Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Introduction 1<br />

HEATLOCK Global Service 2-3<br />

<strong>Why</strong> <strong>Hot</strong> <strong>Runner</strong> ? 4<br />

Gate Diameter 5<br />

Nozzel Features 6<br />

Nozzel Selection Guide Table 7<br />

A1-EN Series 8-9<br />

A1-TP Series 10-11<br />

A1-TN Series 12-13<br />

A1-T Series 14-17<br />

A1-VG Series 18-19<br />

A2-MT Series 20-21<br />

<strong>Hot</strong> Half 22-23<br />

<strong>Hot</strong> <strong>Runner</strong> System Structure 24<br />

Manifold Assembly 25<br />

I(F type) Manifold 26<br />

I(B type) Manifold 27<br />

H(F type) Manifold 28<br />

H(B type) Manifold 29<br />

X(F type) Manifold 30<br />

X(B type) Manifold 31<br />

X-X(F type) Manifold 32<br />

X-X(B type) Manifold 33<br />

Ceramic 34-35<br />

Titanium Ring 36<br />

Feed Bush Heater 37-38<br />

Connect Box 39-40<br />

US Connect Box 41<br />

Multi Connect Box 42-43<br />

Connector 44<br />

US Connector 45<br />

HLDC-15A 46<br />

Filter Nozzles 47-48<br />

A1 Nozzle Spare Parts 49-50<br />

Inquiry Form 51

INTRODUCTION<br />

WELCOME TO<br />

HEATLOCK<br />

Your global partner for hot-runner<br />

system technology.<br />

We can offer you excellent localised<br />

service throughout China; the biggest<br />

mould making market in the world, as<br />

well as through our global network of<br />

sales offices and distributors.<br />

<strong>Heatlock</strong> hot-runners are known for their<br />

ceramic components used for insulating<br />

all the contact points between the hotrunner<br />

system and the mould. Ceramic<br />

has only 7% of the heat conductivity of<br />

steel making it an exceptional insulator.<br />

We were the first in the world to use<br />

this technology for hot-runners and<br />

introduced it at the K82 Exhibition.<br />

Today we deliver everything from single<br />

cavity solutions to complete multi cavity<br />

hot halves. If you require your system<br />

to be proven with simulations do we<br />

also provide it for you.<br />

Our production facility in China is<br />

equipped to manufacture components<br />

and systems to the highest <strong>Heatlock</strong><br />

standard with exceptional delivery times<br />

and competitive prices.<br />

<strong>Heatlock</strong>: Your global partner with the<br />

perfect China connection!

Global Service<br />

For a complete list of our distributor around the world, please refer to our website :<br />

www.heatlock.com<br />

<br />

14th Floor, South China Building<br />

1-3 Wyndham Street<br />

Central Hong Kong<br />

Tel : (852) 8120 5469<br />

Fax : (852) 3020 1725<br />

E-mail : frontdesk@heatlock.com<br />

<br />

Room 506, Block B,<br />

ZhiXing International Business Building<br />

South ZhanQian Road, Changping Town<br />

Guangdong, PRC<br />

Zip Code523560<br />

Tel(86) 0769-8382 5600<br />

Fax(86) 0769-8382 5626<br />

E-mail : frontdesk@heatlock.com<br />

www.heatlock.com

HEATLOCK Distributors<br />

Distributors Europe<br />

BULGARIA ITALY RUSSIA<br />

COMMSET LTD A E D Novaya Orbita Co., Ltd<br />

Tel: +359 2 961 113 Tel: 0424/708662 Tel: +7 495 514-83-02, 518-00-41<br />

Fax: +359 2 961 1134 Fax: 0424/418112 Fax: +7 495 933-87-12, 933-87-13<br />

Email: commset@cablebg.net E-mail: aedfern@tin.it E-mail: sales@injection.ru<br />

Website: www.injection.ru<br />

DENMARK NETHERLANDS SWEDEN<br />

N. Helldin AB OBINION Plastics Machinery N. Helldin AB<br />

Tel: +46 511 132 00 Tel: +31 (0)852 73 30 50 / Tel: +46 511 132 00<br />

Fax: +46 511 172 85 +31 (0)497 38 38 09 Fax: +46 511 172 85<br />

E-mail: info@helldin.com Fax: +31 (0)842 24 44 49 E-mail: info@helldin.com<br />

Website: www.helldin.com Cell: +31 (0)6 38 75 30 80 Website: www.helldin.com<br />

