Central ventilation with heat recovery unit KWL 250 - HELIOS ...

Central ventilation with heat recovery unit KWL 250 - HELIOS ...

Central ventilation with heat recovery unit KWL 250 - HELIOS ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Central</strong> <strong>ventilation</strong> <strong>with</strong> <strong>heat</strong> <strong>recovery</strong> <strong>unit</strong> <strong>KWL</strong> <strong>250</strong><br />

Operation and installation instructions no. 91581<br />

It is important for safety reasons and to ensure a satisfactory operation, that<br />

you read and observe this instruction fully before proceeding!<br />

RECEIPT<br />

The cardboard box conatains one of the following items, including a three step<br />

operation switch:<br />

<strong>KWL</strong> <strong>250</strong> Ref.-No. 850.001<br />

<strong>KWL</strong> <strong>250</strong> EH (<strong>with</strong> electric <strong>heat</strong>er battery) Ref.-No. 850.010<br />

<strong>KWL</strong> <strong>250</strong> WW (<strong>with</strong> water <strong>heat</strong>er batery) Ref.-No. 851.001<br />

Please check delivery immediately on receipt for accuracy and damage, please<br />

notifiy carrier immediately. In case of delayed notification, any possible claim may<br />

be void.<br />

STORAGE<br />

When storing for a prolonged time the following steps are to be taken to avoid damaging<br />

influences: protection by dry air and dustproof packing (plastic bags <strong>with</strong><br />

drying agent and moisture indicators). The storage area must be free of water, vibration<br />

and temperature variations.<br />

When storing for several years <strong>with</strong> non rotation of motor an inspection of the bearings<br />

<strong>with</strong> possible relubrication and an installation inspection in accordance <strong>with</strong><br />

VDE 0530 are absolutely necessary before starting operation. Damages due to<br />

improper storage, transportation or installation are not liable for warranty.<br />

OPERATION / USE<br />

The <strong>unit</strong> is designed to ventilate a combination of living rooms, bathrooms and kitchens<br />

in a single storey dewelling up to120 m 2 . The <strong>unit</strong> is equipped <strong>with</strong> a <strong>heat</strong><br />

<strong>recovery</strong> battery. It must not be connected to kitchen hoods or laboratory extract<br />

fans. The standard equipment allows a working temperature range from -20°C up<br />

to 40°C. For operation under difficult conditions, e.g. high humidity, long periods<br />

of standstill, high air pollution or through climatic (e.g. operating temperature over<br />

40°C), technical or electronic influences other than standard operations may not<br />

be suitable. For this reason please enquire and obtain operation release. A release<br />

by a third party is not valid.<br />

MODE OF ACTION<br />

In the <strong>heat</strong> exchanger the cold outside air and the warm extracted air "crosses over"<br />

<strong>with</strong>out touching. Through this exchange the energy of the warm air is tranfered to<br />

the incoming air. Additionally a thermostat controlled <strong>heat</strong>ing element warms up the<br />

inlet air (in extreme cold weather conditions) to the required temperature. The inlet<br />

air is directed to the living rooms and bedrooms through ducting and valves. The<br />

used air is extracted from the bathrooms, toilets and kitchens. It flows back to the<br />

fan via the ducting systems, transfering <strong>heat</strong> before being released into the open air.<br />

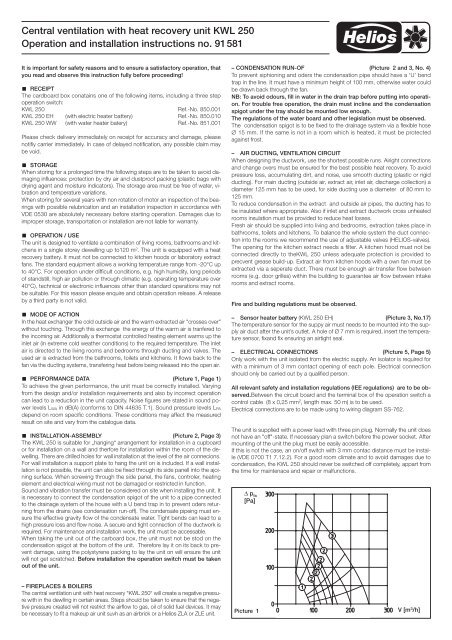

PERFORMANCE DATA (Picture 1, Page 1)<br />

To achieve the given performance, the <strong>unit</strong> must be correctly installed. Varying<br />

