electric heating elements for radiators and towel rails - Rotfil

electric heating elements for radiators and towel rails - Rotfil

electric heating elements for radiators and towel rails - Rotfil

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

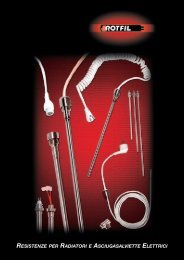

ELECTRIC HEATING ELEMENTS<br />

FOR RADIATORS AND TOWEL RAILS

<strong>Rotfil</strong> s.r.l. established in 1977 is the first manufacturer in Italy of cartridge heaters <strong>and</strong> is also the head<br />

quarter of a group of international companies including Jeka GmbH in Germany, AZ Technology in Tunisia<br />

<strong>and</strong> Elmat srl in Italy.<br />

<strong>Rotfil</strong> s.r.l. offers, there<strong>for</strong>e, a complete range of <strong>electric</strong> <strong>heating</strong> <strong>elements</strong> <strong>for</strong> <strong>radiators</strong> <strong>and</strong> <strong>towel</strong> <strong>rails</strong> including:<br />

- PTC self limiting <strong>elements</strong> <strong>Rotfil</strong><br />

- Constant power <strong>heating</strong> element class I with thermostat + thermofuse TOP Jeka<br />

- Constant power <strong>heating</strong> element class II with thermostat + thermofuse<br />

- Heating cables <strong>for</strong> Radiators <strong>and</strong> Towel-dryers<br />

- Flexible <strong>heating</strong> <strong>elements</strong> Elmat<br />

<strong>Rotfil</strong> srl quality system is certified ISO 9001 since 1996 <strong>and</strong> <strong>for</strong> its <strong>heating</strong> <strong>elements</strong> <strong>for</strong> <strong>radiators</strong> <strong>and</strong> <strong>towel</strong><br />

<strong>rails</strong> has obtained a wide range of certifications including VDE, UL, CSA.<br />

<strong>Rotfil</strong> s.r.l. continues with always greater determination its continuous growth path started more than 30<br />

Year ago, offering also <strong>for</strong> the household market its long experience accumulated in the development of<br />

<strong>electric</strong> heaters <strong>for</strong> the most different applications including automotive, industrial, military, medical,<br />

nuclear, aeronautical, space etc.<br />

2<br />

UNI EN ISO 9001:2000<br />

CERT-00858-96-AQ-TRI-SINCERT

What does PTC technology mean?<br />

PTC means "Positive Temperature Coefficient" <strong>and</strong> characterizes the <strong>electric</strong>al behaviour of the<br />

semiconductor heater segment that is the base component of the <strong>heating</strong> element.<br />

Each semiconductor element generates the heat output as the thin resistive wire in a constant power<br />

heater, but with a very significant difference: with increasing temperature the resistance of the PTC element<br />

rises instantaneously <strong>and</strong> reduces automatically the power output (P = V 2 /R) generating the so called<br />

"self-limiting" effect.<br />

Many segments are combined inside a PTC <strong>Rotfil</strong> heater generating there<strong>for</strong>e the desired output in a very<br />

wide power range (from 30 W to 1500 W <strong>and</strong> even more).<br />

°C<br />

°C<br />

Watt<br />

Watt<br />

PTC ROTFIL HEATER<br />

Time<br />

CONSTANT POWER HEATER Time<br />

How do <strong>Rotfil</strong> PTC <strong>elements</strong> work?<br />

The <strong>Rotfil</strong> PTC <strong>elements</strong> can be assembled both horizontally or vertically inside a fluid filled radiator<br />

(water with anti-freeze protection).<br />

Depending on the combination radiator / PTC <strong>heating</strong> element, the system will reach an equilibrium<br />

surface temperature. The PTC self-limiting effect will prevent over temperatures.<br />

The <strong>heating</strong> up process will automatically go through three phases:<br />

- 1. start- up<br />

In the first 60 sec the PTC works at 130% circa of the nominal power ( "turbo boost power" effect)<br />

to trigger best the convection inside the radiator.<br />

- 2. nominal power phase<br />

In this phase the PTC <strong>heating</strong> <strong>elements</strong> reaches the equilibrium temperature working at the nominal power<br />

- 3. energy saving phase<br />

With the increasing of the ambient temperature the power output decreases until a new equilibrium<br />

is reached where the power consumption is reduced ( typically at 70% - 80% of the nominal power)<br />

3

Which are the advantages of <strong>Rotfil</strong> PTC <strong>elements</strong> <strong>for</strong> the radiator manufacturers?<br />