Email: avermeijden@obinion.com<br />

Website: www.obinion.com<br />

FINLAND NORWAY SYRIA<br />

Valmisosa Oy Deli Verkt¿ySenter AS Polymeric Technical Products<br />

Phone: +358-2-6331744 Tel: +47 6495 6218 Tel: +963 11 6351510<br />

Fax: +358-2-6331746 Fax: +47 6495 6202 Fax: +963 11 6351510<br />

E-mail: valmis@dnainternet.net E-mail: dvs@strack.no E-mail: wayoub@gmx.net<br />

GERMANY POLAND SWITZERLAND<br />

i-mold GmbH & Co.KG Roal S.C. N. Helldin AB<br />

Phone: +49 (0) 6161-8070-11 PL-61 381 Poznan Tel: +46 511 132 00<br />

Fax:+49 (0) 6161-8070-33 Phone: +48 61 843 4581 Fax: +46 511 172 85<br />

E-mail: info@i-mold.com Fax: +48 61 843 4581 E-mail: info@helldin.com<br />

E-mail: jackowiak@poczta.onet.pl Website: www.helldin.com<br />

ISRAEL PORTUGAL UNITED KINGDOM<br />

A.Zilka Marketing & Engineering Ltd. SOREP Lda, Diemould Service Co Ltd.<br />

Tel: +972-3-5584-936 Tel: 351 244 572 800 Tel: (+44) 1494 523811<br />

Fax: +972-3-5584-937 Fax: +351 244 572 801 Fax: (+44) 1494 452898<br />

Cell: +972-505-250-029 (Avraham Zilka) E-mail: fruivo@sorep.co.pt E-mail: sales@dms-diemould.co.uk<br />

Email: ranzilka@bezeqint.net<br />

Website: www.sorep.co.pt<br />

Distributors Asia<br />

PRC INDIA INDONESIA<br />

<strong>Heatlock</strong> Co. Ltd. Pillai and Peter Associates Pvt. Ltd. PT. Ladang Baja Murni<br />

Room 506, Block B. Phone: 0091-22-862 69 00 Jl. Danau Sunter Selatan Blok O 3/40<br />

ZhiXing International Business Building Fax: 0091-22-862 69 00 Sunter Agung Podomoro<br />

South ZhangQian Road, Changping Town E-mail: anish@giasbmc.vsnl.net.in Jakarta Utara<br />

DongGuan, GuangDong, PRC<br />

Indonesia<br />

Phone: (86)0769-8382 5600<br />

Email address: ibmmould@hotmail.com<br />

Fax: (86) 0769-8382 5626 Telp: +62 21 6511595<br />

E-mail: frontdesk@heatlock.com +62 21 6510508<br />

Fax: +62 21 6510244<br />

HONG KONG<br />

<strong>Heatlock</strong> Co. Ltd.<br />

14th Floor South China Building<br />

1-3 Wyndham Street, Central, Hong Kong<br />

Phone: (852) 8120 5469<br />

Fax: (852) 2653 5230<br />

E-mail: frontdesk@heatlock.com<br />

Distributors North America<br />

CANADA<br />

Diemould Service Co (Canada) Ltd Phone: (519) 737-6743 Fax: (519) 737-6744<br />

1875 Blackacre Drive Phone: (800) 265 4885 Fax: (800) 845 3807<br />

Oldcastle, Ontario,N0R 1L0<br />

E-mail: sales@dmscomponents.com<br />

U.S.A.<br />

Diemold Supply DMS Inc. Die Mold Supply DMS Inc. Diemold Service Company<br />

17197 Newhope Street, Unit I, 15 Duffy Dr. 1026 National Parkway<br />

Fountain Valley, California 92708 Taunton, Massachusetts 02780-4056 Schaumburg, Illinois 60173-4519<br />

