Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

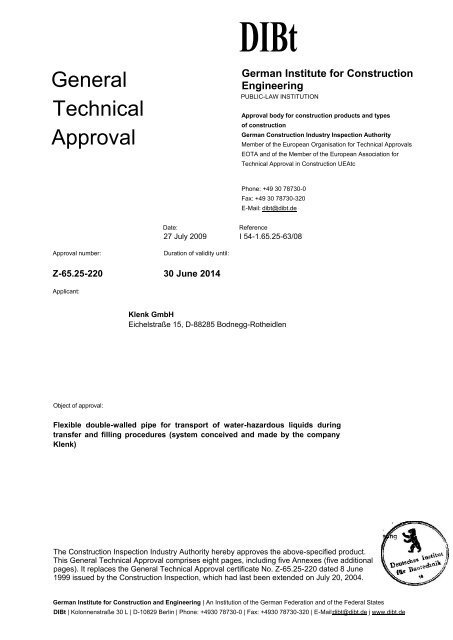

DIBt<br />

<strong>General</strong><br />

<strong>Technical</strong><br />

<strong>Approval</strong><br />

German Institute for Construction<br />

Engineering<br />

PUBLIC-LAW INSTITUTION<br />

<strong>Approval</strong> body for construction products and types<br />

of construction<br />

German Construction Industry Inspection Authority<br />

Member of the European Organisation for <strong>Technical</strong> <strong>Approval</strong>s<br />

EOTA and of the Member of the European Association for<br />

<strong>Technical</strong> <strong>Approval</strong> in Construction UEAtc<br />

Phone: +49 30 78730-0<br />

Fax: +49 30 78730-320<br />

E-Mail: dibt@dibt.de<br />

Date:<br />

Reference<br />

27 July 2009 I 54-1.65.25-63/08<br />

<strong>Approval</strong> number:<br />

Duration of validity until:<br />

Z-65.25-220 30 June 2014<br />

Applicant:<br />

Klenk GmbH<br />

Eichelstraße 15, D-88285 Bodnegg-Rotheidlen<br />

Object of approval:<br />

Flexible double-walled pipe for transport of water-hazardous liquids during<br />

transfer and filling procedures (system conceived and made by the company<br />

Klenk)<br />

The Construction Inspection Industry Authority hereby approves the above-specified product.<br />

This <strong>General</strong> <strong>Technical</strong> <strong>Approval</strong> comprises eight pages, including five Annexes (five additional<br />

pages). It replaces the <strong>General</strong> <strong>Technical</strong> <strong>Approval</strong> certificate No. Z-65.25-220 dated 8 June<br />

1999 issued by the Construction Inspection, which had last been extended on July 20, 2004.<br />

German Institute for Construction and Engineering | An Institution of the German Federation and of the Federal States<br />

DIBt | Kolonnenstraße 30 L | D-10829 Berlin | Phone: +4930 78730-0 | Fax: +4930 78730-320 | E-Mail: dibt@dibt.de j www.dibt.de

DIBt<br />

<strong>General</strong> <strong>Technical</strong> <strong>Approval</strong> Page 2 of 8 | 27 July 2009<br />

Z-65.25-220<br />

I. GENERAL PROVISIONS<br />

1 This <strong>General</strong> <strong>Technical</strong> <strong>Approval</strong> provides evidence that the approved product is suited for application and<br />

use within the meaning of the building and construction regulations enacted by the different Federal States.<br />

2 This <strong>General</strong> <strong>Technical</strong> <strong>Approval</strong> does not replace the permits, licences and certifications otherwise required<br />

by the German law for the execution of building and/or construction projects.<br />

