European Technical Approval Technical Approval ETA 12 ... - Hempel

European Technical Approval Technical Approval ETA 12 ... - Hempel

European Technical Approval Technical Approval ETA 12 ... - Hempel

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

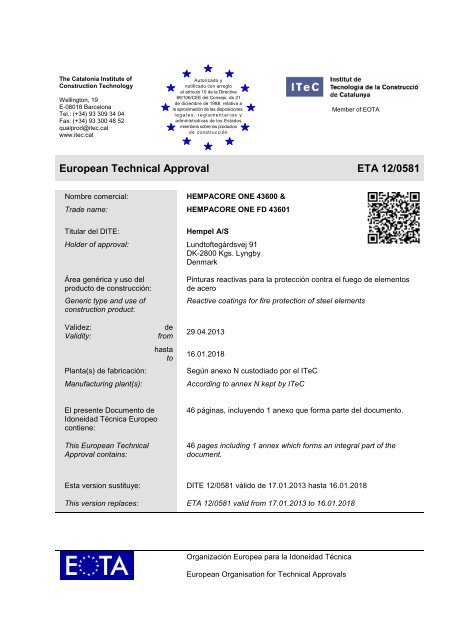

The Catalonia Institute of<br />

Construction Technology<br />

Wellington, 19<br />

E-08018 Barcelona<br />

Tel.: (+34) 93 309 34 04<br />

Fax: (+34) 93 300 48 52<br />

qualprod@itec.cat<br />

www.itec.cat<br />

Autorizado y<br />

notificado con arreglo<br />

al artículo 10 de la Directiva<br />

89/106/CEE del Consejo, de 21<br />

de diciembre de 1988, relativa a<br />

la aproximación de las disposiciones<br />

l e g a l e s , r e g l a m e n t a r i a s y<br />

administrativas de los Estados<br />

miembros sobre los productos<br />

de construcción<br />

Member of EOTA<br />

<strong>European</strong> <strong>Technical</strong> <strong>Approval</strong><br />

<strong>ETA</strong> <strong>12</strong>/0581<br />

Nombre comercial:<br />

Trade name:<br />

HEMPACORE ONE 43600 &<br />

HEMPACORE ONE FD 43601<br />

Titular del DITE:<br />

Holder of approval:<br />

Área genérica y uso del<br />

producto de construcción:<br />

Generic type and use of<br />

construction product:<br />

Validez:<br />

Validity:<br />

Planta(s) de fabricación:<br />

Manufacturing plant(s):<br />

de<br />

from<br />

hasta<br />

to<br />

<strong>Hempel</strong> A/S<br />

Lundtoftegårdsvej 91<br />

DK-2800 Kgs. Lyngby<br />

Denmark<br />

Pinturas reactivas para la protección contra el fuego de elementos<br />

de acero<br />

Reactive coatings for fire protection of steel elements<br />

29.04.2013<br />

16.01.2018<br />

Según anexo N custodiado por el ITeC<br />

According to annex N kept by ITeC<br />

El presente Documento de<br />

Idoneidad Técnica Europeo<br />

contiene:<br />

This <strong>European</strong> <strong>Technical</strong><br />

<strong>Approval</strong> contains:<br />

46 páginas, incluyendo 1 anexo que forma parte del documento.<br />

46 pages including 1 annex which forms an integral part of the<br />

document.<br />

Esta version sustituye:<br />

This version replaces:<br />

DITE <strong>12</strong>/0581 válido de 17.01.2013 hasta 16.01.2018<br />

<strong>ETA</strong> <strong>12</strong>/0581 valid from 17.01.2013 to 16.01.2018<br />

Organización Europea para la Idoneidad Técnica<br />

<strong>European</strong> Organisation for <strong>Technical</strong> <strong>Approval</strong>s

Page 2 of 46 of <strong>ETA</strong> <strong>12</strong>/0581, issued on 29.04.2013<br />

I<br />

LEGAL BASES AND GENERAL CONDITIONS<br />

1. This <strong>European</strong> <strong>Technical</strong> <strong>Approval</strong> is issued by the Catalonia Institute of Construction<br />

Technology (ITeC) in accordance with:<br />

- Council Directive 89/106/EEC 1 of 21 December 1988 on the approximation of laws,<br />

regulations and administrative provisions of Member States relating to construction<br />

products modified by the Council Directive 93/68/EEC 2 and Regulation (EC) Nº 1882/2003<br />

of the <strong>European</strong> Parliament and of the Council 3 ;<br />

- Real Decreto 1630/1992, de 29 de diciembre, por el que se dictan disposiciones para la<br />

libre circulación de productos de la construcción en aplicación de la Directiva<br />

89/106/CEE 4 ;<br />

- Real Decreto 1328/1995, de 28 de julio, por el que se modifican, en aplicación de la<br />

Directiva 93/68/CEE, las disposiciones para la libre circulación, aprobadas por el Real<br />

Decreto 1630/1992, de 29 de diciembre (BOE 19-8-95) y la Orden CTE/2276/2002 de 4<br />

de septiembre;<br />

- Common Procedural Rules for Requesting, Preparing and the Granting of <strong>European</strong><br />

<strong>Technical</strong> <strong>Approval</strong>s set out in the Annex to Commission Decision 94/23/EC 5 ;<br />

- Guideline for <strong>European</strong> <strong>Technical</strong> <strong>Approval</strong> of Fire Protective Products, <strong>ETA</strong>G 018, Part 1:<br />

General and Part 2: Reactive coatings for fire protection of steel elements.<br />

2. The Catalonia Institute of Construction Technology (ITeC) is authorised to check whether the<br />

provisions of this <strong>European</strong> <strong>Technical</strong> <strong>Approval</strong> are met. Checking may take place in the<br />

manufacturing plants. Nevertheless, the responsibility for the conformity of the products with the<br />

<strong>European</strong> <strong>Technical</strong> <strong>Approval</strong> and for their fitness for the intended use remains with the holder<br />

of the <strong>European</strong> <strong>Technical</strong> <strong>Approval</strong>.<br />

3. This <strong>European</strong> <strong>Technical</strong> <strong>Approval</strong> is not to be transferred to manufacturers or agents of<br />

manufacturers other than those indicated on page 1; or manufacturing plants other than those<br />

indicated on page 1 of this <strong>European</strong> <strong>Technical</strong> <strong>Approval</strong>.<br />

4. This <strong>European</strong> <strong>Technical</strong> <strong>Approval</strong> may be withdrawn by the Catalonia Institute of Construction<br />

Technology (ITeC) pursuant to information by the Commission according to Article 5(1) of<br />

Council Directive 89/106/EEC.<br />

5. Reproduction of this <strong>European</strong> <strong>Technical</strong> <strong>Approval</strong> including transmission by electronic means<br />

shall be in full. However, partial reproduction can be made with the written consent of the<br />

Catalonia Institute of Construction Technology (ITeC). In this case, partial reproduction has to<br />

be designated as such. Texts and drawings of advertising brochures shall not contradict or<br />

misuse the <strong>European</strong> <strong>Technical</strong> <strong>Approval</strong>.<br />

6. This <strong>European</strong> <strong>Technical</strong> <strong>Approval</strong> is issued in Spanish by the Catalonia Institute of<br />

Construction Technology (ITeC). This version corresponds fully to the version circulated in<br />

EOTA. Translations into other languages have to be designated as such.<br />

1<br />

2<br />

3<br />

4<br />

5<br />

Official Journal of the <strong>European</strong> Communities Nº L 40, 11.2.1989, p.<strong>12</strong>.<br />

Official Journal of the <strong>European</strong> Communities Nº L 220, 30.8.1993, p.1.<br />

Official Journal of the <strong>European</strong> Union Nº L 284, 31.10.2003, p.1.<br />

Boletín Oficial del Estado nº 34 de 9 de febrero de 1993.<br />

Official Journal of the <strong>European</strong> Communities Nº L 17, 20.1.1994, p.34.

Page 3 of 46 of <strong>ETA</strong> <strong>12</strong>/0581, issued on 29.04.2013<br />

II<br />

SPECIFIC CONDITIONS OF THE EUROPEAN TECHNICAL APPROVAL<br />

1 Definition of product and intended use<br />

1.1 Definition of the construction product<br />

HEMPACORE ONE 43600 and HEMPACORE ONE FD 43601 are spray-applied or, for small<br />

areas, brush-applied solvent based reactive coatings. HEMPACORE ONE FD 43601 is the fast<br />

drying version of HEMPACORE ONE 43600 and both reactive coatings have the same<br />

composition except for the solvents that evaporate out of the end use product.<br />

The reactive coating systems for fire protection consist of the primer, the intumescent coating<br />

and, depending on the environmental use category, the topcoat where appropriate (see section<br />

1.2.2).<br />

All the systems shown in Table 1 have been assessed in this <strong>ETA</strong> under option 3, as described<br />

in the foreword of <strong>ETA</strong>G 018 Part 2.<br />

1.2 Intended use<br />

1.2.1 Fire protection<br />

HEMPACORE ONE 43600 and HEMPACORE ONE FD 43601 are used as reactive coating<br />

systems to fire protect beams and columns made of structural steel to achieve a fire resistance<br />

duration in accordance with EN 13501-2 6 .<br />

HEMPACORE ONE 43600 and HEMPACORE ONE FD 43601 are intended to fire protect<br />

various sizes of open sections (H and I) and square and circular hollow columns for up to a fire<br />

resistance classification in accordance with Annex 1, in the design temperatures range of<br />

350 ºC to 750 ºC.<br />

The detailed field of application regarding fire protection of HEMPACORE ONE 43600 and<br />

HEMPACORE ONE FD 43601 is given in Annex 1.<br />

1.2.2 Use categories related to environmental conditions<br />

Depending on the environmental use category the following systems have been approved.<br />

Table 1: Systems according to use categories.<br />

Primer (irrespective of the use<br />

Reactive coating<br />

environmental category)<br />

Two component epoxy, e.g:<br />

<strong>Hempel</strong>’s Shopprimer E 15280 (1)<br />

Hempadur 15570 (1)<br />

Hemudur 18500 (2)<br />

Hempadur 15553 (1)<br />

Short/medium oil alkyd, e.g:<br />

Hempaquick primer 13300 (1)<br />

Hemulin primer 18310 (2)<br />

HEMPACORE ONE 43600<br />

Zinc rich epoxy, e.g:<br />

Hempadur Zinc 17360 (1)<br />

HEMPACORE ONE FD 43601<br />

Acrylic, e.g:<br />

<strong>Hempel</strong>’s 17020 (1)<br />

One component epoxy, e.g:<br />

<strong>Hempel</strong>’s Uniprimer 13140 (1)<br />

Three component Zinc rich epoxy, e.g:<br />

Hemudur Zinc 18560 (2)<br />

(1) (2) solvent borne; water borne<br />

Topcoat (depending on the<br />

environmental use category)<br />

Category Type X<br />

(including Types Y, Z 1 and Z 2)<br />

Hempathane HS 55610<br />

Hempathane Topcoat 55210<br />

Hemuthane Enamel 58510<br />

Hempatex Hi-build 46410<br />

Hempatex Enamel 56360<br />

Hemucryl Enamel Hi-build 58030<br />

Hempathane HS 55810<br />

Category Type Y<br />

(including Types Z 1 and Z 2)<br />

Without topcoat or with the<br />

topcoats Type X approved<br />

6 EN 13501-2:2010 Fire classification of construction products and building elements Part 2: Classification using data from fire<br />

resistance tests, excluding ventilation services implemented.

