Ring Indexing Table Type XL - ZZ-Antriebe GmbH

Ring Indexing Table Type XL - ZZ-Antriebe GmbH

Ring Indexing Table Type XL - ZZ-Antriebe GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

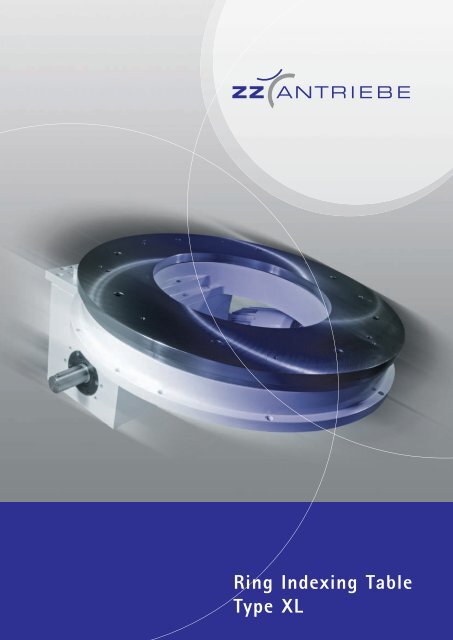

<strong>Ring</strong> <strong>Indexing</strong> <strong>Table</strong><br />

<strong>Type</strong> <strong>XL</strong>

<strong>Ring</strong> <strong>Indexing</strong> <strong>Table</strong> <strong>Type</strong> <strong>XL</strong><br />

Rotary <strong>Indexing</strong> <strong>Table</strong> <strong>Type</strong> XZ<br />

<strong>Ring</strong> <strong>Indexing</strong> <strong>Table</strong><br />

<strong>Type</strong> <strong>XL</strong><br />

<strong>Ring</strong> <strong>Indexing</strong> <strong>Table</strong> <strong>Type</strong> <strong>XL</strong><br />

<strong>ZZ</strong> ring indexing tables are used in handling and assembly systems. The drive unit based on a cylindrical<br />

cam, fitted to the outer ring, results in a relatively large internal diameter of the ring and a<br />

high accuracy in the positioning capability. This produces a high dynamic and a smooth acceleration<br />

response. The form of the construction allows a very flat table.<br />

Advantages of the <strong>ZZ</strong> <strong>Ring</strong> <strong>Indexing</strong> <strong>Table</strong><br />

• Suitable for extremely large static and<br />

dynamic power<br />

• Flat construction and at the same time,<br />

a large diameter<br />

• Smooth running, even at fast switching<br />

actuations<br />

• Interlocking in the latching phase<br />

• High accuracy of repeatability<br />

• Vibration-free<br />

• Minimum maintenance<br />

• Minimum power requirements<br />

• Low requirements of a regulation and<br />

control system<br />

Basic Construction<br />

The <strong>ZZ</strong> ring indexing tables have been designed<br />

to provide customers with a large free area inside<br />

the ring to accommodate their handling<br />

or robotic units. Thus, special machines can be<br />

constructed in a compact manner.<br />

As an alternative to the ring indexing tables<br />

type <strong>XL</strong> shown in this catalogue, the <strong>ZZ</strong> rotary<br />

indexing tables type XZ with a cylindrical cam,<br />

present an excellent approach to solving any<br />

problems. These are based on a component subassembly<br />

consisting of a cylindrical cam and<br />

a star wheel tipped with rollers, pressed into<br />

the axial positioned cam rollers. Thus, the hollow<br />

drive shaft, where the star wheel is fitted,<br />

can be of a larger diameter. This in turn, allows<br />

higher clock rates.<br />

A separate catalogue is available for the rotary<br />

indexing tables type XZ .<br />

For further information please visit our homepage:<br />

www.zz-antriebe.com<br />

A <strong>ZZ</strong> ring indexing table consists of three finished cast sections. The top ring section - the driven ring<br />

table – is fitted to the lower ring section by way of a ring roller bearing sub-assembly and sealed with<br />

a circular sealing lip. This method of bearing assembly allows a very large loading by axial forces and at<br />

