HKF 200 - Kärcher

HKF 200 - Kärcher

HKF 200 - Kärcher

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

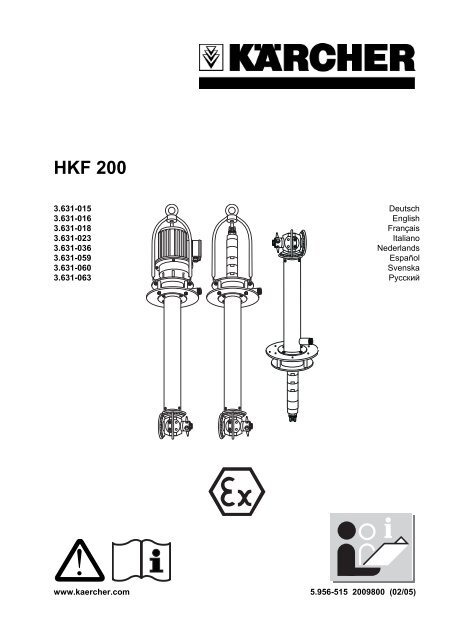

<strong>HKF</strong> <strong>200</strong><br />

3.631-015 Deutsch<br />

3.631-016 English<br />

3.631-018 Français<br />

3.631-023 Italiano<br />

3.631-036 Nederlands<br />

3.631-059 Español<br />

3.631-060 Svenska<br />

3.631-063 Русский<br />

!<br />

www.kaercher.com 5.956-515 <strong>200</strong>9800 (02/05)

Operating Instructions<br />

Please issue to the operator,<br />

ensure they read it before starting the initial operation and<br />

store it in a safe place for future use.<br />

About these operating instructions<br />

Read these instructions through carefully before<br />

the initial startup of the internal cleaner. Pay<br />

particular attention to all safety information.<br />

Store the instructions in a safe place for future<br />

use.<br />

These instructions are intended for<br />

the following target groups<br />

All users<br />

Users are instructed labourers, owner/operators<br />

and skilled persons.<br />

Skilled persons<br />

Skilled persons whose vocational training<br />

enables them to set up and startup equipment<br />

and systems.<br />

Environmental protection<br />

Please dispose of the packaging in an<br />

environmentally friendly way<br />

The packaging material can be recycled. Please<br />

do not throw the packaging in the domestic waste<br />

but place it in recycling containers.<br />

Please dispose of used units in an<br />

environmentally friendly way<br />

Used units contain valuable recyclable materials,<br />

which should be recycled. Batteries, oil and<br />

similar materials must not be allowed to get into<br />

the environment. Please therefore ensure that<br />

you use suitable collection systems to dispose<br />

of old units.<br />

Cleaning liquids<br />

Please do not allow them to get into the environment.<br />

Protect the soil and dispose of waste oil in<br />

an environmentally friendly way.<br />

Wastewater containing mineral oil<br />

Please do not allow it to get into the ground, bodies<br />

of water or the sewers.

