www.sylvaniaheaters.com

www.sylvaniaheaters.com

www.sylvaniaheaters.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>www</strong>.<strong>sylvaniaheaters</strong>.<strong>com</strong>

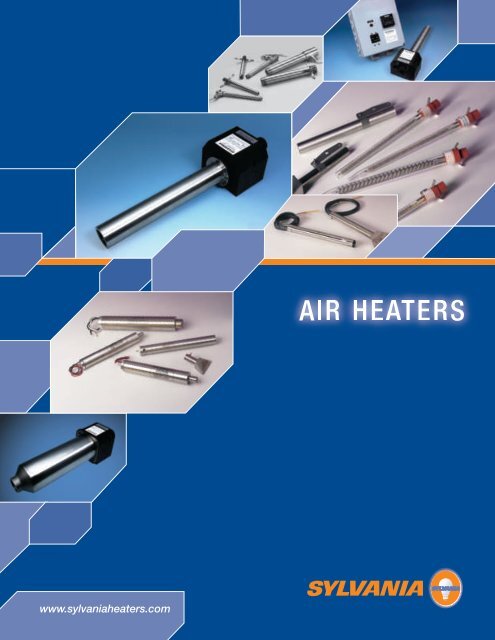

CONTENTS<br />

Products & Applications . . . . 1<br />

About Air Heaters . . . . . . . . . 2<br />

Air Heaters . . . . . . . . . . . 4-17<br />

Reference Data . . . . . . . . . 18

Aerospace:<br />

• Combustion/flow simulation<br />

Packaging:<br />

• High speed poly-coated<br />

paperboard sealing<br />

• High speed heat shrink<br />

installations<br />

• Forming<br />

• Curing adhesives<br />

• Sterilizing bottles or cartons<br />

Automotive<br />

• Hot air bonding of body<br />

panels<br />

• Curing adhesives<br />

• Vacuum forming<br />

• Simulation of engine exhaust<br />

• Fuel Cell testing<br />

Plastics/Rubber:<br />

• Salt removal from rubber<br />

extrusions<br />

• Bending and forming of<br />

plastics<br />

• De-flashing of molded parts<br />

Textiles:<br />

• Welding plastic or vinyl<br />

fabrics<br />

• Heat treating specialty<br />

fabrics<br />

Semiconductor and<br />

Electronics:<br />

• Air knife in wave solder<br />

machines<br />

• Soldering/desoldering<br />

PC boards, lead frames,<br />

capacitors<br />

• Wafer and PC board drying<br />

• Heat shrinking wire<br />

insulation<br />

• Preheating process gases<br />

Sterilization:<br />

• Pharmaceuticals<br />

• Medical/surgical hardware<br />

• Packaging materials<br />

Paper/Printing<br />

• Speed drying coated paper<br />

• Adhesive activation<br />

• Ink drying<br />

WARNING: OSRAM SYLVANIA Air/Inert Gas Heaters should be used to heat air or an inert gas only. Use with explosive<br />

gases or in an explosive ambient can result in an explosive event, possibly leading to a serious accident or injury.

With air temperatures controllable to 1400°F ±1°, SYLVANIA Air Heaters are your solution for many critical applications. Whether you<br />

are sealing, melting, drying, sterilizing, bonding, or soldering, SYLVANIA Air Heaters with our patented Serpentine coil give you the<br />

