Document Printing - Xeikon

Document Printing - Xeikon

Document Printing - Xeikon

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Document</strong> <strong>Printing</strong>

2<br />

“High<br />

quality is a must, a given. It is expected as the norm.”<br />

Keith Whitehead - Production Director at Howard Hunt, UK<br />

A Challenging Market<br />

Provides Great Opportunities<br />

CONSUMERS<br />

QUALITY IS<br />

companies to retain high-value<br />

With the average consumer receiving 6,500 marketing<br />

messages per day, marketeers are finding it increasingly<br />

difficult to achieve the desired response. Consumers are<br />

bombarded with messages from multiple channels.<br />

So much so that they have started tuning out what is not<br />

relevant or interesting to them. Marketeers are embracing<br />

individualized, cross-media communication in an effort to<br />

reach the unreachable consumer, and to attract new<br />

and retain existing customers.<br />

DEMAND RELEVANCE<br />

Getting in touch with prospects or<br />

customers is no longer a guarantee<br />

of success. The issue is to<br />

communicate, to enter into effective<br />

dialogue. That is why today’s<br />

direct marketing is not only about<br />

personalized, but individualized<br />

and relevant cross-media communication.<br />

Effective campaigns<br />

A GIVEN<br />

Relevance encourages consumers<br />

to read a message, but the<br />

quality is what makes it stick.<br />

And in a world where consumers<br />

have the power of choice, quality<br />

is a given. With companies<br />

communicating through multiple<br />

channels, it is important that any<br />

printed message reflects the same<br />

clients and to attract very select<br />

niches as printed communication<br />

has come to be associated with<br />

‘exclusivity’ and ‘importance’. Direct<br />

marketing campaigns therefore<br />

demand technology that can marry<br />

individualized, relevant content and<br />

striking design for each individual<br />

communication piece.<br />

In the myriad of media channels, print is losing ground.<br />

But it is not all doom and gloom. The internet and<br />

digitization have opened up tremendous opportunities<br />

as well, particularly for digital printing.<br />

use an intelligent combination of<br />

digital media and print. Campaigns<br />

will become more sophisticated,<br />

relying even more on database<br />

intelligence than is currently the<br />

visual brand identity and quality<br />

standard as all other forms of<br />

brand expression. In an increasingly<br />

digitized world, printed direct<br />

marketing pieces will enable<br />

case. The creation of individualized,<br />

100% relevant messages<br />

depends greatly on the quality<br />

of databases and data mining<br />

programs. Any halfway measures<br />

or cutting corners in the data<br />

management or data analysis<br />

stage will reduce effectiveness!

“We are moving away from cut-sheet for productivity reasons and the<br />

continuous-fed operation of the <strong>Xeikon</strong> 8000 plays a key role in this,<br />

particularly for transactional mail applications. The press also eliminates<br />

the need for human intervention at the finish of a print run – reducing the<br />

risks of mishandling. Quality and productivity are essentially the name of<br />

the game, and the <strong>Xeikon</strong> 8000 positions us well to win on both fronts.”<br />

