Hydraulik Broschüre_GB - MANN+HUMMEL

Hydraulik Broschüre_GB - MANN+HUMMEL

Hydraulik Broschüre_GB - MANN+HUMMEL

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

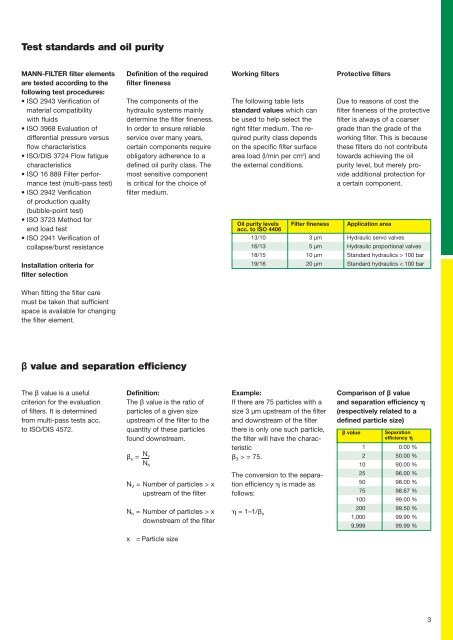

Test standards and oil purity<br />

MANN-FILTER filter elements<br />

are tested according to the<br />

following test procedures:<br />

• ISO 2943 Verification of<br />

material compatibility<br />

with fluids<br />

• ISO 3968 Evaluation of<br />

differential pressure versus<br />

flow characteristics<br />

• ISO/DIS 3724 Flow fatigue<br />

characteristics<br />

• ISO 16 889 Filter performance<br />

test (multi-pass test)<br />

• ISO 2942 Verification<br />

of production quality<br />

(bubble-point test)<br />

• ISO 3723 Method for<br />

end load test<br />

• ISO 2941 Verification of<br />

collapse/burst resistance<br />

Definition of the required<br />

filter fineness<br />

The components of the<br />

hydraulic systems mainly<br />

determine the filter fineness.<br />

In order to ensure reliable<br />

service over many years,<br />

certain components require<br />

obligatory adherence to a<br />

defined oil purity class. The<br />

most sensitive component<br />

is critical for the choice of<br />

filter medium.<br />

Working filters<br />

The following table lists<br />

standard values which can<br />

be used to help select the<br />

right filter medium. The required<br />

purity class depends<br />

on the specific filter surface<br />

area load (l/min per cm 2 ) and<br />

the external conditions.<br />

Oil purity levels<br />

acc. to ISO 4406<br />

13/10<br />

16/13<br />

Filter fineness<br />

3 µm<br />

5 µm<br />

Protective filters<br />

Due to reasons of cost the<br />

filter fineness of the protective<br />

filter is always of a coarser<br />

grade than the grade of the<br />

working filter. This is because<br />

these filters do not contribute<br />

towards achieving the oil<br />

purity level, but merely provide<br />

additional protection for<br />

a certain component.<br />

Application area<br />

Hydraulic servo valves<br />

Hydraulic proportional valves<br />

18/15<br />

10 µm<br />

Standard hydraulics > 100 bar<br />

Installation criteria for<br />

filter selection<br />

19/16<br />

20 µm<br />

Standard hydraulics < 100 bar<br />

When fitting the filter care<br />

must be taken that sufficient<br />

space is available for changing<br />

the filter element.<br />

β value and separation efficiency<br />

The β value is a useful<br />

criterion for the evaluation<br />

of filters. It is determined<br />

from multi-pass tests acc.<br />

to ISO/DIS 4572.<br />

Definition:<br />

The β value is the ratio of<br />

particles of a given size<br />

upstream of the filter to the<br />

quantity of these particles<br />

found downstream.<br />

β x = N v<br />

N h<br />

Example:<br />

If there are 75 particles with a<br />

size 3 µm upstream of the filter<br />

and downstream of the filter<br />

there is only one such particle,<br />

the filter will have the characteristic<br />

β 3 > = 75.<br />

Comparison of β value<br />

and separation efficiency <br />

(respectively related to a<br />

defined particle size)<br />

β value<br />

1<br />

2<br />

10<br />

Separation<br />

efficiency <br />

0.00 %<br />

50.00 %<br />

90.00 %<br />

N V = Number of particles > x<br />

upstream of the filter<br />

The conversion to the separation<br />

efficiency is made as<br />

follows:<br />

25<br />

50<br />

75<br />

100<br />

96.00 %<br />

98.00 %<br />

98.67 %<br />

99.00 %<br />

N h = Number of particles > x<br />

downstream of the filter<br />

= 1–1/β x<br />

200<br />

1,000<br />

9,999<br />

99.50 %<br />

99.90 %<br />

99.99 %<br />

x = Particle size<br />

3