Session I - Tech#4 Muhlenchemie

Session I - Tech#4 Muhlenchemie

Session I - Tech#4 Muhlenchemie

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Esterase in Baking<br />

Dr. Lutz Popper, Mühlenchemie GmbH & Co. KG, Ahrensburg, Germany<br />

Esterases split ester bonds into acids and alcohols, binding water in the process. This<br />

reaction is known as hydrolysis, and the esterases are therefore classified as hydrolases. In<br />

spite of this common feature the subclass of the esterases (EC 3.1) is distinguished by<br />

numerous enzymes, some of which catalyse the reaction of very different biomolecules in a<br />

highly specific manner. Tab. 1 shows examples of esterases that are also used in the<br />

production of foods.<br />

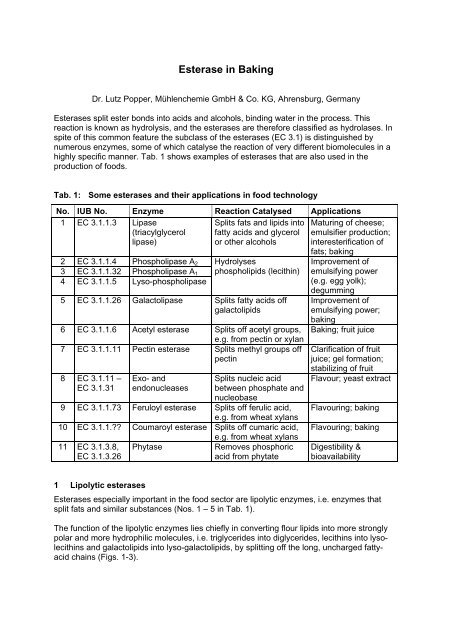

Tab. 1: Some esterases and their applications in food technology<br />

No. IUB No. Enzyme Reaction Catalysed Applications<br />

1 EC 3.1.1.3 Lipase<br />

(triacylglycerol<br />

lipase)<br />

Splits fats and lipids into<br />

fatty acids and glycerol<br />

or other alcohols<br />

Maturing of cheese;<br />

emulsifier production;<br />

interesterification of<br />

2 EC 3.1.1.4 Phospholipase A 2<br />

3 EC 3.1.1.32 Phospholipase A 1<br />

4 EC 3.1.1.5 Lyso-phospholipase<br />

Hydrolyses<br />

phospholipids (lecithin)<br />

5 EC 3.1.1.26 Galactolipase Splits fatty acids off<br />

galactolipids<br />

6 EC 3.1.1.6 Acetyl esterase Splits off acetyl groups,<br />

e.g. from pectin or xylan<br />

7 EC 3.1.1.11 Pectin esterase Splits methyl groups off<br />

pectin<br />

8 EC 3.1.11 –<br />

EC 3.1.31<br />

Exo- and<br />

endonucleases<br />

Splits nucleic acid<br />

between phosphate and<br />

nucleobase<br />

9 EC 3.1.1.73 Feruloyl esterase Splits off ferulic acid,<br />

e.g. from wheat xylans<br />

10 EC 3.1.1.?? Coumaroyl esterase Splits off cumaric acid,<br />

e.g. from wheat xylans<br />

11 EC 3.1.3.8, Phytase<br />

Removes phosphoric<br />

EC 3.1.3.26<br />

acid from phytate<br />

fats; baking<br />

Improvement of<br />

emulsifying power<br />

(e.g. egg yolk);<br />

degumming<br />

Improvement of<br />

emulsifying power;<br />

baking<br />

Baking; fruit juice<br />

Clarification of fruit<br />

juice; gel formation;<br />

stabilizing of fruit<br />

Flavour; yeast extract<br />

Flavouring; baking<br />

Flavouring; baking<br />

Digestibility &<br />

bioavailability<br />

1 Lipolytic esterases<br />

Esterases especially important in the food sector are lipolytic enzymes, i.e. enzymes that<br />

split fats and similar substances (Nos. 1 – 5 in Tab. 1).<br />

The function of the lipolytic enzymes lies chiefly in converting flour lipids into more strongly<br />

polar and more hydrophilic molecules, i.e. triglycerides into diglycerides, lecithins into lysolecithins<br />

and galactolipids into lyso-galactolipids, by splitting off the long, uncharged fattyacid<br />

chains (Figs. 1-3).

