</strong> content <strong>Greiner</strong> Extrusion, Friedrich-Schiedel-Strasse 1, 4542 Nussbach, Austria, www.greiner-extrusion.at Company headquarters Krems münster,<br />

District court of Steyr, Austria Commercial register no. FN 285487 i UID ATU 62967347 Design / Concept seso media group gmbh Photos <strong>Greiner</strong> Extrusion GmbH, Working Group for PVC and <strong>the</strong> Environment<br />

registered association Text / Layout Kommhaus Media Enterprise, www.mediaenterprise.at Printing Bösmüller Publication 6 times annually Total circulation 750<br />

Information OF <strong>Greiner</strong> Extrusion<br />

Quality is no accident (page 2)<br />

A future for PVC? (page 3)<br />

A calibration of its own: solid steel from top to toe (page 4)<br />

January <strong>2009</strong>

Information oF <strong>Greiner</strong> Extrusion<br />

1/<strong>2009</strong><br />

1/<strong>2009</strong><br />

Edition 3<br />

focus quality INSIDE PARTNERSHIP<br />

Edition 3<br />

Information oF <strong>Greiner</strong> Extrusion<br />

WHAT IS<br />

QUALITY<br />

Dear Business Partner,<br />

“The ordinary gives <strong>the</strong> world its existence, <strong>the</strong> extraordinary<br />

its value.”<br />

oscar Wilde<br />

There is no question about where we stand at<br />

<strong>Greiner</strong> Extrusion and how we want to be seen.<br />

Our goal is to offer you <strong>the</strong> right profile extrusion<br />

solution by providing an extraordinary service.<br />

Our services will enable you to produce top quality<br />

products with full process security.<br />

Fulfilling your requirements is how we see quality;<br />

providing you with <strong>the</strong> reliability of stable production<br />

conditions through our services and putting<br />

absolute high-performance at your finger tips if<br />

this is what you want – with our tailored solutions<br />

for profile extrusion.<br />

Quality is no accident. Intelligence and willpower<br />

are needed for this. In <strong>the</strong> case of an intelligent<br />

solution <strong>the</strong> price is never <strong>the</strong> most important<br />

issue. What matters is that it pays off. Because<br />

<strong>the</strong>re is scarcely anything to be had in this world<br />

of ours that someone else will not be able to make<br />

a great deal worse for a little less money.<br />

Our aim, however, is to see to it that our business<br />

partners only get <strong>the</strong> finest quality. This is<br />

why we continue to develop our highly functional<br />

services and work constantly on innovation. Your<br />

success, your process security and manufacturing<br />

quality give us our drive. And that is what<br />

quality means to us.<br />

Best wishes,<br />

Yours,<br />

Robert Grieshofer<br />

CEO<br />

QUALITY<br />

IS NO ACCIDENT<br />

Checking processes and tolerances assures continuous high reliability.<br />

Perfectly coordinated extrusion tooling and machines<br />

are of vital importance for an optimal extrusion<br />

process. Continuous quality management<br />

(QM) assures a permanent equal standard for <strong>the</strong><br />

products that are delivered.<br />

“Our production is not mass production. With our<br />

individually tailored tooling, systematic control<br />

methods ensure that quality is not something that<br />

happens by a lucky chance, but it is <strong>the</strong> result of<br />

processes that are fully under control”, Norbert<br />

Freund, head of QM at <strong>Greiner</strong> Extrusion said.<br />

Check lists and documentation<br />

<strong>Greiner</strong> Extrusion maintains its own department<br />

for <strong>the</strong> assurance and management of product<br />

quality with a staff of three and has done so for<br />

<strong>the</strong> past five years.<br />

The tasks of this department include supporting<br />

quality thinking among <strong>the</strong> employees, <strong>the</strong> processing<br />