from the design and/or installation requireements and also by incorrect operation<br />

can lead to a reduction in the <strong>unit</strong> capacity. Noise figures are stated in sound power<br />

levels L WA in dB(A) (conforms to DIN 44635 T.1). Sound pressure levels L PA<br />

depend on room specific conditions. These conditions may affect the measured<br />

result on site and vary from the catalogue data.<br />

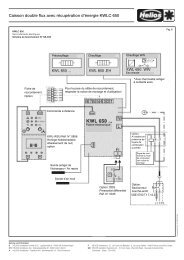

INSTALLATION-ASSEMBLY (Picture 2, Page 3)<br />

The <strong>KWL</strong> <strong>250</strong> is suitable for „hanging“ arrangement for installation in a cupboard<br />

or for installation on a wall and therfore for installation <strong>with</strong>in the room of the dewelling.<br />

There are drilled holes for wall installation at the level of the air connecions.<br />

For wall installation a support plate to hang the <strong>unit</strong> on is included. If a wall installation<br />

is not possible, the <strong>unit</strong> can also be fixed through its side panell into the ajoining<br />

surface. When screwing through the side panel, the fans, controler, <strong>heat</strong>ing<br />

element and electrical wiring must not be damaged or restricted in function.<br />

Sound and vibration transfer must be considered on site when installing the <strong>unit</strong>. It<br />

is necessary to connect the condensation spigot of the <strong>unit</strong> to a pipe connected<br />

to the drainage system of the house <strong>with</strong> a U bend trap in to prevent oders returning<br />

from the drains (see condensation run-off). The condensate pipeing must ensure<br />

the effective gravity flow of the condensate water. Tight bends can lead to a<br />

high pressure loss and flow noise. A secure and tight connection of the ductwork is<br />

required. For maintenance and installation work, the <strong>unit</strong> must be accessable.<br />

When taking the <strong>unit</strong> out of the carboard box, the <strong>unit</strong> must not be stod on the<br />

condensation spigot at the bottom of the <strong>unit</strong>. Therefore lay it on its back to prevent<br />

damage, using the polystyrene packing to lay the <strong>unit</strong> on will ensure the <strong>unit</strong><br />

will not get scratched. Before installation the operation switch must be taken<br />

out of the <strong>unit</strong>.<br />

– CONDENSATION RUN-OF (Picture 2 and 3, No. 4)<br />

To prevent siphioning and oders the condensation pipe should have a ‘U’ bend<br />

trap in the line. It must have a minimum height of 100 mm, otherwise water could<br />

be drawn back through the fan.<br />

NB: To avoid odours, fill in water in the drain trap before putting into operation.<br />

For trouble free operation, the drain must incline and the condensation<br />

spigot under the tray should be mounted low enough.<br />

The regulations of the water board and other legislation must be observed.<br />

The condensation spigot is to be fixed to the drainage system via a flexible hose<br />

∅ 15 mm. If the same is not in a room which is <strong>heat</strong>ed, it must be protected<br />

against frost.<br />

– AIR DUCTING, VENTILATION CIRCUIT<br />

When designing the ductwork, use the shortest possible runs. Airight connections<br />

and change overs must be ensured for the best possible <strong>heat</strong> <strong>recovery</strong>. To avoid<br />

pressure loss, accumulating dirt, and noise, use smooth ducting (plastic or rigid<br />

ducting). For main ducting (outside air, extract air, inlet air, discharge collection) a<br />

diameter 125 mm has to be used, for side ducting use a diameter of 80 mm to<br />