Fig. 1: Effect of lipases on triglycerides Fig. 2: Effect of phospholipases on<br />

phosphatidylcholine (lecithin<br />

fraction)<br />

Bread volume [ml/100 g flour]<br />

200<br />

180<br />

160<br />

140<br />

polar lipids<br />

total lipids<br />

non-polar lipids<br />

volume prior to baking<br />

0 200 200 300 400 500 600 700 800 900<br />

1000<br />

Re-added wheat lipid [mg/100 g flour]<br />

Fig. 3:<br />

Effect of galactolipase on<br />

monogalactosyl diglyceride<br />

Fig. 4:<br />

Effect of polar and non-polar<br />

wheat lipids on the volume yield<br />

of defatted wheat flour (modified<br />

from MacRitchie and Gras, 1973)<br />

The resulting structures with a greater affinity with water interact strongly with the proteins of<br />

the gluten. In the dough phase the lipids are already largely associated with the protein, so<br />

after their modification they are already in the right position for an optimum effect on the<br />

protein.<br />

Over the past few years, lipolytic enzymes have steadily gained significance in flour<br />

standardization – especially in the field of baking improvers and baking premixes. In the<br />

premixes these enzymes can partially or wholly replace emulsifiers, making it possible to<br />

reduce dosages, simplify label declarations and cut costs.<br />

A suitable product series for this purpose is Alphamalt EFX. In developing it, Mühlenchemie<br />

took the heterogeneous nature of the wheat lipids into account (Tab. 2).

Tab. 2: Lipids in wheat flour (0.405 % ash)<br />

Total lipids (14 % m.b.) 1,280<br />

Non-polar lipids 457<br />

Polar lipids 823<br />

Phosphatides (lecithin) 250<br />

Phosphatidyl acid 30<br />

Phosphatidyl glycerol 51<br />

Phosphatidyl cholin 27<br />

Phosphatidyl ethanolamine<br />

traces<br />

Phosphatidyl serine 15<br />

Lyso-phosphatidyl cholin 117<br />

Lyso-phosphatidyl ethanolamine 10<br />

Galactolipids 249<br />

Other polar lipids 320<br />

The result is an esterase with which the fatty-acid residues can be split off from a wide range<br />

of substrates. However, the enzyme has a preference for longer chains (over C8), which<br />

means that even in the presence of butter fat there is very little risk of an off-taste caused by<br />

the release of volatile fatty acids.<br />

If an enzyme is to act on the lipids it first has to gain access to them by diffusion. For this<br />

reason the Alphamalt EFX series is most suitable for baking methods with long fermentation<br />

times, e.g. baguettes (as shown for Alphamalt EFX Super in Fig. 5 and 6), although the<br />

effects are already visible with short proof times such as those for split rolls.<br />

Basic treatment:<br />

FAA, 1 SKB/g<br />

ADA, 40 ppm<br />

Asc., 160 ppm<br />

SSL, 0.3 %<br />

0 ppm 10 ppm 25 ppm 50 ppm<br />

743 748 787 856<br />

1.5 h,<br />

normal proof<br />

Volume yield,<br />

mL/100 g flour<br />

803 852 882 935<br />

2 h,<br />

over-proof 1<br />

863 937 965 1015<br />

2.5 h,<br />

over-proof 2<br />

Fig. 5:<br />

Effect of Dosage and Proof Time on Baguette Rolls with<br />

Alphamalt EFX Super

1.5 h,<br />

normal proof,<br />

no EFX Super<br />

1.5 h,<br />

normal proof<br />

2 h,<br />

over-proof 1<br />

2.5 h,<br />

over-proof 2<br />

Basic treatment:<br />

FAA, 1 SKB/g<br />

ADA, 40 ppm<br />

Asc., 160 ppm<br />

SSL, 0.3 %<br />

743 856 935 1015<br />

Volume yield,<br />

mL/100 g flour<br />

Fig. 6:<br />

Effect of Proof Time on Baguette Rolls with Alphamalt<br />

EFX Super (50 ppm)<br />

For applications with short proof times, especially, it is advisable to test combinations with<br />

emulsifiers such as DATEM or SSL. It is often possible to enhance the baking properties or<br />

reduce the dose of emulsifier. With Alphamalt EFX, dough stability and fermentation<br />

tolerance are constantly adjusted to the requirements of the baking process: the longer the<br />

proof time, the more chance Alphamalt has to develop its activity.<br />

So it is that the user has a flexible, adaptable flour improvement system at his disposal that<br />

makes it possible to control dough stability and volume yield.<br />

The dosage is only 5 – 50 ppm (0.5 – 5 g to 100 kg of flour). Large doses should only be<br />

used in conjunction with short proof times. An overdose does not increase the effect. On the<br />

contrary: it may even result in a slight loss of volume yield.<br />

Wheat flour contains about 1.5% lipids (fat-like substances) which fall into two categories:<br />

non-polar lipids that are not miscible with water, and polar lipids. The polar lipids include the<br />

lecithins and compounds of sugars and fats, for instance galactolipids. The effects of polar<br />

and non-polar lipids on the volume yield of flour were already described by MacRitchie and<br />