Phone: 714-751-1615 Tel:(800) 265-5885 Tel: (847) 466-0103<br />

Phone: 800-421-3993 Fax:(800) 845-3807 Tel: 888-766-8006<br />

Fax: 714-751-3861 Fax: (847) 466-0108<br />

Fax: 800-953-9561 Fax: 800-367-4199<br />

Distributors Australia<br />

Australia<br />

EOC Normalien Pty Ltd Phone: (03) 9583 0166<br />

51 Shearson Crescent Fax: (03) 9584 1119<br />

Mentone,Victoria<br />

E-mail: eocaust@netspace.net.au<br />

3194,Australia

<strong>Why</strong> <strong>Hot</strong> <strong>Runner</strong><br />

How you can be more effective and more competitive by using our<br />

ceramically insulated HEATLOCK hot runner system.<br />

The old way with a cold sprue<br />

fig.1<br />

Improved efficiency with a<br />

HEATLOCK sprue bushing<br />

fig.2<br />

Reduce flow length in cold steel by<br />

68%<br />

fig.3<br />

Direct gating usually is the most<br />

effective way<br />

fig.4<br />

www.heatlock.com

Gate Diameter<br />

For bushes and torpedoes<br />

Shotweight per bush in grams<br />

2000<br />

1000<br />

500<br />

200<br />

100<br />

20<br />

10<br />

6<br />

2<br />

1<br />

1<br />

2<br />

3<br />

0.75 1.25 1.75 2.25 3.2 4.7 6.4 7.9<br />

1.0 1.5 2.0 2.5 4.0 5.5 7.2<br />

Gate diameter<br />

1. Low viscosity materials, PS, PE, PP<br />

2. Medium viscosity materials ABS, SAN, PA, POM<br />

3. High viscosity materials PC, PMMA, Noryl, PUR, re-inforced materials<br />

Note : 1. For TP nozzle, gate diameter reduces 30%<br />

2. For filled materials, gate diameter increases 20%<br />

The diagram above gives a guideline figure for<br />

the gate diameter needed for different plastics<br />

and shot weights.<br />

Note: If the gate diameter is too small, an<br />

unnecessarily high bushing temperature will have<br />

to be set for the gate not to freeze between shots.<br />

The suggested figures are approximate. Gate<br />

dimension may be influenced by the shape of the<br />

part and the design of the mould etc.<br />

The balance between shot weight, injection rate,<br />

tool temperature, temperature pattern opposite<br />

gate, cooling around gate and injection pressure<br />

are all factors that affect gate size. A small gate<br />

freezes quicker than a large gate. On injection<br />

moulding with very short cycle times and short<br />

injection times, it may be necessary to design<br />

gate cooling so that it does not overheat.<br />

If the sprue bushing is feeding a runner which<br />

has a gate into a cavity, it may be suitable to make<br />

the bushing gate larger than actually necessary.<br />

This way pressure drop and shear will be reduced.<br />

If an electric sprue bushing is used to feed a<br />

runner, this means that length of flow in cold steel<br />

has been reduced equivalent to the bushing length.<br />

Due to this cross section, the runner can be made<br />

smaller than usual. This is important in order to<br />

get shortest possible cycle time.<br />

Start with a smaller gate that indicated in the table.