the same time, retaining a small run-out tolerance.<br />

The bearing of the circular drive shaft is in the form of a special four-point bearing. This bearing,<br />

integrated into the large diameter of the ring table, allows an acceptance of high axial forces and large<br />

tilting moments, that is directly absorbed in the housing. In this way, excellent combined responses are<br />

achieved for accuracy, stability, loading capability and smooth running.<br />

The bearing unit and the rotating drive shaft are sealed with a shaft sealing ring at the centre bore<br />

through to the outer diameter.<br />

In the lower housing, there is a hardened and ground cam roller on a thrust bearing shaft with tapered<br />

roller bearings. The applied rotation movement is converted to a smooth stepping movement, without<br />

acceleration transients, due to the optimised path of the cams.<br />

The schematic construction shows the positive,<br />

form-fit engagement of at least 2 cam rollers with<br />

the driven cylindrical cam. Depending on the type<br />

of cam, wider cams allow a partial engagement<br />

with more the 2 cam rollers. In combination with<br />

an optimised cam path, a good distribution of<br />

loading is achieved which results in a better quality<br />

of transmission in the phases of engagement and<br />

disengagement of the cams. The overall accuracy<br />

of the cam system is dependent on the precision of<br />

the rollers and the close-tolerance strength of the<br />

cam web.<br />

1

Maximum Static Loading<br />

Accuracy<br />

<strong>Indexing</strong> Steps<br />

The cam rollers are fitted in the driven table with the largest possible radius to ensure a maximum<br />

transfer of torque. This arrangement allows a very high output torque and at the same time, a high<br />

degree of indexing accuracy and a small moment of inertia.<br />

Maximum Static Loading<br />

<strong>XL</strong>510 <strong>XL</strong>800 <strong>XL</strong>801 <strong>XL</strong>1200 <strong>XL</strong>1600 <strong>XL</strong>2100<br />

Axial load (daN) 75.00 13.000 13.000 21.000 28.000 56.000<br />

Radial load (daN) 75.00 13.000 13.000 21.000 28.000 56.000<br />

Swing torque (daNm) 720 1.760 1.760 3.500 4.820 11.650<br />

Accuracy<br />

Accuracy<br />

Axial runout<br />

R (mm) EE (mm) A (mm) (mm)<br />

<strong>XL</strong>510 182,5 ±0,015 510 0,03<br />

<strong>XL</strong>800 310,0 ±0,020 800 0,04<br />

<strong>XL</strong>801 310,0 ±0,020 800 0,04<br />

<strong>XL</strong>1200 500,0 ±0,030 1200 0,05<br />

<strong>XL</strong>1600 700,0 ±0,040 1600 0,07<br />

<strong>XL</strong>2100 950,0 ±0,050 2100 0,09<br />

R<br />

Ø A<br />

r<br />

r<br />

E = – · EE<br />

R<br />

Permissible <strong>Indexing</strong> Steps depending on the Number of Stations and the Gear Size<br />

<strong>Indexing</strong><br />

<strong>Indexing</strong> Static<br />

<strong>Type</strong><br />

Steps<br />

Angle Torque<br />

Output Torque (Nm)<br />

Static Coefficients<br />

[°] [Nm] 25min -1 50min -1 75min -1 100min -1 150min -1 C v C a K<br />

2 <strong>XL</strong>510 345 6307 2598 2582 2556 2520 2417 1.760 5.528 0,515<br />

<strong>XL</strong>800 18105 6450 6325 6117 5826 4995 1.500 5.755 0,619<br />

4 <strong>XL</strong>510 180 6307 2688 2659 2612 2545 2355 1.760 5.528 0,494<br />

<strong>XL</strong>800 210 10713 3870 3710 3444 3071 2006 1.760 5.528 0,423<br />