Loïc Lefebvre - Head of Business Development for Data One and<br />

Group Diffusion Plus, France.<br />

3<br />

KEEP UP THE<br />

PRODUCTIVITY<br />

Opportunity creates demand. With<br />

the increased availability of data<br />

capturing and data mining tools<br />

the demand for more and more<br />

sophisticated campaigns grows.<br />

Also, direct marketing is increasingly<br />

trigger-based, which means<br />

that speed is of the essence.<br />

Soaring print volumes and increasingly<br />

complex campaigns place<br />

high requirements on print systems<br />

in terms of processing power<br />

and productivity. And with ever<br />

tighter deadlines you cannot afford<br />

to have a weak link. Seamless<br />

integration of your press with the<br />

rest of your workflow is therefore<br />

a must.<br />

MIND THE<br />

ENVIRONMENT<br />

More and more print buyers and<br />

consumers have embraced ecology<br />

and expect their suppliers to<br />

do the same. Digital printing is an<br />

environmentally friendly concept.<br />

You print only what you need -<br />

targeted and to the copy. But some<br />

digital printing technologies are<br />

more eco-friendly than others,<br />

especially when it comes to recyclability<br />

– an issue not to be taken<br />

lightly. Germany has adopted legislation<br />

that makes printers explicitly<br />

warn consumers if prints are<br />

not recyclable, and the EU is likely<br />

to follow suit. A label shouting ‘not<br />

recyclable, keep separate’ may<br />

not be everyone’s idea of a great<br />

marketing campaign. Recyclability<br />

is an environmental issue, but<br />

one with economic consequences.<br />

Think twice before you invest!

4<br />

“Due to its unparalleled combination of quality and print capacity,<br />

the <strong>Xeikon</strong> 8000 is a perfect fit for our book printing and publishing,<br />

direct mail, and commercial print applications. There is no other<br />

technology currently available that offers these unique capabilities.”<br />

Burt Scherman - President of Strategic Content Imaging, US<br />

BOOK ON DEMAND<br />

IS ON THE RISE<br />

Just like marketing and advertising,<br />

the publishing sector is seeing<br />

increasing personalization and<br />

versioning. Web-to-print fulfillment<br />

has become an integral part of<br />

the publishing business, offering<br />

the level of interactivity users have<br />

grown used to. With digital printing<br />

as the enabling technology, print<br />

on demand of books has emerged,<br />

not least because it addresses<br />

many of the challenges the sector<br />

faces. Cost and revenue considerations<br />

are the main drivers for<br />

publishers to go digital.<br />

As much as 30% of printed books<br />

remain unsold and end up being<br />

pulped. Matching supply to demand<br />

is made possible by digital<br />

print on demand since small runs<br />

can be produced cost-effectively.<br />

Digital printing is extremely flexible<br />

in that it allows last-minute<br />

changes and updates to be made<br />

in short turnaround times. Inventory<br />

and the associated risks and costs<br />

can be virtually eliminated. The<br />

result: fewer costs and reduced<br />

waste, so less impact on the<br />

environment.<br />

Initially used mainly for backlists,<br />

self-publications and photo books,<br />

book on demand applications<br />

today range from academic publications<br />

to technical manuals and<br />

product guides. Digital book printing<br />

is becoming mainstream, yet<br />

it is still a largely untapped market<br />

and therefore a high growth area<br />

for digital printing.