Nozzle Features<br />

www.heatlock.com<br />

16-11-2011

16-11-2011<br />

A1 Nozzle<br />

*** Good<br />

** Ok<br />

* Contact HEATLOCK<br />

-- Not recommend<br />

Feed Channel (mm)<br />

Low-viscosity PE, PS, PP<br />

Medium-viscosity<br />

ABS, PA, POM, SAN<br />

High-viscosity<br />

Lowviscosity<br />

PS/PE<br />

PP<br />

ABS/SAN<br />

POM<br />

Mediumviscosity<br />

LCP<br />

PBT<br />

PET<br />

PA6/PA6.6<br />

PC/PMMA<br />

Highviscosity<br />

PPO<br />

PES/PEK<br />

PPS/PEI<br />

L/M/H<br />

viscosity +<br />

additives<br />

GF/CF/FR<br />

EN1<br />

4<br />

200<br />

100<br />

40<br />

EN2 EN3<br />

6 9<br />

500 850<br />

270 400<br />

150 280<br />

***<br />

***<br />

***<br />

***<br />

**<br />

***<br />

**<br />

*<br />

***<br />

***<br />

***<br />

**<br />

***<br />

EN4<br />

14<br />

1650<br />

800<br />

550<br />

PPT1 PPT2<br />

TP1 TP2 TP3<br />

4 6 9<br />

200 500 850<br />

100 270 400<br />

40 150 280<br />

***<br />

***<br />

***<br />

**<br />

**<br />

**<br />

*<br />

*<br />

***<br />

***<br />

**<br />

**<br />

**<br />

TP4<br />

14<br />

1650<br />

800<br />

550<br />

NPT1 NPT2<br />

TN1 TN2 TN3<br />

4 6 9<br />

140 330 580<br />

60 220 340<br />

20 70 200<br />

***<br />

***<br />

***<br />

**<br />

--<br />

*<br />

*<br />

*<br />

**<br />

*<br />

--<br />

--<br />

*<br />

TN4<br />

14<br />

1200<br />

650<br />

400<br />

VG1<br />

4<br />

160<br />

70<br />

20<br />

VG2 VG3<br />

6 9<br />

390 700<br />

85 300<br />

50 180<br />

***<br />

***<br />

***<br />

*<br />

*<br />

*<br />

*<br />

*<br />

***<br />

*<br />

*<br />

*<br />

*<br />

VG4<br />

14<br />

1200<br />

550<br />

380<br />

A2MT<br />

4<br />

140<br />

60<br />

*<br />

***<br />

***<br />

***<br />

**<br />

--<br />

*<br />

*<br />

*<br />

**<br />

**<br />

*<br />

*<br />

--<br />

Nozzle Selection Guide Table

www.heatlock.com

A1EN Series<br />

(mm)<br />

Size L L1 L(+) d1 d2 d3 d4 d5 d6 d7 d8 L2 D1 D2 D3 D4 D5 D6<br />

A1EN1040 40 40.58<br />

A1EN1050 50 50.60<br />

A1EN1060 60 60.61<br />

C30<br />

C30<br />

5 4 6 29 20 23 18 1.5 6.7 6 23<br />

A1EN1080 80 80.65<br />

T30<br />

T30<br />

20 6 23<br />

A1EN1100 100 100.69<br />

A1EN1120 120 120.73<br />

A1EN2040 40 40.58<br />

A1EN2060 60 60.61<br />

A1EN2080 80 80.65<br />

C40<br />

C40<br />

A1EN2100 100 100.69 5 6 8 35 24 27 24.5 2 8 8 27<br />

T36<br />

T36<br />

A1EN2120 120 120.73<br />

26.5 6 27<br />

A1EN2140 140 140.77<br />

A1EN2160 160 160.80<br />

A1EN3060 60 60.61<br />

A1EN3080 80 80.65<br />

A1EN3100 100 100.69<br />

C62<br />

C62<br />

A1EN3120 120 120.73 10 9 12 48 34 39 32 2 9 12 39<br />

T50<br />

T50<br />

A1EN3140 140 140.77<br />

34 9 39<br />

A1EN3160 160 160.80<br />

A1EN3180 180 180.84<br />

A1EN4080 80 80.65<br />

A1EN4100 100 100.69<br />

A1EN4120 120 120.73<br />

C56<br />

C56<br />

A1EN4140 140 140.77 20 14 16 52 38 44 34.5 3 9 16 44<br />

T54<br />

T54<br />

A1EN4160 160 160.80<br />

36.5 14 44<br />

A1EN4180 180 180.84<br />

A1EN4200 200 200.88<br />

** D3 Dimension: T is Titanium<br />

Length Expansion (L1 = L + X.XX) (mm)<br />

The software nozzle est.rar calculating L1 length is available on our website, please go to<br />

http://www.heatlock.com/cad/cad.htm and use the pull down menu to download it.<br />

