DigiCoater Brochure..pdf

DigiCoater Brochure..pdf

DigiCoater Brochure..pdf

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Health & Safety<br />

The <strong>DigiCoater</strong> is manufactured to CE specification by C&J Inc. The system uses UV<br />

varnishes and washes which must be used in line with health & safety data sheets.<br />

Morgana Systems Ltd has investigated various fluids and is recommending those<br />

detailed overleaf. They must therefore be used and disposed of in line with the<br />

instructions and users should wear the appropriate safety equipment i.e. gloves.<br />

The UV lamp used in the <strong>DigiCoater</strong> produces ozone. It is therefore STRONGLY<br />

RECOMMENDED that the unit is vented to the outside. A 16.5’ flexible pipe is<br />

included in the price of the <strong>DigiCoater</strong>. Should the distance to the outside be more<br />

than 16.5’ an additional fan and piping will be required. Morgana Systems Ltd do<br />

not supply these items or fit the supplied venting.<br />

An alternative to outside venting is an ozone elimination unit.<br />

<strong>DigiCoater</strong> <strong>Brochure</strong> Ver001 USA Oct 2008<br />

SPECIFICATIONS<br />

Dimensions<br />

Weight<br />

Made by C & J and distributed by Morgana Systems Ltd<br />

L 52 x W 37 x H 50 inches<br />

1260 lbs<br />

Power requirement 30 amp 220/240v<br />

Maximum speed (feet per minute) 25 - 98<br />

Maximum coating width<br />

20 inches<br />

Maximum coating length<br />

30 inches<br />

Maximum paper weight 120lbs cover stock +<br />

Coating thickness<br />

6 - 14 microns<br />

Coating technology<br />

100% UV curable<br />

Coating capacity 4 x 6.8l<br />

Available finishes<br />

Gloss/Matt/Linen<br />

Cleaning<br />

Fully automatic<br />

<strong>DigiCoater</strong> Configurations<br />

Product<br />

Digicoater 20R-2<br />

Morgana Jogger<br />

Morgana 8000 Sheet Feeder<br />

3909 Upland Way, Marietta, GA 30066, Georgia, USA<br />

Tel: 866 463 5060 Fax: 770 565 6163<br />

www.morganausa.com<br />

email: morganausa@comcast.net<br />

Description<br />

20” width 2 roller system<br />

17.7 x 25 inches<br />

17.7 x 25 inches suction feed<br />

900-701 Roller Guard Safety guard<br />

Options/Parts<br />

20” UV Lamp<br />

20” IR Lamp<br />

Smooth, Textured or Mesh Rollers<br />

Silicon Roller (Blue)<br />

Primer Tank Upgrade (if ordered with machine)<br />

Primer Tank Upgrade (on site upgrade includes 2 new rollers)<br />

Available consumables<br />

Varnishes and Washes<br />

Ultra Matt UV Varnish<br />

High Gloss UV Varnish<br />

Biograph (EPDM Safe) UV Wash<br />

Primer<br />

Qty<br />

5 litres<br />

5 litres<br />

5 litres<br />

5 litres<br />

As part of our continued product improvement plan, specifications and information published here are subject to change without notice.<br />

All specifications are dependent on application, type of stock and print engine used. Specifications quoted were measured on uncoated<br />

and unprinted stock.<br />

p r o d u c t b r o c h u r e<br />

DIGITAL FINISHING FOR DIGITAL PRINTERS<br />

WWW.MORGANAUSA.COM<br />

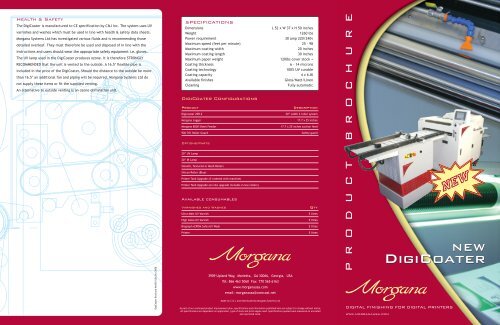

NEW<br />

NEW<br />

<strong>DigiCoater</strong>

Morgana Systems Ltd is pleased to announce the<br />

release of the <strong>DigiCoater</strong>, the world’s first fully<br />

automatic micro format UV coater and Primer suitable<br />

for both Digital and Litho printed work. Compatible<br />

print technologies include photo, ink jet, toner based<br />

digital presses, and Litho presses.<br />

Background<br />

A varnish is a liquid coating applied to a printed surface (for example the outside of<br />

a presentation folder) to add a clear glossy, matt, satin, or neutral finish.<br />

Varnishing, also referred to as Coating or Sealing, can be carried out ‘online’. The<br />

varnish is applied directly (within seconds) after the ink is put on the paper, or<br />

‘offline’ by a separate machine, some time after printing.<br />

There are various kinds of varnish that can be applied to printing, but all share some<br />

common characteristics:<br />

<br />

<br />

A varnish increases colour absorption and speeds up the drying process.<br />

By 'locking in' in the ink under a protective coat, the varnish helps to prevent<br />

the ink rubbing off when the paper is subjected to handling.<br />

Varnishes are used most frequently and successfully on coated papers.<br />

Why UV Varnish?<br />

UV Varnishing<br />

Ultra Violet (UV) Varnishing is a process for achieving a striking type of coating on<br />

printed material. Requiring the use of special Ultraviolet drying machinery, a UV<br />

coating is like a deluxe version of the non-UV varnishes, with the varnish appearing<br />

noticeably richer and more luxurious.<br />

A UV varnish can be applied as either an all-over coating, or as a spot varnish:<br />