<strong>XL</strong>510 270 6307 3653 3640 3619 3590 3505 1.760 5.528 0,329<br />

<strong>XL</strong>800 10713 4819 4722 4561 4336 3691 1.760 5.528 0,329<br />

<strong>XL</strong>510 300 6307 3908 3898 3881 3857 3788 1.760 5.528 0,296<br />

<strong>XL</strong>800 10713 5242 5164 5034 4851 4329 1.760 5.528 0,296<br />

<strong>XL</strong>510 330 6307 4134 4126 4111 4092 4035 1.760 5.528 0,269<br />

<strong>XL</strong>800 10713 5634 5569 5462 5311 4879 1.760 5.528 0,269<br />

6 <strong>XL</strong>510 120 6307 2683 2639 2566 2465 2174 1.760 5.528 0,494<br />

<strong>XL</strong>510 180 6307 3651 3632 3599 3554 3425 1.760 5.528 0,329<br />

<strong>XL</strong>800 18105 8225 8077 7831 7487 6502 1.760 5.528 0,329<br />

<strong>XL</strong>1200 29785 8677 8053 7012 5555 1393 1.760 5.528 0,329<br />

<strong>XL</strong>510 270 6307 4591 4582 4568 4547 4490 1.760 5.528 0,219<br />

<strong>XL</strong>800 18105 11036 10970 10861 10708 10270 1.760 5.528 0,219<br />

<strong>XL</strong>1200 29785 12587 12310 11847 11200 9350 1.760 5.528 0,219<br />

<strong>XL</strong>510 300 6307 4805 4798 4786 4770 4724 1.760 5.528 0,197<br />

<strong>XL</strong>800 18105 11762 11709 11620 11496 11142 1.760 5.528 0,197<br />

<strong>XL</strong>1200 29785 13729 13504 13130 12605 11107 1.760 5.528 0,197<br />

<strong>XL</strong>510 330 6307 4984 4978 4969 4955 4917 1.760 5.528 0,179<br />

<strong>XL</strong>800 18105 12399 12355 12282 12179 11887 1.760 5.528 0,179<br />

<strong>XL</strong>1200 29785 14795 14609 14300 13866 12628 1.760 5.528 0,179<br />

8 <strong>XL</strong>510 120 6307 3361 3329 3276 3201 2987 1.760 5.528 0,37<br />

<strong>XL</strong>510 180 6307 4332 4317 4294 4260 4165 1.760 5.528 0,247<br />

<strong>XL</strong>800 18105 10201 10089 9902 9640 8892 1.760 5.528 0,247<br />

<strong>XL</strong>1200 29785 11329 10862 10085 8997 5889 1.760 5.528 0,247<br />

<strong>XL</strong>1600 40882 20279 19163 17303 14698 7257 1.760 5.528 0,247<br />

<strong>XL</strong>510 270 6307 5134 5128 5117 5102 5060 1.760 5.528 0,165<br />

<strong>XL</strong>800 18105 12954 12904 12821 12704 12372 1.760 5.528 0,165<br />

<strong>XL</strong>1200 29785 15770 15563 15218 14734 13353 1.760 5.528 0,165<br />

<strong>XL</strong>1600 40882 26805 26309 25482 24325 21017 1.760 5.528 0,165<br />

<strong>XL</strong>510 300 6307 5298 5293 5285 5273 5239 1.760 5.528 0,148<br />

<strong>XL</strong>800 18105 13595 13554 13487 13393 13123 1.760 5.528 0,148<br />

<strong>XL</strong>1200 29785 16988 16821 16541 16149 15030 1.760 5.528 0,148<br />

<strong>XL</strong>1600 40882 28405 28004 27334 26396 23717 1.760 5.528 0,148<br />

<strong>XL</strong>510 330 6307 5430 5426 5419 5409 5381 1.760 5.528 0,135<br />

<strong>XL</strong>800 18105 14134 14100 14045 13967 13744 1.760 5.528 0,135<br />

<strong>XL</strong>1200 29785 18089 17950 17719 17395 16470 1.760 5.528 0,135<br />

<strong>XL</strong>1600 40882 29782 29450 28897 28122 25908 1.760 5.528 0,135<br />

12 <strong>XL</strong>510 120 6307 4329 4307 4271 4220 4075 1.760 5.528 0,247<br />

