LIM-2 Logic Inspection Module

LIM-2 Logic Inspection Module

LIM-2 Logic Inspection Module

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

A Flow Control Application<br />

Using the <strong>LIM</strong>-2 <strong>Logic</strong> <strong>Inspection</strong> <strong>Module</strong><br />

The Application<br />

Parts are processed through a heat<br />

tunnel on a continuous motion<br />

conveyor. Opposed mode photoelectric<br />

sensors are placed at the<br />

entrance and exit of the heat tunnel to<br />

monitor part flow. An <strong>LIM</strong>-2 and an<br />

LSR-64 shift register module process<br />

the information from the sensors<br />

and activate an alarm if a part does<br />

not emerge from the tunnel when it<br />

should. The length of the parts and<br />

the spacing between adjacent parts<br />

may be random.<br />

Application Concept<br />

The System<br />

A narrow beam is established near<br />

both the entrance and the exit of the<br />

heat tunnel using SM30 Series sensors<br />

with rectangular aperture assemblies<br />

on the emitter and the receiver. The<br />

Bi-Modal receiver outputs are wired<br />

for dark operate and sinking (NPN)<br />

operation.<br />

When the beam of the entrance sensors<br />

is blocked, data is input to the LSR-64<br />

shift register. The length of the part<br />

corresponds to the number of clock<br />

pulses entered during the time that<br />

the entrance beam is blocked. Clock<br />

pulses are generated using an ECONO-<br />

BEAM SE61E/SE61R combination as<br />

a slot sensor to count pulses produced<br />

by a timing sprocket attached to one<br />

of the conveyor drive shafts.<br />

The LSR-64 is programmed to output<br />

when the part is clocked to the exit of<br />

the tunnel. This information becomes<br />

the gate input for the <strong>LIM</strong>-2. The exit<br />

sensors supply a DATA signal to the<br />

<strong>LIM</strong>-2 when the beam is blocked by<br />

an exiting part. The exit sensors must<br />

“see” the leading edge of an exiting part<br />

at any time during the gate period in<br />

order to prevent an alarm.<br />

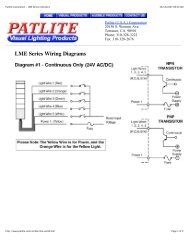

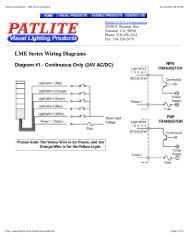

Hookup Diagram<br />

Timing Diagram (assumes shift length of 5)<br />

4