Hempel Corporate Responsibility Report 2011

Hempel Corporate Responsibility Report 2011

Hempel Corporate Responsibility Report 2011

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Ethical Behaviour | Our People | Community Engagement | Procurement | Health & Safety | Environment<br />

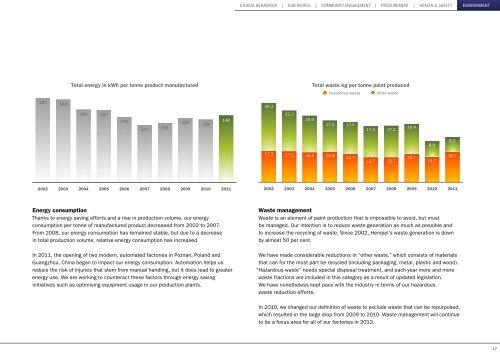

Total energy in kWh per tonne product manufactured<br />

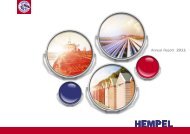

Total waste kg per tonne paint produced<br />

hazardous waste other waste<br />

187<br />

183<br />

26.3<br />

161<br />

160<br />

145<br />

127<br />

131<br />

143<br />

139<br />

148<br />

22.2<br />

20.0<br />

17.2<br />

17.5<br />

17.0<br />

17.2<br />

16.4<br />

8.4<br />

8.1<br />

17.3<br />

17.0<br />

16.4<br />

16.6<br />

15.7<br />

13.7<br />

13.7<br />

15.7<br />

14.1<br />

16.7<br />

2002<br />

2003<br />

2004<br />

2005<br />

2006<br />

2007<br />

2008<br />

2009<br />

2010<br />

<strong>2011</strong><br />

2002<br />

2003<br />

2004<br />

2005<br />

2006<br />

2007<br />

2008<br />

2009<br />

2010<br />

<strong>2011</strong><br />

Energy consumption<br />

Thanks to energy saving efforts and a rise in production volume, our energy<br />

consumption per tonne of manufactured product decreased from 2002 to 2007.<br />

From 2008, our energy consumption has remained stable, but due to a decrease<br />

in total production volume, relative energy consumption has increased.<br />

In <strong>2011</strong>, the opening of two modern, automated factories in Poznan, Poland and<br />

Guangzhou, China began to impact our energy consumption. Automation helps us<br />

reduce the risk of injuries that stem from manual handling, but it does lead to greater<br />

energy use. We are working to counteract these factors through energy saving<br />

initiatives such as optimising equipment usage in our production plants.<br />

Waste management<br />

Waste is an element of paint production that is impossible to avoid, but must<br />

be managed. Our intention is to reduce waste generation as much as possible and<br />

to increase the recycling of waste. Since 2002, <strong>Hempel</strong>’s waste generation is down<br />

by almost 50 per cent.<br />

We have made considerable reductions in “other waste,” which consists of materials<br />

that can for the most part be recycled (including packaging, metal, plastic and wood).<br />

“Hazardous waste” needs special disposal treatment, and each year more and more<br />

waste fractions are included in this category as a result of updated legislation.<br />

We have nonetheless kept pace with the industry in terms of our hazardous<br />

waste reduction efforts.<br />

In 2010, we changed our definition of waste to exclude waste that can be repurposed,<br />

which resulted in the large drop from 2009 to 2010. Waste management will continue<br />

to be a focus area for all of our factories in 2012.<br />

17