Shot Weight<br />

Size (g) Low-viscosity Med-viscosity High-viscosity Gate size<br />

A1-EN size 1

www.heatlock.com

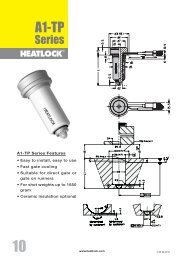

A1TP Series<br />

(mm)<br />

Size L L1 d1 d2 d3 d4 d5 d6 d7 d8 L2 H D1 D2 D3 D4 D5 D6 D7<br />

A1TP1040 40 40.11<br />

A1TP1050 50 50.13<br />

A1TP1060 60 60.15<br />

C30<br />

C30<br />

4 11 29 20 23 18 0.6 6 0.2 11 23<br />

A1TP1080 80 80.19<br />

T30<br />

T30<br />

20 6 23 9<br />

A1TP1100 100 100.23<br />

A1TP1120 120 120.26<br />

A1TP2040 40 40.08<br />

A1TP2060 60 60.16<br />

A1TP2080 80 80.20<br />

C40<br />

C40<br />

A1TP2100 100 100.24 6 14 35 24 27 24.5 0.8 7.5 0.2 14 27<br />

T36<br />

T36<br />

A1TP2120 120 120.28<br />

26.5 6 27 12<br />

A1TP2140 140 140.31<br />

A1TP2160 160 160.35<br />

A1TP3060 60 60.17<br />

A1TP3080 80 80.21<br />

A1TP3100 100 100.25<br />

C62<br />

C62<br />

A1TP3120 120 120.29 9 19 48 34 39 32 1.2 9.5 0.3 19 39<br />

T50<br />

T50<br />

A1TP3140 140 140.32<br />

34 9 39 16.5<br />

A1TP3160 160 160.36<br />

A1TP3180 180 180.40<br />

A1TP4080 80 80.21<br />

A1TP4100 100 100.25<br />

A1TP4120 120 120.29<br />

C56<br />

C56<br />

A1TP4140 140 140.33 14 25 52 38 44 34.5 1.8 10.5 0.4 25 44<br />

T54<br />

T54<br />

A1TP4160 160 160.37<br />

36.5 14 44 22.5<br />

A1TP4180 180 180.40<br />

A1TP4200 200 200.44<br />

** D3 Dimension: T is Titanium<br />

Length Expansion (L1 = L + X.XX) (mm)<br />

The software nozzle est.rar calculating L1 length is available on our website, please go to<br />

http://www.heatlock.com/cad/cad.htm and use the pull down menu to download it.<br />

Shot Weight<br />

Size (g) Low-viscosity Med-viscosity High-viscosity Gate size<br />

A1-TP size 1

www.heatlock.com

A1TN Series<br />

(mm)<br />

Size L L1 d1 d2 d3 d4 d5 d6 d7 d8 L2 D1 D2 D3 D4 D5 D6 H<br />

A1TN1040 40 40.11<br />

A1TN1050 50 50.13<br />

A1TN1060 60 60.15<br />

C30<br />

C30<br />

4 11 29 20 23 18 0.6 6 11 23<br />

A1TN1080 80 80.19<br />

T30<br />

T30<br />

20 6 23 0.2<br />

A1TN1100 100 100.23<br />

A1TN1120 120 120.26<br />

A1TN2040 40 40.08<br />

A1TN2060 60 60.16<br />

A1TN2080 80 80.20<br />

C40<br />

C40<br />

A1TN2100 100 100.24 6 14 35 24 27 24.5 0.8 7.5 14 27<br />

T36<br />

T36<br />

A1TN2120 120 120.28<br />

26.5 6 27 0.2<br />

A1TN2140 140 140.31<br />

A1TN2160 160 160.35<br />

A1TN3060 60 60.17<br />

A1TN3080 80 80.21<br />

A1TN3100 100 100.25<br />

C62<br />

C62<br />

A1TN3120 120 120.29 9 19 48 34 39 32 1.2 9.5 19 39<br />

T50<br />

T50<br />

A1TN3140 140 140.32<br />

34 9 39 0.3<br />

A1TN3160 160 160.36<br />

A1TN3180 180 180.40<br />

A1TN4080 80 80.21<br />

A1TN4100 100 100.25<br />

A1TN4120 120 120.29<br />

C56<br />

C56<br />

A1TN4140 140 140.33 14 25 52 38 44 34.5 1.8 10.5 25 44<br />

T54<br />

T54<br />

A1TN4160 160 160.37<br />

36.5 14 44 0.4<br />

A1TN4180 180 180.40<br />

A1TN4200 200 200.44<br />

** D3 Dimension: T is Titanium<br />

Length Expansion (L1 = L + X.XX) (mm)<br />

The software nozzle est.rar calculating L1 length is available on our website, please go to<br />

http://www.heatlock.com/cad/cad.htm and use the pull down menu to download it.<br />

