Brochure in PDF - SPM Instrument

Brochure in PDF - SPM Instrument

Brochure in PDF - SPM Instrument

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

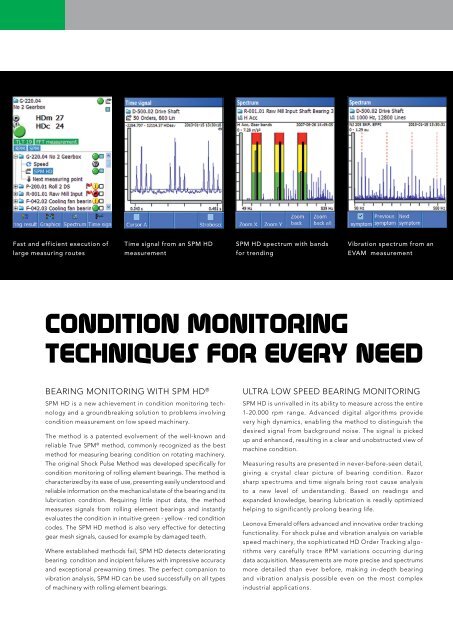

Fast and efficient execution of<br />

large measur<strong>in</strong>g routes<br />

Time signal from an <strong>SPM</strong> HD<br />

measurement<br />

<strong>SPM</strong> HD spectrum with bands<br />

for trend<strong>in</strong>g<br />

Vibration spectrum from an<br />

EVAM measurement<br />

condition monitor<strong>in</strong>g<br />

techniques for every need<br />

beAr<strong>in</strong>g monitor<strong>in</strong>g with spm hD ®<br />

spm hD is a new achievement <strong>in</strong> condition monitor<strong>in</strong>g technology<br />

and a groundbreak<strong>in</strong>g solution to problems <strong>in</strong>volv<strong>in</strong>g<br />

condition measurement on low speed mach<strong>in</strong>ery.<br />

the method is a patented evolvement of the well-known and<br />

reliable true spm ® method, commonly recognized as the best<br />

method for measur<strong>in</strong>g bear<strong>in</strong>g condition on rotat<strong>in</strong>g mach<strong>in</strong>ery.<br />

the orig<strong>in</strong>al shock pulse method was developed specifically for<br />

condition monitor<strong>in</strong>g of roll<strong>in</strong>g element bear<strong>in</strong>gs. the method is<br />

characterized by its ease of use, present<strong>in</strong>g easily understood and<br />

reliable <strong>in</strong>formation on the mechanical state of the bear<strong>in</strong>g and its<br />

lubrication condition. requir<strong>in</strong>g little <strong>in</strong>put data, the method<br />

measures signals from roll<strong>in</strong>g element bear<strong>in</strong>gs and <strong>in</strong>stantly<br />

evaluates the condition <strong>in</strong> <strong>in</strong>tuitive green - yellow - red condition<br />

codes. the spm hD method is also very effective for detect<strong>in</strong>g<br />

gear mesh signals, caused for example by damaged teeth.<br />

where established methods fail, spm hD detects deteriorat<strong>in</strong>g<br />

bear<strong>in</strong>g condition and <strong>in</strong>cipient failures with impressive accuracy<br />

and exceptional prewarn<strong>in</strong>g times. the perfect companion to<br />

vibration analysis, spm hD can be used successfully on all types<br />

of mach<strong>in</strong>ery with roll<strong>in</strong>g element bear<strong>in</strong>gs.<br />

ultrA low speeD beAr<strong>in</strong>g monitor<strong>in</strong>g<br />

spm hD is unrivalled <strong>in</strong> its ability to measure across the entire<br />

1-20.000 rpm range. Advanced digital algorithms provide<br />

very high dynamics, enabl<strong>in</strong>g the method to dist<strong>in</strong>guish the<br />

desired signal from background noise. the signal is picked<br />

up and enhanced, result<strong>in</strong>g <strong>in</strong> a clear and unobstructed view of<br />

mach<strong>in</strong>e condition.<br />

measur<strong>in</strong>g results are presented <strong>in</strong> never-before-seen detail,<br />

giv<strong>in</strong>g a crystal clear picture of bear<strong>in</strong>g condition. razor<br />

sharp spectrums and time signals br<strong>in</strong>g root cause analysis<br />

to a new level of understand<strong>in</strong>g. based on read<strong>in</strong>gs and<br />

expanded knowledge, bear<strong>in</strong>g lubrication is readily optimized<br />

help<strong>in</strong>g to significantly prolong bear<strong>in</strong>g life.<br />

leonova emerald offers advanced and <strong>in</strong>novative order track<strong>in</strong>g<br />

functionality. for shock pulse and vibration analysis on variable<br />

speed mach<strong>in</strong>ery, the sophisticated hD order track<strong>in</strong>g algorithms<br />

very carefully trace rpm variations occurr<strong>in</strong>g dur<strong>in</strong>g<br />

data acquisition. measurements are more precise and spectrums<br />

more detailed than ever before, mak<strong>in</strong>g <strong>in</strong>-depth bear<strong>in</strong>g<br />

and vibration analysis possible even on the most complex<br />

<strong>in</strong>dustrial applications.

![[Machine Guard MG-4] - SPM Instrument](https://img.yumpu.com/26505839/1/184x260/machine-guard-mg-4-spm-instrument.jpg?quality=85)