Design studies of a square ring shaped force sensor - Integrated ...

Design studies of a square ring shaped force sensor - Integrated ...

Design studies of a square ring shaped force sensor - Integrated ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

INTERNATIONAL JOURNAL OF APPLIED ENGINEERING RESEARCH, DINDIGUL<br />

Volume 1, No 4, 2011<br />

© Copyright 2010 All rights reserved <strong>Integrated</strong> Publishing Association<br />

RESEARCH ARTICLE ISSN 09764259<br />

3. Finite Element Model and Analysis<br />

Similar finite element analysis has been done for <strong>ring</strong> <strong>shaped</strong> <strong>force</strong> <strong>sensor</strong> earlier by various<br />

researchers. The s<strong>of</strong>tware ABAQUS standard student edition 6.7.2 has been used for<br />

modeling and analysis <strong>of</strong> the <strong>force</strong> <strong>sensor</strong>s developed. A three dimensional quarter <strong>of</strong> the<br />

idealized <strong>square</strong> <strong>ring</strong> has been designed and suitable boundary conditions have been defined<br />

for finite element analysis. A three dimensional solid continuum 8 node element with reduced<br />

integration is considered and the analysis is <strong>of</strong> linear type. The material is <strong>of</strong> isotropic nature.<br />

The axial <strong>force</strong> is applied in compression mode as an indication <strong>of</strong> methodology using<br />

ABAQUS 6.7.2 s<strong>of</strong>tware for studying stress – strain and axial deflection pattern. Suitable<br />

procedure for finite element analysis <strong>of</strong> the quarter <strong>of</strong> the <strong>ring</strong> has been adopted and the stress,<br />

strain and axial deflection patterns have been plotted. The findings <strong>of</strong> the finite element<br />

analysis may be summarized in form <strong>of</strong> stress, strain and axial deflection patterns (Fig 24).<br />

4. Results & Discussions<br />

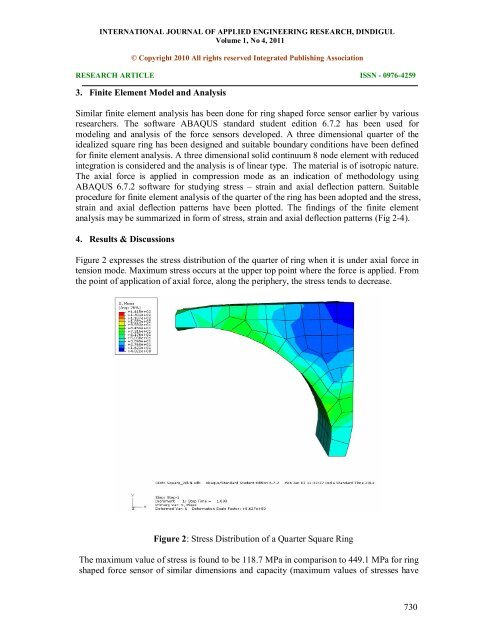

Figure 2 expresses the stress distribution <strong>of</strong> the quarter <strong>of</strong> <strong>ring</strong> when it is under axial <strong>force</strong> in<br />

tension mode. Maximum stress occurs at the upper top point where the <strong>force</strong> is applied. From<br />

the point <strong>of</strong> application <strong>of</strong> axial <strong>force</strong>, along the periphery, the stress tends to decrease.<br />

Figure 2: Stress Distribution <strong>of</strong> a Quarter Square Ring<br />

The maximum value <strong>of</strong> stress is found to be 118.7 MPa in comparison to 449.1 MPa for <strong>ring</strong><br />

<strong>shaped</strong> <strong>force</strong> <strong>sensor</strong> <strong>of</strong> similar dimensions and capacity (maximum values <strong>of</strong> stresses have<br />

730