Shot Weight<br />

Size (g) Low-viscosity Med-viscosity High-viscosity Gate size<br />

A1-TN size 1

www.heatlock.com

www.heatlock.com

www.heatlock.com

A1VG Series<br />

(mm)<br />

** D3 Dimension: T is Titanium<br />

Length Expansion (L1 = L + X.XX) (mm)<br />

The software nozzle est.rar calculating L1 length is available on our website, please go to<br />

http://www.heatlock.com/cad/cad.htm and use the pull down menu to download it.<br />

A1-VG size 1 160 70 20<br />

A1-VG size 2 390 85 50<br />

A1-VG size 3 700 300 180<br />

A1-VG size 4 1200 550 380<br />

(mm)<br />

Shot Weight<br />

Size (g) Low-viscosity Med-viscosity High-viscosity<br />

Order example :<br />

A1VG--X--XXX---XX<br />

(Series No.) (L)<br />

(d10)<br />

A1VG--1-- 040-- 11

www.heatlock.com 16-11-2011

A2MT<br />

A2MT Series<br />

Series L L1 d d1 d2 d3 d4 d5 d6 d7 L2 D D1 D2 D3 D5 D6 D7 D8<br />

A2MT04040102 40 40.13 10 8 8 T50 48 34 39 32 7.5 10 8 8 T50 39 39 34 13<br />

A2MT04080102 80 80.23<br />

(mm)<br />

A2MT04060162 60 60.18<br />

A2MT04080162 80 80.23 16 8 8 T54 52 38 44 34.5 7.5 16 8 8 T54 44 44 36.5 13<br />