control, precision, and long life you need for greater productivity.<br />

1<br />

Max Max<br />

Product Features kW Air Temp Air Press Use with Page<br />

°F (°C) PSI (Bar) Blower?<br />

Series I, II, III<br />

Basic heater with quartz<br />

insulator tube. Ideal for<br />

“spot” heating applications.<br />

0.6 – 2.4<br />

1 phase<br />

1600 (871)<br />

7 (0.5)<br />

No<br />

4<br />

Hot Air Tool<br />

Compact size. Built in “K”<br />

thermocouple allows for<br />

precise ±1 degree control.<br />

1.5 – 3.5<br />

1 phase<br />

1400 (760)<br />

60 (4)<br />

No<br />

6<br />

Serpentine II, VI<br />

Triple-pass exchanger<br />

housing improves<br />

efficiency and safety.<br />

2.0 – 8.0<br />

1 phase<br />

1500 (815)<br />

25 (1.7)<br />

No<br />

8<br />

Threaded Inline<br />

Serpentine element in<br />

high-pressure pipe for<br />

critical processes.<br />

1.6 – 18.0<br />

1/3 phase<br />

1400 (760)<br />

150 (10)<br />

No<br />

10<br />

SureHeat® JET<br />

All-purpose heater with two<br />

built-in “K” thermocouples<br />

for precise control and<br />

overtemp protection.<br />

3.0 – 8.0<br />

1 phase<br />

1400 (760)<br />

60 (4)<br />

Yes<br />

12<br />

SureHeat® MAX<br />

All-purpose heater with two<br />

built-in “K” thermocouples<br />

for precise control and<br />

overtemp protection.<br />

6.0 – 36.0<br />

1/3 phase<br />

1400 (760)<br />

60 (4)<br />

Yes<br />

14<br />

Flanged Inline<br />

Heavy-duty flanged heater<br />

for high-pressure and flow<br />

applications. “K” thermocouples<br />

measure phase<br />

temperatures and provide<br />

overtemp protection.<br />

36.0–192.0<br />

3 phase<br />

1400 (760)<br />

150 (10)<br />

Yes<br />

16

2<br />

Selecting an Air Heater<br />

The energy (kW) requirement is calculated from the following<br />

formula:<br />

kW = SCFM x (Texit – Tinlet)<br />

2500<br />

SCFM = Air flow in Standard* Cubic Feet per Minute<br />

Tinlet = Inlet Air Temperature (°F) (typically 70°F)<br />

Texit = Desired Exit Air Temperature (°F)<br />

Example: Heating 10 SCFM from ambient temperature<br />

(70°F) to 800°F:<br />

kW = 10 SCFM x (800°F – 70°F) = 2.9 kW<br />

2500<br />

Conversion Formulas:<br />

(Liters per Minute)/28.3 = Cubic Feet per Minute<br />

°C = 5/9 (°F – 32)<br />

°F = 9/5°C + 32<br />

*Please refer below for an explanation of Standard flowrate<br />

Air Sources<br />

If used properly, heater life of<br />

5000 hours or greater can<br />

be expected. To ensure long<br />

heater life and safe operation,<br />

follow these guidelines.<br />

Also read and understand<br />

your heater Operating Manual<br />

before use. Failure to follow<br />

these guidelines can result in<br />

heater damage, failure, or<br />

personal injury.<br />

Air Sources<br />

In general, <strong>com</strong>pressed air,<br />

and air from regenerative<br />

blowers may be used to<br />

supply OSRAM SYLVANIA air<br />

heaters. Your air source should<br />

be clean and dry. Dirt, grease,<br />

oil, or oil vapors, or corrosive<br />

or reactive gases will damage<br />

an air heater. Also, use air or<br />

inert gas only. Do not use with<br />

volatile or <strong>com</strong>bustible gases.<br />

pressure air for your air heating<br />

system. Blower size is based<br />

on the maximum amount of<br />

airflow (CFM or LPM) it can<br />

produce without any inlet or<br />

exit restrictions. When a heater<br />

or other restriction is attached<br />

to a blower, the maximum flow<br />

decreases. If the blower is<br />

severely restricted, the blower<br />

motor can overheat and fail.<br />

When designing your heating<br />

system, you should try to<br />

minimize air restrictions, and<br />

select a blower sufficient to<br />

over<strong>com</strong>e the backpressure<br />

generated by the heater,<br />

flare, and associated piping.<br />

Because of their small size,<br />

the Series, Hot Air Tool, and<br />

Serpentine II heaters should<br />

not be used with regenerative<br />

blowers.<br />

Compressed Air<br />

Compressed air is <strong>com</strong>monly<br />

available in most factories. It<br />

is high-pressure regulated air<br />

(typically to 100psi), and often<br />

contains oil for lubricating<br />

pneumatic valves and equipment.<br />

You must filter this oil to<br />

prevent fouling and damage to<br />

OSRAM SYLVANIA’s<br />

electric air heater elements.<br />

When measuring <strong>com</strong>pressed<br />

air flow rates, be sure you<br />

are measuring Standard CFM<br />

or Standard LPM units. The<br />

“Standard” means that the<br />

units are measured at<br />

standard temperature and<br />

pressure. Many flow meters<br />

are labeled SCFM, but this is<br />

incorrect at the higher<br />

pressures produced by<br />

<strong>com</strong>pressed air. For accurate<br />

flow measurements, you must<br />

consult your flow meter<br />

manual for converting CFM<br />

to “Standard” CFM. In the<br />

diagram below, the flow meter<br />

reading (CFM) is converted<br />

to SCFM using a Dwyer balltype<br />

flow meter conversion.<br />

Regenerative Blowers<br />

Regenerative blowers are<br />

<strong>com</strong>pact and inexpensive<br />

clean air sources. They can<br />

provide large amounts of low-

For detailed<br />

operating instructions,<br />

visit <strong>www</strong>.<strong>sylvaniaheaters</strong>.<strong>com</strong><br />