5<br />

<strong>Xeikon</strong> Meets Both Challenges and Opportunities<br />

In the document printing market<br />

the keys to success are quality,<br />

workflow performance and environmental<br />

responsibility, and that<br />

is exactly what we offer. With the<br />

<strong>Xeikon</strong> 8500, the <strong>Xeikon</strong> 8600<br />

and the <strong>Xeikon</strong> 8800 you have a<br />

choice of eco-friendly high-performance<br />

digital duplex presses,<br />

fully integrated digital workflows,<br />

application-tuned<br />

toners and a range of input and<br />

output accessories.<br />

requirements, since they boast the<br />

same superior image quality. The<br />

<strong>Xeikon</strong> 8800 stands out, offering<br />

an unmatched ratio of quality to<br />

productivity as well as the lowest<br />

TCOP.<br />

By teaming up with specialized<br />

partners worldwide, we have<br />

also built up useful knowledge<br />

of data mining and campaign<br />

management. Based on open<br />

industry standards, our solutions<br />

fit seamlessly in any production<br />

environment, increasing your<br />

productivity. You will discover how<br />

high-quality digital color printing<br />

can be profitable business!<br />

All three are web-fed presses<br />

and able to handle scalable print<br />

media widths, which allows you to<br />

produce a wide array of standard<br />

and non standard formats and<br />

virtually unlimited image lengths.<br />

Which of the three you choose will<br />

largely depend on your productivity

6<br />

A Range of High-Performance Digital Presses<br />

THE PRODUCTIVITY<br />

presses are intrinsically faster<br />

Two inline densitometers ensure<br />

With <strong>Xeikon</strong>, there is no trade-off to be made between<br />

quality and productivity. Engineered to perfection,<br />

the electrophotographic imaging process remains the<br />

industry standard for quality and reliability. That is why<br />

<strong>Xeikon</strong> presses use dry toner electrophotography.<br />

Well-engineered, robust and reliable, they all deliver<br />

impeccable quality regardless the speed. Your choice will<br />

depend on your productivity and print media requirements,<br />

and rest assured there is at least one that fits the bill!<br />

YOU NEED<br />

The <strong>Xeikon</strong> 8500, the <strong>Xeikon</strong><br />

8600 and the <strong>Xeikon</strong> 8800 boast<br />

a unique combination of features<br />

designed to up and maintain<br />

your productivity.<br />

Being web-fed, they are one<br />

up on the competition. Web-fed<br />

and ideal for fast, heavy-duty<br />

print jobs without limitations in<br />

sheet or image length.<br />

There is more to productivity<br />

than speed. That is why they<br />

have been made extremely<br />

robust and reliable, with<br />

superior uptimes of up to 90%.<br />

automatic density and register<br />

control, and allow you to<br />

fine-tune during printing.<br />

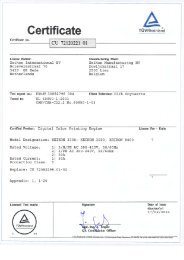

<strong>Xeikon</strong> 8500 <strong>Xeikon</strong> 8600 <strong>Xeikon</strong> 8800<br />

Print media width 320 - 512 mm (12,6” x 20,2”) 320 - 512 mm (12,6” x 20,2”) 320 - 512 mm (12,6” x 20,2”)<br />

Imaging width 504 mm (19.8”) 504 mm (19.8”) 504 mm (19.8”)<br />

Toner <strong>Xeikon</strong> QA-P toner <strong>Xeikon</strong> QA-P toner <strong>Xeikon</strong> QA-P toner<br />

Addressability 1200 x 3600 dpi with variable dot density 1200 x 3600 dpi with variable dot density 1200 x 3600 dpi with variable dot density<br />

Web speed up to 12.0 m/min (39 ft/min) up to 14.5 mm/min (47 ft/min) up to 19.2 m/min (63 ft/min)<br />

Print speed up to 160 ppm (9,600 pages/hour) up to 195 ppm (11,700 pages/hour) up to 260 ppm (15,600 pages/hour)**<br />

Duty cycle*** up to 5,000,000 pages/month up to 6,000,000 pages/month up to 10,000,000 pages/month<br />

*A4 full color pages, duplex printing, print speed depends on print media weight<br />

**Optional, existing <strong>Xeikon</strong> 8000 engines are field upgradeable<br />

***A4 full color pages, duplex printing and operating at full capacity in three-shift mode

7<br />

“It’s not just the increased productivity that swung us towards the <strong>Xeikon</strong>.<br />

The <strong>Xeikon</strong> also offers superb print quality. Its 1200 dpi resolution enables<br />