- Intrinsic safety (no risk of over<strong>heating</strong>, burnings or fire)<br />

- No need of thermofuse <strong>and</strong> there<strong>for</strong>e no more burnt heaters also in case of partial filling<br />

- Reduced diameter <strong>and</strong> length vs constant power heaters (in particular 11 mm diameter also <strong>for</strong> class II <strong>elements</strong>)<br />

- No cold lengths (differently <strong>for</strong>m constant power heaters which require not <strong>heating</strong> zones <strong>for</strong> the<br />

thermostat <strong>and</strong> the thermofuse)<br />

- Better circulation <strong>and</strong> faster heat-up times<br />

- Absolutely no noise due to cavitation effects<br />

- Uni<strong>for</strong>m <strong>heating</strong> also <strong>for</strong> "design" <strong>radiators</strong> with very narrow space around the heater (in some cases<br />

it would be even impossible to work with constant power heaters because thermostat would switch<br />

off be<strong>for</strong>e circulation starts properly).<br />

- Tanks to the investment <strong>for</strong> the product development <strong>and</strong> industrialization, <strong>Rotfil</strong> has made PTC technology<br />

af<strong>for</strong>dable <strong>and</strong> cost effective <strong>for</strong> the <strong>radiators</strong> <strong>and</strong> <strong>towel</strong> <strong>rails</strong> market allowing solutions until<br />

now simply impossible.<br />

Ø16<br />

500W class II –constant power heater<br />

Ø11<br />

500W class II – <strong>Rotfil</strong> PTC heater<br />

cold cold cold<br />

Constant power heater<br />

<strong>Rotfil</strong> PTC heater<br />

4

Why is <strong>Rotfil</strong> PTC Technology more advanced?<br />

Thanks to the experience derived from many other applicative fields, <strong>Rotfil</strong> srl has been the first heater<br />

manufacturer to invest in the advantages of the PTC self-limiting heaters <strong>for</strong> the <strong>electric</strong> <strong>radiators</strong> <strong>and</strong> <strong>towel</strong><br />

dryers market ,<strong>Rotfil</strong> is now proud to be recognized by the leading Radiator manufacturers worldwide as<br />

a reference <strong>and</strong> milestone <strong>for</strong> this specific technology.<br />

<strong>Rotfil</strong> srl is proud to have been the first to define with VDE engineers the st<strong>and</strong>ard to measure the wattage<br />

<strong>for</strong> the PTC <strong>for</strong> radiator application. The power is defined in such a way reproducing effectively the<br />

wattage released in the real application.<br />

Thanks to the very limited in-rush current effect of <strong>Rotfil</strong> PTC heaters, there is absolutely no counter<br />

indication <strong>and</strong> the <strong>elements</strong> work properly with the electronic ambient thermostats normally used <strong>for</strong><br />

the constant power heaters.<br />

Moreover, <strong>Rotfil</strong> PTC heaters are the only ones <strong>for</strong> the radiator market which are made with an innovative<br />

production process (patent pending) which obtains the internal insulation without magnesium oxide,<br />

thus eliminating completely any potential risk of<br />

contamination of the semiconductor segments<br />

through this hygroscopic material.<br />

This makes the <strong>Rotfil</strong> PTC heaters unbeatable <strong>for</strong><br />

reliability <strong>and</strong> long-lasting duration.<br />

Why does the "easy-connection systems<br />

ROTFIL" make Your life simpler?<br />

<strong>Rotfil</strong> PTC <strong>heating</strong> <strong>elements</strong> are now also available<br />

with the innovative "quick fit " system which, thanks<br />

to a IP64 connector, allows the inter- changeability<br />

of the cable with incredible advantages in terms of:<br />

- product st<strong>and</strong>ardization <strong>and</strong> stock rationalization<br />

- extreme flexibility (no more problems of cable too<br />

short or with the wrong plug)<br />

- simple assembly of the <strong>heating</strong> <strong>elements</strong> on the radiator since there is no cable (the cable can be assembled<br />

in a second step by the radiator manufacturer according to length, plug type etc. requested by the customer).<br />

<strong>Rotfil</strong> PTC <strong>heating</strong> <strong>elements</strong> range<br />

At pages 6 – 12 of this catalogue You can find the technical data sheets of the main st<strong>and</strong>ard <strong>Rotfil</strong> PTC<br />

<strong>heating</strong> <strong>elements</strong>.<br />

Upon request other types are available with special wattages or exits: <strong>Rotfil</strong> technical office will put at disposal<br />

of the customer its significant experience to develop the most suitable product <strong>for</strong> every single application.<br />