Controls<br />

A good control system is<br />

critical for long heater life.<br />

Before turning your control system<br />

on, you must have<br />

sufficient airflow through the<br />

heater before applying power.<br />

(Applies to heaters without<br />

SureHeat or Hot Air System<br />

over-temperature protection.)<br />

Only qualified individuals should<br />

install OSRAM SYLVANIA heaters<br />

and controls. Follow all<br />

applicable electrical codes and<br />

use proper wiring.<br />

Open-Loop (Manual) Control<br />

This simple method of control<br />

uses a manually operated<br />

power controller to apply a<br />

fixed voltage to the heating<br />

element. Using this system,<br />

the operator manually adjusts<br />

the controller to change heater<br />

temperature. Note that if the<br />

airflow is suddenly interrupted,<br />

the element could fail. The<br />

open-loop controller is generally<br />

used with OSRAM SYLVANIA’s<br />

Series heaters.<br />

Closed-Loop (Feedback)<br />

Control<br />

A closed-loop heater control<br />

system uses a power controller,<br />

temperature controller, and<br />

thermocouple to provide a<br />

constant output temperature,<br />

regardless of changes in airflow.<br />

The temperature controller<br />

also provides a convenient<br />

display of your process air<br />

temperature.<br />

Power Controller<br />

Phase angle fired SCR (Silicon<br />

Controlled Rectifier) power controls<br />

will provide the smoothest<br />

power regulation for OSRAM<br />

SYLVANIA Air Heaters.<br />

Other power controls may be<br />

suitable, such as distributive<br />

zero cross SSR (Solid State<br />

Relays) or other fast-switching<br />

SSR’s, but you should contact<br />

OSRAM SYLVANIA for approval<br />

before use.<br />

Temperature Controller<br />

Use only digital temperature<br />

controls with type-K thermocouple<br />

inputs. The temperature<br />

control output must match the<br />

input of the power control. (i.e.<br />

4-20mA, or 0-10VDC).<br />

A standard PID-type control<br />

with a wide proportional band<br />

setting will work best to minimize<br />

temperature overshoot.<br />

PID parameters may be<br />

auto-tuned, but only at temperatures<br />

well below the<br />

maximum of the heater. If the<br />

temperature rises too high<br />

during auto-tune, turn power<br />

off immediately.<br />

When using a Solid State Relay<br />

power control, the temperature<br />

controller cycle time should be<br />

set for 100ms or less.<br />

Thermocouple<br />

Use only a fine-wire (.030”<br />

max wire dia.), exposedjunction,<br />

type-K thermocouple<br />

placed within 1” of the heater<br />

exit for accurate temperature<br />

readings. Other thermocouple<br />

styles, or varying the distance<br />

from the heater exit will result<br />

in temperature measurement<br />

errors and/or heater failure.<br />

3

4<br />

Specifications<br />

• Air temperatures to 1600˚F<br />

(871˚C)<br />

• Quartz outer tube housing.<br />

• Nozzled (Style B) or openended<br />

(Style A) design<br />

• High-temperature silicone<br />

rubber Rear Adapter/<br />

Terminal Assembly<br />

• Maximum air pressure 7 PSI<br />

(0.5 bar)<br />

• Maximum inlet temperature<br />

120˚F (49˚C)<br />

• CE <strong>com</strong>pliant<br />

Performance<br />

1600<br />

Series Heaters<br />

Air Flow in SLPM<br />

0 11.75 23.5 47 94 142 189 236 283<br />

871<br />

1400<br />

760<br />

Air Temperature ˚F<br />

1200<br />

1000<br />

800<br />

649<br />

538<br />

427<br />

Air Temperature ˚C<br />

600<br />

400<br />

Series I<br />

Series II<br />

Series III<br />

316<br />

204<br />

0<br />

0 25 50 100 200 300 400 500 600<br />

Air Flow in SCFH<br />

0

Installation<br />

For detailed<br />

operating instructions,<br />

visit <strong>www</strong>.<strong>sylvaniaheaters</strong>.<strong>com</strong><br />

Mtg. Screw<br />

No. 3-48<br />

Clamp<br />

Adapter for nylon pressure tubing<br />

1.37"<br />

(34mm)<br />

Style A Tube<br />

Nut<br />

Lockwasher<br />

Terminal<br />

5<br />

OD "B"<br />

"A"<br />

Style B Tube<br />

1.00" (25.4mm)<br />

"A"<br />

ID "C"<br />

Products<br />

Part Number Tube Style Max. Watts Max. Volts Tube Length Tube O.D. Nozzle I.D. (Style B)<br />