<strong>XL</strong>800 18105 10183 10017 9741 9353 8246 1.760 5.528 0,247<br />

<strong>XL</strong>510 180 6307 5133 5123 5107 5084 5020 1.760 5.528 0,165<br />

<strong>XL</strong>800 18105 12946 12872 12749 12577 12084 1.760 5.528 0,165<br />

<strong>XL</strong>1200 29785 15737 15429 14915 14196 12142 1.760 5.528 0,165<br />

<strong>XL</strong>1600 40882 26719 25965 24707 22947 17918 1.760 5.528 0,165<br />

<strong>XL</strong>2100 55482 29692 28188 25682 22172 12146 1.760 5.528 0,165<br />

<strong>XL</strong>510 270 6307 5663 5659 5652 5642 5613 1.760 5.528 0,11<br />

<strong>XL</strong>800 18105 15142 15109 15055 14978 14759 1.760 5.528 0,11<br />

<strong>XL</strong>1200 29785 20370 20233 20005 19685 18772 1.760 5.528 0,11<br />

<strong>XL</strong>1600 40882 32413 32077 31519 30736 28501 1.760 5.528 0,11<br />

<strong>XL</strong>2100 55482 38458 37790 36676 35116 30660 1.760 5.528 0,11<br />

<strong>XL</strong>510 300 6307 5759 5755 5749 5741 5718 1.760 5.528 0,099<br />

<strong>XL</strong>800 18105 15582 15555 15511 15449 15272 1.760 5.528 0,099<br />

<strong>XL</strong>1200 29785 21485 21374 21189 20931 20191 1.760 5.528 0,099<br />

<strong>XL</strong>1600 40882 33616 33345 32892 32258 30448 1.760 5.528 0,099<br />

<strong>XL</strong>2100 55482 40532 39990 39088 37825 34215 1.760 5.528 0,099<br />

2<br />

3

<strong>Indexing</strong> Steps<br />

Technical Drawings<br />

<strong>XL</strong> 510 · <strong>XL</strong> 800<br />

<strong>Indexing</strong><br />

Steps<br />

<strong>Type</strong><br />

<strong>Indexing</strong> Static<br />

Output Torque (Nm)<br />

Static Coefficients<br />

Angle Torque<br />

[°] [Nm] 25min -1 50min -1 75min -1 100min -1 150min -1 C v C a K<br />

<strong>XL</strong>510 330 6307 5833 5830 5825 5818 5799 1.760 5.528 0,09<br />

<strong>XL</strong>800 18105 15932 15910 15874 15823 15676 1.760 5.528 0,09<br />

<strong>XL</strong>1200 29785 22436 22344 22192 21978 21367 1.760 5.528 0,09<br />

<strong>XL</strong>1600 40882 34594 34370 33996 33472 31976 1.760 5.528 0,09<br />

<strong>XL</strong>2100 55482 42289 41842 41096 40052 37069 1.760 5.528 0,09<br />

16 <strong>XL</strong> 510 120 6307 4925 4908 4880 4841 4730 1.760 5.528 0,185<br />

<strong>XL</strong> 800 18105 12169 12043 11833 11538 10696 1.760 5.528 0,185<br />

<strong>XL</strong>1200 150 29785 16932 16597 16037 15254 13016 1.760 5.528 0,148<br />

<strong>XL</strong>1600 40882 28264 27438 26062 24135 18629 1.760 5.528 0,148<br />

<strong>XL</strong>2100 55482 31893 30248 27507 23670 12705 1.760 5.528 0,148<br />

<strong>XL</strong>510 180 6307 5536 5529 5517 5499 5450 1.760 5.528 0,123<br />

<strong>XL</strong>800 18105 14580 14524 14430 14299 13925 1.760 5.528 0,123<br />

<strong>XL</strong>1200 29785 19042 18808 18420 17876 16322 1.760 5.528 0,123<br />

<strong>XL</strong>1600 40882 30870 30297 29341 28003 24179 1.760 5.528 0,123<br />

<strong>XL</strong>2100 55482 35910 34768 32864 30199 22585 1.760 5.528 0,123<br />