us to print much sharper images which makes a real difference when we<br />

need to print corporate IDs with very fine typefaces.”<br />

Barrie Stevens - Marketing Manager at McLays, UK<br />

UNCOMPROMISING<br />

QUALITY<br />

Quality is a given. That is why<br />

the <strong>Xeikon</strong> 8500, the <strong>Xeikon</strong> 8600<br />

and the <strong>Xeikon</strong> 8800 are packed<br />

with features to make sure they<br />

produce nothing less than offsetchallenging<br />

print quality.<br />

The unique combination of<br />

1200 x 3600 dpi addressability<br />

and 4 bit variable dot density<br />

offers rich color depth and subtle<br />

contrasts. Sharp and crisp<br />

details enable adding micro text,<br />

for instance to prevent<br />

counterfeiting.<br />

Powerful screening libraries<br />

help to exploit the 1200 dpi imaging<br />

to the fullest. The screen<br />

ruling can be adjusted for every<br />

image element, ensuring<br />

superior image quality.<br />

Two inline densitometers and<br />

high performance process<br />

algorithms vouch for uniform<br />

and accurate colors and color<br />

consistency between jobs and<br />

between presses.<br />

The 4 process colors plus<br />

one of a range of standard or<br />

custom-made spot colors provide<br />

an extended color gamut.<br />

Unique and patented One-Pass-<br />

Duplex technology enables<br />

perfect front-to-back registration<br />

and simultaneous doublesided<br />

printing. This ensures<br />

100% data integrity, which is<br />

crucial for documents containing<br />

critical financial information<br />

and helps avoid embarrassing<br />

situations.<br />

100% DATA<br />

INTEGRITY

8<br />

A Seamlessly Integrated Graphic Arts Workflow<br />

PRODUCTIVITY AND QUALITY<br />

on one or more Windows-based<br />

prevent counterfeiting, the X-800<br />

More, better, faster and cheaper. Or how to produce larger<br />

volumes of increasingly better print quality for ever more<br />

complex designs, quicker, at lower cost, and still be<br />

profitable? The answer to these challenges is to create a<br />

fast and efficient digital workflow that can be automated<br />

and integrated, without having to compromise on quality.<br />

And our X-800 digital front-end offers you just that.<br />

Benefit from the X-800’s numerous<br />

features to minimize downtime<br />

and increase productivity while<br />

maintaining maximum flexibility<br />

and quality:<br />

unequaled streaming<br />

technology<br />

integrated engine controller<br />

platforms to form a personalized<br />

workflow. This modular architecture<br />

also allows you to separate<br />

the pre-press functionality from the<br />

press operation, which simplifies<br />

your operators’ tasks.<br />

SCALABLE DESIGN<br />

allows dynamic addition of production<br />

data or other variable elements,<br />

such as sequential numbers<br />

or barcodes, to already RIP-ed<br />

documents.<br />

OPEN STANDARDS<br />

Thanks to our focus on open<br />

intelligent load balancing<br />

The X-800 boasts multi-threaded<br />

industry standards, the X-800<br />

RIP-while-print<br />

software, which makes it highly<br />

enables the implementation of<br />

parallel RIP-ing and compres-<br />

scalable. You can take advantage<br />

fully automated workflows in any<br />

sion<br />

of multiple CPUs on one system or<br />

production environment. It en-<br />

post-RIP impositioning<br />

add additional offline RIP platforms<br />

sures seamless integration and<br />

page picking<br />

to provide extra processing power<br />

connectivity with your existing<br />

ICC color management<br />

if needed. The X-800 is compatible<br />

workflow and any market-leading<br />

Post-RIP color adjustment<br />

with all the <strong>Xeikon</strong> engines along<br />

applications (MIS solutions, design<br />

the upgrade path, making it easy<br />

packages, workflow systems …).<br />

MODULAR ARCHITECTURE<br />

to grow your business.<br />

By minimizing human intervention,<br />

The X-800’s powerful functions<br />

automation improves accuracy and<br />

are provided in separate modules.<br />

All server modules can be installed<br />

on the X-800 streamer system or<br />

METADATA<br />

To enable tracking of your productions<br />

from print to delivery or to<br />

repeatability, and reduces errors,<br />

which results in enhanced<br />

productivity and cost savings.