125 mm.<br />

To reduce condensation in the extract and outside air pipes, the ducting has to<br />

be insulated where appropriate. Also if inlet and extract ductwork cross un<strong>heat</strong>ed<br />

rooms insulation must be provided to reduce <strong>heat</strong> losses.<br />

Fresh air should be supplied into living and bedrooms, extraction takes place in<br />

bathrooms, toilets and kitchens. To balance the whole system the duct connection<br />

into the rooms we recommend the use of adjustable valves (<strong>HELIOS</strong>-valves).<br />

The opening for the kitchen extract needs a filter. A kitchen hood must not be<br />

connected directly to the<strong>KWL</strong> <strong>250</strong> unless adequate protection is provided to<br />

precvent grease build-up. Extract air from kitchen hoods <strong>with</strong> a own fan must be<br />

extracted via a seperate duct. There must be enough air transfer flow between<br />

rooms (e.g. door grilles) <strong>with</strong>in the building to guarantee air flow between intake<br />

rooms and extract rooms.<br />

Fire and building regulations must be observed.<br />

– Sensor <strong>heat</strong>er battery (<strong>KWL</strong> <strong>250</strong> EH) (Picture 3, No.17)<br />

The temperature sensor for the suppy air must needs to be mounted into the supply<br />

air duct after the <strong>unit</strong>’s outlet. A hole of Ø 7 mm is required, insert the temperature<br />

sensor, fixand fix ensuring an airtight seal.<br />

– ELECTRICAL CONNECTIONS (Picture 5, Page 5)<br />

Only work <strong>with</strong> the <strong>unit</strong> isolated from the electric supply. An isolator is required for<br />

<strong>with</strong> a minimum of 3 mm contact opening of each pole. Electrical connection<br />

should only be carried out by a qualified person.<br />

All relevant safety and installation regulations (IEE regulations) are to be observed.Between<br />

the circuit board and the terminal box of the operation switch a<br />

control cable (8 x 0,25 mm 2 , length max. 50 m) is to be used.<br />

Electrical connections are to be made using to wiring diagram SS-762.<br />

The <strong>unit</strong> is supplied <strong>with</strong> a power lead <strong>with</strong> three pin plug. Normally the <strong>unit</strong> does<br />

not have an "off"-state. If necessary plan a switch before the power socket. After<br />

mounting of the <strong>unit</strong> the plug must be easily accessible.<br />

If this is not the case, an on/off switch <strong>with</strong> 3 mm contac distance must be installe<br />

(VDE 0700 T1 7.12.2). For a good room climate and to avoid damages due to<br />

condensation, the <strong>KWL</strong> <strong>250</strong> should never be switched off completely, appart from<br />

the time for maintenace and repair or malfunctions.<br />

∆ p fa<br />

[Pa]<br />

– FIREPLACES & BOILERS<br />

The central <strong>ventilation</strong> <strong>unit</strong> <strong>with</strong> <strong>heat</strong> <strong>recovery</strong> “<strong>KWL</strong> <strong>250</strong>“ will create a negative pressure<br />

<strong>with</strong> in the dewlling in certain areas. Steps should be taken to ensure that the negative<br />

pressure created will not restrict the airflow to gas, oil of solid fuel devices. It may<br />

be necessary to fit a makeup air <strong>unit</strong> suvh as an airbrick or a Helios ZLA or ZLE <strong>unit</strong>.<br />

Picture 1<br />

V [m 3 /h]

<strong>Central</strong> <strong>ventilation</strong> <strong>with</strong> <strong>heat</strong> <strong>recovery</strong> <strong>unit</strong> <strong>KWL</strong> <strong>250</strong><br />