<strong>XL</strong>510 270 6307 5890 5887 5882 5874 5852 1.760 5.528 0,082<br />

<strong>XL</strong>800 18105 16213 16188 16147 16088 15922 1.760 5.528 0,082<br />

<strong>XL</strong>1200 29785 23239 23136 22963 22721 22030 1.760 5.528 0,082<br />

<strong>XL</strong>1600 40882 35374 35119 34694 34099 32400 1.760 5.528 0,082<br />

<strong>XL</strong>2100 55482 43739 43231 42385 41201 37817 1.760 5.528 0,082<br />

<strong>XL</strong>510 300 6307 5950 5947 5943 5937 5919 1.760 5.528 0,074<br />

<strong>XL</strong>800 18105 16512 16491 16458 16411 16276 1.760 5.528 0,074<br />

<strong>XL</strong>1200 29785 24146 24062 23922 23726 23167 1.760 5.528 0,074<br />

<strong>XL</strong>1600 40882 36236 36029 35685 35203 33827 1.760 5.528 0,074<br />

<strong>XL</strong>2100 55482 45404 44992 44307 43348 40607 1.760 5.528 0,074<br />

<strong>XL</strong>510 330 6307 5996 5993 5990 5984 5970 1.760 5.528 0,067<br />

<strong>XL</strong>800 18105 16743 16727 16699 16660 16548 1.760 5.528 0,067<br />

<strong>XL</strong>1200 29785 24888 24818 24703 24541 24079 1.760 5.528 0,067<br />

<strong>XL</strong>1600 40882 36913 36743 36458 36060 34923 1.760 5.528 0,067<br />

<strong>XL</strong>2100 55482 46759 46420 45853 45060 42795 1.760 5.528 0,067<br />

24 <strong>XL</strong>510 120 3090 2670 2659 2641 2616 2543 1.760 5.528 0,123<br />

<strong>XL</strong>800 10713 8565 8482 8343 8148 7592 1.760 5.528 0,123<br />

<strong>XL</strong>1200 150 29785 21446 21219 20839 20308 18789 1.760 5.528 0,099<br />

<strong>XL</strong>1600 40882 33526 32983 32077 30810 27189 1.760 5.528 0,099<br />

<strong>XL</strong>2100 55482 40351 39268 37464 34937 27718 1.760 5.528 0,099<br />

<strong>XL</strong>510 180 3090 2844 2840 2832 2820 2788 1.760 5.528 0,082<br />

<strong>XL</strong>800 10713 9541 9504 9442 9356 9109 1.760 5.528 0,082<br />

<strong>XL</strong>1200 29785 23221 23063 22799 22430 21376 1.760 5.528 0,082<br />

<strong>XL</strong>1600 40882 35333 34956 34327 33447 30932 1.760 5.528 0,082<br />

<strong>XL</strong>2100 55482 43657 42905 41652 39898 34884 1.760 5.528 0,082<br />

<strong>XL</strong>510 270 3090 2933 2931 2928 2923 2908 1.760 5.528 0,055<br />

<strong>XL</strong>800 10713 10091 10074 10047 10008 9898 1.760 5.528 0,055<br />

<strong>XL</strong>1200 29785 26221 26150 26033 25869 25400 1.760 5.528 0,055<br />

<strong>XL</strong>1600 40882 38060 37893 37613 37222 36104 1.760 5.528 0,055<br />

<strong>XL</strong>2100 55482 49159 48825 48268 47488 45260 1.760 5.528 0,055<br />

<strong>XL</strong>510 300 3090 2947 2946 2943 2939 2927 1.760 5.528 0,049<br />

<strong>XL</strong>800 10713 10182 10169 10147 10116 10027 1.760 5.528 0,049<br />

<strong>XL</strong>1200 29785 26783 26726 26631 26499 26119 1.760 5.528 0,049<br />

<strong>XL</strong>1600 40882 38529 38393 38167 37850 36945 1.760 5.528 0,049<br />

<strong>XL</strong>2100 55482 50179 49909 49457 48826 47021 1.760 5.528 0,049<br />