<strong>HKF</strong> <strong>200</strong><br />

Contents<br />

English<br />

A. For your safety<br />

1. Safety information and tips<br />

2. Noise control<br />

3. Approved operators<br />

4. Personal protective equipment<br />

5. What to do in emergencies<br />

6. Proper intended use<br />

7. Special conditions in Ex-areas<br />

8. Schematic sketch of the area classification<br />

9. Area classification<br />

B. Function<br />

C. Technical Specifications<br />

1. Dimensional diagram <strong>HKF</strong> <strong>200</strong> E /<br />

<strong>HKF</strong> <strong>200</strong> C<br />

2. Dimensional diagram <strong>HKF</strong> <strong>200</strong> ET<br />

3. Dimensional diagram <strong>HKF</strong> <strong>200</strong> C2<br />

4. Dimensional diagram <strong>HKF</strong> <strong>200</strong> P<br />

5. Dimensional diagram <strong>HKF</strong> <strong>200</strong> PT<br />

6. Dimensional diagram <strong>HKF</strong> <strong>200</strong> PU<br />

7. Installation example <strong>HKF</strong> <strong>200</strong> PU<br />

8. Technical specifications<br />

<strong>HKF</strong> <strong>200</strong> E / ET / P<br />

9. Technical specifications<br />

<strong>HKF</strong> <strong>200</strong> PT / PU / C / C2<br />

10. Cleaning liquids<br />

11. List of materials<br />

12. Nozzle selection<br />

D. Operation<br />

1. Preparing for the initial startup<br />

2. Initial operation switch ON<br />

3. Shut-down procedure switch OFF<br />

E. Maintenance<br />

1. Maintenance instructions<br />

2. Maintenance intervals<br />

F. Troubleshooting<br />

1. Fault information<br />

2. Locating faults<br />

G. Accessories<br />

H. Guarantee<br />

I. Declaration of conformity<br />

5.956-515

A. For Your Safety<br />

English <strong>HKF</strong> <strong>200</strong><br />

1. Safety Information and Tips<br />

The following symbols are used in these operating<br />

instructions:<br />

! Danger!<br />

Denotes a direct, pending hazard. Failure to observe<br />

this information can cause fatal or severe<br />

injuries.<br />

Caution!<br />

Denotes a possibly hazardous situation. Failure<br />

to observe this information can lead to slight injuries<br />

or damage to property.<br />

i Important!<br />

Denotes user tips and important information.<br />

Incorrect operation or misuse can cause dangers<br />

for the operator and other persons due to:<br />

high pressure,<br />

high electric voltages (for electrical drive<br />

units with 230 or 400 V),<br />

Cleaning agents or used cleaning liquid,<br />

hot parts of the system, if hot cleaning liquids<br />

are used,<br />

Explosion danger.<br />

Please ensure you read the following before<br />

operating the system for the first time to avoid<br />

incorrect operations and hazards<br />

All safety information in the attached brochure<br />

"Safety information for high-pressure cleaning<br />

systems" No. 5.951-949,<br />

These operating instructions,<br />

The respective national regulatory legislation,<br />

The safety information enclosed with the cleaning<br />

agents used (usually on the packaging<br />

label).<br />

To avoid hazards due to incorrect operation, the<br />

system must only be operated by persons who<br />

have been instructed in its use,<br />

have proven their operating skills,<br />

have been deployed to use the machine.<br />

The operating instructions must be accessible<br />

to each user.<br />

! Danger!<br />

There is a risk of injuries or possible risk to health<br />

due to:<br />

the drive unit of the internal cleaner (crushing<br />

hazard). Only start up the drive unit of the internal<br />

cleaner in closed containers.<br />

The cleaner gives off a high-pressure spray,<br />

therefore only start up the internal cleaner in<br />

closed containers,<br />

Residual materials in containers, which are<br />

cleaned or from the cleaning liquid used.<br />

Therefore follow the prescribed protective<br />

measures,<br />

Falling internal cleaner at a low submersion<br />

depth. In this case you should additionally<br />

secure the internal cleaner,<br />

Falling containers, therefore additionally secure<br />

the container and internal cleaner,<br />

Hot hoses and hot frame when using hot cleaning<br />

liquids.<br />

When running the machine with hot cleaning<br />

liquids, do not touch the frame and supply<br />

line and wear appropriate protective clothing.<br />

Accidental startup after interrupting the<br />

mains voltage. Switch off the internal cleaner<br />

and high-pressure pump drive units in case<br />

of any faults.<br />

A1<br />

5.956-515

<strong>HKF</strong> <strong>200</strong><br />

A. For Your Safety<br />

English<br />

5. What to do in Emergencies<br />

Risk of explosion and fire when using corresponding<br />

cleaning agents and residual materials<br />

in containers. In these cases contact<br />

Kärcher to find out how these cleaning agents<br />

are to be used.<br />

Caution!<br />

In order to prevent damage to the spray head,<br />

ensure that it is freely positioned in the container.<br />

The spray head must never bump against<br />

the container wall.<br />

2. Noise Control<br />

The sound level of the internal cleaner with<br />

compressed air motor and without a silencer is<br />

max. 83 dB(A), see "Technical specifications". If<br />

parts which amplify sound (e.g. large metal plates,<br />

metal containers) are sprayed, a risk from<br />

noise can occur. In this case ear protection must<br />

be worn.<br />

3. Approved Operators<br />

Approved operators are persons who are 18<br />

and over and qualified to use this system (exceptions<br />

for trainees, see BGV D15 Art. 6).<br />

4. Personal Protective Equipment<br />

Depending on the concentration of and health<br />

hazard caused by the cleaning liquid used, wear<br />

liquid repellent protective clothing,<br />

protective goggles or face protection,<br />

impermeable gloves,<br />

impermeable footwear.<br />

Switch off the separate high-pressure pump,<br />

Switch off the drive unit of the internal cleaner,<br />

and at the same time<br />

– if the drive unit is electrical unplug it or<br />

switch off the power supply<br />

– if the drive unit is run on compressed air<br />

shut off the compressed air supply<br />

Shut off the cleaning liquid supply.<br />

6. Proper, Intended Use<br />

HFK <strong>200</strong> internal cleaners are spraying devices<br />

for cleaning barrels, containers and tank trucks.<br />

The cleaning head of the <strong>HKF</strong> <strong>200</strong> E / ET / C /<br />

P / PT is placed in the container through an opening<br />

with a diameter of at least <strong>200</strong> mm.<br />

<strong>HKF</strong> <strong>200</strong> ET / PT = min. 140 mm<br />

<strong>HKF</strong> <strong>200</strong> C2 = min. 300 mm<br />

The <strong>HKF</strong> <strong>200</strong> PU is intended for stationary operation.<br />