“A” “B” “C”<br />

Series I<br />

010226 A 1050 180 6.88" .41" —<br />

(175mm) (10mm) —<br />

014372 A 1000 130 7.75" .41" —<br />

(197mm) (10mm) —<br />

014682 B 680 145 7.88" .41" .07"<br />

(200mm) (10mm) (2mm)<br />

014683 B 650 105 8.75" .41" .07"<br />

(222mm) (10mm) (2mm)<br />

Series II<br />

016501 A 1125 130 3.88" .41" —<br />

(98mm) (10mm) —<br />

016503 A 850 80 3.88" .41" —<br />

(98mm) (10mm) —<br />

016502 B 600 95 4.88" .41" .07"<br />

(124mm) (10.4mm) (2mm)<br />

016504 B 650 70 4.88" .41" .07"<br />

(124mm) (10mm) (2mm)<br />

Series III<br />

017558 A 2050 160 6.88" .59" —<br />

(175mm) (15mm) —<br />

017575 B 1450 135 7.88" .59" .12"<br />

(200mm) ( 15mm) (3mm)<br />

Accessories<br />

Part Number<br />

Description<br />

057081 Open Loop (Manual) power controller 25A<br />

Outer Shields — Open End<br />

015509 For Series I 014372<br />

017853 For Series II<br />

Outer Shields — Flared<br />

037261 For Series I 010226, 014682

6<br />

Specifications<br />

• Air temperatures controllable<br />

to 1400˚F (760˚C)<br />

• Built-in “K” type thermocouple<br />

• 1/4” hose barb air<br />

connection<br />

• Maximum inlet temperature<br />

120˚F (49˚C)<br />

• Maximum air pressure<br />

60 PSI (4Bar)<br />

• Slotted exit for flare<br />

attachment<br />

• 304 Stainless Steel body<br />

• 3’ (914mm) power and<br />

thermocouple leads<br />

• CE <strong>com</strong>pliant<br />

Performance<br />

Air Flow in SLPM<br />

0<br />

1500<br />

200 400 600<br />

1300<br />

Hot Air Tools<br />

1500W / 120V<br />

2000W / 240V<br />

3500W / 240V<br />

800<br />

650<br />

Temperature ˚F<br />

1100<br />

900<br />

500<br />

Temperature ˚C<br />

700<br />

350<br />

500<br />

0 500 1000 1500<br />

Air Flow in SCFH

Installation<br />

For detailed<br />

operating instructions,<br />

visit <strong>www</strong>.<strong>sylvaniaheaters</strong>.<strong>com</strong><br />

.81" (20.6mm) Dia.<br />

8.88" (225.6mm)<br />

Hose Barb<br />

7<br />

.74" (18.8mm)<br />

ID<br />

.62" (15.8mm)<br />

Electrical & TC Leads<br />

.88" (22.4mm)<br />

Dia.<br />

Products<br />

Part Max. Max. Max. Min.<br />

Number Watts Volts Amps Flow<br />

SCFH (SLPM)<br />

068462 1500W 120 13 30 (14)<br />

068463 2000W 240 9 70 (33)<br />

068464 3500W 240 15 90 (43)<br />

Accessories<br />

Part Number<br />

Description<br />

068472 Flare (includes clamp)<br />

.06" x 2.5" (1.52mm x 63.5mm) opening<br />

057081 Open Loop (manual) Power Control, 25A, 240V, 1<br />

066823 Closed Loop Power Control, 30A, 240V, 4–20mA (used with 070429)<br />

070429 Digital Temperature Control, 1/16 DIN (used with 066823), 4–20mA<br />

.06"x 2.5" Opening<br />

(1.52mm x 63.5mm)<br />

FLARE<br />

2.19"<br />

(55.6mm)