Gras in 1973. According to these authors it is only the polar lipids that bring about an<br />

increase in volume (Fig. 4).<br />

At first glance it may seem odd that the use of (totally non-polar) fats in baking usually<br />

increases the volume of the baked goods, at least at low dosages (up to about 10%). But we<br />

have to remember that in contrast to the trials that led to Fig. 4, the fat is added to an intact<br />

flour in which polar and non-polar lipids are present in their natural ratio and in their usual<br />

positions. In this case the addition of polar lipids evidently results in increased volume. One<br />

might compare the effect to that of a lubricant that makes the dough more pliant, allowing the<br />

“layers” to slide over each other.<br />

2 Xylanolytic esterases<br />

The function of other esterases consists in splitting off aromatic acid residues from the xylans<br />

(pentosans) of the grain (Fig. 7). In the xylans, ferulic acid and cumaric acid are bound to the<br />

pendant arabinose groups. Through them the xylan chains can be linked with each other and<br />

also with proteins (Fig. 8 and 9). In a reaction called “oxidative gel formation” they thus<br />

increase the water-binding capacity of the dough and result in higher viscosity and reduced<br />

extensibility.

Fig. 7:<br />

Enzymatic hydrolysis sites in<br />

wheat xylan<br />

Fig. 8:<br />

Cross-linking of wheat gluten and<br />

xylan (modified from Hoseney<br />

and Faubion, 1981)<br />

Fig. 9:<br />

Interaction of feruloyl side-chains in<br />

arabinoxylan (modified from Williamson et al.,<br />

1998)<br />

Splitting of the bonds with xylan by the esterases leads to a breakdown of gel-forming<br />

structures and thus to softening of the dough. Single released molecules of these acids are<br />

important precursors of flavour, for example in the maturing of sour dough and also in the<br />

biochemical (“natural”) synthesis of vanilla. A further application is total liquefaction, for<br />

example in the production of ethanol from grain.<br />

A ferulic acid esterase (FAE) from Streptomyces werraensis is described by José-Luis Copa<br />

Patiño et. al. When developing this enzyme for marketing we found – not surprisingly – that<br />

the micro-organism produces a large number of ligno- and hemicellulolytic enzymes (Tab. 3)<br />

of which very few had so far been investigated for their effect on dough and baking<br />

properties.

Ferulic acid esterase will shortly be available commercially as Alphamalt FSR. Its main<br />

function will lie in optimizing the rheological properties of dough (Fig. 10) and in reducing the<br />

cost of enzymes through combination with other xylanolytic enzymes.<br />

160<br />

Extensibility L (mm)<br />

150<br />

140<br />

130<br />

120<br />

110<br />

100<br />

90<br />

80<br />

0.00 0.05 0.10 0.15 0.20 0.25<br />

FAE dosage (%)<br />

Fig. 10: Effect of feruloyl esterase (crude extract) on<br />

the extensibility in the alveogram<br />

Tab. 3: Enzymatic activity in the culture supernatant of Streptomyces werraensis<br />

UAH 44 in various different nutrient media<br />

Substrate<br />

Enzyme<br />

Medium<br />

1 2 3 4 5 6 7 8 9 10<br />

AZCL-amylose Amylase + - - + - + ± ++++ - -<br />

AZCL-arabinan (debranched) Endo-1,5-a-L-arabinase + ++ + +++++ +++ +++ +++ +++ ++++ ++++<br />

AZCL-arabinoxylan (wheat) Endo-xylanase ++++ ++++ ++++ +++ +++ +++ +++ ++ +++ +++<br />

AZCL-HE cellulose Endo-cellulase - + - ++ - - - - +++ +<br />

AZCL-curdlan Endo-1,3-b-glucanase - +++ ± +++ + + + ++ ++++ +++<br />

AZCL-dextran Endo-1,6-a-glucanase - - - - - - - - - -<br />

AZCL-galactan (potato) Endo-1,4-b-galactanase - ± - ++++ ++ ++ ++ + ++++ +++<br />

AZCL-galactomannan b-mannanase - - - + - - - - + ±<br />

AZCL-b-glucan Malt b-glucanase ++ +++ ++++ +++ ++++ +++ ++++ +++ +++ ++<br />

AZCL-pullulan Limit dextrinase - - - - - - - - - -<br />

AZCL-xylan(oat) Endo-xylanase ++ ++++ ++ ++++++ ++++++ + +++++ ++ ++++++ +++<br />