Page 4 of 46 of <strong>ETA</strong> <strong>12</strong>/0581, issued on 29.04.2013<br />

The environmental use categories are specified in <strong>ETA</strong>G 018 Part 2, section 2.2.2:<br />

• Type X: external use<br />

• Type Y: internal use and semi-exposed conditions<br />

• Type Z 1 : internal use with high humidity conditions<br />

• Type Z 2 :internal use<br />

1.3 Assumed working life<br />

The provisions made in this <strong>European</strong> <strong>Technical</strong> <strong>Approval</strong> (<strong>ETA</strong>) are based on an assumed<br />

working life of the reactive coatings for fire protection HEMPACORE ONE 43600 and<br />

HEMPACORE ONE FD 43601 of at least 10 years, provided that the conditions laid down in<br />

sections 4.2, 5.1 and 5.2 for the packaging, transport, storage and installation as well as<br />

appropriate use, maintenance and repair are met.<br />

The indications given on the working life cannot be interpreted as a guarantee given by the<br />

manufacturer or the <strong>Approval</strong> Body, but should only be regarded as a means for choosing the<br />

appropriate products in relation to the expected economically reasonable working life of the<br />

works.<br />

2 Characteristics of products and methods of verification<br />

The assessment of the fitness of HEMPACORE ONE 43600 and HEMPACORE ONE FD 43601<br />

for the intended use considering the essential requirements was performed following the<br />

Guideline for <strong>European</strong> <strong>Technical</strong> <strong>Approval</strong> 018 for Fire Protective Products Part 1: General and<br />

Part 2: Reactive coatings for fire protection of steel elements.<br />

2.1 Mechanical resistance and stability (ER 1)<br />

Not relevant.<br />

2.2 Safety in case of fire (ER 2)<br />

2.2.1 Reaction to fire<br />

The reactive coating systems including all the primers and topcoats listed in Table 1 have a<br />

performance determined for a reaction to fire Class D-s2,d0 according to EN 13501-1 7 .<br />

This Class applies to reactive coating systems applied on substrates of structural steel (S<br />

designation) and stainless steel.<br />

2.2.2 Fire resistance<br />

The product has been tested according to EN 13381-8 8 . Fire resistance classes have been<br />

defined according to EN 13501-2 and are presented in Annex 1.<br />

2.2.3 Smouldering fire exposure<br />

The verification under exposure to the smouldering fire curve according to EN 13381-8, Annex<br />

A, has been carried out and the product meets the requirements established in EN 13381-8.<br />

2.3 Hygiene, health and the environment (ER 3)<br />

2.3.1 Release of dangerous substances<br />

According to the manufacturer’s declaration, the product specification has been compared with<br />

the regulated dangerous substances listed on the database established on the EC construction<br />

website, with Annex XVII and Annex XIV of REACH and with the ECHA Candidate List of<br />

Substances of Very High Concern to verify that they do not contain such substances above the<br />

acceptable limits.<br />

7 EN 13501-1:2007 Fire classification of construction products and building elements. Part 1: Classification using data from<br />

reaction to fire tests implemented.<br />

8 EN 13381-8:2010 Test methods for determining the contribution to the fire resistance of structural members. Part 8: Applied<br />

reactive protection to steel members.

Page 5 of 46 of <strong>ETA</strong> <strong>12</strong>/0581, issued on 29.04.2013<br />

In addition to the specific clauses relating to dangerous substances contained in this <strong>European</strong><br />

<strong>Technical</strong> <strong>Approval</strong>, there may be other requirements applicable to the products falling within its<br />

scope (e.g. transposed <strong>European</strong> legislation and national laws, regulations and administrative<br />

provisions). In order to meet the provisions of the EU Construction Products Directive, these<br />

requirements need also to be complied with, when and where they apply.<br />

2.4 Safety in use (ER 4)<br />

Not relevant.<br />

2.5 Protection against noise (ER 5)<br />

Not relevant.<br />

2.6 Energy economy and heat retention (ER 6)<br />

Not relevant.<br />

2.7 Aspects of durability, serviceability and identification of the products<br />

2.7.1 Durability and serviceability<br />

The primers and topcoats indicated in section 1.2.2 of this <strong>ETA</strong> are compatible with the reactive<br />

coatings, having regard to the provisions given in clause 4.2.2. The verifications were made in<br />

accordance with <strong>ETA</strong>G 018, Part 2, section 5.7.2.2. The approved environmental use<br />

categories shall be taken from section 1.2.2 of this <strong>ETA</strong>.<br />

2.7.2 Identification of products<br />

The <strong>ETA</strong> is issued for the system on the basis of agreed data/information, deposited with the<br />

Catalonia Institute of Construction Technology which identifies the system components that<br />

have been assessed and judged. Identification tests according to <strong>ETA</strong>G 018 Part 2, section<br />

5.7.3, have been carried out on components, which confirm that the system under assessment<br />

conforms to its declared characteristics.<br />

3 Evaluation and attestation of conformity and CE marking<br />

3.1 System of attestation of conformity<br />

According to the decision 1999/454/EC 9 of the <strong>European</strong> Commission, system 1 of attestation<br />

of conformity applies. This system of attestation of conformity is defined as follows:<br />

System 1:<br />

Certification of the conformity of the product by a notified certification body on the<br />

basis of:<br />

(a) Tasks for the manufacturer:<br />

(1) Factory production control<br />

(2) Further testing of samples taken at the factory by the manufacturer in accordance with<br />

a prescribed test plan<br />

(b) Tasks for the approved body:<br />

(3) Initial type testing of the product<br />

(4) Initial inspection of the factory and of factory production control<br />

(5) Continuous surveillance, assessment and approval of factory production control<br />

Note: Approved bodies are also referred to as “notified bodies”.<br />

9<br />

Official Journal of the <strong>European</strong> Communities Nº L178, 14.7.1999, p. 52

Page 6 of 46 of <strong>ETA</strong> <strong>12</strong>/0581, issued on 29.04.2013<br />

3.2 Responsibilities<br />

3.2.1 Tasks of the manufacturer<br />

3.2.1.1 Factory production control<br />

The manufacturer shall exercise permanent internal control of production. All the elements,<br />

requirements and provisions adopted by the manufacturer shall be documented in a systematic<br />

manner in the form of written policies and procedures, including records of results performed in<br />

accordance with the Control Plan. This production control system shall ensure that the product<br />

is in conformity with this <strong>European</strong> <strong>Technical</strong> <strong>Approval</strong> (<strong>ETA</strong>).<br />

Only the raw materials and materials stated in the technical documentation of this <strong>ETA</strong> may be<br />

used in the production of the products.<br />

The factory production control shall be in accordance with the Control Plan relating to this <strong>ETA</strong>,<br />

and part of its technical documentation. The Control Plan is laid down in the context of the<br />

factory production control system operated by the manufacturer and deposited with the ITeC. 10<br />

The results of factory production control shall be recorded and evaluated in accordance with the<br />

provisions of the Control Plan. On request they shall be presented to the ITeC.<br />

The personnel involved in the production process shall be identified, sufficiently qualified and<br />

trained to operate and maintain the production equipment. Machinery and equipment shall be<br />

regularly maintained and this shall be documented. All processes and production procedures<br />

shall be recorded at regular intervals.<br />

All testing equipment is maintained, calibrated and/or verified against measurement standards<br />

traceable to relevant international or national measurement standards.<br />

The manufacturer shall ensure that handling, preservation and storage of test equipment is<br />

such that its accuracy and fitness for purpose is maintained. The calibration of all test<br />

equipment shall be repeated if any repair or failure occurs which could upset the calibration of<br />

the test equipment.<br />

The manufacturer shall maintain a traceable documentation of the production process from<br />

purchasing or delivery of raw or basic raw materials up to the storage and delivery of finished<br />

products.<br />

Products that do not comply with requirements as specified in the <strong>ETA</strong> shall be separated from<br />

the conforming products and marked as such. The manufacturer shall register non-compliant<br />

production and action(s) taken to prevent further non-conformities. External complaints shall<br />

also be documented, as well as actions taken.<br />

The following table specifies properties that should be controlled and minimum frequencies of<br />

control. The test methods and thereshold values have been laid down in the Control Plan.<br />

Table 2: FPC test plan for HEMPACORE ONE 43600 and HEMPACORE ONE FD 43601.<br />

Property Control Acceptance Minimum frequency<br />

Incoming material<br />

Char depth<br />

Insulating efficiency<br />

Specific gravity<br />

Sag resistance<br />

QC certificate check<br />

Internal procedure<br />

Internal procedure according<br />

to Annex A of <strong>ETA</strong>G 018-2<br />

Internal procedure<br />

Internal procedure<br />

Manufacturer’s<br />

specification<br />

Manufacturer’s<br />

specification<br />

Manufacturer’s<br />

specification<br />

Manufacturer’s<br />

specification<br />

Manufacturer’s<br />

specification<br />

Every delivery<br />

Every batch<br />

Every 10 th batch or at<br />

least once per month<br />

Every batch<br />

Every batch<br />

10 The Control Plan is a confidential part of the <strong>ETA</strong> and only handed over to the approved body or bodies involved in the<br />

procedure of attestation of conformity.

Page 7 of 46 of <strong>ETA</strong> <strong>12</strong>/0581, issued on 29.04.2013<br />

Table 2: FPC test plan for HEMPACORE ONE 43600 and HEMPACORE ONE FD 43601.<br />

Property Control Acceptance Minimum frequency<br />

Viscosity<br />

Internal procedure<br />

Manufacturer’s<br />

specification<br />

Every batch<br />

Drying<br />

Internal procedure<br />

Manufacturer’s<br />

specification<br />

Every batch<br />

Non-volatile content<br />

Internal procedure<br />

Manufacturer’s<br />

specification<br />

Every batch<br />

Fineness of grinding<br />

Internal procedure<br />

Manufacturer’s<br />

specification<br />

Every batch<br />

3.2.1.2 Other tasks of the manufacturer<br />

The manufacturer shall, on the basis of a contract, involve a body which is approved for the<br />

tasks referred to in section 3.1 in the field of reactive coatings in order to undertake the actions<br />

laid down in section 3.2.2. For this purpose, the Control Plan referred to in sections 3.2.1.1 and<br />

3.2.2 shall be handed over by the manufacturer to the approved body involved.<br />

The manufacturer shall make a declaration of conformity, stating that the construction product is<br />

in conformity with the provisions of the <strong>ETA</strong> <strong>12</strong>/0581 issued on 29.04.2013.<br />

3.2.2 Tasks of approved bodies<br />

The approved body shall perform the activities referred to above according to the specific<br />

conditions, in accordance with the provisions laid down in the Control Plan relating to this <strong>ETA</strong>.<br />

The approved body shall retain the essential points of its actions referred to above and state the<br />

results obtained and conclusions drawn in a written report.<br />

3.2.2.1 Initial type testing<br />

The verifications on which this <strong>ETA</strong> is based have been carried out on representative samples<br />

from the current production. The results of the tests performed as part of the assessment shall<br />

be used for initial type-testing (ITT) unless changes in the manufacturing procedure affect the<br />

product properties.<br />

Any change in the manufacturing procedure which may affect the properties of the product shall<br />

be notified and the necessary type-testing revised according to the Control Plan.<br />

3.2.2.2 Initial inspection of factory and the factory production control<br />

The approved body shall assess the factory production control system to check that the factory<br />

production control is in conformity with this <strong>European</strong> <strong>Technical</strong> <strong>Approval</strong> and any subsidiary<br />

information. The approved body shall ensure that the manufacturer has acceptable premises,<br />

technical equipment and competent staff to produce the product as described in this <strong>ETA</strong>.<br />

3.2.2.3 Continuous surveillance, assessment and approval of factory production control<br />

Continuous surveillance of the factory production control is necessary to ensure continuing<br />

conformity with the <strong>ETA</strong>. It is recommended that surveillance inspections be conducted least<br />

twice per year.<br />

3.2.2.4 Certification<br />

Once the ITT, the initial inspection and surveillance of the FPC have been performed and<br />

whether a favourable conclusion can be drawn on the basis of available information, the notified<br />

certification body shall issue an EC Certificate of product Conformity, permitting the<br />

manufacturer to issue an EC Declaration of Conformity, enabling CE Marking of the product.<br />

In cases where the provisions of this <strong>European</strong> <strong>Technical</strong> <strong>Approval</strong> and its Control Plan are no<br />

longer fulfilled, the certification body shall withdraw the certificate and inform the Catalonia<br />

Institute of Construction Technology (ITeC) without delay.