To this end it must be installed vertically<br />

upright, tightly fitting in a "dome" with flange.<br />

The containers to be cleaned are placed over<br />

the internal cleaner. (See the dimensional diagram<br />

and installation example <strong>HKF</strong> <strong>200</strong> PU for<br />

an illustration of the installation). A separate<br />

high-pressure pump is connected to the internal<br />

cleaner by a high-pressure hose.<br />

i Important!<br />

A list of approved cleaning liquids is given in<br />

Chapter C. Technical Specifications.<br />

It is not proper, intended use<br />

outside closed containers,<br />

with higher pressures and higher temperatures<br />

than those given in the "Technical Specifications".<br />

5.956-515<br />

A2

A. For Your Safety<br />

English <strong>HKF</strong> <strong>200</strong><br />

7. Special Conditions in the Ex-Area<br />

1. The internal cleaner may only be used in Area<br />

0 of containers, if the containers do not exceed<br />

3m diameter in size with a standard container<br />

height or a comparable container size.<br />

2. The cleaning liquid must not contain more<br />

than 1% by weight of undissolved solids.<br />

3. The internal cleaner must be electrostatically<br />

grounded.<br />

4. The cleaning liquid pump may only be run if it<br />

is filled with liquid.<br />

5. The nominal pressure of the pump must not<br />

exceed 50 bar for use with solvents.<br />

6 The pump's flow rate must not exceed 50 l/min<br />

when used with solvents.<br />

7. The compressed air motor or the electrical<br />

gear motor may only be run if the cleaning liquid<br />

is fed to the internal cleaner.<br />

8. The speed in rpm of the spraying head must<br />

not exceed 40 1/min.<br />

9. The operating temperature of the cleaning liquid<br />

must not exceed 95 °C if water with cleaning<br />

agents added is used.<br />

10. The operating temperature of the cleaning liquids<br />

must not exceed 20° C where solvents,<br />

lyes (alkaline solutions) and acids are used.<br />

11. The internal cleaner is to be inspected after<br />

a reasonable operating time to ensure it has a<br />

perfect condition and function (including<br />

checking that the drive motor is concentrically<br />

located relative to the gland part, and checking<br />

bearing bushes and drive seals for wear or<br />

leaks). Repair if necessary.<br />

12. The internal cleaner may only be operated<br />

with cleaning liquids and used in media if the<br />

materials it is made from have adequate resistance<br />

against these.<br />

13. Cleaning liquids, which contain combustible<br />

solvent fractions must correspond to the temperature<br />

classes IIA and IIB. Solvents in the temperature<br />

class IIC must not be sprayed.<br />

14. The internal cleaner must not be permanently<br />

placed in Area 0, only while the container<br />

is being cleaned. The operating regulations applicable<br />

within the scope of the BetrSichV (operating<br />

safety regulations) and other national regulations<br />

are to be complied with. It must be taken<br />

into consideration that the connection between<br />

the container and internal cleaner placed<br />

in the container does not have a flame arrester.<br />

15. Hoses must be electrostatically conductive<br />

(resistance R < 1 MÙ)<br />

16. Only cleaning liquids with a conductivity<br />

G > 1000 pS/m may be used.<br />

17. All parts in contact with the media are to be<br />

connected to the earth connection system.<br />

A3<br />

5.956-515

<strong>HKF</strong> <strong>200</strong><br />

A. For Your Safety<br />

English<br />

8. Schematic Sketch of the Area Classification<br />

Telescopic jib<br />

Area 1<br />

Winch for telescopic jib<br />

Winch for lifting and lowering<br />

the spraying head<br />

High-pressure spray head<br />

Slewing equipment<br />

Area 0/20<br />

Rotating<br />

spray head<br />

Area 1<br />

Clear<br />

medium<br />

Circulation<br />

medium<br />

Electrically conductive<br />

hose<br />

Circulation container with<br />

filter equipment<br />

- push-in strainer<br />

- suction basket (strainer)<br />

- fine filter<br />

5.956-515<br />

A4

A. For Your Safety<br />

English <strong>HKF</strong> <strong>200</strong><br />

9. Area Classification<br />

In the BetrSichV and EN 1127-1, hazardous<br />

(potentially explosive) areas are classified in<br />

areas according to the frequency and duration<br />

of the occurrence of hazardous, potentially atmospheres.<br />

It is the responsibility of the owner/operator<br />

to defined these areas.<br />

Information on area classification can be found<br />

in the BetrSichV, EN 1127-1, BGR 104 - Ex-Guidelines<br />

of BG Chemie and in DIN EN 60 079-10.<br />

Area 0<br />

is an area in which a hazardous, potentially explosive<br />

atmosphere exists constantly, frequently<br />

or for long periods of time as a mixture of air<br />

and combustible gases, vapours or mists and<br />

sprays.<br />

Area 20<br />

is an area in which a hazardous, potentially explosive<br />

atmosphere in the form of a cloud of<br />

combustible dust contained in the air exists constantly,<br />

frequently or for long periods of time.<br />

Area 21<br />

is an area in which a hazardous, potentially explosive<br />

atmosphere in the form of a cloud of<br />

combustible dust contained in the air can occasionally<br />

form during standard operation.<br />

Area 22<br />

is an area in which a hazardous, potentially explosive<br />

atmosphere in the form of a cloud of<br />

combustible dust contained in the air does not<br />

form during standard operation or only for a<br />

short time.<br />

Area 1<br />

is an area in which a hazardous, potentially explosive<br />

atmosphere consisting of a mixture of<br />

air and combustible gases, vapours or mists<br />

and sprays can occasionally form during standard<br />

operation.<br />

Area 2<br />

is an area in which a hazardous, potentially explosive<br />

atmosphere consisting of a mixture of<br />

air and combustible gases, vapours or mists<br />

and sprays does not normally occur during standard<br />

operation or only for a short time.<br />

A5<br />

5.956-515

<strong>HKF</strong> <strong>200</strong><br />

B. Function<br />

English<br />

Function<br />

The internal cleaner consists of a drive parts,<br />

the Carrier pipe and the cleaning head.<br />

The nozzles in the cleaning head rotate about<br />

two axes and therefore cover all areas of the<br />

container.<br />

An electrical or compressed air motor rotates<br />

the cleaning head. The speed in rpm is therefore<br />

independent of the pressure and quantity of<br />

cleaning liquid. In electrical drive units the<br />

speed is either constant or can be adjusted between<br />

two stages, where pneumatic drives are<br />

used the speed can be adjusted via the compressed<br />

air.<br />

5.956-515<br />

B1

C. Technical Data<br />

English <strong>HKF</strong> <strong>200</strong><br />