A2MT04060164 60 60.18<br />

A2MT04080164 80<br />

80.23<br />

** D3 Dimension: T is Titanium<br />

Shot Weight<br />

Size (g) Low-viscosity Med-viscosity Gate size<br />

A2MT<br />

(mm)<br />

Gate layout<br />

(view from cavity)<br />

Order example :<br />

A2MT--X--XXX---XX-X<br />

(Series No.) (L) (D) (tip Qty )<br />

A2MT-04-- 080-- 22- 2<br />

16-11-2011

www.heatlock.com

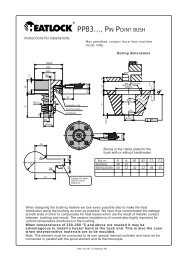

<strong>Hot</strong> <strong>Runner</strong> System Structure<br />

Manifold Design<br />

Feed bush<br />

Ceramic back<br />

support<br />

Back spacer<br />

Purge guard<br />

Thermocouple<br />

Manifold<br />

Tubular heater<br />

Bush<br />

Ceramic<br />

centre spacer<br />

Centre location<br />

spacer<br />

www.heatlock.com

Manifold Assembly

36<br />

46<br />

46<br />

56<br />

56<br />

56

100<br />

100<br />

100

Titanium Ring<br />

Size Item code<br />

Size 1 TIM03002308 30 23<br />

TIM03602708 36 27<br />

Size 2 TIM04002708 40 27<br />

TIM05002708 50 27<br />

Size 3 TIM05003908 50 39<br />

Size 4 TIM05404408 54 44<br />

Nozzle band heater<br />

Part No.<br />

Thermocouple<br />

White (2x) Live<br />

Yellow/Green Earth<br />

Red Negative [ + ]<br />

Blue Positive [ - ]<br />

Part No. Dimension a b Watts<br />

D-CY-BH127150 33x10 27 33 150<br />

D-CY-BH230200 36x10 30 36 200<br />

D-CY-BH233200 39x10 33 39 200<br />

D-CY-BH235250 41x10 35 41 250<br />

D-CY-BH347250 53x10 47 53 250<br />

D-CY-BH451300 57x10 51 57 300<br />

Nozzle band heater bore<br />

Part No. A B<br />

D-CY-BH127150 40 30<br />

D-CY-BH230200 43 32<br />

D-CY-BH233200 45 32<br />

D-CY-BH235250 48 34<br />

D-CY-BH347250 62 40<br />

D-CY-BH451300 65 40<br />

www.heatlock.com<br />

22/07/2011

DSPXX30XX<br />

Item code L A Band sheet Heater<br />

DSP4503008<br />

DSP4503010<br />

8<br />

10<br />

DSP4503012 45 12<br />

BS230020250<br />

---<br />

DSP4503014<br />

14<br />

DSP4503016<br />

16<br />

DSP7003008 70 8 BS230036400<br />

DSPXX02508<br />

Item code L A Band sheet Heater<br />

DSP4002508<br />

40<br />

---<br />

DSP5002508<br />

50<br />

8<br />

---<br />

BS15240210200<br />

DSP7002508<br />

70<br />

BS15240410350<br />

DSP6003508<br />

Item code L A Band sheet Heater<br />

DSP6003508<br />

60 8 --- BS235030550<br />

DSP52032XX<br />

Item code L A Band sheet Heater<br />

DSP5203208<br />

DSP5203210<br />

DSP5203212<br />

DSP5203214<br />

DSP5203216<br />

52<br />

8<br />

10<br />

12<br />

14<br />

16<br />

BSS35362004 BS230020250

Feed bush heater wiring<br />

* A heated feed bush is recommended for all polymers except PE, PP and PS.<br />

Heater<br />

Thermocouple<br />

White (2x) Live<br />

Yellow/Green Earth<br />

Red Positive [ + ]<br />

Blue Negative [ - ]<br />

Feed bush heater bore<br />

www.heatlock.com

Connector Box<br />

Type L1<br />

6 PIN 70<br />

10 PIN 83<br />

No.<br />

Pin<br />

CONNB06 6<br />

CONNB10 10

Connector Box<br />

Type L1<br />

16 PIN 103<br />

24 PIN 130<br />

No.<br />

Pin<br />

CONNB16 16<br />

CONNB24 24<br />

<br />

www.heatlock.com

US Standard Connector Boxes<br />

Type L1<br />

10 PIN 83<br />

16 PIN 103<br />

24 PIN 130<br />

No.<br />

Pin<br />

US-CONNB10 10<br />

US-CONNB16 16<br />

US-CONNB24 24

Multi Connector Box<br />

Type L1<br />

16 PIN 103<br />

24 PIN 130<br />

<br />

www.heatlock.com

Multi Connector Box<br />

Type L1<br />

16 PIN 103<br />

24 PIN 130

Connector<br />

Insert male<br />

No.<br />

MASKINHA06<br />

MASKINHA10<br />

MASKINHA16<br />

MASKINHA24<br />

Description<br />

Insert male, 6-pin<br />

Insert male, 10-pin<br />

Insert male, 16-pin<br />

Insert male, 24-pin<br />

Insert female<br />

No.<br />

MASKINHO06<br />

MASKINHO10<br />

MASKINHO16<br />

MASKINHO24<br />