Page 8 of 46 of <strong>ETA</strong> <strong>12</strong>/0581, issued on 29.04.2013<br />

3.3 CE marking<br />

3.3.1 General<br />

The CE marking shall be affixed to the packaging of product and to the accompanying<br />

commercial documents. The letters “CE” shall be followed by the identification number of the<br />

approved certification body, where relevant, and be accompanied by the following additional<br />

information:<br />

• The name and address of the <strong>ETA</strong>-holder.<br />

• The last two digits of year in which the CE marking was affixed.<br />

• The number of the EC Certificate of Conformity for the product.<br />

• The number of the <strong>European</strong> <strong>Technical</strong> <strong>Approval</strong>.<br />

• The reference of <strong>ETA</strong> Guideline 018 Part 1 and 2.<br />

• The product trade name/identification.<br />

• Reference to the <strong>ETA</strong> for the relevant characteristics.<br />

3.3.2 Example of CE marking<br />

Example of CE marking and accompanying information for product:<br />

“CE” symbol<br />

xxxx<br />

<strong>Hempel</strong> A/S<br />

Lundtoftegårdsvej 91<br />

DK-2800 Kgs. Lyngby<br />

Denmark<br />

Number of the notified body<br />

Name and address of the manufacturer<br />

YY<br />

xxxx-CPD-xxxx<br />

<strong>ETA</strong> <strong>12</strong>/0581<br />

<strong>ETA</strong>G 018, Part 1 and 2<br />

Fire Protective products<br />

HEMPACORE ONE 43600 /<br />

HEMPACORE ONE FD 43601<br />

Last two digits of year of affixing CE marking<br />

Number of the EC Certificate of Conformity<br />

Number of the <strong>ETA</strong><br />

Reference to the corresponding <strong>ETA</strong>G<br />

Product name<br />

See <strong>ETA</strong> for relevant<br />

characteristics<br />

4 Assumptions under which the fitness of the product(s) for the intended<br />

use was favourably assessed<br />

The detailed description and conditions of the manufacturing process of product, and all the<br />

relevant design and installation criteria of product are specified in the technical documentation<br />

of the manufacturer deposited with the ITeC. The main aspects of this information are specified<br />

in the following chapters.<br />

4.1 Manufacturing<br />

The <strong>European</strong> <strong>Technical</strong> <strong>Approval</strong> is issued for the reactive coatings HEMPACORE ONE 43600<br />

and HEMPACORE ONE FD 43601 on the basis of agreed data/information deposited with the<br />

ITeC, which identifies the products that have been assessed and judged. Changes to the

Page 9 of 46 of <strong>ETA</strong> <strong>12</strong>/0581, issued on 29.04.2013<br />

products or production processes, which could result in this deposited data/information being<br />

incorrect, should be notified to ITeC before the changes are introduced. ITeC will decide<br />

whether such changes affect the <strong>ETA</strong> and consequently the validity of the CE marking on the<br />

basis of the <strong>ETA</strong> and, if so, whether further assessment or alterations to the <strong>ETA</strong> shall be<br />

necessary.<br />

4.2 Installation<br />

The manufacturer shall provide an installation guide for his product in accordance with the<br />

installation provisions followed for the assessement in this <strong>ETA</strong>.<br />

4.2.1 Reactive coating<br />

4.2.2 Primer<br />

This <strong>ETA</strong> is issued under the assumption that the application of HEMPACORE ONE 43600 and<br />

HEMPACORE ONE FD 43601 occurs in accordance with the manufacturer’s instructions.<br />

A primer from the list of approved primers in section 1.2.2, or other compatible primers of the<br />

same family as specified by the manufacturer, shall be used. For galvanised steel, Hempadur<br />

15553 shall be used. For stainless steel or thermally sprayed aluminium steel, Hempadur 15570<br />

shall be used.<br />

The steel specification, the preparation of the steel surface and the application of the primers<br />

shall be in accordance with the manufacturer’s instructions.<br />

4.2.3 Topcoat<br />

A topcoat from the list of approved topcoats in section 1.2.2 shall be used. The application of<br />

the topcoats shall be in accordance with the manufacturer’s instructions.<br />

5 Recommendations<br />

5.1 Recommendations on packaging, transport and storage<br />

In the accompanying documentation or on the containers, the manufacturer shall give<br />

information as to transport and storage.<br />

At least the following shall be indicated: type of storage (container, tank, etc.), minimum and<br />

maximum temperature for transport and storage. In case of combustible components or other<br />

potentially dangerous substances the instructions shall contain indications about limitations<br />

and/or conditions for handling, transport and storage.<br />

5.2 Recommendations on use, maintenance and repair<br />

The assessment of the fitness for use is based on the assumption that necessary maintenance<br />

and repair, if required, is carried out in accordance with the manufacturer’s instructions during<br />

the assumed intended working life.<br />

The topcoat, where necessary, shall protect the reactive coating from moisture and other<br />

environmental influences. Therefore it shall always be kept in a proper state. In case of an<br />

execution without topcoat the control shall refer to the reactive coating. If the maintenance work<br />

related to the reactive coating or the topcoating is necessary, the manufacturer’s instructions<br />

shall be respected.<br />

On behalf of the Catalonia Institute of Construction Technology.<br />

Barcelona, 29 April 2013<br />

Anton Maria Checa Torres<br />

General Manager, ITeC

Page 10 of 46 of <strong>ETA</strong> <strong>12</strong>/0581, issued on 29.04.2013<br />

ANNEX 1<br />

Product performance: Fire resistance<br />

1. This Annex relates to the use of HEMPACORE ONE 43600 and HEMPACORE ONE FD 43601 for<br />

the fire protection of:<br />

• open sections (‘H’ and ‘I’ shaped) steel beams and columns (see Tables A1.1 to A1.18),<br />

• square and circular hollow steel columns (see Tables A1.19 to A1.36).<br />

The precise scope is given in the tables which specify the dry film thickness of intumescent coating<br />

(without primer and topcoat) required to achieve the classification R for various design<br />

temperatures and section factors.<br />

2. The product is approved on the basis of:<br />

• <strong>Approval</strong> testing in accordance with EN 13381-8:2010 and <strong>ETA</strong>G 018, Part 1 and 2.<br />

• Design of the dry film thickness of intumescent coating for the fire protection of open sections<br />

following the graphical analysis in accordance with Annex E of EN 13381-8:2010.<br />

• Design of the dry film thickness of intumescent coating for the fire protection of square and<br />

circular hollow sections following the numerical regression analysis in accordance with Annex E<br />

of EN 13381-8:2010.<br />

3. The data presented in this Annex for beams refer to a three-sided fire exposure and for columns to<br />

a four-sided fire exposure.<br />

4. The data presented in this Annex are applicable to structural steel (S designation) sections in<br />

accordance with EN 10025 11 , excluding S185, blast cleaned to ISO 8501-1 Sa 2 ½ or equivalent,<br />

primed with the compatible primers in accordance with clause 4.2.2. The data are also applicable<br />

to structural galvanised steel according to EN ISO 1461 <strong>12</strong> primed with Hempadur 15553, as well as<br />

to structural stainless steel according to EN 10088 13 and thermally sprayed aluminium steel primed<br />

with Hempadur 15570.<br />

5. The data are applicable to assemblies with or without topcoat.<br />

6. The thicknesses given for open H- and I-sections also apply to steel sections of other shapes, e.g.<br />

U, L and T-sections under consideration of the same A/V value.<br />

7. The application of the reactive coating on steel tension members made of structural steel in<br />

accordance with EN 10025 is not assessed by this <strong>ETA</strong>.<br />

11 EN 10025-1 to 6: 2004-2005. Hot rolled products of structural steels.<br />

<strong>12</strong> EN ISO 1461: 2009. Hot dip galvanized coatings on fabricated iron and steel articles - Specifications and test methods.<br />

13 EN 10088-1 to 5: 2005-2009. Stainless steels.

Page 11 of 46 of <strong>ETA</strong> <strong>12</strong>/0581, issued on 29.04.2013<br />

Table A1.1: Beams, 3-sided open H- or I-sections.<br />

Section Factor<br />

Design Temperature 350 ºC<br />

Thickness (mm) required for the RF period –only intumescent coating<br />

m -1 15 min 30 min 45 min 60 min 90 min <strong>12</strong>0 min 180 min 240 min<br />