8<br />

Specifications<br />

• Air temperatures controllable<br />

to 1500˚F (815˚C)<br />

• Serpentine II to 3.6kW<br />

• Serpentine VI to 8.0kW<br />

• Triple Pass Heat Exchanger<br />

uses in<strong>com</strong>ing air to cool<br />

outer shell<br />

• Maximum air pressure<br />

25 PSI (1.7 bar)<br />

• Replaceable element<br />

assemblies<br />

• CE <strong>com</strong>pliant<br />

Performance<br />

1600<br />

1400<br />

1200<br />

Serpentine II Maximum Performance<br />

Air Flow in SLPM<br />

0 94 189 283 378 472 566<br />

871<br />

760<br />

649<br />

Temperature ˚F<br />

1000<br />

800<br />

600<br />

400<br />

200<br />

2 kW<br />

2.8 kW<br />

3.6 kW<br />

3.6 kW (Two-stage)<br />

538<br />

427<br />

316<br />

204<br />

93.4<br />

Temperature ˚C<br />

0<br />

0 200 400 600 800 1000 1200<br />

Air Flow in SCFH<br />

0<br />

1600<br />

1400<br />

1200<br />

Serpentine VI Maximum Performance<br />

Air Flow in SLPM<br />

0 94 189 283 378 472 566 661 755 850 944 1045 1133<br />

871<br />

760<br />

649<br />

Temperature ˚F<br />

1000<br />

800<br />

600<br />

400<br />

200<br />

5 kW<br />

6 kW<br />

6 kW (Two-stage)<br />

8 kW<br />

538<br />

427<br />

316<br />

204<br />

93.4<br />

Temperature ˚C<br />

0<br />

0 200 400 600 800 1000 1200 1400 1600 1800 2000 2200 2400<br />

Air Flow in SCFH<br />

0

Installation<br />

Element<br />

Housing Assembly<br />

For detailed<br />

operating instructions,<br />

visit <strong>www</strong>.<strong>sylvaniaheaters</strong>.<strong>com</strong><br />

“D” Dia.<br />

“A”<br />

“A” Dia.<br />

“B”<br />

“E” NPT<br />

Air Inlet<br />

“B”<br />

“C”<br />

Products<br />

12" (304.8mm)<br />

Leads<br />

9<br />

Serpentine II Elements used with housing 029763<br />

Part Max. Max. Max. Length “A” O.D. “B”<br />

Number Watts Volts Amps<br />

029765 2kW 240 8.3 8.20" (208mm) 0.63" (16mm)<br />

029766 2.8kW 240 11.7 8.20" (208mm) 0.63" (16mm)<br />

029767 3.6kW 240 15 8.20" (208mm) 0.63" (16mm)<br />

060418 3.6kW (Two-stage) 240 15 8.63" (219mm) 0.63" (16mm)<br />

Serpentine VI Elements used with housing 057088<br />

Part Max. Max. Max. Length “A” O.D. “B”<br />

Number Watts Volts Amps<br />

040291 5kW 240 20.8 10.88" (276mm) 1.25" (32mm)<br />

040292 6kW 240 25 10.88" (276mm) 1.25" (32mm)<br />

061429 6kW (Two-stage) 240 25 10.88" (276mm) 1.25" (32mm)<br />

056548 8kW 240 33.3 10.88" (276mm) 1.25" (32mm)<br />

Housing Assemblies<br />

Part Serpentine “A” “B” “C” “D” “E”<br />

Number Type<br />

029763 ll 1.6" 9.0" 10.0" 0.7" 3/8" NPT<br />

(40mm) (229mm) (254mm) (18mm)<br />

057088 Vl 2.1" 11.9" 12.9" 1.4" 3/4" NPT<br />

(54mm) (302mm) (327mm) (35mm)<br />

Accessories<br />

Part Number<br />

Description<br />

039739 Serp II base adaptor assembly<br />

042339 Serp VI base adaptor assembly<br />

029485 Serp II TC holder (includes TC)<br />

040299 Serp VI TC holder (includes TC)<br />

039272 “K” type thermocouple probe, 3/16" (4.8mm) O.D.<br />

066823 Closed loop power control, 240V, 30A, 4–20mA<br />

057081 Open loop (manual) power control, 240V, 25A<br />

070429 Digital temperature controller, 1/16 DIN, 4–20mA

10<br />

Specifications<br />

• Air temperatures to 1400˚F<br />

(760˚C)<br />

• For applications requiring<br />

high pressure air<br />

• Both ends threaded 3/8",<br />

1/2", 1-1/4", and 2-1/2" NPT<br />

• 304 Stainless Steel housing<br />

• CE <strong>com</strong>pliant<br />

Style A<br />

• Should be used whenever<br />

an absolute leak-proof<br />

system (up to 150 PSI) is<br />

required<br />

• Two high temperature power<br />

feedthroughs<br />

• Maximum inlet temperature<br />

900˚F (482˚C)<br />

Style B<br />

• Maximum air pressure 150<br />

PSI, but will have slight air<br />

leakage through power wire<br />

strands<br />

• 12" (305mm) flexible power<br />

wires<br />

• Maximum inlet temperatures<br />

200°F (93˚C)<br />

Performance<br />

1600<br />

1400<br />

1200<br />

Inline Heaters Maximum Performance<br />

Air Flow in SLPM<br />

0 94 189 283 378 472 566 661 755 850 944 1045 1133 1416 1888 2360 2832 3304 3776<br />