1. Dimensional Diagram <strong>HKF</strong> <strong>200</strong> E / <strong>HKF</strong> <strong>200</strong> C<br />

Cable entry for round cable<br />

min. Ø 10mm 4x1,5mm²<br />

Ø 30<br />

Hanging bracket<br />

Order-No. 4.034-126<br />

Hole pattern of the<br />

mounting flange<br />

Ø 250<br />

Ø 9<br />

Ø 180<br />

Ø 225<br />

565<br />

615<br />

120°<br />

3x120°<br />

Delivery connection M22x1.5<br />

Area 1<br />

Category 2 respectively 3<br />

Area 0/20<br />

Category 1<br />

Hole circle Ø225<br />

Flange Ø250<br />

Prescribed direction<br />

of rotation<br />

Standard length 800<br />

300 - 1500 special design<br />

X= Minimum inlet Ø180<br />

XX= Rotational Ø<strong>200</strong><br />

x<br />

xx<br />

C1<br />

5.956-515

<strong>HKF</strong> <strong>200</strong><br />

C. Technical Data<br />

English<br />

2. Dimensional Diagram <strong>HKF</strong> <strong>200</strong> ET<br />

Cable entry for round cable<br />

min. Ø 10 mm, 4x1.5 mm²<br />

Ø30<br />

Hanging bracket<br />

Order-No. 4.034-126<br />

Hole pattern of the mounting flange<br />

Delivery connection M 22x1.5<br />

Area 1<br />

Category 2 respectively 3<br />

Area 0/20<br />

Category 1<br />

Hole circle Ø 225<br />

Flange Ø 250<br />

Prescribed direction of rotation<br />

Standard length 500<br />

X = Minimum inlet Ø 140<br />

XX = Rotational Ø 142<br />

5.956-515<br />

C2

C. Technical Data<br />

English <strong>HKF</strong> <strong>200</strong><br />

3. Dimensional Diagram <strong>HKF</strong> <strong>200</strong> C2<br />

Cable entry for round cable<br />

min. Ø 10mm 4x1,5mm²<br />

Ø 30<br />

Hanging bracket<br />

Order No. 4.034-126<br />

Hole pattern of the<br />

mounting flange<br />

Ø 250<br />

Ø 9<br />

Ø 180<br />

Ø 225<br />

565<br />

615<br />

120°<br />

3x120°<br />

Delivery connection M22x1.5<br />

Area 1<br />

Category 2 respectively 3<br />

Area 0/20<br />

Category 1<br />

Hole circle Ø225<br />

Flange Ø250<br />

2 special nozzles,<br />

Nozzles can be<br />

switched over manually<br />

Prescribed direction<br />

of rotation<br />

Standard length 800<br />

300 - 1500 special design<br />

2 nozzles<br />

X= Minimum inlet Ø300<br />

XX= Rotational Ø320<br />

x<br />

xx<br />

C3<br />

5.956-515

Ø 225<br />

Ø 9<br />

<strong>HKF</strong> <strong>200</strong><br />

C. Technical Data<br />

English<br />

4. Dimensional Diagram <strong>HKF</strong> <strong>200</strong> P<br />

Hole pattern of the mounting flange<br />

Ø 250<br />

Ø30<br />

Ø 180<br />

120°<br />

3x120°<br />

290<br />

540<br />

Area 1<br />

Category 2 respectively 3<br />

Delivery connection M22x1.5<br />

Area 0/20<br />

Category 1<br />

EXH<br />

1<br />

2<br />

Air outlet glands<br />

(2 hoses DN 6,<br />

at least 1.5mm)<br />

Hole circle Ø225<br />

Flange Ø250<br />

Air requirement 300l/min<br />

at 5 bar<br />

Prescribed direction<br />

of rotation<br />

Standard length 800 (P) / 500 (PT)<br />

300 - 1500 special design (P)<br />

Air inlet glands<br />

(1 hose DN 6)<br />

X= Minimum inlet Ø180<br />

XX= Rotational Ø<strong>200</strong><br />

x<br />

xx<br />

5.956-515<br />

C4

C. Technical Data<br />

English <strong>HKF</strong> <strong>200</strong><br />

5. Dimensional Diagram <strong>HKF</strong> <strong>200</strong> PT<br />

Hole pattern of the mounting flange<br />

Hanging bracket<br />

Order-No. 4.034-016<br />

Area 1<br />

Category 2 respectively 3<br />

Delivery connection<br />

M 22x1.5<br />

Area 0/20<br />

Category 1<br />

Flange Ø 250<br />

”X”<br />

Air outlet glands<br />

(2 hoses DN 6)<br />

Hole circle Ø 225<br />

Prescribed direction of rotation<br />

Air requirement 300 l/min at 5 bar<br />

Standard length 500<br />

300-1500 special design<br />

Air inlet glands (1 hose DN 6)<br />

X = Minimum inlet Ø 140<br />

XX = Rotational Ø 142<br />

C5<br />

5.956-515

<strong>HKF</strong> <strong>200</strong><br />

C. Technical Data<br />

English<br />

6. Dimensional Diagram <strong>HKF</strong> <strong>200</strong> PU<br />

22,5°<br />

Ø16<br />

22,5°<br />

Ø20<br />

6x60°<br />

60°<br />

x<br />

20°<br />

Ø9<br />

xx<br />

Ø160<br />

Ø225<br />

Ø250<br />

Compressed air 1/4"-Ø8<br />

Air requirement<br />

300l/min at 5 bar<br />

Exhaust air 3/8"-Ø12<br />

Delivery connection<br />

M22x1.5<br />

300<br />

Area 0/20<br />

Category 1<br />

28<br />

665<br />

Area 1<br />

Category 2 respectively 3<br />

min. 400<br />

300<br />

(65)<br />

X= Minimum inlet Ø180<br />

XX= Rotational Ø<strong>200</strong><br />

Ø250<br />

5.956-515<br />

C6

C. Technical Data<br />

English <strong>HKF</strong> <strong>200</strong><br />

7. Installation Example <strong>HKF</strong> <strong>200</strong> PU<br />

o I N<br />

Ex<br />

Maintenance unit<br />

Compressed air filter<br />

Compressed air<br />

4-7 bar 300 l/h<br />

1/2"<br />

Exhaust air<br />

1/4"<br />

3/8"<br />

Holding device<br />

(Holding device with safety<br />

switch = option)<br />

<strong>HKF</strong> <strong>200</strong> PU<br />

Grating<br />

Compact circulation tank<br />

LxBxH=2700x1500x650 mm<br />

Push-in strainer<br />

SHD- R 3000 LM<br />

50 l/min-50 bar 6,8 kW<br />

Option<br />

Filter monitoring<br />

P MIN PMAX P W<br />

M<br />

Wire plate filter<br />

Exhaust air<br />

Ø100<br />

Suction filter<br />

slewable<br />

Clear rinsing<br />

agent supply<br />

customer-supplied<br />

C7<br />

5.956-515

<strong>HKF</strong> <strong>200</strong><br />

C. Technical Data<br />

English<br />

8. Technical Specifications<br />

Units<br />

<strong>HKF</strong> <strong>200</strong> E<br />

(3x400V)<br />

<strong>HKF</strong> <strong>200</strong> E<br />

(3x42V)<br />

<strong>HKF</strong> <strong>200</strong> ET <strong>HKF</strong> <strong>200</strong> P<br />

Order No. 3.631-015 3.631-018 3.631-063 3.631-016<br />

Throughput (MAX) l/h 10 000 10 000 10 000 10 000<br />

Max. flow rate for use<br />

with solvent<br />

Max. temperature for water<br />

with cleaning agents<br />

Max. temperature for<br />

solvents, lyes, acids<br />

l/h<br />

°C<br />

°C<br />

3000 3000 3000 3000<br />

95 95 95 95<br />

20 20 20 20<br />

Max. operating pressure bar <strong>200</strong> <strong>200</strong> <strong>200</strong> <strong>200</strong><br />

Max. operating pressure<br />

for use with solvents<br />

bar<br />

50 50 50 50<br />

Voltage V 230/400 42 (D) 230/400 –<br />

Type of current 3~ 3~ 3~ –<br />

Frequency Hz 50 50 50 –<br />

Rated power consumption W 120 120 120 –<br />

Compressed air<br />

bar<br />

l/min<br />

–<br />

–<br />

Functional speed drive 1/min 18,5 18,5 18,5 10–20<br />

Sound level<br />

(EN 60704-1)<br />

High-pressure connection DN 15<br />

M22x1.5<br />

–<br />

–<br />

–<br />

–<br />

4–7<br />

500<br />

dB(A) 70 70 70 83<br />

without<br />

silencer<br />

DN 15<br />

M22x1.5<br />

DN 15<br />

M22x1.5<br />

DN 15<br />

M22x1.5<br />

Min. container opening mm Ø <strong>200</strong> Ø <strong>200</strong> Ø 140 Ø <strong>200</strong><br />