9<br />

Graphic Arts Workflow<br />

MIS (JDF/JMF)<br />

Layout<br />

X-800 Streamer<br />

DataBase<br />

VDP application<br />

X-800 DFE<br />

X-800 Streamer<br />

Resources<br />

Composition rules<br />

Object Store<br />

X-800 Streamer<br />

Marketing<br />

PrePress <strong>Xeikon</strong> Digital Front-end <strong>Printing</strong><br />

Finishing<br />

FULL PDF/VT SUPPORT<br />

The latest release of the <strong>Xeikon</strong><br />

X-800 workflow fully supports the<br />

PDF/VT Standard. Based on JDF<br />

job-ticket driven workflows, PDF/<br />

VT allows end-to-end automation<br />

and streamlining for variable data<br />

printing processes. Decoupling data<br />

from the process, metadata based<br />

filtering of records or pages, rulebased<br />

imposition, reliable tracking<br />

and tracing… they all add up to<br />

professional automation, a top 3<br />

decision criterion when investing.<br />

XEIKON MYPRESS,<br />

STATE-OF-THE-ART<br />

USER INTERFACE<br />

Worldwide customer requirement<br />

feedback, practical tips from <strong>Xeikon</strong><br />

press operators and scientific<br />

research by leading university<br />

usability experts resulted in<br />

MyPress, <strong>Xeikon</strong>’s unique user<br />

interface design. MyPress is a new<br />

engine controller that allows more<br />

productive and convenient use.

10<br />

A Seamlessly Integrated IPDS Workflow<br />

TOP-NOTCH PRODUCTIVITY<br />

CONSISTENT, SUPERIOR<br />

SEAMLESS INTEGRATION<br />

Increasingly complex, high-quality, high-volume, individualized<br />

campaigns. That is where the market is headed. This<br />

poses challenges in terms of print quality and productivity,<br />

but also in terms of data processing. Increasingly large and<br />

complex databases, data mining applications and pre-press<br />

tools are required to develop full color individualized<br />

documents that vary not only text, but images as well.<br />

A seamlessly integrated workflow is ever more crucial.<br />

That is why we have long-standing partnerships with<br />

leading providers of such pre-press tools.<br />

The <strong>Xeikon</strong> IPDS Controller<br />

handles the IPDS input data<br />

stream directly without any<br />

conversions in-between and<br />

allows RIP-ing on the fly, enabling<br />

you to operate at rated engine<br />

speeds at all times.<br />

DATA INTEGRITY<br />

Due to its architecture, an IPDS<br />

workflow ensures the integrity<br />

QUALITY<br />

The X-800 is packed with features<br />

to ensure superior as well as<br />

consistent image quality:<br />

ICC color management<br />

support for 5th color<br />

automatic color and front-toback<br />

registration<br />

previewing<br />

post-RIP color adjustment<br />

automatic printer calibration<br />

The X-800 and <strong>Xeikon</strong> IPDS<br />

Controller integrate seamlessly<br />

into your existing workflow.<br />

BEST OF BOTH WORLDS<br />

With the <strong>Xeikon</strong> IPDS Controller<br />

and X-800 digital front-end you<br />

get the best of both worlds: native<br />

IPDS data stream support at rated<br />

engine speed for high-volume<br />

production of transactional<br />

And we have more: in combination with our X-800 digital<br />

front-end, the <strong>Xeikon</strong> IPDS Controller is the missing link<br />

to convert your typical B&W transactional workflow to full<br />

color! But not only that. It enables high-end variable data<br />

workflows for the most sophisticated individualized<br />

cross-media campaigns.<br />

of your data throughout the production<br />

process. The bi-directional<br />

communication enables feedback<br />

loops, security and data integrity<br />

checks.<br />

automatic tone curve<br />

adjustment<br />

COST SAVINGS<br />

Eliminate stock outs and overstock<br />

of pre-printed forms! With the<br />

X-800 and <strong>Xeikon</strong> IPDS Controller<br />

documents and native PostScript<br />

or PDF support for any other<br />

printing work you may have.<br />

you print what is needed, when it<br />

is needed, and in full color.