58 0,220 0,287 0,919 1,414 - - - -<br />

60 0,220 0,299 0,953 1,444 - - - -<br />

65 0,220 0,329 0,999 1,521 - - - -<br />

70 0,220 0,360 1,045 1,598 - - - -<br />

75 0,220 0,390 1,091 1,675 - - - -<br />

80 0,220 0,421 1,137 1,751 - - - -<br />

85 0,220 0,451 1,183 1,828 - - - -<br />

90 0,220 0,482 1,229 1,926 - - - -<br />

95 0,220 0,5<strong>12</strong> 1,275 2,034 - - - -<br />

100 0,220 0,543 1,321 2,142 - - - -<br />

105 0,220 0,573 1,367 2,249 - - - -<br />

110 0,220 0,604 1,413 2,357 - - - -<br />

115 0,220 0,634 1,459 2,464 - - - -<br />

<strong>12</strong>0 0,220 0,664 1,505 2,572 - - - -<br />

<strong>12</strong>5 0,220 0,695 1,551 2,679 - - - -<br />

130 0,220 0,725 1,597 2,787 - - - -<br />

135 0,229 0,756 1,643 2,894 - - - -<br />

140 0,247 0,786 1,689 3,002 - - - -<br />

145 0,265 0,817 1,735 3,110 - - - -<br />

150 0,283 0,847 1,781 3,217 - - - -<br />

155 0,302 0,878 1,827 - - - - -<br />

160 0,320 0,908 1,876 - - - - -<br />

165 0,338 0,939 1,930 - - - - -<br />

170 0,356 0,968 1,984 - - - - -<br />

175 0,374 0,997 2,037 - - - - -<br />

180 0,392 1,025 2,091 - - - - -<br />

185 0,410 1,054 2,145 - - - - -<br />

190 0,428 1,083 2,198 - - - - -<br />

195 0,446 1,1<strong>12</strong> 2,252 - - - - -<br />

200 0,465 1,141 2,305 - - - - -<br />

205 0,483 1,169 2,359 - - - - -<br />

210 0,501 1,198 2,413 - - - - -<br />

215 0,519 1,227 2,466 - - - - -<br />

220 0,537 1,256 2,520 - - - - -<br />

225 0,555 1,285 2,574 - - - - -<br />

230 0,573 1,313 2,627 - - - - -<br />

235 0,591 1,342 2,681 - - - - -<br />

240 0,609 1,371 2,735 - - - - -<br />

245 0,627 1,400 2,788 - - - - -<br />

250 0,646 1,429 2,842 - - - - -<br />

255 0,664 1,457 2,896 - - - - -<br />

260 0,682 1,486 2,949 - - - - -<br />

265 0,700 1,515 3,040 - - - - -<br />

270 0,718 1,544 3,357 - - - - -<br />

275 0,736 1,573 3,673 - - - - -<br />

280 0,754 1,602 3,990 - - - - -<br />

285 0,772 1,630 - - - - - -<br />

290 0,790 1,659 - - - - - -<br />

295 0,809 1,688 - - - - - -<br />

300 0,827 1,717 - - - - - -<br />

305 0,845 1,746 - - - - - -<br />

310 0,863 1,774 - - - - - -<br />

315 0,881 1,803 - - - - - -<br />

320 0,899 1,832 - - - - - -<br />

325 0,917 1,860 - - - - - -<br />

330 0,935 1,889 - - - - - -

Page <strong>12</strong> of 46 of <strong>ETA</strong> <strong>12</strong>/0581, issued on 29.04.2013<br />

Table A1.2: Beams, 3-sided open H- or I-sections.<br />

Section Factor<br />

Design Temperature 400 ºC<br />

Thickness (mm) required for the RF period –only intumescent coating<br />

m -1 15 min 30 min 45 min 60 min 90 min <strong>12</strong>0 min 180 min 240 min<br />

58 0,220 0,220 0,379 0,923 1,685 - - -<br />

60 0,220 0,220 0,395 0,955 1,724 - - -<br />

65 0,220 0,220 0,437 1,003 1,822 - - -<br />

70 0,220 0,232 0,479 1,051 1,981 - - -<br />

75 0,220 0,250 0,520 1,100 2,164 - - -<br />

80 0,220 0,269 0,562 1,148 2,348 - - -<br />

85 0,220 0,287 0,604 1,196 2,532 - - -<br />

90 0,220 0,306 0,646 1,244 2,716 - - -<br />

95 0,220 0,325 0,687 1,292 2,899 - - -<br />

100 0,220 0,343 0,729 1,340 3,083 - - -<br />

105 0,220 0,362 0,771 1,389 - - - -<br />

110 0,220 0,380 0,813 1,437 - - - -<br />

115 0,220 0,399 0,854 1,485 - - - -<br />

<strong>12</strong>0 0,220 0,417 0,896 1,533 - - - -<br />

<strong>12</strong>5 0,220 0,436 0,938 1,581 - - - -<br />

130 0,220 0,454 0,974 1,630 - - - -<br />

135 0,220 0,473 1,008 1,678 - - - -<br />

140 0,220 0,491 1,043 1,726 - - - -<br />

145 0,220 0,510 1,077 1,774 - - - -<br />

150 0,220 0,529 1,1<strong>12</strong> 1,822 - - - -<br />

155 0,220 0,547 1,146 1,873 - - - -<br />

160 0,220 0,566 1,181 1,926 - - - -<br />

165 0,220 0,584 1,216 1,979 - - - -<br />

170 0,220 0,603 1,250 2,032 - - - -<br />

175 0,220 0,621 1,285 2,085 - - - -<br />

180 0,220 0,640 1,319 2,138 - - - -<br />

185 0,220 0,658 1,354 2,191 - - - -<br />

190 0,220 0,677 1,389 2,245 - - - -<br />

195 0,220 0,695 1,423 2,298 - - - -<br />

200 0,220 0,714 1,458 2,351 - - - -<br />

205 0,220 0,732 1,492 2,404 - - - -<br />

210 0,220 0,751 1,527 2,457 - - - -<br />

215 0,220 0,770 1,562 2,510 - - - -<br />

220 0,220 0,788 1,596 2,563 - - - -<br />

225 0,220 0,807 1,631 2,617 - - - -<br />

230 0,220 0,825 1,665 2,670 - - - -<br />

235 0,220 0,844 1,700 2,723 - - - -<br />

240 0,220 0,862 1,735 2,776 - - - -<br />

245 0,220 0,881 1,769 2,829 - - - -<br />

250 0,229 0,899 1,804 2,882 - - - -<br />

255 0,259 0,918 1,838 2,935 - - - -<br />

260 0,289 0,936 1,867 2,989 - - - -<br />

265 0,319 0,960 1,892 3,042 - - - -<br />

270 0,349 0,987 1,918 3,095 - - - -<br />

275 0,379 1,013 1,943 3,148 - - - -<br />

280 0,409 1,040 1,969 3,201 - - - -<br />

285 0,439 1,067 1,994 - - - - -<br />

290 0,469 1,094 2,019 - - - - -<br />

295 0,499 1,<strong>12</strong>1 2,045 - - - - -<br />

300 0,529 1,148 2,070 - - - - -<br />

305 0,560 1,175 2,096 - - - - -<br />

310 0,590 1,202 2,<strong>12</strong>1 - - - - -<br />

315 0,620 1,228 2,146 - - - - -<br />

320 0,650 1,255 2,172 - - - - -<br />

325 0,680 1,282 2,197 - - - - -<br />

330 0,710 1,309 2,222 - - - - -

Page 13 of 46 of <strong>ETA</strong> <strong>12</strong>/0581, issued on 29.04.2013<br />

Table A1.3: Beams, 3-sided open H- or I-sections.<br />

Section Factor<br />

Design Temperature 450 ºC<br />

Thickness (mm) required for the RF period –only intumescent coating<br />

m -1 15 min 30 min 45 min 60 min 90 min <strong>12</strong>0 min 180 min 240 min<br />

58 0,220 0,220 0,246 0,430 1,209 1,847 - -<br />

60 0,220 0,220 0,255 0,449 1,236 1,956 - -<br />

65 0,220 0,220 0,278 0,497 1,303 2,248 - -<br />

70 0,220 0,220 0,301 0,545 1,370 2,539 - -<br />

75 0,220 0,220 0,324 0,593 1,437 2,830 - -<br />

80 0,220 0,220 0,347 0,641 1,504 3,<strong>12</strong>1 - -<br />

85 0,220 0,220 0,370 0,689 1,571 - - -<br />

90 0,220 0,220 0,393 0,736 1,638 - - -<br />

95 0,220 0,220 0,416 0,784 1,705 - - -<br />

100 0,220 0,220 0,440 0,832 1,772 - - -<br />

105 0,220 0,239 0,463 0,880 1,839 - - -<br />

110 0,220 0,257 0,486 0,928 1,944 - - -<br />

115 0,220 0,275 0,509 0,970 2,058 - - -<br />

<strong>12</strong>0 0,220 0,294 0,532 1,009 2,172 - - -<br />

<strong>12</strong>5 0,220 0,3<strong>12</strong> 0,555 1,047 2,286 - - -<br />

130 0,220 0,330 0,578 1,086 2,400 - - -<br />

135 0,220 0,349 0,601 1,<strong>12</strong>5 2,514 - - -<br />

140 0,220 0,367 0,624 1,164 2,628 - - -<br />

145 0,220 0,385 0,647 1,203 2,742 - - -<br />

150 0,220 0,404 0,670 1,242 2,856 - - -<br />

155 0,220 0,422 0,693 1,281 2,970 - - -<br />

160 0,220 0,440 0,716 1,320 3,084 - - -<br />

165 0,220 0,459 0,739 1,358 3,198 - - -<br />

170 0,220 0,477 0,762 1,397 - - - -<br />

175 0,220 0,495 0,786 1,436 - - - -<br />

180 0,220 0,514 0,809 1,475 - - - -<br />

185 0,220 0,532 0,832 1,514 - - - -<br />

190 0,220 0,550 0,855 1,553 - - - -<br />

195 0,220 0,569 0,878 1,592 - - - -<br />

200 0,220 0,587 0,901 1,630 - - - -<br />

205 0,220 0,605 0,924 1,669 - - - -<br />

210 0,220 0,624 0,948 1,708 - - - -<br />

215 0,220 0,642 0,980 1,747 - - - -<br />

220 0,220 0,660 1,0<strong>12</strong> 1,786 - - - -<br />

225 0,220 0,679 1,044 1,825 - - - -<br />

230 0,220 0,697 1,077 1,862 - - - -<br />

235 0,220 0,715 1,109 1,896 - - - -<br />

240 0,220 0,734 1,141 1,930 - - - -<br />

245 0,220 0,752 1,173 1,964 - - - -<br />

250 0,220 0,770 1,205 1,999 - - - -<br />

255 0,220 0,789 1,237 2,033 - - - -<br />

260 0,220 0,807 1,269 2,067 - - - -<br />

265 0,220 0,825 1,301 2,101 - - - -<br />

270 0,220 0,844 1,334 2,135 - - - -<br />

275 0,220 0,862 1,366 2,169 - - - -<br />

280 0,220 0,880 1,398 2,203 - - - -<br />

285 0,220 0,899 1,430 2,237 - - - -<br />

290 0,220 0,917 1,462 2,272 - - - -<br />

295 0,220 0,935 1,494 2,306 - - - -<br />

300 0,235 0,955 1,526 2,340 - - - -<br />

305 0,273 0,978 1,558 2,374 - - - -<br />

310 0,311 1,000 1,591 2,408 - - - -<br />

315 0,349 1,022 1,623 2,442 - - - -<br />

320 0,387 1,045 1,655 2,476 - - - -<br />

325 0,426 1,067 1,687 2,510 - - - -<br />

330 0,464 1,089 1,719 2,544 - - - -

Page 14 of 46 of <strong>ETA</strong> <strong>12</strong>/0581, issued on 29.04.2013<br />

Table A1.4: Beams, 3-sided open H- or I-sections.<br />

Section Factor<br />

Design Temperature 500 ºC<br />

Thickness (mm) required for the RF period –only intumescent coating<br />

m -1 15 min 30 min 45 min 60 min 90 min <strong>12</strong>0 min 180 min 240 min<br />