871<br />

760<br />

649<br />

Temperature ˚F<br />

1000<br />

800<br />

600<br />

400<br />

200<br />

0<br />

316<br />

1.6 kW<br />

4.0 kW<br />

204<br />

6.0 kW<br />

18.0 kW<br />

93.4<br />

0<br />

0 200 400 600 800 1000 1200 1400 1600 1800 2000 2200 2400 3000 4000 5000 6000 7000 8000<br />

Air Flow in SCFH<br />

538<br />

427<br />

Temperature ˚C

Installation<br />

For detailed<br />

operating instructions,<br />

visit <strong>www</strong>.<strong>sylvaniaheaters</strong>.<strong>com</strong><br />

3/8" THREADED INLINES<br />

.375" NPT<br />

Male<br />

STYLE A<br />

0.7" (17mm)<br />

.87" Dia.<br />

(22mm)<br />

#10–32<br />

2-Places<br />

10.75"<br />

(273mm)<br />

1.0"<br />

(25mm)<br />

.375" NPT<br />

Female<br />

4.3"<br />

(109mm)<br />

3/8 NPT<br />

Male<br />

STYLE B<br />

.95"<br />

(24mm)<br />

3/8 NPT<br />

Male<br />

0.7" (17mm)<br />

10.6"<br />

(270mm)<br />

(2) #16 AWG<br />

Wire 12" Long<br />

(305mm)<br />

1.3"<br />

(33mm)<br />

0.95" Dia.<br />

(24mm)<br />

3/8 NPT<br />

Female<br />

11<br />

1/2" THREADED INLINES<br />

.5" NPT<br />

Male<br />

STYLE A<br />

#10–32<br />

2-Places<br />

.5" NPT<br />

Male<br />

4.3"<br />

(109mm)<br />

.5" NPT<br />

Male<br />

1.13"<br />

(29mm)<br />

.5" NPT<br />

Male<br />

STYLE B<br />

(2) #14 AWG<br />

Wire 12" Long<br />

(305mm)<br />

2.0"<br />

(51mm)<br />

1.2" Dia.<br />

(30mm)<br />

0.84" (21mm)<br />

0.84" (21mm)<br />

9.0"<br />

(229mm)<br />

1.0"<br />

(25mm)<br />

9.5"<br />

(241mm)<br />

.5" NPT<br />

Female<br />

1-1/4" THREADED INLINES<br />

1.7"<br />

(43mm)<br />

1.25" NPT<br />

#10–32<br />

Male<br />

2-Places<br />

STYLE A<br />

1.25" NPT<br />

Male<br />

5.0"<br />

(127mm)<br />

1.7"<br />

(43mm)<br />

1.25" NPT<br />

Male<br />

STYLE B<br />

1.8"<br />

(46mm)<br />

.5" NPT<br />

Male<br />

#10 AWG<br />

Wire 12" Long<br />

(305mm)<br />

1.2"<br />

(30mm)<br />

2.0"<br />

(51mm)<br />

11.3"<br />

(287mm)<br />

1.0"<br />

(25mm)<br />

12.2"<br />

(310mm)<br />

1.25" NPT<br />

Female<br />

2-1/2" THREADED INLINE<br />

STYLE B<br />

60˚<br />

(typ)<br />

2.1"<br />

(54mm)<br />

STYLE B<br />

12.2"<br />

(310mm)<br />

Products<br />

Heater Size (NPT) Max. Watts Max. Volts Max. Amps Part No., Style A Part No., Style B<br />

3/8" 1.6kW 170 9.4 038821 038822<br />

1/2" 4.0kW 220 18.2 038823 038824<br />

1-1/4" 6.0kW 220 27.3 038825 038826<br />

2-1/2" 18.0kW 240 75.0 (1 ) /44.0 (3 ) N/A 063007<br />

Accessories<br />

Part Number<br />

Description<br />

057081 Open loop (manual) power control, 240V, 25A<br />

066823 Closed loop power control, 240V, 30A<br />

070429 Temperature controller — 1 ⁄16 DIN, 4–20mA<br />

039272 “K” Type Thermocouple Probe

12<br />

Specifications<br />

• Air temp controllable to 1400°F (760°C) ±1°<br />

• Power 3.0kW - 8.0kW 240V~ 1<br />

• Two internal “K” TC sensors for control and safety:<br />

o S1 measures inlet temp.<br />

o S2 measures exit temp.<br />

• Rapid heat-up and cool-down.<br />

• Maximum air pressure 60 PSI (4 Bar)<br />

• CE, UL <strong>com</strong>pliant<br />

• ‘Ceramic-only’ design for food<br />

packaging applications.<br />

• Max inlet temp 200°F (93°C)<br />

• Use SureHeat JET CONTROL<br />

(purchased separately) for easy installation.<br />

Performance

Installation<br />

For detailed<br />

operating instructions,<br />

visit <strong>www</strong>.<strong>sylvaniaheaters</strong>.<strong>com</strong><br />