“The seamless integration of the X-800 IPDS digital front-end with our existing production<br />

workflow was another key factor in our decision to further invest in <strong>Xeikon</strong>. With variable<br />

data processing, the integrity of the data is imperative. For web to print applications<br />

(GOCAD) our clients enter their files directly via an extranet and the data then flows<br />

seamlessly through the process without the need for any data conversion.”<br />

Loïc Lefebvre - Head of Business Development for Data One and Group Diffusion Plus, France<br />

11<br />

IPDS Workflow<br />

MIS (JDF/JMF)<br />

Layout<br />

X-800 + IPDS<br />

DataBase<br />

VDP application<br />

PrintServer<br />

X-800 + IPDS<br />

Resources<br />

Composition rules<br />

IPDS<br />

Marketing<br />

PrePress<br />

Central Server <strong>Xeikon</strong> DFE<br />

<strong>Printing</strong> Finishing<br />

One central print server communicates with all your prepress tools and<br />

digital printing presses. You can continue using the tools and applications<br />

you are familiar with. The X-800 and <strong>Xeikon</strong> IPDS Controller integrate<br />

seamlessly into your existing workflow.

12 “The<br />

most compelling reason for opting for dry toner, other than its<br />

image quality, was the environmental aspect. Our large customers<br />

demand that we deliver eco-friendly solutions, and inkjet prints today,<br />

even with water-based inks, are not sufficiently deinkable.”<br />

Per Larsson - Sales and Marketing Manager at Parajett, Sweden<br />

Application-Tuned Toner<br />

EXTENDED COLOR GAMUT<br />

TWO SIDED FULL COLOR<br />

black list, US-C-070928PROP-<br />

Because we develop our proprietary dry toner in-house,<br />

we can vouch for its outstanding quality and performance.<br />

Innovative, market-driven R&D ensures it is continually<br />

improved, so you can meet the ever-rising quality and<br />

productivity standards.<br />

Our FA toner has set the standard for quality and eco-friendliness.<br />

Our novel QA-P toner enhances those standards while<br />

raising the bar for productivity. It has been developed specially<br />

for document and book printing markets and offers benefits<br />

in the field of fusing, increased color gamut and speed.<br />

FA and QA-P toners are available<br />

in the 4 process colors (CMYK)<br />

and off-the-shelf spot colors (red,<br />

green, blue, orange and extra<br />

magenta). Our clear toner is UV<br />

fluorescent and can be used for<br />

low level security applications and<br />

identification marks on transaction<br />

documents and direct mailings,<br />

invisible to the human eye but not<br />

to finishing equipment. We can<br />

also develop custom-made colors<br />

to meet specific brand color or<br />

PRINTING...<br />

INCLUDING MICR<br />

The fifth color station of the<br />

<strong>Xeikon</strong> 8800 can also hold MICR<br />

toner for printing checks and other<br />

transaction documents. It is the<br />

only digital press in its class of<br />

print quality that prints doublesided<br />

full color documents with<br />

MICR characters in one pass! This<br />

way data integrity is guaranteed<br />

and productivity maintained.<br />

IC-65, and EU Standard EN71-3<br />

(heavy metals).<br />

Like all commercially available<br />

<strong>Xeikon</strong> toners they score high on<br />

deinkability. This means that <strong>Xeikon</strong>-printed<br />

paper is guaranteed<br />

to be recyclable. And as paper<br />

recycling is becoming increasingly<br />

important, this is an advantage<br />

worthwhile considering before<br />

making an investment decision!<br />

security requirements.<br />

ENVIRONMENTALLY<br />

PANTONE ® -LICENSED<br />

FA and QA-P toner facilitate the<br />

accurate reproduction of your<br />

customers’ brand image.<br />

FRIENDLY<br />

FA and QA-P toner contain no<br />

solvents, so our presses produce<br />

no hazardous emissions of VOCs<br />

(volatile organic compounds).<br />

They also contain no hazardous<br />

chemicals, which makes them<br />

compliant with the US and EU

“The first technology we looked at was inkjet, but we decided straightaway that, for us, it was not the way<br />

to go. The image quality simply wasn’t good enough. Well, I guess the image quality could be OK, but you<br />

would need special paper, which costs about three times as much as the paper we can use for our<br />

dry toner electrophotography presses. It would just not be cost-effective.”<br />