Operation and installation instructions no. 91581<br />

INSTALLATION OF CONTROL CABLE<br />

The control cable should be shielded and not be placed parallel to the mains supply<br />

cable as interference may cccur.<br />

OPERATION – ADJUSTMENT<br />

The <strong>KWL</strong> <strong>250</strong> is to be controlled manually via the operation switch, which should<br />

be mounted on a convenient place in the house. The operation switch allows following<br />

functions:<br />

– right press button (fan symbol): the desired step for the air flow volume can be<br />

adjusted, the according light shows the chosen step:<br />

MIN (speed step 1) basic air flow, for less intake air needs<br />

NORMAL (speed step 2) normal air flow<br />

MAX (speed step 3) full R.P.M., for maximum intake air needs<br />

– left press button (+ symbol) only important in combination <strong>with</strong> electric <strong>heat</strong>er<br />

battery: The electric <strong>heat</strong>er battery can be switched on and off. When switched<br />

on, the <strong>heat</strong>er battery starts <strong>heat</strong>ing when the temperature is lower than the temperature<br />

pre set point (adjusted on the pot.)<br />

red light (!)<br />

blinking slow Filter needs to be changed ! (if filter monitor is installed)<br />

blinking fast The temperature monitor (Pic .3, No.2.2) for the <strong>heat</strong>er<br />

battery tripped.<br />

blinking constant Both messages appeared..<br />

green light (+) blinking, when availability of <strong>heat</strong>er element is switched<br />

on,<br />

yellow light (°C) Blinking, when electric <strong>heat</strong>er battery is in use.<br />

Speed step 2 can be adjusted to the size of the dewelling. Open the <strong>unit</strong> is to be<br />

opened. Then change the two connections, marked <strong>with</strong> speed step 2 at the<br />

transformer according to wiring diagram in the <strong>unit</strong>. Isolate from the mains supply<br />

before comencing this work all mains.<br />

Note: If the electrical supply of the <strong>KWL</strong> <strong>250</strong> is disconnected, the <strong>unit</strong> will restart<br />

automatically <strong>with</strong> basic air flow (speed step 1) and the availability of the <strong>heat</strong>er<br />

battery.<br />

N.B.: For good room climate and to avoid damage from condensation, the <strong>KWL</strong><br />

<strong>250</strong> should never be switched off apart from cleaning/maintenance work or possible<br />

faults.<br />

Settings on DIP-switch<br />

Switch- Standard- Function<br />

No. setting<br />

1 ON ON position: Electric <strong>heat</strong>er battery to be switched off<br />

during frost protection modus. (must not be OFF!)<br />

2 OFF ON position: Electric <strong>heat</strong>er battery to be switched off on<br />

speed step 1.<br />

3 OFF (only <strong>with</strong> timer) On position:<br />

Supply air to be lowered by 3 °C at night.<br />

(only if a <strong>heat</strong>er battery is used)<br />

4 OFF (only <strong>with</strong> timer) ON position:<br />

Air flow volume to be lowered on speed step 1 at night<br />

5 OFF –<br />

6 ON –<br />

Setting the electric <strong>heat</strong>er battery (<strong>KWL</strong> <strong>250</strong> EH)<br />

The pot for temperature preselection fot the <strong>heat</strong>er battery (pic.3, No.1) is placed<br />

on the extract air cover plate. This pot is factory set at 20 °C and can be adjusted<br />

as required for the supply air. Do not set higher than 25 °C. The <strong>heat</strong>ing battery is<br />

protected against over<strong>heat</strong>ing via a self resetting temperature cut out (pic. 3, No.<br />

2.1). This temperature cutout switches off automatically when the temperature of<br />

65°C has been reached. It switches back on automatically whenf the <strong>heat</strong>er battery<br />

has cooled down. As an additional safety control, a second, non self resetting<br />

thermostat (temperature cut out), switches off the whole <strong>unit</strong> automatically if a<br />

temperature of 80°C is exceeded. This thermostat can be manually reset by pressing<br />

the reset button, which is accessible by removing the white plastic lid.<br />

Regulating the water <strong>heat</strong>er battery (<strong>KWL</strong> <strong>250</strong> WW) (Picture 2)<br />