3 This <strong>General</strong> <strong>Technical</strong> <strong>Approval</strong> is granted without prejudice to the rights, particularly private property rights,<br />

of any third parties.<br />

4 The manufacturer and distributor of the approved product must, without prejudice to more extensive<br />

regulations contained in the SPECIAL PROVISIONS stated below, provide the user of the approved product<br />

with copies of the <strong>General</strong> <strong>Technical</strong> <strong>Approval</strong> by pointing to the fact that the <strong>General</strong> <strong>Technical</strong> <strong>Approval</strong> has<br />

to be available at the place where the approved object or system is used. On request, the involved authorities<br />

are, likewise, to be provided with copies of the <strong>General</strong> <strong>Technical</strong> <strong>Approval</strong>.<br />

5 The <strong>General</strong> <strong>Technical</strong> <strong>Approval</strong> many be reproduced only in whole. The publication of the <strong>Approval</strong> in<br />

excerpts is subject to the German Construction Industry Inspection Authority's prior consent (Deutsches<br />

Institut für Bautechnik, DIBt). Texts and drawings publicized in promotional literature must not be contrary to<br />

the specifications laid down in this <strong>General</strong> <strong>Technical</strong> <strong>Approval</strong>. All translations of the <strong>General</strong> <strong>Technical</strong><br />

<strong>Approval</strong> must contain the hint phrase "Translation of the original German version not reviewed by the<br />

German Construction Industry Inspection Authority (DIBt)".<br />

6 The <strong>General</strong> <strong>Technical</strong> <strong>Approval</strong> is granted subject to revocation at any time. The terms of the <strong>General</strong><br />

<strong>Technical</strong> <strong>Approval</strong> can subsequently be altered and/or amended, particularly if new technical knowledge<br />

requires doing so.

DIBt<br />

<strong>General</strong> <strong>Technical</strong> <strong>Approval</strong> Page 3 of 8 | 27 July 2009<br />

Z-65.25-220<br />

II. SPECIAL PROVISIONS<br />

1 Object of approval and scope of application<br />

(1) This <strong>General</strong> <strong>Technical</strong> <strong>Approval</strong> concerns and relates to flexible double-walled (jacketed) hose<br />

lines with leak detection, a system conceived and made by the company Klenk, bearing the type<br />

designation DWSL and comprising an associated intermediate layer serving as a spacer element and a<br />

hose connection fitting consisting of connection fittings, nipples and sleeves or hose connecting pieces<br />

existing on the hose side, including connection parts, such as clamps, hose screw connections or<br />

flanges or tanker couplings and the material needed for sealing them. The flexible pipes are<br />

manufactured including inner hoses in sizes from DN 15 up to DN 75 and lengths of up to 50m. They<br />

are suited for connection to a vacuum leak detector that allows to detect negative pressures of up to<br />

-550mbar and alarm vacuum levels of at least -325mbar (as for the design of the flexible double-walled<br />

pipe, please refer to Annex 1 hereto).<br />

(2) The leak detector reacts and warns optically and acoustically if, in consequence of leaks in the<br />

walls of the flexible double-walled pipe, the pressure level in the monitored space rises.<br />

(3) The flexible double-walled pipes are admitted for the conveying of water-hazardous liquids during<br />

transfer and/or filling operations at pumping pressures of up to 10bar.<br />

(4) The flexible double-walled pipes are admitted for use within a temperature range from -20°C up to<br />

+60°C on condition that evidence is furnished with regard to their suitability in regard to all materials<br />

and liquids that, during the transfer of the related water-hazardous liquid, could get in touch with each<br />

other in a certain section of the admissible overall temperature range.<br />

(5) The <strong>General</strong> <strong>Technical</strong> <strong>Approval</strong> is hereby granted without prejudice to the provisos on testing or<br />

other law sectors, such as the Directive 97/23/EC (Pressure Equipment Directive), the eleventh<br />

regulation on the device safety law (regulation on placing devices and safety systems in circulation for<br />

hazardous areas - explosion protection regulation and the ordinances on § 18 of the German<br />

Occupational Safety and Health Act, the German Ordinance on Industrial Safety and Health and the<br />