Length incl. bracket up to<br />

middle of nozzle<br />

mm 1415 1415 1115 1220<br />

Standard immersed depth mm 800 800 500 800<br />

Weight kg 40 40 38 30<br />

Ambient conditions<br />

temperature<br />

Type of protection<br />

°C +2....+40 +2....+40 +2....+40 +2....+40<br />

II 1/2 G c T4 II 1/3 D c 120 °C<br />

5.956-515<br />

C8

C. Technical Data<br />

English <strong>HKF</strong> <strong>200</strong><br />

9. Technical Specifications<br />

Units <strong>HKF</strong> <strong>200</strong> PT <strong>HKF</strong> <strong>200</strong><br />

PU<br />

<strong>HKF</strong> <strong>200</strong> C<br />

<strong>HKF</strong> <strong>200</strong> C2<br />

Order No. 3.631-036 3.631-023 3.631-059 3.631-060<br />

Throughput (MAX) l/h 10 000 10 000 10 000 10 000<br />

Max. flow rate for use<br />

with solvent<br />

Max. temperature for water<br />

with cleaning agents<br />

Max. temperature for<br />

solvents, lyes, acids<br />

l/h<br />

°C<br />

°C<br />

3000 3000 3000 3000<br />

95<br />

95 95 95<br />

20 20 20 20<br />

Max. operating pressure bar <strong>200</strong> <strong>200</strong> <strong>200</strong> <strong>200</strong><br />

Max. operating pressure for<br />

use with solvents<br />

bar<br />

50 50 50 50<br />

Voltage V – – 400 400<br />

Type of current – – 3~ 3~<br />

Frequency Hz – – 50 50<br />

Rated power consumption W – – 300 300<br />

Compressed air<br />

bar<br />

l/min<br />

4–7<br />

500<br />

4–7<br />

594<br />

Functional speed drive 1/min 10–20 10–20 10/20 10/20<br />

Sound level<br />

(EN 60704-1)<br />

dB(A) 83<br />

without<br />

silencer<br />

High-pressure connection DN 15<br />

M22x1.5<br />

83<br />

without<br />

silencer<br />

DN 15<br />

M22x1.5<br />

–<br />

–<br />

–<br />

–<br />

70 70<br />

DN 15<br />

M22x1.5<br />

DN 15<br />

M22x1.5<br />

Min. container opening mm Ø 140 Ø <strong>200</strong> Ø <strong>200</strong> Ø 300<br />