The progressive <strong>heat</strong>ing is via the built-in water <strong>heat</strong>er battery (18). The supply<br />

and return pipeing on site must be so routed or fully insulated supply to prevent<br />

frost damage. A thermostatic valve <strong>with</strong> remote sensor is to be fixed in the supply<br />

pipe of the <strong>heat</strong>er battery on site. The remote controller is to be fixed above the<br />

<strong>KWL</strong>-connecting spigot “supply air“ into the supply air ducting. Usung the remote<br />

sensor and the thermostatic valve in the water supply the supply air temperature<br />

is controlled. The thermostatic valve is not included and must be supplied and set<br />

on site.<br />

A water control system which is a Helios accessory (ref. WHST 300) is shown in<br />

picture 2. This provides a complete control for the water supply and return.<br />

ATTENTION: If the supply air ducting is to pass through cold areas Insulation must<br />

be applied to prevent temperature losses on before entering the room being supplied.<br />

Frost protection of the water <strong>heat</strong>er battery (Picture 2)<br />

Intake and extract ductwork must be insulated to avoid ice build up on the water<br />

<strong>heat</strong>er battery. Immediately after the water <strong>heat</strong>er battery there is a frost protection<br />

thermostat (20). If the temperature off the water <strong>heat</strong>er battery is lower than to +5<br />

°C the thermo sensor closes. This volt free contact of the thermostat is to be<br />

connected <strong>with</strong> the <strong>heat</strong>er control so that the shunt valve opens as soon as the<br />

<strong>heat</strong>er and circulating pump are switched off. This forced control avoids the ice<br />

build up on the water <strong>heat</strong>er battery. If the <strong>unit</strong> is switched off at any time in winter<br />

the warn water coil should be drained off to prevent frost damage to the coil.<br />

Frost protection of the <strong>heat</strong> exchanger battery:<br />

The sensor (Picture 3, No. 3) for frost protection is located in the extract air ducting.<br />

This sensor controls the supply air fan so that ice and frost can not build up in<br />

the extract air ducting or the <strong>heat</strong> exchanger. Warm air e.g. from the bathroom<br />

etc. contains high humidity that can condensate easily. Therefore the temperature<br />

in the <strong>heat</strong> exchanger must not drop so low that water freezes in it. When the outside<br />

temperature drops the extract temperature drops as well. If the temperature of<br />

the extract air is close to the freezing point, the supply air fan switches off for a<br />

certain period of time until the <strong>heat</strong> exchanger is warms up sufficienty. The frost<br />

protection thermostat is factory set and normally needs no adjustment.<br />

– Summer Service<br />

During the warmer months (apart from the <strong>heat</strong>ing period) it is not necessary to recover<br />

<strong>heat</strong>. The <strong>recovery</strong> battery can be replaced <strong>with</strong> a summer insert (Accessory <strong>KWL</strong>-<br />

SOE <strong>250</strong>, Ref. No. 0855). Through this the outside air enters directly into the house<br />

<strong>with</strong>out being warmed up. The temperature adjusting pot (<strong>KWL</strong> <strong>250</strong> EH) or the thermostat<br />

(<strong>KWL</strong> <strong>250</strong> WW) must be positioned on low temperature otherwise unnecessary<br />

<strong>heat</strong>ing will be the result. Remember to reset the thermostat the following autumn<br />

and replace the <strong>heat</strong> exchanger <strong>unit</strong> again.<br />

– Accessories, switches, controllers<br />

It is not admissible to use accessories which are not recommended by Helios, in<br />

case of damage this will lead to a loss of warranty. The use of an electronic or<br />

transformer speed controller is not permissible.<br />

CLEANING AND MAINTENANCE<br />

Isolate the <strong>unit</strong> from the electric supply before carring out any work on the <strong>unit</strong>.<br />