58 0,220 0,220 0,220 0,307 0,946 1,467 - -<br />

60 0,220 0,220 0,220 0,319 0,966 1,500 - -<br />

65 0,220 0,220 0,220 0,349 1,018 1,584 - -<br />

70 0,220 0,220 0,234 0,379 1,069 1,667 - -<br />

75 0,220 0,220 0,253 0,408 1,<strong>12</strong>1 1,750 - -<br />

80 0,220 0,220 0,271 0,438 1,173 1,834 - -<br />

85 0,220 0,220 0,290 0,468 1,224 2,019 - -<br />

90 0,220 0,220 0,308 0,497 1,276 2,230 - -<br />

95 0,220 0,220 0,327 0,527 1,327 2,441 - -<br />

100 0,220 0,220 0,345 0,557 1,379 2,652 - -<br />

105 0,220 0,220 0,364 0,587 1,431 2,863 - -<br />

110 0,220 0,220 0,382 0,616 1,482 3,074 - -<br />

115 0,220 0,220 0,401 0,646 1,534 - - -<br />

<strong>12</strong>0 0,220 0,220 0,419 0,676 1,585 - - -<br />

<strong>12</strong>5 0,220 0,220 0,438 0,706 1,637 - - -<br />

130 0,220 0,220 0,456 0,735 1,689 - - -<br />

135 0,220 0,220 0,475 0,765 1,740 - - -<br />

140 0,220 0,220 0,493 0,795 1,792 - - -<br />

145 0,220 0,227 0,5<strong>12</strong> 0,825 1,843 - - -<br />

150 0,220 0,247 0,530 0,854 1,923 - - -<br />

155 0,220 0,267 0,549 0,884 2,007 - - -<br />

160 0,220 0,288 0,567 0,914 2,092 - - -<br />

165 0,220 0,308 0,586 0,944 2,176 - - -<br />

170 0,220 0,328 0,604 0,978 2,261 - - -<br />

175 0,220 0,348 0,623 1,0<strong>12</strong> 2,345 - - -<br />

180 0,220 0,369 0,641 1,046 2,430 - - -<br />

185 0,220 0,389 0,660 1,080 2,514 - - -<br />

190 0,220 0,409 0,678 1,115 2,599 - - -<br />

195 0,220 0,430 0,697 1,149 2,683 - - -<br />

200 0,220 0,450 0,715 1,183 2,767 - - -<br />

205 0,220 0,470 0,734 1,217 2,852 - - -<br />

210 0,220 0,491 0,752 1,251 2,936 - - -<br />

215 0,220 0,511 0,771 1,286 3,021 - - -<br />

220 0,220 0,531 0,789 1,320 3,105 - - -<br />

225 0,220 0,552 0,808 1,354 3,190 - - -<br />

230 0,220 0,572 0,826 1,388 - - - -<br />

235 0,220 0,592 0,845 1,422 - - - -<br />

240 0,220 0,613 0,863 1,457 - - - -<br />

245 0,220 0,633 0,882 1,491 - - - -<br />

250 0,220 0,653 0,900 1,525 - - - -<br />

255 0,220 0,673 0,919 1,559 - - - -<br />

260 0,220 0,694 0,937 1,593 - - - -<br />

265 0,220 0,714 0,962 1,628 - - - -<br />

270 0,220 0,734 0,989 1,662 - - - -<br />

275 0,220 0,755 1,017 1,696 - - - -<br />

280 0,220 0,775 1,045 1,730 - - - -<br />

285 0,220 0,795 1,072 1,764 - - - -<br />

290 0,220 0,816 1,100 1,799 - - - -<br />

295 0,220 0,836 1,<strong>12</strong>8 1,833 - - - -<br />

300 0,220 0,856 1,156 1,864 - - - -<br />

305 0,220 0,877 1,183 1,893 - - - -<br />

310 0,220 0,897 1,211 1,922 - - - -<br />

315 0,220 0,917 1,239 1,951 - - - -<br />

320 0,220 0,938 1,266 1,980 - - - -<br />

325 0,220 0,958 1,294 2,009 - - - -<br />

330 0,234 0,978 1,322 2,038 - - - -

Page 15 of 46 of <strong>ETA</strong> <strong>12</strong>/0581, issued on 29.04.2013<br />

Table A1.5: Beams, 3-sided open H- or I-sections.<br />

Section Factor<br />

Design Temperature 550 ºC<br />

Thickness (mm) required for the RF period –only intumescent coating<br />

m -1 15 min 30 min 45 min 60 min 90 min <strong>12</strong>0 min 180 min 240 min<br />

58 0,220 0,220 0,220 0,246 0,592 1,222 - -<br />

60 0,220 0,220 0,220 0,254 0,619 1,249 - -<br />

65 0,220 0,220 0,220 0,276 0,686 1,318 - -<br />

70 0,220 0,220 0,220 0,297 0,753 1,386 - -<br />

75 0,220 0,220 0,220 0,318 0,820 1,454 - -<br />

80 0,220 0,220 0,220 0,339 0,887 1,523 - -<br />

85 0,220 0,220 0,225 0,361 0,951 1,591 - -<br />

90 0,220 0,220 0,243 0,382 0,996 1,659 - -<br />

95 0,220 0,220 0,261 0,403 1,040 1,728 - -<br />

100 0,220 0,220 0,278 0,424 1,085 1,796 - -<br />

105 0,220 0,220 0,296 0,446 1,<strong>12</strong>9 1,882 - -<br />

110 0,220 0,220 0,314 0,467 1,174 2,045 - -<br />

115 0,220 0,220 0,332 0,488 1,219 2,207 - -<br />

<strong>12</strong>0 0,220 0,220 0,349 0,509 1,263 2,369 - -<br />

<strong>12</strong>5 0,220 0,220 0,367 0,531 1,308 2,531 - -<br />

130 0,220 0,220 0,385 0,552 1,353 2,693 - -<br />

135 0,220 0,220 0,402 0,573 1,397 2,855 - -<br />

140 0,220 0,220 0,420 0,594 1,442 3,017 - -<br />

145 0,220 0,220 0,438 0,616 1,486 3,180 - -<br />

150 0,220 0,220 0,456 0,637 1,531 - - -<br />

155 0,220 0,220 0,473 0,658 1,576 - - -<br />

160 0,220 0,220 0,491 0,679 1,620 - - -<br />

165 0,220 0,220 0,509 0,701 1,665 - - -<br />

170 0,220 0,220 0,526 0,722 1,709 - - -<br />

175 0,220 0,220 0,544 0,743 1,754 - - -<br />

180 0,220 0,220 0,562 0,764 1,799 - - -<br />

185 0,220 0,220 0,580 0,786 1,843 - - -<br />

190 0,220 0,220 0,597 0,807 1,905 - - -<br />

195 0,220 0,220 0,615 0,828 1,971 - - -<br />

200 0,220 0,220 0,633 0,849 2,037 - - -<br />

205 0,220 0,220 0,650 0,871 2,103 - - -<br />

210 0,220 (0,221) 0,668 0,892 2,169 - - -<br />

215 0,220 0,248 0,686 0,913 2,234 - - -<br />

220 0,220 0,276 0,704 0,934 2,300 - - -<br />

225 0,220 0,303 0,721 0,961 2,366 - - -<br />

230 0,220 0,330 0,739 0,993 2,432 - - -<br />

235 0,220 0,357 0,757 1,025 2,497 - - -<br />

240 0,220 0,385 0,774 1,057 2,563 - - -<br />

245 0,220 0,4<strong>12</strong> 0,792 1,089 2,629 - - -<br />

250 0,220 0,439 0,810 1,<strong>12</strong>1 2,695 - - -<br />

255 0,220 0,467 0,828 1,153 2,760 - - -<br />

260 0,220 0,494 0,845 1,185 2,826 - - -<br />

265 0,220 0,521 0,863 1,217 2,892 - - -<br />

270 0,220 0,549 0,881 1,249 2,958 - - -<br />

275 0,220 0,576 0,898 1,282 3,083 - - -<br />

280 0,220 0,603 0,916 1,314 3,288 - - -<br />

285 0,220 0,631 0,934 1,346 3,492 - - -<br />

290 0,220 0,658 0,953 1,378 3,697 - - -<br />

295 0,220 0,685 0,976 1,410 3,901 - - -<br />

300 0,220 0,713 0,998 1,442 - - - -<br />

305 0,220 0,740 1,020 1,474 - - - -<br />

310 0,220 0,767 1,042 1,506 - - - -<br />

315 0,220 0,795 1,064 1,538 - - - -<br />

320 0,220 0,822 1,087 1,570 - - - -<br />

325 0,220 0,849 1,109 1,602 - - - -<br />

330 0,220 0,876 1,131 1,634 - - - -

Page 16 of 46 of <strong>ETA</strong> <strong>12</strong>/0581, issued on 29.04.2013<br />

Table A1.6: Beams, 3-sided open H- or I-sections.<br />

Section Factor<br />

Design Temperature 600 ºC<br />

Thickness (mm) required for the RF period –only intumescent coating<br />

m -1 15 min 30 min 45 min 60 min 90 min <strong>12</strong>0 min 180 min 240 min<br />

58 0,220 0,220 0,220 0,220 0,444 1,057 - -<br />

60 0,220 0,220 0,220 0,220 0,462 1,082 - -<br />

65 0,220 0,220 0,220 0,233 0,509 1,144 - -<br />

70 0,220 0,220 0,220 0,252 0,555 1,206 - -<br />

75 0,220 0,220 0,220 0,270 0,602 1,268 - -<br />

80 0,220 0,220 0,220 0,288 0,649 1,330 - -<br />

85 0,220 0,220 0,220 0,306 0,695 1,392 - -<br />

90 0,220 0,220 0,220 0,325 0,742 1,454 - -<br />

95 0,220 0,220 0,220 0,343 0,788 1,516 - -<br />

100 0,220 0,220 0,220 0,361 0,835 1,578 - -<br />

105 0,220 0,220 0,220 0,379 0,882 1,640 - -<br />

110 0,220 0,220 0,236 0,398 0,928 1,702 - -<br />

115 0,220 0,220 0,254 0,416 0,973 1,764 - -<br />

<strong>12</strong>0 0,220 0,220 0,273 0,434 1,017 1,826 - -<br />

<strong>12</strong>5 0,220 0,220 0,291 0,452 1,060 1,921 - -<br />

130 0,220 0,220 0,309 0,471 1,104 2,040 - -<br />

135 0,220 0,220 0,328 0,489 1,148 2,158 - -<br />

140 0,220 0,220 0,346 0,507 1,191 2,276 - -<br />

145 0,220 0,220 0,364 0,525 1,235 2,394 - -<br />

150 0,220 0,220 0,382 0,544 1,279 2,5<strong>12</strong> - -<br />

155 0,220 0,220 0,401 0,562 1,322 2,630 - -<br />

160 0,220 0,220 0,419 0,580 1,366 2,748 - -<br />

165 0,220 0,220 0,437 0,598 1,410 2,867 - -<br />

170 0,220 0,220 0,456 0,617 1,453 2,985 - -<br />

175 0,220 0,220 0,474 0,635 1,497 3,103 - -<br />

180 0,220 0,220 0,492 0,653 1,541 3,221 - -<br />

185 0,220 0,220 0,511 0,671 1,584 - - -<br />

190 0,220 0,220 0,529 0,690 1,628 - - -<br />

195 0,220 0,220 0,547 0,708 1,672 - - -<br />

200 0,220 0,220 0,566 0,726 1,715 - - -<br />

205 0,220 0,220 0,584 0,744 1,759 - - -<br />

210 0,220 0,220 0,602 0,763 1,803 - - -<br />

215 0,220 0,220 0,620 0,781 1,846 - - -<br />

220 0,220 0,220 0,639 0,799 1,896 - - -<br />

225 0,220 0,220 0,657 0,817 1,945 - - -<br />

230 0,220 0,220 0,675 0,836 1,995 - - -<br />

235 0,220 0,220 0,694 0,854 2,045 - - -<br />

240 0,220 0,220 0,7<strong>12</strong> 0,872 2,095 - - -<br />

245 0,220 0,220 0,730 0,890 2,145 - - -<br />

250 0,220 0,220 0,749 0,909 2,194 - - -<br />

255 0,220 0,220 0,767 0,927 2,244 - - -<br />

260 0,220 0,220 0,785 0,945 2,294 - - -<br />

265 0,220 0,249 0,803 0,976 2,344 - - -<br />

270 0,220 0,287 0,822 1,007 2,394 - - -<br />

275 0,220 0,326 0,840 1,038 2,443 - - -<br />

280 0,220 0,364 0,858 1,069 2,493 - - -<br />

285 0,220 0,402 0,877 1,100 2,543 - - -<br />

290 0,220 0,440 0,895 1,131 2,593 - - -<br />

295 0,220 0,478 0,913 1,162 2,643 - - -<br />

300 0,220 0,517 0,932 1,193 2,692 - - -<br />

305 0,220 0,555 0,950 1,224 2,742 - - -<br />

310 0,220 0,593 0,970 1,254 2,792 - - -<br />

315 0,220 0,631 0,990 1,285 2,842 - - -<br />

320 0,220 0,670 1,010 1,316 2,892 - - -<br />

325 0,220 0,708 1,030 1,347 2,941 - - -<br />

330 0,220 0,746 1,050 1,378 2,991 - - -

Page 17 of 46 of <strong>ETA</strong> <strong>12</strong>/0581, issued on 29.04.2013<br />