Skimmed milk Protease - + - +++ +++ - ++ - +++ +++<br />

3 Proteases with esterase activity<br />

Esterase activity is sometimes found in unexpected places – for example in some proteases,<br />

where it is a genuine side activity of the protease molecule. The reason is that the reaction<br />

catalysed by proteases is very similar to ester cleavage (Fig. 9).<br />

Protease: -R 1 CH-CO-NH-CR 2 - + H 2 O ↔ -R 1 CH-COO - + + H 3 N-CR 2 -<br />

Esterase: R 1 -CO-O-R 2 + H 2 O ↔ R 1 -COOH + R 2 -OH<br />

Fig. 11: Representations of reactions catalysed by protease<br />

and esterase<br />

The active centre of serine proteases (subtilisin, trypsin, chymotrypsin) is similar to that of the<br />

lipases. Both contain the same catalytic triad, the amino acid asparagine, histidine and

serine. Papain also has an unspecific effect on lipids, whereas metallo-proteases show no<br />

esterase activity.<br />

The “side effect” plays a certain positive role in the maturing of cheese, where it aids the<br />

development of flavour, but our experience shows that it has no significance at all in baking.<br />

In other applications it can be a great nuisance, for example in the production of precious<br />

vegetable oils, where proteases are used to increase the yield.<br />

4 Phytase<br />

Phytases have found wide applications in feed rations. They degrade phytate, an antinutritive<br />

factor found in cereals and legumes. Phytic acid binds iron, calcium and other<br />

bivalent metal ions, necessary as growth factors and stabilizing agents for enzymes. Phytic<br />

acid also inhibits microorganisms including yeasts, probably by its ion binding properties.<br />

Phytate<br />

Myo-inositol<br />

6-phytase<br />

cereals<br />

H<br />

H 2 O 3 PO<br />

H<br />

H 2 O 3 PO<br />

H<br />

OPO 3 H 2<br />

OPO 3 H 2<br />

H 2 O 3 PO<br />

H<br />

H<br />

OPO 3 H 2<br />

H 6 H 2 O<br />

6 H 3 PO 4<br />

HO<br />

H<br />

HO H<br />

H<br />

OH<br />

OH<br />

HO<br />

H<br />

H OH<br />

H<br />

3-phytase<br />

microorganisms<br />

Fig. 12: Action of phytases on phytate<br />

Phytases split the ester bond between phosphoric acid and inositol, hence depriving phytic<br />

from is ion binding capability (Fig. 12).<br />

Although cereals and legumes also contain phytases, those are not able to break down all<br />

the phytate under normal conditions of processing and digestions. In particular wholegrain<br />

cereal preparations contain a high amount of phytate, which is sterically separated from the<br />

grain’s own phytase (Fig. 13). Furthermore, the level of phytase underlies large natural<br />

fluctuations. Therefore, microbial phytase can be used to improve the nutritive value of food<br />

(and feed) from cereals and legumes.

Phytate<br />

Phytase<br />

2%<br />

13%<br />

85%<br />

8%<br />

15%<br />

34%<br />

40%<br />

Aleuron<br />

Germ<br />

Endosperm<br />

Scutellum<br />

Other<br />

3%<br />

Fig. 13: Distribution of phytate and phytase in wheat<br />

(modified from Zimmermann et al., 2000)<br />

In baking, phytases are able to contribute to dough stability and volume yield, probably due<br />

to a better availability of ions for dough stabilization and microbial (yeast) activity .<br />

5 Other esterases<br />

As far as we know, the enzymes listed as items 6 to 8 in Tab. 1 are not used directly in<br />

baking applications. Although acetyl esterase has a certain effect on wheat xylan, this is<br />

without significance as yet. Nucleases have only been put to technical use indirectly in<br />

baking to produce yeast hydrolysates that have the effect of intensifying the flavour or<br />

replacing salt.<br />

6 References<br />

Copa-Patiño, J.L., Caballero, A., Popper, L., Arenas, M., Soliveri, J., 2007. Empleo de un<br />

complejo enzimático producido por una cepa de actinomicetos en procesos de<br />

panificación. Poster presentation, XXI Congreso Nacional de Microbiología, Sevilla,<br />

Spain, September 17-20.<br />

Hoseney,R.C., Faubion, J.M., 1981. A mechanism for the oxidative gelation of wheat flour<br />

water-soluble pentosans. Cereal Chem. 58(5), 421-424.<br />

MacRitchie, F., and Gras, P. W. 1973. The role of flour lipids in baking. Cereal Chem. 50(3),<br />

292-302.<br />

Williamson, G., Kroon, P.A. and Faulds, C.B., 1998. Hairy plant polysaccharides: a close<br />

shave with microbial esterases. Microbiol. 144, 2011-2023.<br />

Zimmermann, B., Krämer, K., Biesalski, H.-K., Drochner, W., 2000. Zur Bedeutung<br />

pflanzlicher und mikrobieller Phytasen in der Humanernährung. Teil 1: Charakteristik<br />

und Wirkung von Phytinsäure und Phytasen. Ernährungs-Umschau 47(11), 423-427.