– Opening of door (Pic. 3, page 4)<br />

The door is secured <strong>with</strong> screws and can be opened after removing the screws.<br />

– Filter<br />

The <strong>unit</strong> filters are as follows:<br />

• Outside air: Prefilter G 3 Part.-No. 0043<br />

Finefilter F 5 Part.-No. 0044<br />

alternatively: (F 7, Part.-No. 0045, eg for persons <strong>with</strong> allergies)<br />

• Extract air: Prefilter G 3 Part.-No. 0043<br />

The outside air and the extract air filter are to be checked and changed regularly,<br />

depending on degree of pollution at least every 3 months. For hygiene reasons,<br />

the fine filter should be changed after every year at least. Check the correct the air<br />

flow direction when refitting the filter. In areas of heavy air pollution, a filter box<br />

(LFBR 125, Part.-No. 8577) should to be placed in an easily accessible area upstream<br />

of the <strong>unit</strong>. These filters must be regullary cleaned and changed.

<strong>Central</strong> <strong>ventilation</strong> <strong>with</strong> <strong>heat</strong> <strong>recovery</strong> <strong>unit</strong> <strong>KWL</strong> <strong>250</strong><br />

Operation and installation instructions no. 91581<br />

– Filter control<br />

A filter control is not provided as standard. If it is required, a differential pressure<br />

switch (as accessory obtainable DDS switch, Ref.-no. 0445) can be connected to<br />

the <strong>KWL</strong>C. The holes for the pressure hoses (see picture 4) are in the casing (see<br />

picture 4). One connection point is in the top of the casing the <strong>with</strong> the other the<br />

pipe passing through the top of the casing to the connection pointin the side of<br />

the extract chamber. The link must be removed on the "FI" circuit boardand the<br />

DDS connectoins made as shown..<br />

– Fans<br />

The fans are to be maintained and cleaned every 12 months at least. For cleaning<br />

use a small brush and an oil free cleaning fluid. Make sure that no water gets into<br />

the motor. Fan must be completely dry before re-using.<br />

To dismantle the <strong>unit</strong>, screw of the cover plate extract air (pic. 3, No. 15) or supply<br />

air (pic. 3, No. 16), disconnection of the plug connectors, pulling of the fans to<br />

the front. Than disassemble impeller from casing.<br />

– Heat <strong>recovery</strong> battery<br />

To be cleaned at least twice a year. Pull out the <strong>unit</strong> carefully. For cleaning put in<br />

warm soapy water (do not use cleaning fluids that can damage the aluminium or<br />

leave residual oders/gases) and finally clean <strong>with</strong> warm water. When re-assembling<br />

ensure correct installation.<br />

• Make sure that summer-insert was exchanged for the <strong>heat</strong>er <strong>recovery</strong> element.<br />

– Substantially reduced air flow<br />

• Filters (6 and 7) could be dirty. Change or clean filoters (see maintenance)<br />

– Water emission out of <strong>unit</strong><br />

possibly the condensation water can not drain off properly.<br />

Reasons for this problem:<br />

• Condensation drain is blocked up or not drainging properly (check installation).<br />

• Condensation gathering in the tray, because the condensation spigot has<br />

been pushed to the top/ into the <strong>unit</strong> (e.g. by standing the <strong>unit</strong> on the con<br />

densation out let pipe in the bottom during inatallation).<br />

Corrective: Take <strong>heat</strong> exchanger from the <strong>unit</strong> and move the condensation spigot<br />

softly downwards.<br />

Having tried the above solutions, if the problem still exists the contact your installer/supplier<br />

giving the serial number from the <strong>unit</strong>’s nameplate.<br />

– Valves: To be cleaned at least annually.<br />

– Outer grilles: Check yearly that grilles are free from leaves etc.<br />

SOURCES OF MALFUNCTION<br />

Prior to working on the <strong>unit</strong> ensure it is isolated from the electrical mains<br />