of complaints as well as checking goods<br />

on both issue and arrival. Extensive check list<br />

and photo documentation assures that all tooling<br />

and machinery is in perfect order on issue for<br />

delivery.<br />

“When our products permanently meet <strong>the</strong> requirements<br />

of our customers – that is <strong>the</strong> point<br />

when we can begin to talk about quality”, Norbert<br />

Freund said.<br />

In step with practice and totally efficient<br />

QM means more than simply assuring quality. It<br />

comprises <strong>the</strong> whole issue of evaluating and optimizing<br />

current working processes, responsibilities<br />

and <strong>the</strong> clarity of digital documentation. The<br />

analysis and causal research of faults, getting rid<br />

of all fault sources and streng<strong>the</strong>ning of quality<br />

consciousness are among <strong>the</strong> QM tasks.<br />

All employees have <strong>the</strong> opportunity to participate<br />

in regular group discussions on quality assurance<br />

measures, in our quality circles. What this<br />

does is it changes <strong>the</strong> people affected into active<br />

participants in <strong>the</strong> quality process while motivating<br />

<strong>the</strong>m to take part in bringing all our efforts<br />

in line with real current practice. The experience<br />

and <strong>the</strong> suggestions our people bring in are valuable<br />

support.<br />

Fast start-up<br />

When <strong>the</strong> coordination process has been completed<br />

<strong>the</strong> finished product must cover all tolerances<br />

to ensure that customer acceptance can<br />

be swiftly and efficiently carried out. Success is<br />

<strong>the</strong> confirmation of <strong>the</strong> effort put in by <strong>the</strong> QM<br />

employees. Complaints have been cut down to a<br />

minimum, product reliability and process security<br />

boosted and <strong>the</strong> time taken for a start-up process<br />

minimized.<br />

Extensive check lists and photo documentation assures that <strong>the</strong> tooling is in a thoroughly satisfactory condition in <strong>the</strong> course of <strong>the</strong><br />

goods issue controlling.<br />

Service<br />

and more<br />

The Service Department<br />

intensifies its technical consulting.<br />

Process engineer Oliver Schürrer was been appointed<br />

a technical customer consultant in October<br />

reinforcing <strong>the</strong> Service Department that was<br />

set up five years ago. His tasks include <strong>the</strong> expert<br />

appraisal, coordination of repair work and <strong>the</strong> general<br />

overhauling of tooling toge<strong>the</strong>r with <strong>the</strong> planning<br />

of technician assignments. The enthusiastic<br />

Oliver Schürrer, a senior technician with many years experience abroad.<br />

mountain biker has been in <strong>the</strong> company for ten<br />

years and has completed <strong>the</strong> demanding company<br />

internal technical training course. <strong>Greiner</strong> Extrusion<br />

uses DigiOM, <strong>the</strong> digital system for <strong>the</strong> documentation<br />

and optimization in tooling production for <strong>the</strong><br />

replacement, repair and <strong>the</strong> general overhauling of<br />

tooling. This system available exclusively to <strong>Greiner</strong><br />

Extrusion customers has <strong>the</strong> benefit of making<br />

traceability and <strong>the</strong> exchange of information in <strong>the</strong><br />

renewal and repair of tooling easier.<br />

a future for PVC?<br />

Sustainability is <strong>the</strong> decisive issue.<br />

PVC is not only one of <strong>the</strong> most important plastics;<br />

it is also one of <strong>the</strong> most controversial. PVC expert<br />

Werner Preusker states his view and provides perspectives<br />

for PVC in this interview.<br />

What does <strong>the</strong> future hold for PVC?<br />

Preusker: PVC has a positive outlook for <strong>the</strong> future<br />

thanks to its versatility. What <strong>the</strong> future holds is to<br />

a great extent dependent on efforts in <strong>the</strong> industry<br />

too and how successful it is in making PVC a more<br />

sustainable material. This is a continuous task and<br />

process. The crux of <strong>the</strong> matter here is for <strong>the</strong> entire<br />

PVC industry with everyone involved - and this includes<br />

<strong>the</strong> processors, manufacturers and machinery<br />

producers - to give full support to <strong>the</strong> continued<br />

development of <strong>the</strong> sustainability initiative. I see <strong>the</strong><br />

starting point for this as very favorable on <strong>the</strong> basis<br />

of what we have achieved so far.<br />

How is PVC performing on <strong>the</strong> market?<br />

PVC is achieving good growth rates in Europe as a<br />

result of <strong>the</strong> good value for money it represents plus<br />

its sound properties as a material. PVC has been<br />

able to demonstrate its full repertoire of strengths<br />

in <strong>the</strong> window profile area in particular and it is <strong>the</strong><br />

number one material choice. Among its advantages<br />

is <strong>the</strong> fact that it does not need to be painted.<br />

Are <strong>the</strong>re new applications for plastic windows?<br />

Ever more producers on <strong>the</strong> market are offering<br />

windows for passive energy houses. These windows<br />

have a low <strong>the</strong>rmal transmittance value. The<br />

insulation values of <strong>the</strong> frame and <strong>the</strong> pane must be<br />

equal o<strong>the</strong>rwise condensation ga<strong>the</strong>rs in <strong>the</strong> frame.<br />

