ICA_Feb 07.pdf - Roof & Facade

ICA_Feb 07.pdf - Roof & Facade

ICA_Feb 07.pdf - Roof & Facade

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Transportation<br />

The Advantages of Steel Fibre<br />

Reinforced Concrete (SFRC)<br />

The addition of steel fibres to concrete is an important step in research towards improving its properties. The<br />

areas of potential use are expanding. For example, steel fibres not only offer a solution for the low-tensile<br />

strength of concrete but give pseudo-ductile properties to brittle concrete. Finally, the steel fibres provide good<br />

energy-absorption which, in turn, offers a technical solution to certain specific loading conditions.<br />

FIBRE reinforced concrete is a composite material<br />

whose bearing strength is determined by the<br />

combination of its two constituent parts: the concrete<br />

and the fibres.<br />

P c<br />

= P m<br />

+ P f<br />

This assumes there is a close interaction between the<br />

two materials. Where a load is applied, this results in a<br />

deformation. Depending on the composite’s state of<br />

deformation of the composite, this interaction is<br />

governed by (1) the ratio between the elasticity moduli<br />

(n = E f<br />

/E m<br />

), (2) the transmission of the stress from the<br />

concrete to the fibres, and (3) the uniformity of<br />

distribution of the fibres.<br />

Steel fibres with hooked ends maximise these<br />

interaction fibres because the use of high-tensile drawn<br />

steel wire and the anchored hooked ends of the fibres,<br />

which make it possible to use the whole length of fibre<br />

to transmit the maximum amount of force and to<br />

prevent any splitting force from being exerted on the<br />

concrete. Furthermore, a uniform distribution of fibres<br />

in the concrete is obtained via the easy handling quality<br />

of steel fibre bundles.<br />

Reinforcement with steel fibres only show its full<br />

value in the post-elastic deformation phase. The sudden<br />

brittle failure of reinforced concrete is transformed into<br />

slow, controlled crack propagation under the influences<br />

of forces such as compression, tension, flexure, shear,<br />

shrinkage and creep. The intrinsic qualities of using<br />

steel fibres are fully revealed when they span hairline<br />

cracks in the concrete and absorb the tensile forces<br />

present. This process is related to the fibres’ hooks<br />

which are fixed in the concrete and continues until a<br />

high maximum pulling-out force is reached. To avoid<br />

sudden failure of the concrete, the quality of the steel is<br />

selected so that the breaking strength of the fibres is<br />

only exceeded in exceptional cases.<br />

In the case of further loading, the width of the crack<br />

will increase due to the pulling-out of the fibre as the<br />

hooks of the fibre undergo plastic deformation. This<br />

plastic deformation under high tensile stresses is one<br />

of the principle characteristics of steel fibres, and it<br />

allows the steel fibre concrete to achieve a high degree<br />

of toughness (ductility).<br />

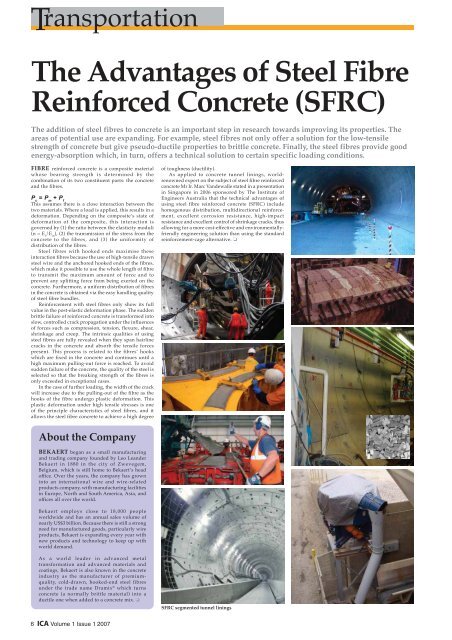

As applied to concrete tunnel linings, worldrenowned<br />

expert on the subject of steel fibre reinforced<br />

concrete Mr Ir. Marc Vandewalle stated in a presentation<br />

in Singapore in 2006 sponsored by The Institute of<br />

Engineers Australia that the technical advantages of<br />

using steel fibre reinforced concrete (SFRC) include<br />

homogenous distribution, multidirectional reinforcement,<br />

excellent corrosion resistance, high-impact<br />

resistance and excellent control of shrinkage cracks, thus<br />

allowing for a more cost-effective and environmentallyfriendly<br />

engineering solution than using the standard<br />

reinforcement-cage alternative. ❏<br />

About the Company<br />

BEKAERT began as a small manufacturing<br />

and trading company founded by Leo Leander<br />

Bekaert in 1880 in the city of Zwevegem,<br />

Belgium, which is still home to Bekaert’s head<br />

office. Over the years, the company has grown<br />

into an international wire and wire-related<br />

products company, with manufacturing facilities<br />

in Europe, North and South America, Asia, and<br />

offices all over the world.<br />

Bekaert employs close to 18,000 people<br />

worldwide and has an annual sales volume of<br />

nearly US$3 billion. Because there is still a strong<br />

need for manufactured goods, particularly wire<br />

products, Bekaert is expanding every year with<br />

new products and technology to keep up with<br />

world demand.<br />

As a world leader in advanced metal<br />

transformation and advanced materials and<br />

coatings, Bekaert is also known in the concrete<br />

industry as the manufacturer of premiumquality,<br />

cold-drawn, hooked-end steel fibres<br />

under the trade name Dramix ® which turns<br />

concrete (a normally brittle material) into a<br />

ductile one when added to a concrete mix. ❏<br />

SFRC segmented tunnel linings<br />

6 <strong>ICA</strong> Volume 1 Issue 1 2007