Please note that the <strong>DigiCoater</strong> is not able to “Spot Varnish”<br />

UV Varnishing a document protects it against scratching and enhances the image<br />

Creates a great first impression of the document and the printer<br />

Instantly raises the interest level of the recipient<br />

Adds to the drama and punch of the message<br />

Increases the perceived value of the product<br />

Makes the printing more likely to be read and kept<br />

<br />

<br />

<br />

<br />

<br />

<br />

Compact footprint<br />

Fully automatic operation<br />

Dual path coating stations<br />

Can be used to prime printing stock<br />

Variable coating thickness<br />

Multiple supply tanks with auto wash<br />

Sheet weight 120lbs cover stock +<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Filtered recirculation system<br />

Variable speed to 98 feet pm<br />

Adjustable scraper blade<br />

Enclosed system for dust free prints<br />

Adjustable jogger<br />

20 inch widths (17.7 inch from feeder)<br />

Fully adjustable air feeder<br />

The World’s First Fully<br />

Automated Micro Format UV<br />

Coater and Primer Coating<br />

System<br />

The <strong>DigiCoater</strong> is the World’s First Fully Automated Micro Format UV Coater and<br />

Primer Coating System that also has the ability to apply both an aqueous primer<br />

(for uncoated media to be printed) and a post print UV protective coating from the<br />

same device. All this in the footprint of less than half that of traditional devices.<br />

The <strong>DigiCoater</strong> is compatible with most print technologies including liquid ink and<br />

toner based digital engines, photo, ink jet, conventional litho digital and more…<br />

Multifunctional<br />

The <strong>DigiCoater</strong> does the job of three machines in one. Coating, priming and curing.<br />

Its patented Primer Coating & IR Curing Station, solves printing media consistency<br />

issues. Now you can primer-coat unique uncoated media to give superior and<br />

consistent printing results, cut down on set up times and limit colour correcting to<br />

a minimum. Once printed, you can apply a UV protective coating in either hi-gloss<br />

or matt.<br />

The design of the <strong>DigiCoater</strong> allows both matt and gloss to be available for<br />

immediate use at all times. Alternatively, 2 different textures can be available at<br />

all times i.e. smooth and linen. This unique feature greatly improves productivity<br />

and reduces waste.<br />

The universal feeder can be used to feed other finishing devices such as laminators<br />

or ink jet printers.<br />

Please note that when the priming station is fitted only one coating station is<br />

available.<br />

Latest Technology<br />

The <strong>DigiCoater</strong> uses an innovative touch screen interface to monitor and control<br />

every action from roller position to<br />

coating selection and flow.<br />

Easy To Use<br />

Simple one-finger operation. Never<br />

before has operation of a UV Coater<br />

been so easy. The intelligent touch<br />

screen interface allows you to<br />

control every aspect of production<br />

from start to finish. Variable data<br />

fields allow you to precisely control<br />

throughput speed. Select from<br />

primer, coating station and which<br />

coating tanks to use. Clean ups are fully automatic with cleaning and drain times<br />

specified through the touch screen control panel.<br />

Types of Varnish<br />

Gloss Varnish<br />

A gloss varnish is often used to enhance the appearance of documents, brochures or<br />

flyers, as the coating reflects back the light and makes colours appear richer and<br />

more vivid. A gloss coating can add impact to the print, especially in sales or<br />

promotional material, where optimum presentation of images is important.<br />

Matt Varnish<br />

A matt varnish gives the printed surface a non-glossy, smooth look. This type of seal<br />

is sometimes used to ‘soften’ the appearance of a printed image. Small text in a<br />

leaflet or booklet can be easier to read on a surface coated with matt vanish as the<br />

coating scatters the light and reduces glare.<br />

Textured UV Varnish<br />

A textured UV varnish allows the designer to create a special effect on the printed<br />

surface. This technique can also be used to reinforce the tactile properties of the<br />

product that is being depicted i.e., the effect of linen finish paper.<br />

Coverage<br />

Coverage is dependent on the thickness of the coating and the absorption of the<br />

stock being used. Test results show coverage between 250 and 800 17 x 11” sheets<br />

per litre of coating solution.<br />

Why use substrate primers<br />

Primers are coatings applied to substrates to achieve maximum printing<br />

performance. High quality digital printing requires substrates to have high levels of<br />

chemical and physical consistency. Most synthetic substrates can be upgraded to<br />

such levels with the application of substrate primers.<br />

Primers can be applied to suitable substrates at the client site to reduce costs and<br />

increase substrate diversity. A variety of Flexo and Gravure coating machines can<br />

be used for this purpose.<br />

Substrate primers improve ElectroInk transfer, fixing and adhesion. They also<br />

maximize the life span of press consumables, like the PIP foil and machine blanket.