Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

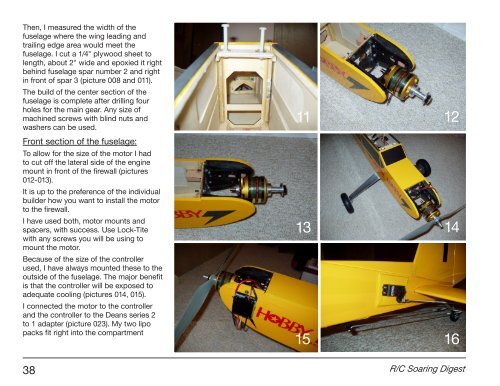

Then, I measured the width of the<br />

fuselage where the wing leading and<br />

trailing edge area would meet the<br />

fuselage. I cut a 1/4" plywood sheet to<br />

length, about 2" wide and epoxied it right<br />

behind fuselage spar number 2 and right<br />

in front of spar 3 (picture 008 and 011).<br />

The build of the center section of the<br />

fuselage is <strong>com</strong>plete after drilling four<br />

holes for the main gear. Any size of<br />

machined screws with blind nuts and<br />

washers can be used.<br />

Front section of the fuselage:<br />

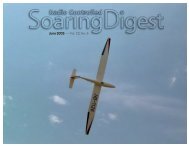

To allow for the size of the motor I had<br />

to cut off the lateral side of the engine<br />

mount in front of the firewall (pictures<br />

012-013).<br />

It is up to the preference of the individual<br />

builder how you want to install the motor<br />

to the firewall.<br />

I have used both, motor mounts and<br />

spacers, with success. Use Lock-Tite<br />

with any screws you will be using to<br />

mount the motor.<br />

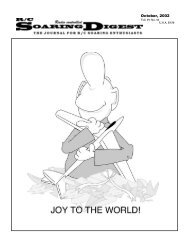

Because of the size of the controller<br />

used, I have always mounted these to the<br />

outside of the fuselage. The major benefit<br />

is that the controller will be exposed to<br />

adequate cooling (pictures 014, 015).<br />

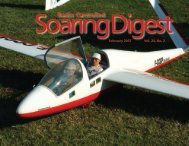

I connected the motor to the controller<br />

and the controller to the Deans series 2<br />

to 1 adapter (picture 023). My two lipo<br />

packs fit right into the <strong>com</strong>partment<br />

11 12<br />

13 14<br />

15 16<br />

38 R/C Soaring Digest