Wiring Notes:<br />

• S1 and S2 sensors are “K” type thermocouples.<br />

• S1 measures inlet air temperature.<br />

• S2 measures exit air temperature.<br />

• See Operating Manual for control settings.<br />

13<br />

Products<br />

Part Number Description Max Watts Max Volts Max Amps<br />

074718 SureHeat JET 3.0kW Heater 3.0kW 240V~ 1 50/60 Hz 12.5<br />

074719 SureHeat JET 8.0kW Heater 8.0kW 240V~ 1 50/60 Hz 33.3<br />

Accessories<br />

Part Number Description Max Watts Max Volts Max Amps<br />

074722 SureHeat JET CONTROL 8.0kW 240V~ 1 50/60 Hz 35

14<br />

Specifications<br />

• Air temp controllable to 1400°F (760°C) ±1°<br />

• Power 6.0kW - 36.0kW 240/380/480V~ 1 /3<br />

• Two internal “K” TC sensors for control and safety:<br />

o S1 measures inlet temp.<br />

o S2 measures exit temp.<br />

• Rapid heat-up and cool-down.<br />

• Maximum air pressure 60 PSI (4 Bar)<br />

• CE, UL <strong>com</strong>pliant<br />

• ‘Ceramic-only’ design for food<br />

packaging applications.<br />

• Max inlet air temp 200°F (93°C)<br />

Performance

Installation<br />

For detailed<br />

operating instructions,<br />

visit <strong>www</strong>.<strong>sylvaniaheaters</strong>.<strong>com</strong><br />

Wiring Notes:<br />

• S1 and S2 sensors are "K" type thermocouples.<br />

• S1 measures inlet air temperature.<br />

• S2 measures exit air temperature.<br />

• See Operating Manual for control settings.<br />

Installation Notes:<br />

• 18kW, 36kW heater is 16" (406.4mm) long.<br />

• 6kW, 10k W heater is 12" (304.8mm) long.<br />

• Difference is 4" (101.6mm) shorter nozzle tube.<br />

15<br />

Products<br />

Part Number Description Max Max Volts Max<br />

Watts<br />

Amps<br />

074723 SureHeat MAX 6.0kW Heater 6.0kW 240V~ 1 50/60 Hz 25.0<br />

074724 SureHeat MAX 6.0kW Heater 6.0kW 240V~ 3 50/60 Hz 14.5<br />

074725 SureHeat MAX 6.0kW Heater 6.0kW 380V~ 3 50/60 Hz 9.1<br />

074726 SureHeat MAX 6.0kW Heater 6.0kW 480V~ 3 50/60 Hz 7.2<br />

074727 SureHeat MAX 10.0kW Heater 10.0kW 240V~ 1 50/60 Hz 41.7<br />

074728 SureHeat MAX 10.0kW Heater 10.0kW 240V~ 3 50/60 Hz 24.1<br />

074729 SureHeat MAX 10.0kW Heater 10.0kW 380V~ 3 50/60 Hz 15.2<br />

074731 SureHeat MAX 10.0kW Heater 10.0kW 480V~ 3 50/60 Hz 12.0<br />

074732 SureHeat MAX 18.0kW Heater 18.0kW 240V~ 3 50/60 Hz 43.4<br />

074733 SureHeat MAX 18.0kW Heater 18.0kW 380V~ 3 50/60 Hz 27.4<br />

074734 SureHeat MAX 18.0kW Heater 18.0kW 480V~ 3 50/60 Hz 21.7<br />

074735 SureHeat MAX 30.0kW Heater 30.0kW 380V~ 3 50/60 Hz 45.6<br />

074736 SureHeat MAX 36.0kW Heater 36.0kW 480V~ 3 50/60 Hz 43.4<br />

Accessories<br />

Part Number<br />

Description<br />

074829 1/16 DIN Digital temperature control (for S2)<br />

074835 Thermal safety switch (for S1)

16<br />

Specifications<br />

• Designed for high pressure, high<br />

flow applications<br />

• Air/inert gas temperatures to<br />

1400˚F (760˚C)<br />

• Uses SureHeat overtemperature<br />

protection system<br />

• Up to 192kW in a <strong>com</strong>pact 2'<br />

(610mm) long size<br />

• Maximum air pressure<br />

150 PSI (10 Bar)<br />

• 304 Stainless Steel<br />

ASME welded 300 lb. flanged<br />

housing<br />

• Maximum inlet temperature 900˚F<br />

(482˚C)<br />

• Built-in “K” type<br />

thermocouple<br />

Performance<br />

Flanged Inline Heater Maximum Performance<br />

1600<br />

871<br />

1400<br />

1200<br />

36 kW<br />

72 kW<br />

144 kW<br />

192 kW<br />

760<br />

649<br />

Exit Air Temperature ˚F<br />

1000<br />

800<br />

600<br />

400<br />

538<br />

427<br />

316<br />

204<br />

Temperature ˚C<br />

200<br />

93.4<br />

0<br />

0 200 400 600 800 1000<br />

Air Flow in SCFM

Installation<br />

For detailed<br />

operating instructions,<br />

visit <strong>www</strong>.<strong>sylvaniaheaters</strong>.<strong>com</strong><br />