German Ordinance on Hazardous Substances).<br />

(6) Owing to this <strong>General</strong> <strong>Technical</strong> <strong>Approval</strong>, the assessment in regard to the approved product's<br />

compliance with the regulations of the Federal Water Act, including the type-approval procedure<br />

required by the German Water Management Law (§ 19 h WHG 1 ) are inapplicable.<br />

(7) The validity period of this <strong>General</strong> <strong>Technical</strong> <strong>Approval</strong> (see page 1) relates to the utilisation of the<br />

approved product, meaning its installation, mounting or incorporation and not to its possible later use.<br />

2 Provisions concerning the construction of the product<br />

2.1 <strong>General</strong><br />

The flexible double-walled pipes (jacketed hose lines with leak detection), a system conceived and made<br />

by the company Klenk, bearing the type designation DWSL, have to comply with the SPECIAL<br />

PROVISIONS as defined in this decision, including the data and details deposited with the German<br />

Institute for Construction Engineering.<br />

1<br />

Federal Water Act (Water Management Law, WHG) of 19 August 2002

DIBt<br />

<strong>General</strong> <strong>Technical</strong> <strong>Approval</strong> Page 4 of 8 | 27 July 2009<br />

Z-65.25-220<br />

2.2 Characteristics and structure<br />

(1) The inner and outer hoses correspond to the type D or SD (i.e. with or without spring steel wire<br />

equipment) as specified in the standard DIN EN 12115 2 and the TRbF 131/2 3 (TRbF = <strong>Technical</strong><br />

Regulations for Combustible Liquids). They must be suited for use within the scope of applications<br />

defined in above section 1.<br />

The same materials are used for both the inner and outer hoses. The hose material for the realisation<br />

of the internal layer according to Table 4 of standard DIN EN 12115 is to be chosen so that its<br />

suitability in view of the materials and the admitted liquid getting in touch with each other while<br />

conveying it through the pipe, is ensured. The same applies also in regard to the operating temperature<br />

of the pipe. The materials used for the manufacture of the hose fittings must, likewise, be suited for use<br />

in connection with the liquid to be conveyed.<br />

(2) The monitored space is realised using an intermediate layer consisting of thermoplastic<br />

poly(ether)ester elastomers following the specifications laid down in DIN EN 12115. This material is<br />

commonly known as Hytrel®. This intermediate layer consists of a plastic net that has been pulled over<br />

the inner hose.<br />

(3) The metal fittings and joints are made in compliance with DIN EN 14420 4 and tested as specified<br />

in DIN EN 12266 5 .<br />

(4) The sealants are made in compliance with DIN 3771, parts 1 to 5 6 and must meet the<br />

requirements specified in DIN ISO 1817 7 .<br />

(5) The mounting of the flexible double-walled pipe is to be realised in compliance with the mounting<br />

instructions deposited with the German Institute for Construction Engineering.<br />

(6) Proof of the functional reliability of the approved product has been furnished in compliance with the<br />

requirements specified in DIN EN 12115 and in the "<strong>Approval</strong> Principles specified for Leak Detectors<br />

for Double-walled (Jacketed) Pipes (ZG-LAGR)" issued by the German Institute for Construction<br />

Engineering (DIBt) in August 1994 and in the <strong>Technical</strong> Regulations for Combustible Liquids (TRbF)<br />

131, part 2, No. 5.7, in DIN EN ISO 8031 8 , DIN EN 14420, parts 1 to 6, and DIN 28450, DIN EN 1266-<br />

1/-2, DIN 3771, parts 1 to 5, plus DIN ISO 1817 with respect to the nominal size combinations<br />

according to Annex 2 hereto,<br />

2 DIN EN 12115:1999-08 Rubber and thermoplastics hoses and hose assemblies for liquid or gaseous<br />

chemicals – Specification;<br />

3 TRbF 131-2:1992-08 <strong>Technical</strong> Regulations for Combustible Liquids – Hose lines<br />

4 DIN EN 14420-1:2007-0 Hose fittings with clamp units - Part 1: Requirements, survey, designation and<br />

testing;<br />

DIN EN 14420-2:2005-05 Hose fittings with clamp units - Part 2: Hose side parts of hose tail;<br />

