Hempel Corporate Responsibility Report 2011

Hempel Corporate Responsibility Report 2011

Hempel Corporate Responsibility Report 2011

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Ethical Behaviour | Our People | Community Engagement | ProcuREment | Health & Safety | Environment<br />

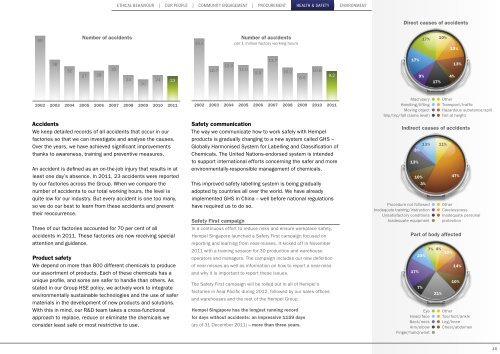

Direct causes of accidents<br />

60<br />

Number of accidents<br />

19.1<br />

Number of accidents<br />

per 1 million factory working hours<br />

17%<br />

10%<br />

13%<br />

38<br />

32<br />

27<br />

28<br />

33<br />

24<br />

20<br />

24<br />

23<br />

10.7<br />

12.0<br />

11.0<br />

9.9<br />

13.7<br />

10.2<br />

8.5<br />

10.6<br />

9.2<br />

17%<br />

9% 4%<br />

17%<br />

13%<br />

2002<br />

2003<br />

2004<br />

2005<br />

2006<br />

2007<br />

2008<br />

2009<br />

2010<br />

<strong>2011</strong><br />

Accidents<br />

We keep detailed records of all accidents that occur in our<br />

factories so that we can investigate and analyse the causes.<br />

Over the years, we have achieved significant improvements<br />

thanks to awareness, training and preventive measures.<br />

An accident is defined as an on-the-job injury that results in at<br />

least one day’s absence. In <strong>2011</strong>, 23 accidents were reported<br />

by our factories across the Group. When we compare the<br />

number of accidents to our total working hours, the level is<br />

quite low for our industry. But every accident is one too many,<br />

so we do our best to learn from these accidents and prevent<br />

their reoccurrence.<br />

Three of our factories accounted for 70 per cent of all<br />

accidents in <strong>2011</strong>. These factories are now receiving special<br />

attention and guidance.<br />

Product safety<br />

We depend on more than 800 different chemicals to produce<br />

our assortment of products. Each of these chemicals has a<br />

unique profile, and some are safer to handle than others. As<br />

stated in our Group HSE policy, we actively work to integrate<br />

environmentally sustainable technologies and the use of safer<br />

materials in the development of new products and solutions.<br />

With this in mind, our R&D team takes a cross-functional<br />

approach to replace, reduce or eliminate the chemicals we<br />

consider least safe or most restrictive to use.<br />

2002<br />

2003<br />

2004<br />

2005<br />

2006<br />

2007<br />

2008<br />

2009<br />

2010<br />

<strong>2011</strong><br />

Safety communication<br />

The way we communicate how to work safely with <strong>Hempel</strong><br />

products is gradually changing to a new system called GHS –<br />

Globally Harmonised System for Labelling and Classification of<br />

Chemicals. The United Nations-endorsed system is intended<br />

to support international efforts concerning the safer and more<br />

environmentally-responsible management of chemicals.<br />

This improved safety labelling system is being gradually<br />

adopted by countries all over the world. We have already<br />

implemented GHS in China – well before national regulations<br />

have required us to do so.<br />

Safety First campaign<br />

In a continuous effort to reduce risks and ensure workplace safety,<br />

<strong>Hempel</strong> Singapore launched a Safety First campaign focused on<br />

reporting and learning from near-misses. It kicked off in November<br />

<strong>2011</strong> with a training session for 30 production and warehouse<br />

operators and managers. The campaign includes our new definition<br />

of near-misses as well as information on how to report a near-miss<br />

and why it is important to report these issues.<br />

The Safety First campaign will be rolled out in all of <strong>Hempel</strong>’s<br />

factories in Asia Pacific during 2012, followed by our sales offices<br />

and warehouses and the rest of the <strong>Hempel</strong> Group.<br />

<strong>Hempel</strong> Singapore has the longest running record<br />

for days without accidents: an impressive 1159 days<br />

(as of 31 December <strong>2011</strong>) – more than three years.<br />

Machinery ● ● Other<br />

Handling/lifting ● ● Transport/traffic<br />

Moving object ● ● Hazardous substance/spill<br />

Slip/trip/fall (same level) ● ● Fall at height<br />

Indirect causes of accidents<br />

13%<br />

3%<br />

13%<br />

11%<br />

10% 47%<br />

3%<br />

Procedure not followed ● ● Other<br />

Inadequate training/instruction ● ● Carelessness<br />

Unsatisfactory conditions ● ● Inadequate personal<br />

Inadequate equipment ● protection<br />

Part of body affected<br />

17%<br />

7% 4%<br />

10%<br />

10%<br />

7%<br />

21%<br />

14%<br />

10%<br />

Eye ● ● Other<br />

Head/face ● ● Toe/foot/ankle<br />

Back/neck ● ● Leg/knee<br />

Arm/elbow ● ● Chest/abdomen<br />

Finger/hand/wrist ●<br />

15