17<br />

Products<br />

Heater Part Max. Max. Max. Pipe I.D. Flange O.D. Bolt Circle Replacement SCR<br />

Number* kW Volts Amps “I” “D” “C” Element Power Control<br />

# Holes/Dia. Part Number Part Number<br />

073166 36.0 480 - 3Ø 45 4.0" (102mm) 10.0" (254mm) 8-.088”/7.88” 073167 072765<br />

073377 72.0 480 - 3Ø 87 6.0" (152mm) 12.5" (318mm) 12-.088”/10.62” 073378 072764<br />

073384 144.0 480 - 3Ø 175 8.0" (203mm) 15.0" (381mm) 12-1.00”/13.00” 073385 072763<br />

073153 192.0 480 - 3Ø 235 8.0" (203mm) 15.0" (381mm) 12-1.00”/13.00” 073253 072762<br />

*includes element<br />

A <strong>com</strong>plete functional system must have heater, SCR power control, over-temperature board, and digital temperature control.<br />

Accessories<br />

Part Number<br />

Description<br />

070429 1/16 DIN digital temperature control, 4–20 mA<br />

073262 Over-temperature control board (required)<br />

039272 Replacement “K” type thermocouple probe

18 A. Air Heater Energy Requirement<br />

D. Single Phase Wiring<br />

kW = SCFM x (Texit – Tinlet) / 2500<br />

B. Temperature Conversions<br />

°F = 9/5 (°C) + 32<br />

°C = 5/9 (°F – 32)<br />

C. Air Flow Conversions<br />

SCFM = SCFH / 60 = SLPM / 28.3<br />

SLPM = SCFH / 2.12<br />

SCMH = SCFH / 35.3<br />

SCFM = (Pounds of Air Per Minute) / (.080 lbs/ft3)<br />

SCFM<br />

SCFH<br />

SLPM<br />

SCMH<br />

= Standard Cubic Feet per Minute<br />

= Standard Cubic Feet per Hour<br />

= Standard Liters per Minute<br />

= Standard Cubic Meters per Hour<br />

V = I x R (Volts = Amps x Ohms)<br />

I = W / V (Amps = Watts / Volts)<br />

W = V 2 /R (Watts = (Volts x Volts) / Ohms)<br />

E. Three Phase Wiring<br />

Delta Configuration<br />

R = R 1 = R 2 = R 3<br />

2<br />

Wdelta = 3(V L )/R<br />

Wdelta = 1.73 x V L x I L<br />

IP = I L /1.73<br />

VP = V L<br />

Wye Configuration<br />

R = R 1 = R 2 = R 3<br />

2<br />

Wwye = (V L )/R = 3(V P 2 )/R<br />

Wwye = 1.73 x V L x I P<br />

IP = I L<br />

VP = V L /1.73<br />

Wye Configuration<br />

Delta Configuration

For orders and product information:<br />

OSRAM SYLVANIA<br />

131 Portsmouth Avenue<br />

Exeter, NH 03833 USA<br />

Tel. 800-258-8290<br />

In NH 603-772-4331<br />

Fax 603-772-1072<br />

<strong>www</strong>.<strong>sylvaniaheaters</strong>.<strong>com</strong><br />

OSRAM SYLVANIA<br />

HEADQUARTERS<br />

100 Endicott Street<br />

Danvers, MA 01923<br />

(978) 777-1900<br />

<strong>www</strong>.sylvania.<strong>com</strong><br />

© 2005 OSRAM SYLVANIA<br />

PMC 007<br />

The information and re<strong>com</strong>mendations contained in<br />

this publication are based upon data collected by<br />

OSRAM SYLVANIA and believed to be correct. However,<br />

no guarantee or warranty of any kind, expressed or implied,<br />

is made with respect to the information contained herein,<br />

and OSRAM SYLVANIA assumes no responsibility for the<br />

results of the use of products and processes described<br />

herein. No statements or re<strong>com</strong>mendations made herein<br />

are to be construed as inducements to infringe any relevant<br />

patent, now or hereafter in existence.