DIN EN 14420-3:2005-05 Hose fittings with clamp units - Part 3: Clamp units, bolted or pinned;<br />

DIN EN 14420-4:2007-04 Hose fittings with clamp units - Part 4: Flange connections;<br />

DIN EN 14420-5:2005-05 Hose fittings with clamp units - Part 5: Threaded connections;<br />

DIN EN 14420-6:2007-04 Hose fittings with clamp units - Part 6: TW tank truck couplings;<br />

5 DIN EN 12266-1:2003-06 Industrial valves - Testing of metallic valves - Part 1: Pressure tests, test<br />

procedures and acceptance criteria - Mandatory requirements;<br />

DIN EN 12266-2:2003-05 Industrial valves - Testing of metallic valves - Part 2: Tests, test procedures and<br />

acceptance criteria - Supplementary requirements;<br />

6 DIN 3771-1:1984-12 Fluid systems; O-rings; dimensions as in ISO 3601/1;<br />

DIN 3771-2:1984-12<br />

Fluid systems, O-Rings; testing, marking;<br />

DIN 3771-3:1984-12<br />

Fluid systems; O-rings; materials, field of application;<br />

DIN 3771-4:1984-12<br />

Fluid systems; O-rings; quality acceptance criteria;<br />

DIN 3771-5:1993-11<br />

Fluid systems; O-rings; methods for calculation and dimensions of housings;<br />

7 DIN ISO 1817:2008-08 Rubber, vulcanized - Determination of the effect of liquids (ISO 1817:2005)<br />

8 DIN EN ISO 8031:1997-08 Rubber and plastics hoses and hose assemblies - Determination of electrical<br />

resistance and conductivity (ISO 8031:2009);

DIBt<br />

<strong>General</strong> <strong>Technical</strong> <strong>Approval</strong> Page 5 of 8 | 27 July 2009<br />

Z-65.25-220<br />

2.3 Manufacture and marking<br />

2.3.1 Manufacture of the approved product<br />

2.3.2 Marking<br />

The manufacture of the approved product must take place in the plants and/or factories, the names of<br />

which have been made known to and deposited with the German Institute for Construction Engineering<br />

(Deutsches Institut für Bautechnik, DIBt).<br />

The applicant must provide the flexible double-walled (jacketed) pipes with the conformity mark<br />

(Ü-mark) as required by the ordinances on conformity marks enacted by the different Federal States<br />

and must affix said mark(s) to the fittings existing at the end of the hose (flexible pipe).<br />

The application of any such marks is admitted only if the requirements specified in below section 2.4<br />

have been met. The flexible double-walled pipes need, apart from the marking required by<br />

DIN EN 12115, to be provided with the following indications in addition:<br />

- The type designation<br />

- The name of the manufacturer<br />

2.4 Proof of conformity<br />

2.4.1 <strong>General</strong><br />

The applicant must furnish proof that the approved product complies with the provisions set out in this<br />

<strong>General</strong> <strong>Technical</strong> <strong>Approval</strong> with regard to applicant's factory by providing a corresponding declaration<br />

of conformance, which must base on the factory's production control and an initial type test performed<br />

by a recognised inspection agency authorised to perform such tests.<br />

2.4.2 Factory production control<br />

(1) The applicant, in his capacity as its manufacturer, must establish and carry out a factory production<br />

control system in his own works and must, beyond that, furnish proof that the assembled components,<br />

elements and parts of the flexible double-walled pipe comply with the construction documents that<br />

have been deposited with the German Institute for Constructional Engineering (DIBt). Factory<br />

production control in the above sense means permanent supervision and control of all steps needed<br />

for the production of the approved product. The purpose of the factory production control by routine<br />

item testing is to ensure that the flexible double-walled pipes comply with the specifications defined in<br />

this <strong>General</strong> <strong>Technical</strong> <strong>Approval</strong>.<br />