Table A1.7: Beams, 3-sided open H- or I-sections.<br />

Section Factor<br />

Design Temperature 650 ºC<br />

Thickness (mm) required for the RF period –only intumescent coating<br />

m -1 15 min 30 min 45 min 60 min 90 min <strong>12</strong>0 min 180 min 240 min<br />

58 0,220 0,220 0,220 0,220 0,343 0,804 1,779 -<br />

60 0,220 0,220 0,220 0,220 0,356 0,842 1,823 -<br />

65 0,220 0,220 0,220 0,220 0,390 0,936 2,142 -<br />

70 0,220 0,220 0,220 0,220 0,423 0,998 2,530 -<br />

75 0,220 0,220 0,220 0,220 0,457 1,057 2,917 -<br />

80 0,220 0,220 0,220 0,231 0,490 1,116 - -<br />

85 0,220 0,220 0,220 0,249 0,524 1,175 - -<br />

90 0,220 0,220 0,220 0,267 0,557 1,234 - -<br />

95 0,220 0,220 0,220 0,286 0,591 1,292 - -<br />

100 0,220 0,220 0,220 0,304 0,624 1,351 - -<br />

105 0,220 0,220 0,220 0,323 0,658 1,410 - -<br />

110 0,220 0,220 0,220 0,341 0,691 1,469 - -<br />

115 0,220 0,220 0,220 0,359 0,725 1,528 - -<br />

<strong>12</strong>0 0,220 0,220 0,220 0,378 0,758 1,587 - -<br />

<strong>12</strong>5 0,220 0,220 0,220 0,396 0,792 1,645 - -<br />

130 0,220 0,220 0,220 0,415 0,825 1,704 - -<br />

135 0,220 0,220 0,220 0,433 0,859 1,763 - -<br />

140 0,220 0,220 0,220 0,451 0,892 1,822 - -<br />

145 0,220 0,220 0,220 0,470 0,926 1,899 - -<br />

150 0,220 0,220 0,228 0,488 0,965 1,993 - -<br />

155 0,220 0,220 0,250 0,507 1,0<strong>12</strong> 2,087 - -<br />

160 0,220 0,220 0,272 0,525 1,059 2,182 - -<br />

165 0,220 0,220 0,294 0,543 1,106 2,276 - -<br />

170 0,220 0,220 0,316 0,562 1,152 2,370 - -<br />

175 0,220 0,220 0,338 0,580 1,199 2,465 - -<br />

180 0,220 0,220 0,360 0,599 1,246 2,559 - -<br />

185 0,220 0,220 0,382 0,617 1,293 2,653 - -<br />

190 0,220 0,220 0,404 0,635 1,339 2,748 - -<br />

195 0,220 0,220 0,426 0,654 1,386 2,842 - -<br />

200 0,220 0,220 0,448 0,672 1,433 2,936 - -<br />

205 0,220 0,220 0,470 0,691 1,480 3,031 - -<br />

210 0,220 0,220 0,493 0,709 1,526 3,<strong>12</strong>5 - -<br />

215 0,220 0,220 0,515 0,727 1,573 3,219 - -<br />

220 0,220 0,220 0,537 0,746 1,620 - - -<br />

225 0,220 0,220 0,559 0,764 1,666 - - -<br />

230 0,220 0,220 0,581 0,783 1,713 - - -<br />

235 0,220 0,220 0,603 0,801 1,760 - - -<br />

240 0,220 0,220 0,625 0,819 1,807 - - -<br />

245 0,220 0,220 0,647 0,838 1,853 - - -<br />

250 0,220 0,220 0,669 0,856 1,891 - - -<br />

255 0,220 0,220 0,691 0,875 1,929 - - -<br />

260 0,220 0,220 0,713 0,893 1,967 - - -<br />

265 0,220 0,220 0,735 0,911 2,005 - - -<br />

270 0,220 0,220 0,757 0,930 2,044 - - -<br />

275 0,220 0,220 0,779 0,950 2,082 - - -<br />

280 0,220 0,220 0,801 0,978 2,<strong>12</strong>0 - - -<br />

285 0,220 0,232 0,823 1,007 2,158 - - -<br />

290 0,220 0,277 0,845 1,035 2,196 - - -<br />

295 0,220 0,322 0,867 1,063 2,234 - - -<br />

300 0,220 0,368 0,889 1,091 2,272 - - -<br />

305 0,220 0,413 0,911 1,119 2,310 - - -<br />

310 0,220 0,458 0,933 1,148 2,349 - - -<br />

315 0,220 0,503 0,954 1,176 2,387 - - -<br />

320 0,220 0,549 0,974 1,204 2,425 - - -<br />

325 0,220 0,594 0,993 1,232 2,463 - - -<br />

330 0,220 0,639 1,013 1,260 2,501 - - -

Page 18 of 46 of <strong>ETA</strong> <strong>12</strong>/0581, issued on 29.04.2013<br />

Table A1.8: Beams, 3-sided open H- or I-sections.<br />

Section Factor<br />

Design Temperature 700 ºC<br />

Thickness (mm) required for the RF period –only intumescent coating<br />

m -1 15 min 30 min 45 min 60 min 90 min <strong>12</strong>0 min 180 min 240 min<br />

58 0,220 0,220 0,220 0,220 0,285 0,6<strong>12</strong> 1,615 -<br />

60 0,220 0,220 0,220 0,220 0,296 0,641 1,655 -<br />

65 0,220 0,220 0,220 0,220 0,323 0,7<strong>12</strong> 1,755 -<br />

70 0,220 0,220 0,220 0,220 0,350 0,784 1,867 -<br />

75 0,220 0,220 0,220 0,220 0,377 0,855 2,187 -<br />

80 0,220 0,220 0,220 0,220 0,405 0,927 2,506 -<br />

85 0,220 0,220 0,220 0,220 0,432 0,989 2,826 -<br />

90 0,220 0,220 0,220 0,220 0,459 1,047 3,145 -<br />

95 0,220 0,220 0,220 0,220 0,486 1,106 - -<br />

100 0,220 0,220 0,220 0,225 0,513 1,165 - -<br />

105 0,220 0,220 0,220 0,245 0,541 1,223 - -<br />

110 0,220 0,220 0,220 0,264 0,568 1,282 - -<br />

115 0,220 0,220 0,220 0,284 0,595 1,341 - -<br />

<strong>12</strong>0 0,220 0,220 0,220 0,304 0,622 1,400 - -<br />

<strong>12</strong>5 0,220 0,220 0,220 0,323 0,649 1,458 - -<br />

130 0,220 0,220 0,220 0,343 0,676 1,517 - -<br />

135 0,220 0,220 0,220 0,363 0,704 1,576 - -<br />

140 0,220 0,220 0,220 0,382 0,731 1,634 - -<br />

145 0,220 0,220 0,220 0,402 0,758 1,693 - -<br />

150 0,220 0,220 0,220 0,422 0,785 1,752 - -<br />

155 0,220 0,220 0,220 0,442 0,8<strong>12</strong> 1,810 - -<br />

160 0,220 0,220 0,220 0,461 0,840 1,873 - -<br />

165 0,220 0,220 0,220 0,481 0,867 1,946 - -<br />

170 0,220 0,220 0,220 0,501 0,894 2,018 - -<br />

175 0,220 0,220 0,220 0,520 0,921 2,090 - -<br />

180 0,220 0,220 0,220 0,540 0,952 2,163 - -<br />

185 0,220 0,220 0,220 0,560 1,005 2,235 - -<br />

190 0,220 0,220 0,220 0,579 1,059 2,307 - -<br />

195 0,220 0,220 0,220 0,599 1,1<strong>12</strong> 2,380 - -<br />

200 0,220 0,220 0,220 0,619 1,165 2,452 - -<br />

205 0,220 0,220 0,220 0,638 1,218 2,524 - -<br />

210 0,220 0,220 0,220 0,658 1,272 2,597 - -<br />

215 0,220 0,220 0,220 0,678 1,325 2,669 - -<br />

220 0,220 0,220 0,220 0,697 1,378 2,741 - -<br />

225 0,220 0,220 0,220 0,717 1,431 2,813 - -<br />

230 0,220 0,220 0,236 0,737 1,485 2,886 - -<br />

235 0,220 0,220 0,275 0,757 1,538 2,958 - -<br />

240 0,220 0,220 0,314 0,776 1,591 3,042 - -<br />

245 0,220 0,220 0,353 0,796 1,644 3,137 - -<br />

250 0,220 0,220 0,392 0,816 1,698 3,233 - -<br />

255 0,220 0,220 0,431 0,835 1,751 3,328 - -<br />

260 0,220 0,220 0,470 0,855 1,804 3,424 - -<br />

265 0,220 0,220 0,509 0,875 1,854 3,519 - -<br />

270 0,220 0,220 0,548 0,894 1,883 3,615 - -<br />

275 0,220 0,220 0,587 0,914 1,9<strong>12</strong> 3,710 - -<br />

280 0,220 0,220 0,626 0,934 1,941 3,806 - -<br />

285 0,220 0,220 0,665 0,957 1,970 3,901 - -<br />

290 0,220 0,220 0,704 0,985 1,999 3,997 - -<br />

295 0,220 0,220 0,743 1,013 2,028 - - -<br />

300 0,220 0,220 0,782 1,040 2,057 - - -<br />

305 0,220 0,240 0,822 1,068 2,086 - - -<br />

310 0,220 0,294 0,861 1,096 2,115 - - -<br />

315 0,220 0,348 0,900 1,<strong>12</strong>4 2,144 - - -<br />

320 0,220 0,401 0,939 1,151 2,173 - - -<br />

325 0,220 0,455 0,962 1,179 2,202 - - -<br />

330 0,220 0,509 0,982 1,207 2,231 - - -

Page 19 of 46 of <strong>ETA</strong> <strong>12</strong>/0581, issued on 29.04.2013<br />