supply.<br />

– No air flow<br />

• Check electrical connection / fuses<br />

• The over<strong>heat</strong>ing thermostat 2.2 may have tripped. Remove white plastic cap<br />

and press red button.<br />

– Inlet air is cold<br />

• Set <strong>heat</strong>er thermostat (1) to a higher temperature<br />

• Ductwork in cold areas need extra insulation<br />

Picture Abb. 2 2<br />

General arrangement<br />

Floor (fire protection)<br />

Water control for <strong>KWL</strong> <strong>250</strong> WW<br />

<strong>ventilation</strong> duct/<br />

ceiling<br />

operation switch<br />

extract air<br />

outside air<br />

Shunt valve<br />

Thermostatic valve<br />

<strong>with</strong> remote sensor<br />

in the supply duct<br />

Input air<br />

extract<br />

air<br />

outside<br />

air<br />

extract air<br />

Condensate pipe 15mm<br />

in a frost free area<br />

Drain pipe<br />

to <strong>heat</strong>ing system<br />

warm water<br />

from <strong>heat</strong>ing system<br />

Min.<br />

100mm<br />

Condensate trap<br />

in a frost free area<br />

pump<br />

<strong>heat</strong>ing<br />

control<br />

Volt free contactor<br />

(closed) T2 for<br />

frost protection<br />

Warm Water<br />

(WW) Battery<br />

Floor (fire protection)

<strong>Central</strong> <strong>ventilation</strong> <strong>with</strong> <strong>heat</strong> <strong>recovery</strong> <strong>unit</strong> <strong>KWL</strong> <strong>250</strong><br />

Operation and installation instructions no. 91581<br />

Picture Abb. 3 3<br />

1 Temperature-Pot (Version EH)<br />

2.1 Temperature cut out self resetting<br />

(Version EH)<br />

2.2 Temperature cut out not self resetting<br />

(Version EH)<br />

3 Frost thermostat for <strong>heat</strong> exchanger<br />

4 Condensate outlet<br />

5 Extract pre filter G3<br />

6 Inlet pre filter G3<br />

7 Inlet fine filrter F5<br />

8 Elecrtic <strong>heat</strong>er (Version EH)<br />

9 Supply fan<br />

10 Extract fan<br />

11 Heat exchanger<br />

12 Terminal box<br />

13 Operation switch<br />

14 Door<br />

15 Cover plate extract air<br />

16 Cover plate supply air<br />

17 Temperature sensor supply air<br />

18 Warm water <strong>heat</strong>er battery (Version WW)<br />

19 Flow & return pipes for the warm water(Version WW)<br />

20 Temperature sensor for frost protection ofthe water<br />

<strong>heat</strong>er battery (Version WW)<br />

Parts identification<br />

Input air outside air<br />

extract air extract air<br />

Duct connections<br />

Room side Outside<br />

Input air<br />

extract air outside air<br />

extract air<br />

Picture Abb. 4 4<br />

Hole 7mm dia for DDS<br />

12 mm pipe connections for<br />

the warm water coil<br />

(WW version only)<br />

Input air<br />

extract air<br />

outside air<br />

extract air<br />

Connection hole for DDS<br />

7mm dia hole for DDS<br />

Hole for operation<br />

switch cable<br />

Input air<br />

extract air<br />

outside air<br />

extract air<br />

Condensate outlet 15mm

!<br />

<strong>Central</strong> <strong>ventilation</strong> <strong>with</strong> <strong>heat</strong> <strong>recovery</strong> <strong>unit</strong> <strong>KWL</strong> <strong>250</strong><br />

