CheckStream™ Chemical Injection System - Halliburton

CheckStream™ Chemical Injection System - Halliburton

CheckStream™ Chemical Injection System - Halliburton

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

COMPLETION SOLUTIONS<br />

CheckStream TM Check Valve<br />

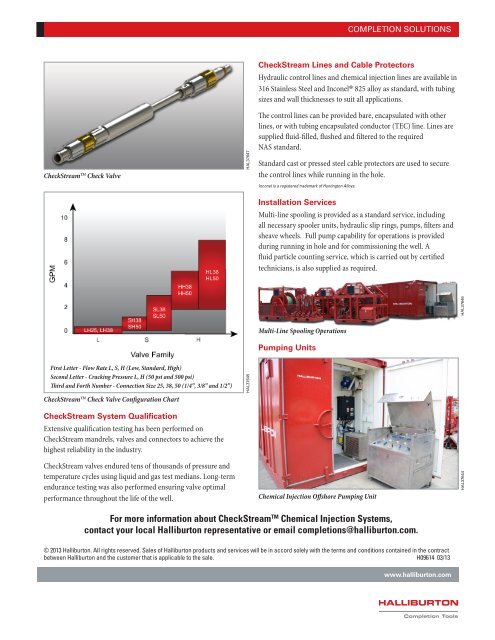

First Letter - Flow Rate L, S, H (Low, Standard, High)<br />

Second Letter - Cracking Pressure L, H (50 psi and 500 psi)<br />

Third and Forth Number - Connection Size 25, 38, 50 (1/4”, 3/8” and 1/2”)<br />

CheckStream TM Check Valve Configuration Chart<br />

CheckStream <strong>System</strong> Qualification<br />

Extensive qualification testing has been performed on<br />

CheckStream mandrels, valves and connectors to achieve the<br />

highest reliability in the industry.<br />

HAL37645 HAL37647<br />

CheckStream Lines and Cable Protectors<br />

Hydraulic control lines and chemical injection lines are available in<br />

316 Stainless Steel and Inconel® 825 alloy as standard, with tubing<br />

sizes and wall thicknesses to suit all applications.<br />

The control lines can be provided bare, encapsulated with other<br />

lines, or with tubing encapsulated conductor (TEC) line. Lines are<br />

supplied fluid-filled, flushed and filtered to the required<br />

NAS standard.<br />

Standard cast or pressed steel cable protectors are used to secure<br />

the control lines while running in the hole.<br />

Inconel is a registered trademark of Huntington Alloys.<br />

Installation Services<br />

Multi-line spooling is provided as a standard service, including<br />

all necessary spooler units, hydraulic slip rings, pumps, filters and<br />

sheave wheels. Full pump capability for operations is provided<br />

during running in hole and for commissioning the well. A<br />

fluid particle counting service, which is carried out by certified<br />

technicians, is also supplied as required.<br />

Multi-Line Spooling Operations<br />

Pumping Units<br />

HAL37646<br />

CheckStream valves endured tens of thousands of pressure and<br />

temperature cycles using liquid and gas test medians. Long-term<br />

endurance testing was also performed ensuring valve optimal<br />

performance throughout the life of the well.<br />

<strong>Chemical</strong> <strong>Injection</strong> Offshore Pumping Unit<br />

HAL37644<br />

For more information about CheckStream TM <strong>Chemical</strong> <strong>Injection</strong> <strong>System</strong>s,<br />

contact your local <strong>Halliburton</strong> representative or email completions@halliburton.com.<br />

© 2013 <strong>Halliburton</strong>. All rights reserved. Sales of <strong>Halliburton</strong> products and services will be in accord solely with the terms and conditions contained in the contract<br />

between <strong>Halliburton</strong> and the customer that is applicable to the sale. H09614 03/13<br />

www.halliburton.com