Table A1.9: Beams, 3-sided open H- or I-sections.<br />

Section Factor<br />

Design Temperature 750 ºC<br />

Thickness (mm) required for the RF period –only intumescent coating<br />

m -1 15 min 30 min 45 min 60 min 90 min <strong>12</strong>0 min 180 min 240 min<br />

58 0,220 0,220 0,220 0,220 0,238 0,480 1,479 -<br />

60 0,220 0,220 0,220 0,220 0,247 0,502 1,516 -<br />

65 0,220 0,220 0,220 0,220 0,270 0,558 1,608 -<br />

70 0,220 0,220 0,220 0,220 0,293 0,614 1,700 -<br />

75 0,220 0,220 0,220 0,220 0,316 0,670 1,793 -<br />

80 0,220 0,220 0,220 0,220 0,339 0,726 1,943 -<br />

85 0,220 0,220 0,220 0,220 0,362 0,782 2,192 -<br />

90 0,220 0,220 0,220 0,220 0,385 0,838 2,442 -<br />

95 0,220 0,220 0,220 0,220 0,408 0,894 2,691 -<br />

100 0,220 0,220 0,220 0,220 0,431 0,950 2,940 -<br />

105 0,220 0,220 0,220 0,220 0,454 1,010 3,190 -<br />

110 0,220 0,220 0,220 0,220 0,477 1,071 - -<br />

115 0,220 0,220 0,220 0,220 0,500 1,131 - -<br />

<strong>12</strong>0 0,220 0,220 0,220 0,220 0,523 1,191 - -<br />

<strong>12</strong>5 0,220 0,220 0,220 0,220 0,546 1,252 - -<br />

130 0,220 0,220 0,220 0,220 0,569 1,3<strong>12</strong> - -<br />

135 0,220 0,220 0,220 0,241 0,592 1,372 - -<br />

140 0,220 0,220 0,220 0,264 0,615 1,433 - -<br />

145 0,220 0,220 0,220 0,286 0,639 1,493 - -<br />

150 0,220 0,220 0,220 0,308 0,662 1,553 - -<br />

155 0,220 0,220 0,220 0,330 0,685 1,614 - -<br />

160 0,220 0,220 0,220 0,353 0,708 1,674 - -<br />

165 0,220 0,220 0,220 0,375 0,731 1,734 - -<br />

170 0,220 0,220 0,220 0,397 0,754 1,795 - -<br />

175 0,220 0,220 0,220 0,419 0,777 1,855 - -<br />

180 0,220 0,220 0,220 0,442 0,800 1,914 - -<br />

185 0,220 0,220 0,220 0,464 0,823 1,973 - -<br />

190 0,220 0,220 0,220 0,486 0,846 2,032 - -<br />

195 0,220 0,220 0,220 0,508 0,869 2,092 - -<br />

200 0,220 0,220 0,220 0,531 0,892 2,151 - -<br />

205 0,220 0,220 0,220 0,553 0,915 2,210 - -<br />

210 0,220 0,220 0,220 0,575 0,938 2,269 - -<br />

215 0,220 0,220 0,220 0,597 0,988 2,328 - -<br />

220 0,220 0,220 0,220 0,619 1,050 2,387 - -<br />

225 0,220 0,220 0,220 0,642 1,111 2,447 - -<br />

230 0,220 0,220 0,220 0,664 1,172 2,506 - -<br />

235 0,220 0,220 0,220 0,686 1,233 2,565 - -<br />

240 0,220 0,220 0,220 0,708 1,295 2,624 - -<br />

245 0,220 0,220 0,220 0,731 1,356 2,683 - -<br />

250 0,220 0,220 0,220 0,753 1,417 2,742 - -<br />

255 0,220 0,220 0,220 0,775 1,478 2,802 - -<br />

260 0,220 0,220 0,220 0,797 1,539 2,861 - -<br />

265 0,220 0,220 0,253 0,820 1,601 2,920 - -<br />

270 0,220 0,220 0,306 0,842 1,662 2,979 - -<br />

275 0,220 0,220 0,358 0,864 1,723 3,154 - -<br />

280 0,220 0,220 0,411 0,886 1,784 3,372 - -<br />

285 0,220 0,220 0,464 0,909 1,846 3,591 - -<br />

290 0,220 0,220 0,517 0,931 1,874 3,809 - -<br />

295 0,220 0,220 0,570 0,955 1,899 4,028 - -<br />

300 0,220 0,220 0,623 0,981 1,924 - - -<br />

305 0,220 0,220 0,676 1,008 1,949 - - -<br />

310 0,220 0,220 0,729 1,034 1,975 - - -<br />

315 0,220 0,220 0,782 1,061 2,000 - - -<br />

320 0,220 0,233 0,835 1,088 2,025 - - -<br />

325 0,220 0,294 0,888 1,114 2,050 - - -<br />

330 0,220 0,355 0,940 1,141 2,075 - - -

Page 20 of 46 of <strong>ETA</strong> <strong>12</strong>/0581, issued on 29.04.2013<br />

Table A1.10: Columns, 4-sided open H- or I-sections.<br />

Section Factor<br />

Design Temperature 350 ºC<br />

Thickness (mm) required for the RF period –only intumescent coating<br />

m -1 15 min 30 min 45 min 60 min 90 min <strong>12</strong>0 min 180 min 240 min<br />

71 0,221 0,386 0,946 2,050 - - - -<br />

75 0,221 0,440 1,032 2,205 - - - -<br />

80 0,221 0,483 1,137 2,399 - - - -<br />

85 0,221 0,526 1,218 2,522 - - - -<br />

90 0,221 0,569 1,298 2,607 - - - -<br />

95 0,221 0,6<strong>12</strong> 1,379 2,692 - - - -<br />

100 0,221 0,655 1,460 2,778 - - - -<br />

105 0,221 0,699 1,540 2,863 - - - -<br />

110 0,221 0,742 1,621 2,948 - - - -<br />

115 0,221 0,785 1,702 3,034 - - - -<br />

<strong>12</strong>0 0,221 0,828 1,782 3,119 - - - -<br />

<strong>12</strong>5 0,224 0,871 1,863 3,204 - - - -<br />

130 0,247 0,914 1,943 3,290 - - - -<br />

135 0,271 0,958 2,024 3,375 - - - -<br />

140 0,295 1,001 2,105 3,460 - - - -<br />

145 0,319 1,044 2,185 3,545 - - - -<br />

150 0,342 1,087 2,266 3,631 - - - -<br />

155 0,366 1,130 2,346 3,716 - - - -<br />

160 0,390 1,187 2,427 3,801 - - - -<br />

165 0,414 1,243 2,501 3,915 - - - -<br />

170 0,434 1,300 2,569 4,141 - - - -<br />

175 0,453 1,357 2,637 4,367 - - - -<br />

180 0,471 1,413 2,706 4,594 - - - -<br />

185 0,490 1,470 2,774 4,820 - - - -<br />

190 0,508 1,526 2,842 5,046 - - - -<br />

195 0,527 1,583 2,910 - - - - -<br />

200 0,546 1,639 2,978 - - - - -<br />

205 0,564 1,696 3,046 - - - - -<br />

210 0,583 1,753 3,115 - - - - -<br />

215 0,601 1,809 3,183 - - - - -<br />

220 0,620 1,866 3,251 - - - - -<br />

225 0,638 1,922 3,319 - - - - -<br />

230 0,657 1,979 3,387 - - - - -<br />

235 0,676 2,035 3,455 - - - - -<br />

240 0,694 2,092 3,524 - - - - -<br />

245 0,713 2,149 3,592 - - - - -<br />

250 0,731 2,205 3,660 - - - - -<br />

255 0,750 2,262 3,728 - - - - -<br />

260 0,768 2,318 3,796 - - - - -<br />

265 0,787 2,375 3,864 - - - - -<br />

270 0,805 2,431 4,111 - - - - -<br />

275 0,824 2,496 4,372 - - - - -<br />

280 0,843 2,574 4,633 - - - - -<br />

285 0,861 2,651 4,895 - - - - -<br />

290 0,880 2,729 5,156 - - - - -<br />

295 0,898 2,806 - - - - - -<br />

300 0,917 2,884 - - - - - -<br />

305 0,935 2,961 - - - - - -<br />

310 0,954 3,038 - - - - - -<br />

315 0,973 3,116 - - - - - -<br />

320 0,991 3,193 - - - - - -<br />

325 1,010 3,271 - - - - - -<br />

330 1,028 3,348 - - - - - -<br />

335 1,047 3,426 - - - - - -<br />

340 1,065 3,503 - - - - - -<br />

342 1,073 3,534 - - - - - -

Page 21 of 46 of <strong>ETA</strong> <strong>12</strong>/0581, issued on 29.04.2013<br />

Table A1.11: Columns, 4-sided open H- or I-sections.<br />

Section Factor<br />

Design Temperature 400 ºC<br />

Thickness (mm) required for the RF period –only intumescent coating<br />

m -1 15 min 30 min 45 min 60 min 90 min <strong>12</strong>0 min 180 min 240 min<br />