<strong>XL</strong>510 330 3090 2958 2957 2954 2951 2941 1.760 5.528 0,045<br />

<strong>XL</strong>800 10713 10252 10241 10223 10197 10123 1.760 5.528 0,045<br />

<strong>XL</strong>1200 29785 27223 27176 27098 26988 26674 1.760 5.528 0,045<br />

<strong>XL</strong>1600 40882 38887 38775 38588 38326 37578 1.760 5.528 0,045<br />

<strong>XL</strong>2100 55482 50975 50751 50378 49856 48365 1.760 5.528 0,045<br />

<strong>XL</strong> 510<br />

<strong>XL</strong> 800<br />

Ø300 for M8x25<br />

(on request)<br />

Ø500 for M8x25<br />

(on request)<br />

4<br />

Technical drawings and 3D-models are available for download on our homepage www.zz-antriebe.com.<br />

5

Technical Drawings<br />

<strong>XL</strong> 801 · <strong>XL</strong> 1200<br />

Technical Drawings<br />

<strong>XL</strong> 1600 · <strong>XL</strong> 2100<br />

<strong>XL</strong> 801<br />

<strong>XL</strong> 1600<br />

Ø500 for M8x25<br />

(on request)<br />

Ø1200 for mounting<br />

holes (on request)<br />

<strong>XL</strong> 1200<br />

<strong>XL</strong> 2100<br />

Ø800 for mounting<br />

holes (on request)<br />

Ø1700 for mounting<br />

holes (on request)<br />

Technical drawings and 3D-models are available for download on our homepage www.zz-antriebe.com.<br />

6<br />

Technical drawings and 3D-models are available for download on our homepage www.zz-antriebe.com.<br />

7

Mounting Positions<br />

for the Geared Motor<br />

Other Cam Gear Variations of<br />

<strong>ZZ</strong> - <strong>Antriebe</strong><br />

Mounting positions for the Geared Motor<br />

Globoid Cam Gears<br />

View of the Component Set<br />

Standard Globoid Cam Gear, <strong>Type</strong> X<br />

A<br />

B<br />

Globoid Cam Gear, <strong>Table</strong> Version, <strong>Type</strong> TX<br />

Globoid Cam Gear, Rotary <strong>Indexing</strong> <strong>Table</strong>, <strong>Type</strong> RTX<br />

C<br />

D<br />

Disk Cam Gear<br />

View of the Component Set<br />

Disk Cam Gear, <strong>Type</strong> Y<br />

E<br />

F<br />

G<br />

H<br />

8<br />

Conditions of Sale and Delivery<br />

Our “General Conditions for the Supply of Gear Units and Drive Elements“ shall apply. All dimensions and illustrations are without obligation. We reserve the right to effect<br />

changes or modifications to the construction, sizes, weights, technical specifications, etc., without prior notice. Valid 04/2007

Our<br />

Production Program<br />

<strong>ZZ</strong> Bevel Gear Units<br />

up to 7000 Nm nominal torque<br />

or 500 kW power. <strong>ZZ</strong> Servoline® series<br />

for high-dynamic drives<br />

<strong>ZZ</strong> Spiral Bevel Gears<br />

with - palloid gear tooth system<br />

- Cyclo-palloid gear tooth system<br />

- HPG-S gear tooth system<br />

<strong>ZZ</strong> Screw Jack Units<br />

with trapezoidal or<br />

ball screw spindle<br />

for loading up to 1000 kN<br />

<strong>ZZ</strong> Cams<br />

as - Globoid cams<br />

- Axial cams<br />

- Radial cams<br />

<strong>ZZ</strong> <strong>Indexing</strong> Units<br />

as globoid, cylinder- or<br />

radial cam gear units<br />

with pendular or stepping function<br />

<strong>ZZ</strong> Special Gear Units<br />

for versatile use in many<br />

different types of application<br />

<strong>ZZ</strong>-<strong>Antriebe</strong> <strong>GmbH</strong><br />

An der Tagweide 12<br />

76139 Karlsruhe<br />

Telefon +(49) 7 21.62 05-0<br />

Telefax +(49) 7 21.62 05-10<br />

info@zz-antriebe.de<br />

www.zz-antriebe.de