Scarcely any o<strong>the</strong>r material can achieve this requirement<br />

better than PVC. Fiber reinforced window profiles<br />

are a recent development that is also on offer.<br />

Extruding, printing and pressing have now made<br />

possible an optimized extrusion line concept from<br />

<strong>Greiner</strong> Extrusion. The integrated system has already<br />

proved itself in practice in <strong>the</strong> UK, South<br />

America and Russia.<br />

Three functions on a single strand<br />

The expanded extrusion line slashes time, personnel<br />

and space requirements. A complete and<br />

ready product is manufactured in a single working<br />

process. “Everything can be perfectly coordinated<br />

and <strong>the</strong> customer has <strong>the</strong> advantage of getting it all<br />

from a single source. Up to two employees per line<br />

can be saved.” Project Manager Walter Roidinger<br />

said, explaining <strong>the</strong> convincing benefits.<br />

Technical<br />

Punching is done in <strong>the</strong> manufacture of many technical<br />

profiles such as cable ducts and roller shutter.<br />

The punching unit is placed between <strong>the</strong> calibration<br />

table and <strong>the</strong> haul-off unit. It can be used for<br />

These replace <strong>the</strong> steel or aluminum reinforcement<br />

in <strong>the</strong> window. The fiber used is cheaper than <strong>the</strong><br />

metal variant while providing comparable stability.<br />

What are <strong>the</strong> trends in <strong>the</strong> building industry?<br />

In window profiles both <strong>the</strong> overall quantity and <strong>the</strong><br />

market share is increasing. PVC is losing ground with<br />

its market share in <strong>the</strong> classic areas of floor coverings<br />

and pipes, but in absolute terms use of <strong>the</strong> material<br />

is growing. The trend to use plastics in modern construction<br />

can readily be established. This is partly <strong>the</strong><br />

result of <strong>the</strong> organic structures of <strong>the</strong> buildings such<br />

as <strong>the</strong> dramatic Kunsthaus in Graz, but also light<br />

construction methods such as <strong>the</strong> membrane roofs<br />

of <strong>the</strong> big new football stadiums. What architects<br />

value in <strong>the</strong>se projects is <strong>the</strong> design flexibility and<br />

<strong>the</strong> possibilities PVC and o<strong>the</strong>r plastics give <strong>the</strong>m.<br />

Recycled material is also of increasing importance in<br />

production. Both <strong>the</strong> annually collected quantity of<br />

PVC for recycling and <strong>the</strong> quantity of recycling material<br />

that it is now technically possible to include in <strong>the</strong><br />

end product are on <strong>the</strong> increase.<br />

Werner Preusker is <strong>the</strong> CEO of <strong>the</strong> working group PVC and <strong>the</strong><br />

Environment, an initiative of <strong>the</strong> PVC industry.<br />

Inline punching and printing<br />

This new extension takes care of punching and printing during <strong>the</strong> extrusion process.<br />

The punching unit as a part of <strong>the</strong> extrusion line.<br />

both single and twin strand tooling. It is a very<br />

simple matter to return <strong>the</strong> punching waste to <strong>the</strong><br />

extrusion process in this integrated configuration.<br />

Profiles are printed primarily with <strong>the</strong> barcodes that<br />

are used for <strong>the</strong> automated logistics and warehouse<br />

management systems. Cutting marks can also be<br />

placed if required. The printer is integrated between<br />

<strong>the</strong> haul-off unit and <strong>the</strong> cut-off device.<br />

The controls<br />

A measuring wheel placed on <strong>the</strong> profile sends <strong>the</strong><br />

impulse to <strong>the</strong> controls that operate <strong>the</strong> punching<br />

unit and <strong>the</strong> printer to a tenth of a millimeter precision.<br />

The punch unit moves in synchronization with<br />

<strong>the</strong> profile on <strong>the</strong> basis of <strong>the</strong> information received<br />

on <strong>the</strong> profile speed. The printer also operated in<br />

dependence on <strong>the</strong> profile speed. Punch positions<br />

and barcodes can be stored on <strong>the</strong> basis of profile<br />

lengths. Up to 300 lengths including printing positions<br />

and punching positions can be saved in <strong>the</strong><br />

system memory.