<strong>Rotfil</strong> PTC <strong>elements</strong> are developed <strong>for</strong> water filled <strong>radiators</strong>, but upon request special PTC <strong>elements</strong> are available<br />

also <strong>for</strong> oil filled <strong>radiators</strong> <strong>and</strong> <strong>towel</strong> <strong>rails</strong>.<br />

5

PTC <strong>heating</strong> <strong>elements</strong> Class I with cable without Plug<br />

Normal type<br />

“Quick-fit” type<br />

Cable Cu/PVC<br />

3X0.75<br />

H05VV-F VDE<br />

L=1500<br />

Cable Cu/PVC<br />

3X0.75<br />

H05VV-F VDE<br />

L=1500<br />

NORMAL TYPE<br />

L<br />

O-RING<br />

1/2” G<br />

Power to<br />

60°C<br />

40W<br />

75W<br />

100W<br />

150W<br />

200W<br />

250W<br />

300W<br />

400W<br />

450W<br />

500W<br />

600W<br />

750W<br />

900W<br />

1000W<br />

1250W<br />

1500W<br />

L<br />

+0<br />

-5%<br />

125mm<br />

125mm<br />

135mm<br />

165mm<br />

205mm<br />

245mm<br />

245mm<br />

325mm<br />

365mm<br />

370mm<br />

450mm<br />

535mm<br />

635mm<br />

675mm<br />

795mm<br />

940mm<br />

L<br />

QUICK FIT TYPE<br />

O-RING<br />

1/2” G<br />

Ø 11<br />

IP64<br />

CLASSE I<br />

230V<br />

Ø 11<br />

6

PTC <strong>heating</strong> <strong>elements</strong> Class I with cable with Schuko Plug<br />

Normal type<br />

“Quick-fit” type<br />

Cable Cu/PVC<br />

3X0.75<br />

H05VV-F VDE<br />

L=1500<br />

Cable Cu/PVC<br />

3X0.75<br />

H05VV-F VDE<br />

L=1500<br />

Schuko plug<br />

Schuko plug<br />

NORMAL TYPE<br />

L<br />

O-RING<br />

1/2” G<br />

Power to<br />

60°C<br />

40W<br />

75W<br />

100W<br />

150W<br />

200W<br />

250W<br />

300W<br />

400W<br />

450W<br />

500W<br />

600W<br />

750W<br />

900W<br />

1000W<br />

1250W<br />

1500W<br />

L<br />

+0<br />

-5%<br />

125mm<br />

125mm<br />

135mm<br />

165mm<br />

205mm<br />

245mm<br />

245mm<br />

325mm<br />

365mm<br />

370mm<br />

450mm<br />

535mm<br />

635mm<br />

675mm<br />

795mm<br />

940mm<br />

L<br />

QUICK FIT TYPE<br />

O-RING<br />

1/2” G<br />

Ø 11<br />

IP64<br />

CLASSE I<br />

230V<br />

Ø 11<br />

7

PTC <strong>heating</strong> <strong>elements</strong> Class I with cable with Switch Plug<br />

Normal type<br />

“Quick-fit” type<br />

Cable Cu/PVC<br />

3X0.75<br />

H05VV-F VDE<br />

L=1500<br />

Switch plug<br />

Cable Cu/PVC<br />

3X0.75<br />

H05VV-F VDE<br />

L=1500<br />

Switch plug<br />

NORMAL TYPE<br />

L<br />

O-RING<br />

1/2” G<br />

Power to<br />

60°C<br />

40W<br />

75W<br />

100W<br />

150W<br />

200W<br />

250W<br />

300W<br />

400W<br />

450W<br />

500W<br />

600W<br />

750W<br />

900W<br />

1000W<br />

1250W<br />

1500W<br />

L<br />

+0<br />

-5%<br />

125mm<br />

125mm<br />

135mm<br />

165mm<br />

205mm<br />

245mm<br />

245mm<br />

325mm<br />

365mm<br />

370mm<br />

450mm<br />

535mm<br />

635mm<br />

675mm<br />

795mm<br />

940mm<br />

L<br />

QUICK FIT TYPE<br />

O-RING<br />

1/2” G<br />

Ø 11<br />

IP64<br />

CLASSE I<br />

230V<br />

Ø 11<br />

8

PTC <strong>heating</strong> <strong>elements</strong> Class II with cable without Plug<br />