Per Larsson - Sales and Marketing Manager at Parajett, Sweden<br />

13<br />

Superb quality on conventional paper substrates<br />

Enjoy unbeaten print media<br />

Optimal Recyclability<br />

Unbeaten<br />

Wide Range of<br />

flexibility in terms of width,<br />

Bonding agents present in<br />

Print Media Flexibility<br />

Weights and Calipers<br />

format, weight, and type! The<br />

<strong>Xeikon</strong> 8500, the <strong>Xeikon</strong> 8600<br />

and the <strong>Xeikon</strong> 8800 can print<br />

on scalable widths and an unmatched<br />

range of substrates.<br />

pretreatment products reduce<br />

the recyclability of printed<br />

material. Because conventional<br />

paper substrates require no<br />

pretreatment when used on a<br />

<strong>Xeikon</strong>, and <strong>Xeikon</strong> toners score<br />

The <strong>Xeikon</strong> 8500, the <strong>Xeikon</strong> 8600<br />

and the <strong>Xeikon</strong> 8800 support<br />

unbridled creativity and valueadded<br />

applications on an<br />

unbeaten range of print media:<br />

From newsprint paper to<br />

paperboard, the <strong>Xeikon</strong> 8500,<br />

the <strong>Xeikon</strong> 8600 and the<br />

<strong>Xeikon</strong> 8800 can handle an<br />

impressive range of weights and<br />

calipers without a crease.<br />

NO COATING OR<br />

PRETREATMENT<br />

Unlike other digital technology, our<br />

dry toner-based imaging technology<br />

delivers uncompromising quality<br />

on conventional paper substrates<br />

without coating or pretreatment!<br />

This helps you save time and<br />

money.<br />

high on deinkability, recyclability<br />

is further improved.<br />

Coated and uncoated paper<br />

and paperboard<br />

Synthetic print media<br />

Label stock<br />

The script files for our range<br />

of certified print media can be<br />

downloaded from our website<br />

www.xeikon.com. Our print script<br />

database is continually updated.<br />

Media weight:<br />

40 - 350 gsm<br />

(27 lb text to 122 lb cover)<br />

Media caliper:<br />

< 550 µm<br />

(

14<br />

From Start to Finish<br />

UNWINDERS<br />

REWINDERS<br />

STACKERS<br />

With the <strong>Xeikon</strong> range of duplex presses you enjoy<br />

maximum configuration flexibility. You can operate them<br />

in roll-to-roll, roll-to-sheet or roll-to-stack configuration,<br />

depending on your application and finishing requirements.<br />

Choose from a range of input and output accessories to<br />

support your productivity and streamline your finishing.<br />

We offer a choice of medium and<br />

large size unwinders to match your<br />

productivity requirements. Our<br />

medium unwinder holds reels up<br />

to Ø 600 (23.6”) and media widths<br />

up to 512 mm (20.1”), while our<br />

jumbo unwinders hold reels of up<br />

to Ø 1370 mm (54”) and media<br />

widths of up to 520 mm (20.5”).<br />

By minimizing the number of stops,<br />

jumbo unwinders maximize the<br />

productivity of your press.<br />

Our rewinders are adapted for<br />

maximum web widths of up to<br />

520 mm (20.5”) and produce<br />

jumbo reels of up to Ø 1370 mm<br />

(54”), ready for further inline or<br />

offline processing. They can also<br />

rewind printed and perforated rolls<br />

and can be equipped with optional<br />

edge-trimming and/or slitting<br />

functions. Fitting seamlessly in<br />

any workflow, they facilitate and<br />

optimize the finishing of all your<br />

print jobs.<br />

When operating your press in webto-sheet<br />

mode, you can count on<br />

the <strong>Xeikon</strong> Stacker to deliver neatly<br />

aligned stacks of up to 450 mm<br />

(17.7”). Do you need larger stacks<br />

or special book block stacks? No<br />

problem! Many of our clients have<br />

already seamlessly integrated their<br />

<strong>Xeikon</strong> equipment with leading<br />

third party stacking solutions.