Length incl. bracket up to<br />

middle of nozzle<br />

mm 920 700 1415 1415<br />

Standard immersed depth mm 500 300 800 800<br />

Weight kg 28 28 45 45<br />

Ambient conditions -<br />

temperature<br />

Type of protection<br />

°C +2....+40 +2....+40 +2....+40 +2....+40<br />

II 1/2 G c T4 II 1/3 D c 120 °C<br />

C9<br />

5.956-515

<strong>HKF</strong> <strong>200</strong><br />

C. Technical Data<br />

English<br />

10. Cleaning Liquids<br />

Solvents<br />

Acids<br />

! Danger!<br />

The relevant special safety regulations must be<br />

complied with when using the unit with solvents<br />

or in hazardous, potentially explosive areas!<br />

Maximum pressure for use with solvents: 50 bar<br />

Maximum flow rate for use with solvents: 50 l/min<br />

Caution!<br />

When using solvents, the sealing materials have<br />

a reduced durability, therefore you must always<br />

rinse the unit immediately after use! Please contact<br />

Kärcher if you have any questions!<br />

1. Hydrocarbons<br />

e.g.: Petroleum<br />

2. Aromatic compounds (solvents)<br />

e.g.: benzene, toluene<br />

3. Ketones<br />

e.g.: MEK (methyl ethyl ketones), acetone<br />

4. Esters<br />

e.g.: butyl acetate, methyl acetate<br />

5. Glycols<br />

e.g.: butyl glycol<br />

6. Mixed solvents<br />

e.g.: butyl acetate 85, isobutyl acetate 85<br />

(85 = 85% butyl acetate + 15 % n-butanol)<br />

7. Regenerated substances, distillates made<br />

from various solvents, which have already<br />

been used for cleaning or similar purposes.<br />

Lyes<br />

Caution!<br />

Increased material erosion if hydrochloric and<br />

sulphuric acid are used, therefore rinse/neutralise<br />

immediately after use! Reduced durability if<br />

impure acids are used! Please contact Kärcher<br />

if you have any questions!<br />

1. Water with acidic cleaning agent<br />

(max. 0 - 1%)<br />

e.g.: Kärcher RM25 cleaning agent<br />

2. Acids (max. temperature +20 °C)<br />

Nitric acid max. 10%<br />

Ethanoic acid max. 10%<br />

Formic acid max. 10%<br />

Phosphoric acid max. 10%<br />

Citric acid max. 10%<br />

Sulphuric acid max. 0.5%<br />

Hydrochloric acid max. 0.5%<br />

Water<br />

1. Water<br />

2. Demineralised water<br />

Other cleaning liquids<br />

When using other cleaning liquids use the materials<br />

list to check the durability!<br />

These cleaning liquids may only be used after<br />

they have been released by Kärcher!<br />

1. Water with alkali cleaning agent<br />

(max. 0 - 2%)<br />

e.g.: Kärcher RM31 cleaning agent<br />

2. Hydrated caustic soda max. 10%,<br />

without hypochlorite fractions<br />

3. Potassium hydroxide max. 10%,<br />

without hypochlorite fractions<br />

5.956-515<br />

C10

C. Technical Data<br />

English <strong>HKF</strong> <strong>200</strong><br />

11. Materials List<br />

Item Description Order No. Material Number Media<br />

contact<br />

1 Protective part 4.394-009 5.000-506 metal plate<br />

1.4301<br />

5.114-077 ring<br />

1.4541<br />

1 X<br />

2 Protective part 4.394-011 1.4301 1 X<br />

3 Circular lamination 5.005-174 1.4541 3 X<br />

4 Housing 5.060-085 1.4305 1 X<br />

5 Housing 5.060-114 1.4305 1 X<br />

6 Shaft 5.100-043 1.4305 1 X<br />

7 Shaft 5.100-044 1.4305 1 X<br />

8 Washer 5.115-122 Teflon - bronze 2 X<br />

9 Flange 5.122-059 1.4305 2 X<br />

10 Flange 5.122-068 1.4305 1 X<br />

11 Pin 5.314-037 1.4541 2 X<br />

12 Bevel gear 5.354-003 1.4305 1 X<br />

13 Bevel gear 5.354-004 1.4305 1 X<br />

14 Coupler 5.471-031 1.4305 1 X<br />

15 Ring 5.570-039 CuSn8F55 4 X<br />

16 Cheese head screw M5x12 6.304-011 1.4571 20 X<br />

17 Cheese head screw M5x16 6.304-012 1.4571 10 X<br />

18 Cheese head screw M8x16 6.304-013 1.4571 1 X<br />

19 Cheese head screw M5x30 6.304-112 A4-70 1<br />

20 Lock washer 8.4 6.343-125 Nirosta X7 1 X<br />

21 O-ring 23.47 x 2.62 6.362-219 EPDM 1 X<br />

22 O-ring 18 x 2,5 6.362-431 FPM 1 X<br />

23 O-ring 17.96 x 2,62 6.363-154 FPM 1 X<br />

24 Lip seal D26 x D38 6.365-423 PTFE 4 X<br />

25 Hexagonal screw M8x16 7.304-538 A4-70 1 X<br />

26 Hexagonal nut M5 7.311-203 A4-70 2 X<br />

27 Cap nut M5 7.311-385 A1-50 4 X<br />

28 Sealing ring 22 7.362-011 Cu 1 X<br />

29 VS screw 7.382-251 1.4571 1 X<br />

30 Shaft 4.100-229 5.100-492 shaft 1.4305<br />

VS screw 1.4571<br />

1 X<br />

C11<br />

5.956-515

<strong>HKF</strong> <strong>200</strong><br />

C. Technical Data<br />

English<br />

12. Nozzle Selection<br />

Throughout<br />

l/h<br />

Pressure<br />

bar<br />

Number<br />

of<br />

nozzles<br />

Nozzle size<br />

mm<br />

Order No.<br />

3000 50 4 1.8 4.765-007 o o – – –<br />

3000 50 2 2.4 5.765-006 x x – – –<br />

3000 60 4 1.65 5.765-082 o o – – –<br />

3000 50 2 2.7 4.765-006 x x – – –<br />

3000 50 1 3.8 4.765-008 o o – – –<br />

3000 80 2 2.5 5.765-018 o o – – –<br />

3800 50 2 2.9 5.765-025 o o – – –<br />

3800 80 2 2.7 4.765-006 x x – – –<br />

6000 50 2 3.8 4.765-008 o o – – –<br />

6000 80 2 3.5 5.768-075 o o o – –<br />

6000 80 1 5.0 of inquiry o o o – –<br />

8000 80 2 3.8 4.765-008 – – x – –<br />

3800 80 2 2,7 6.415-862 – – – x x<br />

<strong>HKF</strong> <strong>200</strong> E<br />

<strong>HKF</strong> <strong>200</strong> P<br />

<strong>HKF</strong> <strong>200</strong> C<br />

<strong>HKF</strong> <strong>200</strong> PT<br />

<strong>HKF</strong> <strong>200</strong> ET<br />

Remarks<br />

The size of the nozzle is imprinted on the key<br />

area of the nozzles.<br />

o = possible<br />

x = fitted as a standard<br />

5.956-515<br />

C12

D. Operation<br />

English <strong>HKF</strong> <strong>200</strong><br />

1. Preparation for the initial startup<br />

Electrical drive unit<br />

! Danger!<br />

Risk of fatal injuries due to high electrical voltage.<br />

The required electrical installations must<br />

only be carried out by a qualified electrician.<br />

The plug socket used must:<br />

be fused with a residual current operated circuit-breaker<br />

with a tripping current of 30 mA,<br />

close to the workplace so that the mains plug<br />

can be quickly removed in case of emergency.<br />

Where the mains connection is fixed, a lockable<br />

master switch must be installed for complete<br />

disconnection from the electricity system.<br />

Electrical drive units 42 V and 400 V<br />

Connect wiring (4-cored) to the three-phase<br />

a.c. motor,<br />

connect the motor cable to the power supply<br />

via a lockable master switch,<br />

switch on spray head and check the direction<br />

of rotation.<br />

The spray head must rotate in the following direction<br />

when in operation:<br />

Pneumatic drive<br />

Caution!<br />

Install a maintenance unit in the compressed air<br />

feed (Kärcher Order No. 6.610-020) in order to<br />

avoid damage to the pneumatic drive due to<br />

condensation and poor lubrication.<br />

The maintenance unit must be designed for<br />

An air throughput of 500 l/min,<br />

Pressures up to 7 Bar.<br />

The maintenance unit consists of:<br />

Water separator,<br />

Pressure regulator with manometer,<br />

Proportional lubricator.<br />

Fill proportional lubricator with suitable lubricating<br />

oil. To do this unscrew the storage tank and<br />

pour in the lubricating oil (See the "Maintenance"<br />

section for oil type and grade).<br />

D1<br />

5.956-515

<strong>HKF</strong> <strong>200</strong><br />

D. Operation<br />

English<br />

Fit the compressed air hoses to the<br />

compressed air motor<br />

i Important!<br />