Normal type<br />

“Quick-fit” type<br />

Cable Cu/PVC<br />

2X0.75<br />

H05VV-F VDE<br />

L=1500<br />

Cable Cu/PVC<br />

2X0.75<br />

H05VV-F VDE<br />

L=1500<br />

NORMAL TYPE<br />

L<br />

O-RING<br />

1/2” G<br />

Power to<br />

60°C<br />

150W<br />

200W<br />

250W<br />

300W<br />

400W<br />

450W<br />

500W<br />

600W<br />

750W<br />

900W<br />

1250W<br />

1500W<br />

L<br />

+0<br />

-5%<br />

165mm<br />

205mm<br />

245mm<br />

245mm<br />

375mm<br />

365mm<br />

370mm<br />

450mm<br />

535mm<br />

635mm<br />

825mm<br />

990mm<br />

L<br />

QUICK FIT TYPE<br />

O-RING<br />

1/2” G<br />

Ø 11<br />

IP64<br />

CLASS II<br />

230V<br />

Ø 11<br />

9

PTC <strong>heating</strong> <strong>elements</strong> Class II with cable with Plug<br />

Normal type<br />

“Quick-fit” type<br />

Cable Cu/PVC<br />

2X0.75<br />

H05VV-F VDE<br />

L=1500<br />

Cable Cu/PVC<br />

2X0.75<br />

H05VV-F VDE<br />

L=1500<br />

Plug<br />

Plug<br />

NORMAL TYPE<br />

L<br />

O-RING<br />

1/2” G<br />

Power to<br />

60°C<br />

150W<br />

200W<br />

250W<br />

300W<br />

400W<br />

450W<br />

500W<br />

600W<br />

750W<br />

900W<br />

1250W<br />

1500W<br />

L<br />

+0<br />

-5%<br />

165mm<br />

205mm<br />

245mm<br />

245mm<br />

325mm<br />

365mm<br />

370mm<br />

450mm<br />

535mm<br />

635mm<br />

825mm<br />

990mm<br />

L<br />

QUICK FIT TYPE<br />

O-RING<br />

1/2” G<br />

Ø 11<br />

IP64<br />

CLASS II<br />

230V<br />

Ø 11<br />

10

PTC <strong>heating</strong> <strong>elements</strong> Class I at 120V with UL approval <strong>and</strong> coiled cable<br />

with US Plug<br />

L<br />

Ø 11<br />

Power to<br />

60°C 120V<br />

75W<br />

100W<br />

150W<br />

200W<br />

250W<br />

300W<br />

400W<br />

500W<br />

600W<br />

750W<br />

900W<br />

1000W<br />

L<br />

+0<br />

-5%<br />

140mm<br />

155mm<br />

190mm<br />

220mm<br />

255mm<br />

290mm<br />

355mm<br />

425mm<br />

490mm<br />

590mm<br />

680mm<br />

750mm<br />

IP64<br />

CLASS I<br />

120V<br />

1/2” G<br />

Coiled cable<br />

PVC plated CU<br />

3X18 AWG<br />

type SVT or SJT<br />

UL/CSA R/C<br />

Length=1000 in extension<br />

O-RING<br />

UL angle 90°<br />

type plug<br />

11

PTC <strong>heating</strong> <strong>elements</strong> Class II with faston<br />

L<br />

Ø 11<br />

Faston<br />

POWER IN<br />

WATER TO 60°C<br />

L<br />

+0<br />

-5%<br />

1/2” G<br />

O-RING<br />

500W<br />

600W<br />

700W<br />

900W<br />

1000W<br />

1250W<br />

1500W<br />

370mm<br />

435mm<br />

475mm<br />

620mm<br />

660mm<br />

825mm<br />

950mm<br />

IP64<br />

CLASS II<br />

230VAC<br />

12

Constant power <strong>heating</strong> <strong>elements</strong> Class II with thermostat <strong>and</strong> thermofuse<br />

With faston type<br />

With lead wires type<br />

Faston male 6.3X0.8<br />

Plastic cap<br />

Faston female<br />

6.3X0.8<br />

+ faston-cover<br />

L<br />

O-RING<br />

M21<br />

Thermofuse 152°C<br />

Power<br />

500W<br />

600W<br />

700W<br />

750W<br />

900W<br />

1000W<br />

1250W<br />

1500W<br />

L<br />

+0<br />

-5%<br />

400mm<br />

470mm<br />

510mm<br />

520mm<br />

650mm<br />

690mm<br />

760mm<br />

900mm<br />

L 55<br />

Copper cable, PVC isolation<br />

M16<br />

O-RING<br />

M21<br />

Ø 14<br />

Thermofuse 121°C<br />

Thermostat 100°C<br />

Ø 16<br />

IP64<br />

CLASS II<br />

230V<br />

Ø 16<br />

Thermostat 100°C<br />

13

Accessories<br />

As complement to its range of <strong>heating</strong> <strong>elements</strong> <strong>for</strong> <strong>radiators</strong> <strong>and</strong> <strong>towel</strong>-dryers, <strong>Rotfil</strong> srl<br />

offers upon request also:<br />

Electronic ambient<br />

thermostats<br />

Heating cables <strong>for</strong><br />

<strong>radiators</strong> <strong>and</strong> <strong>towel</strong> dryers<br />

