Brochure - juki automation systems

Brochure - juki automation systems

Brochure - juki automation systems

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

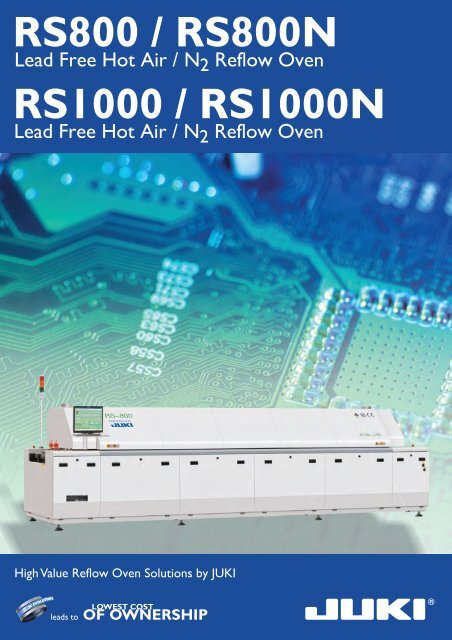

RS800 / RS800N<br />

Lead Free Hot Air / N 2 Reflow Oven<br />

RS1000 / RS1000N<br />

Lead Free Hot Air / N 2 Reflow Oven<br />

High Value Reflow Oven Solutions by JUKI

A Partnership You Can Count On<br />

Sales and Service by JUKI - three years warranty!<br />

Ramp-up zones<br />

Soaking zones<br />

Reflow zones<br />

Cooling zones<br />

Independent air velocity controlling system<br />

allows flexible processing control to easily<br />

handle complicated lead free soldering<br />

requirements.<br />

The RS800 has 2 ramp-up zones, 4 soaking<br />

zones, 2 reflow zones, and 2 cooling zones.<br />

The RS1000 has 3 ramp-up zones, 4 soaking<br />

zones, 3 reflow zones, and 2 cooling zones.<br />

(kW/h)<br />

RS800<br />

Efficient power design and heat management system greatly<br />

improves energy savings while lowering carbon emissions.<br />

(minutes)<br />

• Power savings of 15 to 20 %, due to large aluminum alloy<br />

heat plates (7 mm thick)<br />

• Double insulation around the body prevents heat loss<br />

• Short warm-up time<br />

• Low power consumption:<br />

8.5 to 10.5 kW (8 zones), 10.5 to 12.5 kW (10 zones)<br />

• New and improved highly effective exhaust design with<br />

piping in each zone to extract flux

The cooling configuration recycles the filtered air or N2 back to the<br />

oven chamber reducing thermal loss while getting better flux reclamation.<br />

• Two powerful fans force recirculated cooled air into the cooling zone<br />

• Total cooling length: 800 mm (31.5”)<br />

• Filtration system is easily accessible for quick maintenance<br />

• Easy access to cooling panels for quick maintenance<br />

Every machine comes complete with the most standard features in the industry including:<br />

• Intuitive GUI Interface<br />

• Easy conveyor width adjustment<br />

• Flux management system (N 2 ovens)<br />

• Water chiller system (N 2 ovens)<br />

• L > R or R > L conveyor system free of charge<br />

• Double pin chain with wire mesh (option: chain with center board support)<br />

• Dual exhaust fan motors<br />

• Automatic chain lubrication system<br />

• PCB counter<br />

• PCB/pallet drop alarm<br />

• UPS system<br />

• Light tower<br />

• SMEMA interface<br />

• High end PC with XP OS or higher

Model RS800 / RS800N RS1000 / RS1000N<br />

General<br />

Dimensions (LxWxH) 5,314 x 1,417 x 1,524 mm 6,104 x 1,417 x 1,524 mm<br />

Weight approx. 2,250 kg approx. 2,450 kg<br />

Number of heating zones top 8 / bottom 8 top 10 / bottom 10<br />

Length of heating zones 3,121 mm 3,891 mm<br />

Number of cooling zones<br />

Length of cooling zones<br />

Exhaust volume<br />

top 2<br />

800 mm<br />

10 m 3 / min. x 2 exhausts<br />

Control system<br />

Electric supply*<br />

3 phase, 380 V, 50/60 Hz<br />

Total power 64 kW / 67 kW 80 kW / 83 kW<br />

Starting power approx. 35 kW / 37 kW approx. 40 kW / 42 kW<br />

Normal power consumption approx. 8.5 kW / 10.5 kW approx. 10.5 kW / 12.5 kW<br />

Warming time approx. 25 minutes approx. 35 minutes<br />

Temperature setting range<br />

Temperature control method<br />

Temperature control precision<br />

Temperature deviation on PCB<br />

Nozzle plate<br />

Board dropped alarm<br />

room temperature to 300 °C<br />

PID close loop control + SSR<br />

± 1.0 °C<br />

± 1.5°C (by Juki/JT board test standard)<br />

aluminium alloy plate - 7 mm thick<br />

tower light: yellow - warming; green - normal; red - abnormal<br />

Conveyor system<br />

Range of PCB width<br />

Rails width adjustment<br />

Components clearance<br />

Conveyor direction<br />

Fixed rails side<br />

PCB transmission mode<br />

Conveyor height<br />

Conveyor speed range<br />

Chain lubrication<br />

50 to 450 mm (option: 50 to 610 mm)<br />

motorised<br />

top / bottom clearance of PCB is 25 mm<br />

L→R (option: R→L)<br />

front rail fixed (option: rear rail fixed)<br />

chain with wire mesh (option: chain with center board support)<br />

950 ± 20 mm<br />

300 to 2,000 mm/min<br />

auto lubricating<br />

Cooling system<br />

Cooling method<br />

air oven: forced air; nitrogen oven: water chiller (included)<br />

Options<br />

Nitrogen ready<br />

Oxygen analyser<br />

includes: nitrogen hermetic configuration, N2 flow meter, flux reclaim system, water chiller<br />

to add an oxygen analyser (pipe in)<br />

Nitrogen consumption RS800N - 1000ppm 22 m 3 /h RS1000N - 1000ppm 24 m 3 /h<br />

Center board support<br />

Dual conveyors<br />

there will be no mesh if chosen "chain with center board support"<br />

standard: front and rear rails fixed, 2 central rails are adjustable<br />

Standard for N2 ready oven with suffix of "N"<br />

*All specifications are subject to change.<br />

Juki Automation Systems Europe:<br />

JUKI CORPORATION<br />

Electronics Assembly Systems Business Unit<br />

Headquarter<br />

Solothurn, Switzerland<br />

Phone: +41 32 626 29 29<br />

Fax: +41 32 626 29 30<br />

info-europe@jas-smt.com<br />

www.jas-smt.com<br />

Nuremberg, Germany<br />

Phone: +49 911 93 62 66 0<br />

Fax: +49 911 93 62 66 26<br />

Gatwick Airport, England<br />

Phone: +44 1293 80 45 62<br />

Fax: +44 1293 80 45 72<br />

2-11-1, Tsurumaki, Tama-shi, Tokyo 206-8551, JAPAN<br />

Phone: +81 42 357 2293 Fax: +81 42 357 2285<br />

http://www.<strong>juki</strong>.co.jp<br />

Specifications and appearance may be changed without prior notice.<br />

Feb-2012/0000/Rev.00