If the silencers are too small, the exhaust air<br />

backpressure created causes the pneumatic<br />

drive to run unsafely. Install hoses at the exhaust<br />

air openings.<br />

2. Switch on for initial operation<br />

! Danger!<br />

Risk of injuries due to possibly hot high-pressure<br />

jet given off by the unit. Therefore<br />

only start up the internal cleaner in containers<br />

closed on all sides,<br />

only place the internal cleaner into the container<br />

or change to another container if the<br />

separate high-pressure pump and the unit's<br />

own drive are switched off.<br />

Place the internal cleaner on the container<br />

and secure if necessary,<br />

Connect the high-pressure pump with the internal<br />

cleaner using a high-pressure hose,<br />

Switch on the drive unit of the internal cleaner,<br />

to do this<br />

– Switch on the power supply to the<br />

electrical drive unit<br />

– Open the compressed air supply to the<br />

pneumatic drive<br />

Open the cleaning liquid inlet,<br />

Switch on the separate high-pressure pump.<br />

Install fresh air hose<br />

Fresh air hose size DN 6,<br />

Install exhaust air hoses to connection No. 2.<br />

Install exhaust air hose<br />

Hose length 1-2 m,<br />

Hose size for exhaust air DN 6,<br />

To connection No. 1 and EXH.<br />

5.956-515<br />

D2

D. Operation<br />

English <strong>HKF</strong> <strong>200</strong><br />

3. Shut-down procedure-switch OFF<br />

i Important!<br />

Before starting the shut-down procedure rinse<br />

through the internal cleaner for 30 seconds without<br />

adding cleaning agents. This way you prevent<br />

incrustations and conglutination, and<br />

therefore premature wear of the seals.<br />

Switch off the separate high-pressure pump,<br />

Shut off the cleaning liquid supply,<br />

Switch off the drive unit of the internal cleaner<br />

by<br />

– removing the mains plug of the electrical<br />

drive units or by switching off the power<br />

supply,<br />

– shutting off the compressed air supply to<br />

the pneumatic drive,<br />

Remove the internal cleaner from the container.<br />

D3<br />

5.956-515

<strong>HKF</strong> <strong>200</strong><br />

E. Maintenance<br />

English<br />

1. Maintenance instructions<br />

Regular maintenance is the basis for a safe<br />

operating system (see table on page E2).<br />

Only use original parts or parts recommended<br />

by the manufacturer, such as<br />

Spare and wearing parts,<br />

Accessory parts,<br />

Resources, fuel, etc,<br />

Cleaning agents.<br />

! Danger!<br />

Risk of accidents when working on the system.<br />

When carrying out any work<br />

disconnect the high-pressure pump at the<br />

master switch and secure,<br />

shutoff the cleaning liquid supply,<br />

switch off the drive unit des internal cleaner,<br />

to do this<br />

– remove the mains plug of electrical drive<br />

units or switch off the power supply<br />

– shutoff the compressed air supply to the<br />

pneumatic drive<br />

Who may carry out maintenance works?<br />

Operator<br />

Works marked "owner/operator" may only be<br />

carried out by instructed persons who can<br />

safely operate and service high-pressure<br />

equipment and systems.<br />

Service agreement<br />

To guarantee reliable operation of the system,<br />

we recommend that you take out a service<br />

agreement. Please contact the Kärcher customer<br />

service responsible for you.<br />

5.956-515<br />

E1

E. Maintenance<br />

English <strong>HKF</strong> <strong>200</strong><br />

2. Maintenance intervals<br />

Time Activity Execution Who<br />

Weekly or<br />

every 40<br />

operating<br />

hours<br />

Monthly or<br />

every 160<br />

operating<br />

hours<br />

Check<br />

compressed<br />

air<br />

maintenance<br />

unit<br />

Check that all<br />

screws are<br />

tight<br />

Caution!<br />

Hazard due to compressed air. Shut off the compressed<br />

air before carrying out any maintenance<br />

work and allow any compressed air in the system<br />

to flow out at the maintenance unit first.<br />

Drain off the water in the water separator by<br />

– opening the water drain plug<br />

– drain water off<br />

– close water drain plug<br />

Fill the proportional lubricator with suitable<br />

lubricating oil. To do this unscrew the storage tank<br />

and pour in the lubricating oil. See table below for<br />

lubricating oil types to be used.<br />

Check that all screws are tight.<br />

Operator<br />

Operator<br />

Lubricating oil for compressed air<br />

maintenance unit<br />

(for Order No. 3.631-016, 3.631-036)<br />

Festo spezial<br />

Aral Vitam GF 32<br />

Esso Nuto H 32<br />

Mobil DTE 24<br />

BP Energol HLP 32<br />

E2<br />

5.956-515

<strong>HKF</strong> <strong>200</strong><br />

F. Troubleshooting<br />

English<br />

1. Fault information<br />

! Danger!<br />

Risk of accidents when working on the System.<br />

Before carrying out any work<br />

disconnect the high-pressure pump at the<br />

master switch and secure,<br />

shutoff the cleaning liquid supply,<br />

switch off the drive unit des internal cleaner,<br />

to do this<br />

– remove the mains plug of electrical drive<br />

units or switch off the power supply<br />

– shutoff the compressed air supply to the<br />

pneumatic drive<br />

Who may correct faults?<br />

Operator<br />

Works marked "owner/operator" may only be<br />

carried out by instructed persons who can<br />

safely operate and service high-pressure<br />

equipment and systems.<br />

Qualified electricians<br />

Work marked "qualified electrician" may only<br />

be carried out by persons who have successfully<br />

completed an electrical engineering<br />

vocational course.<br />

Customer service<br />

Works marked "customer service" may only<br />

be carried out by the fitters of Kärcher's customer<br />

service.<br />

5.956-515<br />

F1

F. Troubleshooting<br />

English <strong>HKF</strong> <strong>200</strong><br />

2. Locating faults<br />

Fault Possible cause Solution By whom<br />

Motor wont rotate No voltage supply to motor Check fuses and cables Electrician<br />

Motor rotates but<br />

not the spray head<br />

Spray head rotates<br />

jerkily<br />

Motor protection switch has<br />

tripped<br />

Residual current operated<br />

circuit-breaker has tripped<br />

No compressed air or<br />

pressure too low<br />

Air feed line bent<br />

Mechanical defect in<br />

- Coupling parts<br />

- Drive shaft<br />

- Gearing<br />

Worn thrust rings lead to<br />

increased bevel gear<br />

clearance<br />

Gear teeth of bevel gears<br />

worn<br />

Remove cause of the<br />

overload, reset motor<br />

protection switch<br />

Remove cause and reset<br />

the residual current<br />

operated circuit-breaker<br />

Check compressed air<br />

Check compressed air<br />

hoses<br />

Check parts, replace<br />

defective parts<br />

Replace thrust ring<br />

Replace bevel gears<br />

Electrician<br />

Electrician<br />

Operator<br />

Operator<br />

Customer service<br />

Customer service<br />

Customer service<br />

Uneven cleaning jet Spray nozzles blocked Clean spray nozzles Operator<br />

Spray nozzles damaged Replace spray nozzles Operator<br />

F2<br />

5.956-515

<strong>HKF</strong> <strong>200</strong><br />

G. Accessories<br />

English<br />

Accessories<br />

The HFK <strong>200</strong> internal cleaner can be supplemented with the following accessories:<br />