High quality "T" fittings<br />

L 100<br />

Cold zone<br />

Cable CU/PVC<br />

3X0.75 L=1500<br />

Heating cable:<br />

silicon insulation<br />

1/2” G<br />

Plug<br />

Power<br />

15W/m<br />

30W/m<br />

45W/m<br />

Tension<br />

230V<br />

230V<br />

230V<br />

Custom made packaging, with possibility to include different products, are available upon request<br />

14

Flexible <strong>heating</strong> <strong>elements</strong> Elmat<br />

In the <strong>radiators</strong> <strong>and</strong> <strong>towel</strong> <strong>rails</strong> market there is an always increasing request of flexible<br />

<strong>heating</strong> <strong>elements</strong> to be applied with adhesive on the rear of the so called "dry" <strong>radiators</strong>.<br />

Elmat flexible <strong>heating</strong> <strong>elements</strong> can be easily adapted to curved surfaces, or in case of small<br />

tube sizes <strong>and</strong> allow uni<strong>for</strong>m <strong>heating</strong> also of the lower parts of the <strong>radiators</strong>. Upon request<br />

they can also be supplied with integrated temperature control systems.<br />

Elmat flexible <strong>heating</strong> <strong>elements</strong> can be made according also to very special shapes, <strong>for</strong> the<br />

ambient <strong>heating</strong> of small spaces through "decorative" devices (artistic pictures etc.) <strong>and</strong><br />

can be also applied as<br />

"mist remover" system on<br />

bathroom mirrors.Other<br />

applications concern the<br />

<strong>heating</strong> of second<br />

houses, in downtown<br />

<strong>and</strong> historical centre<br />

houses where there is not<br />

the possibility to heat<br />

with gas or conventional<br />

piping systems, as well<br />

as <strong>for</strong> protection of<br />

valuable surfaces with<br />

frescos or mosaics.<br />

For floor <strong>heating</strong> application, Elmat flexible <strong>heating</strong> <strong>elements</strong> can be made as coils or<br />

as modular <strong>elements</strong>.<br />

Typical applications are <strong>for</strong> ambient <strong>heating</strong> of corridors, bathrooms, gymnasiums, churches etc.<br />

The simplicity of application allows the design of very effective ambient <strong>heating</strong> solutions<br />

with low installation <strong>and</strong> operation costs.<br />

They can be applied on existing floors, allow localized <strong>heating</strong> also in large ambient<br />

<strong>and</strong> can be covered with the most different surfaces like moquettes, carpets, woods etc.<br />

Technical data:<br />

Working temperatures: from -50°C to +100°C <strong>and</strong> specific wattages <strong>for</strong>m 0,001 to<br />

0,2 W/sqcm, Insulation material Mylar® (higher temperatures <strong>and</strong> specific wattages<br />

possible with silicon).<br />

Possibility of rein<strong>for</strong>ced <strong>and</strong> double insulation.<br />

15

ROTFIL s.r.l.<br />

Via Praglia, 15 - 10044 PIANEZZA (TO) ITALY<br />

Tel. +39-011-9683-111 - Fax +39-011-9683-225<br />

e.mail: info@rotfil.com - www.rotfil.com<br />

COMPANY<br />

WITH QUALITY SYSTEM<br />

CERTIFIED BY DNV<br />

= UNI EN ISO 9001/2000 =<br />

Elmat s.r.l.<br />

Vicolo L. Negrelli 8<br />

31038 Paese loc. Castagnole (TV) - Italy<br />

Tel +39-0422-484-198<br />

Fax +39-0422-482-868<br />

e.mail: info@elmatsrl.it<br />

www.elmatsrl.it<br />

JEKA GmbH<br />

Kalterer Straße 27<br />

D-64646 Heppenheim<br />

Deutschl<strong>and</strong> / Germany<br />

T. +49-(0)6252-95920-0<br />

F. +49-(0)6252-95920-95<br />

e.mail: info@jeka-heppenheim.de<br />

www.jeka-heppenheim.de