71 0,221 0,221 0,508 0,950 2,621 - - -<br />

75 0,221 0,221 0,547 1,031 2,722 - - -<br />

80 0,221 0,221 0,596 1,132 2,847 - - -<br />

85 0,221 0,239 0,645 1,206 2,973 - - -<br />

90 0,221 0,299 0,693 1,279 3,099 - - -<br />

95 0,221 0,358 0,742 1,353 3,225 - - -<br />

100 0,221 0,418 0,791 1,426 3,350 - - -<br />

105 0,221 0,446 0,839 1,500 3,476 - - -<br />

110 0,221 0,472 0,888 1,573 3,602 - - -<br />

115 0,221 0,498 0,937 1,647 3,728 - - -<br />

<strong>12</strong>0 0,221 0,523 0,985 1,721 3,854 - - -<br />

<strong>12</strong>5 0,221 0,549 1,034 1,794 4,007 - - -<br />

130 0,221 0,574 1,083 1,868 4,164 - - -<br />

135 0,221 0,600 1,131 1,941 4,322 - - -<br />

140 0,221 0,626 1,186 2,015 4,479 - - -<br />

145 0,221 0,651 1,240 2,088 4,637 - - -<br />

150 0,221 0,677 1,295 2,162 4,794 - - -<br />

155 0,221 0,702 1,349 2,235 4,952 - - -<br />

160 0,221 0,728 1,403 2,309 5,109 - - -<br />

165 0,221 0,753 1,458 2,383 - - - -<br />

170 0,221 0,779 1,5<strong>12</strong> 2,456 - - - -<br />

175 0,221 0,805 1,567 2,534 - - - -<br />

180 0,221 0,830 1,621 2,6<strong>12</strong> - - - -<br />

185 0,221 0,856 1,675 2,690 - - - -<br />

190 0,221 0,881 1,730 2,769 - - - -<br />

195 0,239 0,907 1,784 2,847 - - - -<br />

200 0,257 0,933 1,839 2,925 - - - -<br />

205 0,276 0,958 1,893 3,003 - - - -<br />

210 0,294 0,984 1,947 3,082 - - - -<br />

215 0,313 1,009 2,002 3,160 - - - -<br />

220 0,331 1,035 2,056 3,238 - - - -<br />

225 0,349 1,060 2,110 3,316 - - - -<br />

230 0,368 1,086 2,165 3,395 - - - -<br />

235 0,386 1,1<strong>12</strong> 2,219 3,473 - - - -<br />

240 0,405 1,155 2,274 3,551 - - - -<br />

245 0,423 1,243 2,328 3,629 - - - -<br />

250 0,452 1,330 2,382 3,708 - - - -<br />

255 0,481 1,418 2,437 3,786 - - - -<br />

260 0,510 1,505 2,514 3,864 - - - -<br />

265 0,539 1,593 2,616 4,028 - - - -<br />

270 0,568 1,680 2,719 4,197 - - - -<br />

275 0,597 1,768 2,821 4,367 - - - -<br />

280 0,626 1,855 2,924 4,537 - - - -<br />

285 0,655 1,943 3,026 4,707 - - - -<br />

290 0,684 2,030 3,<strong>12</strong>9 4,877 - - - -<br />

295 0,713 2,118 3,231 5,047 - - - -<br />

300 0,742 2,205 3,334 - - - - -<br />

305 0,771 2,293 3,436 - - - - -<br />

310 0,800 2,380 3,539 - - - - -<br />

315 0,829 2,469 3,641 - - - - -<br />

320 0,858 2,585 3,744 - - - - -<br />

325 0,887 2,702 3,846 - - - - -<br />

330 0,916 2,819 4,115 - - - - -<br />

335 0,945 2,935 4,433 - - - - -<br />

340 0,974 3,052 4,751 - - - - -<br />

342 0,986 3,099 4,878 - - - - -

Page 22 of 46 of <strong>ETA</strong> <strong>12</strong>/0581, issued on 29.04.2013<br />

Table A1.<strong>12</strong>: Columns, 4-sided open H- or I-sections.<br />

Section Factor<br />

Design Temperature 450 ºC<br />

Thickness (mm) required for the RF period –only intumescent coating<br />

m -1 15 min 30 min 45 min 60 min 90 min <strong>12</strong>0 min 180 min 240 min<br />

71 0,221 0,221 0,224 0,535 1,459 2,960 - -<br />

75 0,221 0,221 0,283 0,575 1,586 3,108 - -<br />

80 0,221 0,221 0,357 0,624 1,745 3,292 - -<br />

85 0,221 0,221 0,426 0,674 1,903 3,476 - -<br />

90 0,221 0,221 0,456 0,724 2,062 3,661 - -<br />

95 0,221 0,221 0,486 0,773 2,221 3,845 - -<br />

100 0,221 0,221 0,516 0,823 2,380 4,000 - -<br />

105 0,221 0,221 0,546 0,872 2,506 4,150 - -<br />

110 0,221 0,222 0,576 0,922 2,594 4,300 - -<br />

115 0,221 0,251 0,606 0,972 2,682 4,449 - -<br />

<strong>12</strong>0 0,221 0,280 0,636 1,021 2,770 4,599 - -<br />

<strong>12</strong>5 0,221 0,310 0,666 1,071 2,858 4,749 - -<br />

130 0,221 0,339 0,696 1,<strong>12</strong>1 2,946 4,899 - -<br />

135 0,221 0,369 0,726 1,176 3,034 5,049 - -<br />

140 0,221 0,398 0,756 1,234 3,<strong>12</strong>2 - - -<br />

145 0,221 0,427 0,786 1,291 3,210 - - -<br />

150 0,221 0,450 0,816 1,348 3,298 - - -<br />

155 0,221 0,474 0,846 1,405 3,386 - - -<br />

160 0,221 0,498 0,876 1,462 3,474 - - -<br />

165 0,221 0,521 0,906 1,520 3,562 - - -<br />

170 0,221 0,545 0,936 1,577 3,650 - - -<br />

175 0,221 0,569 0,966 1,634 3,738 - - -<br />

180 0,221 0,593 0,997 1,691 3,826 - - -<br />

185 0,221 0,616 1,027 1,748 4,041 - - -<br />

190 0,221 0,640 1,057 1,806 4,386 - - -<br />

195 0,221 0,664 1,087 1,863 4,731 - - -<br />

200 0,221 0,687 1,117 1,920 5,075 - - -<br />

205 0,221 0,711 1,174 1,977 - - - -<br />

210 0,221 0,735 1,252 2,035 - - - -<br />

215 0,221 0,758 1,331 2,092 - - - -<br />

220 0,221 0,782 1,409 2,149 - - - -<br />

225 0,221 0,806 1,488 2,206 - - - -<br />

230 0,221 0,830 1,567 2,263 - - - -<br />

235 0,221 0,853 1,645 2,321 - - - -<br />

240 0,221 0,877 1,724 2,378 - - - -<br />

245 0,221 0,901 1,802 2,435 - - - -<br />

250 0,221 0,924 1,881 2,519 - - - -<br />

255 0,221 0,948 1,960 2,632 - - - -<br />

260 0,221 0,972 2,038 2,746 - - - -<br />

265 0,221 0,996 2,117 2,860 - - - -<br />

270 0,221 1,019 2,195 2,973 - - - -<br />

275 0,221 1,043 2,274 3,087 - - - -<br />

280 0,221 1,067 2,353 3,201 - - - -<br />

285 0,248 1,090 2,431 3,314 - - - -<br />

290 0,321 1,114 2,533 3,428 - - - -<br />

295 0,393 1,177 2,652 3,542 - - - -<br />

300 0,445 1,314 2,771 3,655 - - - -<br />

305 0,483 1,452 2,890 3,769 - - - -<br />

310 0,521 1,590 3,010 3,901 - - - -<br />

315 0,559 1,728 3,<strong>12</strong>9 4,177 - - - -<br />

320 0,597 1,866 3,248 4,454 - - - -<br />

325 0,635 2,004 3,367 4,730 - - - -<br />

330 0,673 2,142 3,486 5,006 - - - -<br />

335 0,710 2,280 3,606 - - - - -<br />

340 0,748 2,418 3,725 - - - - -<br />

342 0,763 2,473 3,773 - - - - -

Page 23 of 46 of <strong>ETA</strong> <strong>12</strong>/0581, issued on 29.04.2013<br />

Table A1.13: Columns, 4-sided open H- or I-sections.<br />

Section Factor<br />

Design Temperature 500 ºC<br />

Thickness (mm) required for the RF period –only intumescent coating<br />

m -1 15 min 30 min 45 min 60 min 90 min <strong>12</strong>0 min 180 min 240 min<br />

71 0,221 0,221 0,221 0,413 0,889 2,220 - -<br />

75 0,221 0,221 0,221 0,447 0,959 2,399 - -<br />

80 0,221 0,221 0,221 0,482 1,045 2,562 - -<br />

85 0,221 0,221 0,225 0,516 1,132 2,698 - -<br />

90 0,221 0,221 0,278 0,550 1,230 2,835 - -<br />

95 0,221 0,221 0,332 0,585 1,329 2,971 - -<br />

100 0,221 0,221 0,385 0,619 1,427 3,108 - -<br />

105 0,221 0,221 0,430 0,653 1,525 3,244 - -<br />

110 0,221 0,221 0,455 0,687 1,623 3,381 - -<br />

115 0,221 0,221 0,479 0,722 1,721 3,518 - -<br />

<strong>12</strong>0 0,221 0,221 0,504 0,756 1,819 3,654 - -<br />

<strong>12</strong>5 0,221 0,221 0,529 0,790 1,917 3,791 - -<br />

130 0,221 0,221 0,553 0,825 2,016 3,957 - -<br />

135 0,221 0,223 0,578 0,859 2,114 4,164 - -<br />

140 0,221 0,242 0,602 0,893 2,2<strong>12</strong> 4,370 - -<br />

145 0,221 0,261 0,627 0,927 2,310 4,577 - -<br />

150 0,221 0,280 0,651 0,962 2,408 4,784 - -<br />

155 0,221 0,299 0,676 0,996 2,506 4,991 - -<br />

160 0,221 0,317 0,700 1,030 2,604 - - -<br />

165 0,221 0,336 0,725 1,065 2,702 - - -<br />

170 0,221 0,355 0,750 1,099 2,800 - - -<br />

175 0,221 0,374 0,774 1,137 2,898 - - -<br />

180 0,221 0,393 0,799 1,209 2,996 - - -<br />

185 0,221 0,4<strong>12</strong> 0,823 1,280 3,094 - - -<br />

190 0,221 0,434 0,848 1,352 3,192 - - -<br />

195 0,221 0,462 0,872 1,423 3,290 - - -<br />

200 0,221 0,490 0,897 1,495 3,388 - - -<br />

205 0,221 0,518 0,922 1,567 3,486 - - -<br />

210 0,221 0,546 0,946 1,638 3,583 - - -<br />

215 0,221 0,574 0,971 1,710 3,681 - - -<br />

220 0,221 0,601 0,995 1,782 3,779 - - -<br />

225 0,221 0,629 1,020 1,853 3,896 - - -<br />

230 0,221 0,657 1,044 1,925 4,247 - - -<br />

235 0,221 0,685 1,069 1,996 4,597 - - -<br />

240 0,221 0,713 1,093 2,068 4,948 - - -<br />

245 0,221 0,740 1,118 2,140 - - - -<br />

250 0,221 0,768 1,189 2,211 - - - -<br />

255 0,221 0,796 1,301 2,283 - - - -<br />

260 0,221 0,824 1,414 2,355 - - - -<br />

265 0,221 0,852 1,527 2,426 - - - -<br />

270 0,221 0,880 1,640 2,518 - - - -<br />

275 0,221 0,907 1,753 2,635 - - - -<br />

280 0,221 0,935 1,866 2,751 - - - -<br />

285 0,221 0,963 1,978 2,868 - - - -<br />

290 0,221 0,991 2,091 2,984 - - - -<br />

295 0,221 1,019 2,204 3,101 - - - -<br />

300 0,221 1,046 2,317 3,217 - - - -<br />

305 0,221 1,074 2,430 3,334 - - - -<br />

310 0,221 1,102 2,552 3,450 - - - -<br />

315 0,221 1,130 2,679 3,567 - - - -<br />

320 0,221 1,284 2,806 3,683 - - - -<br />

325 0,413 1,437 2,932 3,800 - - - -<br />

330 0,470 1,590 3,059 4,010 - - - -<br />

335 0,514 1,743 3,186 4,364 - - - -<br />

340 0,558 1,896 3,313 4,718 - - - -<br />

342 0,576 1,957 3,363 4,859 - - - -

Page 24 of 46 of <strong>ETA</strong> <strong>12</strong>/0581, issued on 29.04.2013<br />

Table A1.14: Columns, 4-sided open H- or I-sections.<br />

Section Factor<br />

Design Temperature 550 ºC<br />

Thickness (mm) required for the RF period –only intumescent coating<br />

m -1 15 min 30 min 45 min 60 min 90 min <strong>12</strong>0 min 180 min 240 min<br />

71 0,221 0,221 0,221 0,224 0,659 1,473 - -<br />

75 0,221 0,221 0,221 0,281 0,707 1,613 - -<br />

80 0,221 0,221 0,221 0,351 0,767 1,789 - -<br />