Description<br />

Order No.<br />

Compressed air maintenance unit (only for compressed air operation) 6.610-020<br />

Compressed air filter with automatic condensate drain<br />

(only for compressed air operation)<br />

6.414-154<br />

Bracket (VA) HFK <strong>200</strong> P/PT 4.034-016<br />

Bracket (VA) HFK <strong>200</strong> E/ET/C/C2 4.034-126<br />

Domed cover (VA) Ø 560 mm 4.210-022<br />

High pressure hose, NW 13 – 1.5 m* 1) 6.389-126<br />

High pressure hose, NW 13 – 10 m* 1) 4.440-173<br />

Coupling NW 13* 4.403-002<br />

90° threaded connection NW 13* 4.408-023<br />

Compressed air hose (sold by the metre) 6.388-192<br />

Exhaust air silencer with oil separator<br />

auf Anfrage<br />

* Possible for max. 4000 l/h cleaning liquid flow rate. Please inform Kärcher if higher cleaning liquid<br />

flow rates are required.<br />

1) Hoses for use with solvents must be electrostatically conductive!<br />

5.956-515<br />

G1

H. Guarantee<br />

English <strong>HKF</strong> <strong>200</strong><br />

Guarantee<br />

The guarantee terms and conditions issued by<br />

our sales company in each country apply.<br />

In case of guarantee claims, please contact<br />

your dealer or your nearest authorised customer<br />

service agent.<br />

H1<br />

5.956-515

<strong>HKF</strong> <strong>200</strong><br />

I. Declaration of Conformity<br />

English<br />

EC Declaration of Conformity<br />

We herewith declare that the design and type of<br />

machine named in the following as well as the<br />

model marketed by us complies with the relevant<br />

fundamental health and safety requirements<br />

of the EC Directives.<br />

This declaration becomes invalid if modifications<br />

are made to the machine which have not<br />

been previously agreed with us.<br />

Product: Internal cleaner<br />

Type: <strong>HKF</strong> <strong>200</strong> P, <strong>HKF</strong> <strong>200</strong> PU,<br />

<strong>HKF</strong> <strong>200</strong> PT<br />

Relevant EC Directives:<br />

EC Machine Directive (98/37/EC)<br />

EC ATEX Directive (94/9/EC)<br />

Harmonised standards used:<br />

DIN EN 292 - 1<br />

DIN EN 292 - 2<br />

DIN EN 13463 - 1: <strong>200</strong>2<br />

prEN 13463 - 5: <strong>200</strong>2<br />

EN 1127 - 1: 1997<br />

Alfred Kärcher GmbH & Co. KG<br />

Cleaning Systems<br />

Alfred-Kärcher-Str. 28-40<br />

P.O. Box 160<br />

D-71349 Winnenden<br />

Phone: ++ 49 71 95 14-0<br />

Fax: ++ 49 71 95 14-22 12<br />

5.957-454 (06/03)<br />

Alfred Kärcher Kommanditgesellschaft.<br />

Registered office: Winnenden.<br />

Register court: Waiblingen, HRA 169.<br />

Personally liable shareholder:<br />

Kärcher Reinigungstechnik GmbH.<br />

Registered office: Winnenden, 2404 Waiblingen<br />

register court, HRB<br />

Managing Directors: Dr. Bernhard Graf,<br />

Hartmut Jenner, Georg Metz<br />

National standards used: -<br />

No. of nominated test institute: 0123<br />

Test report No. 70043569<br />

Designation:<br />

Ex II 1/2 G c T4<br />

Ex II 1/3 D c 120 °C<br />

Internal measures ensure that serial production<br />

units always comply with the requirements of<br />

the current EC Directives and the standards<br />

used.<br />

The undersigned act on behalf of and with power<br />

of attorney issued by the management.<br />

S. Reiser H. Jenner<br />

5.956-515<br />

I1

I. Declaration of Conformity<br />

English <strong>HKF</strong> <strong>200</strong><br />

EC Declaration of Conformity<br />

We herewith declare that the design and type of<br />

machine named in the following as well as the<br />

model marketed by us complies with the relevant<br />

fundamental health and safety requirements<br />

of the EC Directives.<br />

This declaration becomes invalid if modifications<br />

are made to the machine which have not<br />

been previously agreed with us.<br />

Product: Internal cleaner<br />

Type: <strong>HKF</strong> <strong>200</strong> E, <strong>HKF</strong> <strong>200</strong> ET,<br />

<strong>HKF</strong> <strong>200</strong> C, <strong>HKF</strong> <strong>200</strong> C2<br />

Relevant EC Directives:<br />

EC Machine Directive (98/37/EC)<br />

EC ATEX Directive (94/9/EC)<br />

Harmonised standards used:<br />

DIN EN 292 - 1<br />

DIN EN 292 - 2<br />

DIN EN 60 204 - 1<br />

DIN EN 13463 - 1: <strong>200</strong>2<br />

prEN 13463 - 5: <strong>200</strong>2<br />

EN 1127 - 1: 1997<br />

Alfred Kärcher GmbH & Co. KG<br />

Cleaning Systems<br />

Alfred-Kärcher-Str. 28-40<br />

P.O. Box 160<br />

D-71349 Winnenden<br />

Phone: ++ 49 71 95 14-0<br />

Fax: ++ 49 71 95 14-22 12<br />

5.957-735 (06/03)<br />

Alfred Kärcher Kommanditgesellschaft.<br />

Registered office: Winnenden.<br />

Register court: Waiblingen, HRA 169.<br />

Personally liable shareholder:<br />

Kärcher Reinigungstechnik GmbH.<br />

Registered office: Winnenden, 2404 Waiblingen<br />

register court, HRB<br />

Managing Directors: Dr. Bernhard Graf,<br />

Hartmut Jenner, Georg Metz<br />

National standards used: -<br />

No. of nominated test institute: 0123<br />

Test report No. 70043569<br />

Designation:<br />

Ex II 1/2 G c T4<br />

Ex II 1/3 D c 120 °C<br />

Internal measures ensure that serial production<br />

units always comply with the requirements of<br />

the current EC Directives and the standards<br />

used.<br />

The undersigned act on behalf of and with power<br />

of attorney issued by the management.<br />

S. Reiser H. Jenner<br />

I2<br />

5.956-515

<strong>HKF</strong> <strong>200</strong><br />

English<br />

5.956-515