15<br />

WEB FINISHING MODULE<br />

Our inline Web Finishing Module<br />

(WFM) makes sure your prints will<br />

last a lifetime. It applies an invisible<br />

protective layer that enhances<br />

scratch and scuff resistance, which<br />

prevents damage typically caused<br />

by finishing equipment or mail<br />

sorting systems. It also eliminates<br />

static charges. This significantly<br />

reduces paper jams and misfeeds,<br />

which in turn allows easy postprocessing<br />

and additional finishing.<br />

Because our WFM operates inline<br />

and at rated engine speed, it does<br />

not impact uptime of your press.<br />

“In the direct mail area,<br />

Advantage Mailing, in the<br />

USA, upgraded from a<br />

<strong>Xeikon</strong> 5000 to a <strong>Xeikon</strong><br />

8000 press where they use its<br />

high image quality and inline<br />

finishing in cluding laminating,<br />

UV coating and die cutting to<br />

differenti ate themselves from<br />

the competition.”<br />

Andy Tribute<br />

tribute@attributes.co.uk

Go beyond your limits<br />

ABOUT XEIKON<br />

<strong>Xeikon</strong> is an innovator in digital<br />

printing technology. The company<br />

designs, develops and delivers<br />

web-fed digital color presses for<br />

label and packaging applications,<br />

document printing, as well as commercial<br />

printing. These presses utilize<br />

LED-array-based dry toner electrophotography,<br />

open workflow software<br />

and application-specific toners.<br />

<strong>Xeikon</strong> also manufactures<br />

basysPrint computer-to-plate (CtP)<br />

solutions for the commercial printing<br />

market. These proven CtP systems<br />

combine the latest exposure<br />

techniques with cost-efficient<br />

UV plate technology, high imaging<br />

quality and flexibility.<br />

For the flexographic market, <strong>Xeikon</strong><br />

offers digital platemaking systems<br />

under the ThermoFlexX brand name.<br />

ThermoFlexX systems provide high<br />

resolution plate exposure including<br />

screening, color management, as<br />

well as workflow management.<br />

All the <strong>Xeikon</strong> solutions are designed<br />

with the overarching principles of<br />

profitability, quality, flexibility and sustainability<br />

in mind. With these guiding<br />

principles and a deep, intimate<br />

knowledge of its customers, <strong>Xeikon</strong><br />

continues to be one of the industry’s<br />

leading innovators of products<br />

and solutions.<br />

For more information,<br />

visit www.xeikon.com.<br />

© 2012 <strong>Xeikon</strong> International BV. All rights<br />

reserved. All trademarks are property of<br />

their respective owners. No parts of this<br />

brochure may be reproduced, copied,<br />

adapted, translated or transmitted in any<br />

form or by any means, without prior written<br />

permission from <strong>Xeikon</strong>. The material in<br />

this brochure is for informational purposes<br />

only and is subject to change without<br />

prior notice. No responsibility or liability is<br />

assumed by <strong>Xeikon</strong> for any errors, which<br />

may appear in this brochure.<br />

Printed on <strong>Xeikon</strong> equipment<br />

SegBro_DOC_EN_mar2012<br />

<strong>Xeikon</strong> International BV - T. +31 (0)117 37 50 20 - F. +31 (0)117 37 50 21<br />

Brieversstraat 70 - 4529 GZ Eede - Netherlands - www.xeikon.com - info@xeikon.com<br />

<strong>Xeikon</strong> UK Ltd. - T. +44 (0) 1 904 520 555 - info.uk@xeikon.com<br />

<strong>Xeikon</strong> Scandinavia AB - T. +46 (0) 8 41 00 58 70 - info.se@xeikon.com<br />

<strong>Xeikon</strong> SE Europe S.A.I.C - T. +30 (0) 210 9010 656 - info.seeurope@xeikon.com<br />

Printed on Mondi ColorCopy 200gsm paper.