Operation and installation instructions no. 91581<br />

Picture Abb. 5 5<br />

<strong>KWL</strong><br />

<strong>250</strong> EH<br />

SS-762<br />

Klemmenadapter<br />

Terminalblock<br />

-orange<br />

-blue<br />

-green<br />

-brown<br />

-yellow<br />

-red<br />

-white<br />

-black<br />

or<br />

bl<br />

gn<br />

br<br />

ge<br />

rt<br />

ws<br />

sw<br />

123 4 5 6 7 8<br />

/optional<br />

wahlweise<br />

8 x 0,25 mm² max. 50m<br />

or<br />

bl<br />

gn<br />

br<br />

ge<br />

rt<br />

ws<br />

sw<br />

Datenleitung mit RJ45-Stecker (Adern "gedreht")<br />

Dataline <strong>with</strong> RJ45 plug (wires rotated)<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

Steuerplatine Heizung / Heater element<br />

Betriebsschalter<br />

Circuit board<br />

for/ bei <strong>KWL</strong> <strong>250</strong> optional:<br />

Main switch<br />

EHM <strong>250</strong><br />

MIN<br />

NORMAL<br />

MAX<br />

/ Ref.no.<br />

Standardeinstellung,<br />

siehe Montageanleitung<br />

°C<br />

Best.Nr.<br />

0853<br />

for/ bei<br />

<strong>KWL</strong> <strong>250</strong> WW<br />

bei<br />

<strong>KWL</strong> <strong>250</strong> EH<br />

for/<br />

2 3 4 5 6<br />

1<br />

N<br />

on<br />

off<br />

/ incl.<br />

PWW inkl.<br />

/ incl.<br />

inkl.<br />

<strong>KWL</strong>-WSU Best.Nr. 0856<br />

Wochenzeitschaltuhr<br />

Nachtabsenkung,<br />

optional<br />

88<br />

88<br />

Frostschutzthermostat<br />

Warmwasser<br />

potentialfrei<br />

L<br />

For switch settings<br />

see operation and<br />

maintenance manual<br />

Frost protection thermostat warm water<br />

Volt free contact from thermostat<br />

FI<br />

Weekly timer, night set back<br />

(lowers temperature at night)<br />

optional<br />

<strong>KWL</strong> <strong>250</strong><br />

/ Mains supply<br />

Netzstecker<br />

Externes<br />

Temperaturmodul,<br />

optional<br />

External temperature module<br />

optional<br />

15<br />

20<br />

10<br />

PE<br />

N<br />

L1<br />

P<br />

P<br />

/Ref.no.<br />

25<br />

5<br />

2<br />

1<br />

DDS<br />

Best.Nr.<br />

0445<br />

Drucksensor<br />

°C<br />

Trennschalter / On/off switch<br />

optional, VDE 0700 T1 7.12.2<br />

/Differential<br />

pressure switch<br />

optional<br />

92818 002 SS-762 04.02.04

<strong>Central</strong> <strong>ventilation</strong> <strong>with</strong> <strong>heat</strong> <strong>recovery</strong> <strong>unit</strong> <strong>KWL</strong> <strong>250</strong><br />

Operation and installation instructions no.<br />

Druckschrift-Nr. 91581/ 09.03<br />

Service und Information<br />

D <strong>HELIOS</strong> Ventilatoren GmbH & Co · Lupfenstraße 8 · 78056 VS-Schwenningen F <strong>HELIOS</strong> Ventilateurs · Z.I. La Fosse à la Barbière · 2, rue Louis Saillant · 93605 Aulnay sous Bois Cedex<br />

CH <strong>HELIOS</strong> Ventilatoren AG · Steinackerstraße 36 · 8902 Urdorf / Zürich GB <strong>HELIOS</strong> Ventilation Systems Ltd. · 5 Crown Gate · Wyncolls Road · Severalls Industrial Park ·<br />

A <strong>HELIOS</strong> Ventilatoren · Postfach 854 · Siemensstraße 15 · 6023 Innsbruck Colchester · Essex · CO4 9HZ