Description<br />

Insert female, 6-pin<br />

Insert female, 10-pin<br />

Insert female, 16-pin<br />

Insert female, 24-pin<br />

Housing mould, flange<br />

A series<br />

No.<br />

Description<br />

Lock Qty<br />

Lid (Y/N)<br />

MASKKAFL06<br />

Housing mould, flange 6-pin<br />

1<br />

N<br />

MASKKAFL10<br />

Housing mould, flange 10-pin<br />

2<br />

N<br />

MASKKAFL16<br />

Housing mould, flange 16-pin<br />

2<br />

N<br />

MASKKAFL24<br />

Housing mould, flange 24-pin<br />

2<br />

N<br />

B series<br />

No.<br />

Description<br />

Lock Qty<br />

Lid (Y/N)<br />

MASKKAFL06C<br />

Housing flange with cover 6-pin<br />

1<br />

Y<br />

MASKKAFL16C<br />

Housing flange with cover 16-pin<br />

1<br />

Y<br />

MASKKAFL24C<br />

Housing flange with cover 24-pin<br />

1<br />

Y<br />

Hood loom, top exit<br />

No.<br />

MASKKAKT06<br />

MASKKAKT10<br />

MASKKAKT16<br />

MASKKAKT24<br />

Description<br />

Hood loom, top exit 6-pin<br />

Hood loom, top exit 10-pin<br />

Hood loom, top exit 16-pin<br />

Hood loom, top exit 24-pin<br />

e<br />

Boring<br />

a<br />

b<br />

bottom:c<br />

d<br />

e<br />

6-polig<br />

52<br />

70<br />

32<br />

35<br />

M4<br />

c<br />

d<br />

10-polig<br />

65<br />

83<br />

32<br />

35<br />

M4<br />

R=3<br />

16-polig<br />

24-polig<br />

86<br />

112<br />

103<br />

130<br />

32<br />

32<br />

35<br />

35<br />

M4<br />

M4<br />

a<br />

b–0.1<br />

<br />

www.heatlock.com

US Standard Connector<br />

Male Insert<br />

Item Code<br />

CONNT-10PIN/M<br />

CONNT-16PIN/M<br />

CONNT-24PIN/M<br />

Description<br />

US Spec.Connector 10 Pin,male<br />

US Spec.Connector 16 Pin,male<br />

US Spec.Connector 24 Pin,male<br />

Female Insert<br />

Item Code<br />

CONNT-10PIN/F<br />

CONNT-16PIN/F<br />

CONNT-24PIN/F<br />

Description<br />

US Spec.Connector 10 Pin,female<br />

US Spec.Connector 16 Pin,female<br />

US Spec.Connector 24 Pin,female<br />

Hood, top entry<br />

Item Code<br />

HLE25TEPG21<br />

Description<br />

HEATLOCK<br />

US Spec. Hood, top entry<br />

Housing, mould base<br />

Item Code<br />

HLE25BH<br />

Description<br />

HEATLOCK<br />

US Spec. Housomg, bulkhead mounting

HLDC-15A controller<br />

www.heatlock.com

M1<br />

60/80/150<br />

W<br />

H<br />

M2<br />

60/80/150<br />

W<br />

H<br />

M3<br />

60/80/150<br />

W<br />

H

(<strong>Hot</strong> <strong>Runner</strong> System Department)<br />

Changping Tel : (86) 0769-8382 5600 Fax: (86) 0769-8382 5626<br />

Hong Kong Tel : (852) 8120 5469 Fax: (852) 3020 1725 Email: frontdesk@heatlock.com<br />

Filling the form and fax to us : (86) 0769-8382 5626<br />

For detail information, please go to our web : www.heatlock.com<br />

HEATLOCK MOULDING SYSTEM QUOTE REQUEST FORM<br />

Customer Quote No:<br />

Date:<br />

Company:<br />

Contact:<br />

Address:<br />

Tel: Fax: E-mail:<br />

Please provide the following information, for quotation<br />

Product Description:<br />

Material:<br />

Glass Filled: %<br />

Frame Retardant<br />

PP PE PS SB EVA ABS POM SAN PA6<br />

PMMA ASA CAB PBT PA66 PC PC/ABS PPS<br />

PET PES PPO PSU PEEK LCP PEI PVC S/H<br />

Per Product Weight:<br />

No. of Cavities:<br />

No.of Gates Per Product:<br />

Description of Gate Finish:<br />

Size of Product (L * W * H):<br />

Sprue-gate<br />

Extended Sprue-gate<br />

Ring-gate<br />

Point-gate<br />

Colour:<br />

Transparence<br />

Color or Material Change Necessary: Yes No<br />

Controller: Yes No<br />

Nozzle Length:<br />

Thickness of ’A’ Plate:<br />

Feed Bush<br />

R=<br />

Feed Bush Heater: Yes No<br />

<strong>Hot</strong> Half: Yes<br />

Insulation Plate:<br />

Yes<br />

Project Book: Chinese English<br />

Remarks:<br />

Drawing:<br />

www.heatlock.com