You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

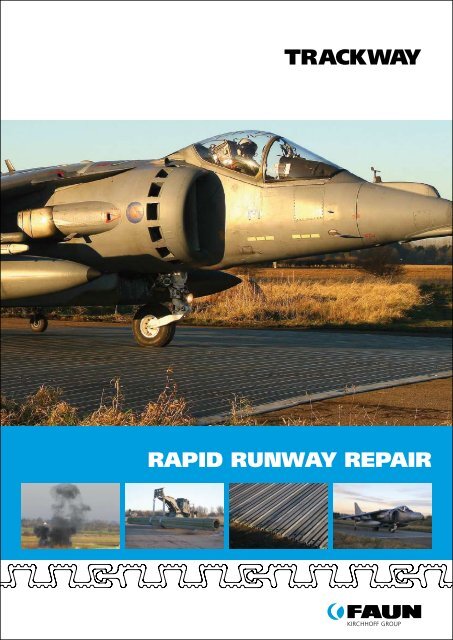

<strong>RAPID</strong> <strong>RUNWAY</strong> <strong>REPAIR</strong>

<strong>RAPID</strong> <strong>RUNWAY</strong> <strong>REPAIR</strong><br />

RRR is FAUN’s Rapid Runway Repair<br />

system utilising modular aluminium mats.<br />

It provides temporary repair to airfields<br />

following an enemy attack or natural<br />

disaster so that flying operations can be<br />

resumed quickly.<br />

It is an effective solution for helicopter<br />

landing pads, hard standing for aircraft,<br />

temporary taxiways and aircraft recovery<br />

when it has overshot a runway.<br />

VITAL<br />

ACCESS<br />

60<br />

27<br />

SELECTED MINIMUM OPERATING STRIP<br />

VITAL<br />

ACCESS<br />

CRATER<br />

<strong>REPAIR</strong>ED CRATER<br />

METHOD OF <strong>REPAIR</strong><br />

1 2 3 4

Method of Repair<br />

Following an attack the damage needs to be identified and<br />

a minimum operating strip selected.<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

Debris cleared away using wheeled tractors.<br />

Fall back and rupture zone of the craters are<br />

cleared away.<br />

Hydraulic hammers cut the craters back to sound material.<br />

Dump trucks, filled by wheeled loaders, fill crater with<br />

course aggregate.<br />

The crater is filled to within 500mm of the surface.<br />

A top layer of fine aggregate is added and compacted<br />

by a dynamic compactor or roller, leaving it just proud of<br />

the surface.<br />

Using a screed beam, towed by wheeled tractors, excess<br />

material is scraped away and the fill finally levelled.<br />

Vehicle mounted suction sweeper removes FOD.<br />

The Rapid Runway Repair mats are unrolled.<br />

The mats are tensioned over the filled crater.<br />

8 Expanding bolts secure the mats.<br />

Where an aircraft may pass close to the edge of the Rapid<br />

Runway Repair mat, side fairing panels are added to<br />

eliminate sharp edges.<br />

The Kit<br />

Rapid Runway Repair Kit compraises:<br />

• RRR Mat – aluminium panels that make up the area mats<br />

• RRR Trailers – the vehicles that carry the mats<br />

• RRR Screed Beam and Trailer<br />

• RRR Accessories<br />

Additional equipment required:<br />

• Mobile lighting towers<br />

• Heavy wheeled shovel loaders<br />

• Medium wheeled shovel loaders<br />

• Heavy wheeled excavators<br />

• Heavy duty tippers / dump trucks<br />

• Dynamic compactor or roller<br />

• Vehicle mounted suction sweeper<br />

• Generators<br />

• Scab repair kit<br />

• Graders<br />

• Hydraulic concrete breakers<br />

• High capacity pumps – for airfields with high water tables<br />

5 6 7 8

UILD DATA<br />

Testing & setup xxxxxxx801<br />

Testing & setup xxxxxxx801<br />

<strong>RAPID</strong> <strong>RUNWAY</strong><br />

R R R<br />

R E P A I R<br />

000<br />

RRR MAT RRR Trailer Screed Beam and Trailer ACCESORIES<br />

00 400<br />

2 x Trackway Assy - 5262198<br />

50M length<br />

201<br />

Mechanical Assembly<br />

300 400<br />

Optional Extra<br />

2 x Trackway Assy - 5262198<br />

50M length<br />

Optional Extra<br />

301<br />

302<br />

Un-loading<br />

• Standard Assembly RRR mat<br />

401<br />

402<br />

403<br />

Welding<br />

• A draw bar trailer Assembly specially<br />

dimensions 22m x 16m<br />

designed for loading and<br />

Spool Assy - 5262196 Packing<br />

•<br />

220<br />

BDR Patches dimensions<br />

unloading the RRR mat<br />

y 3 -5291471 11m xxxxxxx x 16m221<br />

Sub Assembly • Fitted 5262315 with two hydraulically<br />

y 2 - 5291400 • Thickness of RRR mat 32mm operated bolster<br />

222 Assembly<br />

• Weight of RRR mat 13,000kg • Chains and tensions are<br />

1 - 5269265<br />

Mechanical Assembly<br />

• Diameter (when RRR mat is supplied<br />

rolled up) 1.2m<br />

223<br />

301<br />

302<br />

• Un-loading<br />

Made up of four sections each<br />

Assembly 6m long x 1m wide x 1m high<br />

• Each section weighs 1000kg<br />

• A draw bar trailer specially<br />

designed for transporting the<br />

screed beam<br />

401<br />

402<br />

403<br />

• RRR Welding Tensioning Kit<br />

• RRR Bolt Down Kit<br />

Assembly<br />

• RRR Side Fairing Kit<br />

• Other Packing accessory kits<br />

are available to meet<br />

your specifications<br />

• RRR End Fairing Kit<br />

ly<br />

FAUN MV Ltd<br />

Trackway Division<br />

Bryn Cefni Industrial Estate<br />

LLANGEFNI,<br />

Issue Isle of Anglesey A LL77 7XA<br />

Issue Date 26/6/07<br />

Tel: +44 (0) 1248 722777<br />

Fax: +44 (0) 1248 750220<br />

www.fauntrackway.co.uk<br />

sales@fauntrackway.co.uk<br />

Produced by L29 :: 01248 810276<br />

Issue<br />

A<br />

TACTICAL MOBILITY SOLUTIONS<br />

Issue Date 26/6/07