(2) The factory production control of the approved product is to be carried out in the applicant's<br />

manufacturing works by submitting all components and/or individual parts to an incoming control on the<br />

basis of acceptance test certificates as required in section 3.1 of DIN EN 10204 9 , which need to be<br />

prepared based on the following tests and controls:<br />

a) The inner and outer hoses of the flexible double-walled pipe are to be subjected to the tests and<br />

controls required by DIN EN 12115, DIN EN ISO 8031 and EN ISO 1402.<br />

If using flexible double-walled pipes for the conveyance of types of liquids, the flash point of which is<br />

below 55°C, proof with regard to the electrical characteristics of these liquids is to be furnished as<br />

required by DIN EN 12115.<br />

b) The intermediate layer is to be submitted to the AD test (dimension test) and the AR test<br />

(examination of the material certificates) as provided by DIN 3230-3 10 .<br />

c) Verification if the sealants tested in compliance with DIN 3771-3 and DIN ISO 1817 are suited for<br />

use within the scope of application indicated on the delivery note.<br />

9 DIN EN 10204:2005-01 Metallic products - Types of inspection documents.<br />

10 DIN 3230-3:1982-04 <strong>Technical</strong> delivery conditions for valves - Compilation of test methods.

DIBt<br />

<strong>General</strong> <strong>Technical</strong> <strong>Approval</strong> Page 6 of 8 | 27 July 2009<br />

Z-65.25-220<br />

(3) The flexible double-walled pipes must, in addition to the controls and tests provided in Table 6 in<br />

the standards DIN EN 12115 and EN ISO 1402 11 , be subjected to at least the following tests and<br />

controls specified in DIN 3230-3:<br />

- AD test (dimension test) and AR test (examination of the material certificates);<br />

- BN test, including proof of compliance with the admissible leak rate 1 (test of the hose connection<br />

with water for leakproofness at the maximum allowable operating pressure (10bar));<br />

- BQ test (test of the hose connection with water for leakproofness at the 1.5-fold maximum<br />

allowable operating pressure).<br />

In addition to the incoming controls, the connection fittings, including nipples and associated sealants,<br />

are, in the applicant's factory, to be subjected to the following tests and controls required by DIN 3230-<br />

3;<br />

- AD test (dimension test) and AR test (examination of the material certificates);<br />

Prior to using it for the first time, the flexible double-walled hose pipe assembly needs to be subjected<br />

to a leak test as provided by DIN EN 12266-1. The medium to be used for testing is gas. The test is to<br />

be realised by maintaining, at normal ambient temperature, test pressures of (6 ± 1) bar in the inner<br />

hose and of (6 ± 1) bar in the monitored space for at least 60 seconds. No bubbles must rise to the<br />

surface of the water if plunging the hose assembly into the water or, if coated with a special leak<br />

detection liquid, no continuous formation of bubbles must occur.<br />

(4) The results of the factory production control need to be recorded and analysed. The recordings<br />

must, at least, contain the following details:<br />

- Designation of the approved product;<br />

- Type of test or control;<br />

- Date of manufacture and testing of the approved product;<br />

- Results of the controls and/or tests;<br />

- Signature of the person responsible for the factory production control.<br />

The applicant must keep all recordings on file for at least five years. If requested to do so, they need to<br />

be submitted to the German Institute for Construction Engineering (DIBt) and/or the responsible<br />

supreme building control authority.<br />

Once the test results are insufficient, the applicant must immediately take all measures required in<br />

order to eliminate the related fault and/or insufficiency.<br />

Inner and outer hoses, intermediate layers, connection fittings, nipples, sleeves and associated<br />

sealants that fail to meet the requirements, are to be handled in such a manner that they cannot be<br />

confused with conforming components of the same kind. After elimination of the fault and/or<br />

insufficiency, the corresponding test or control must, as far as technically feasible and required as<br />

evidence that the fault and/or insufficiency has been eliminated, be repeated immediately.<br />

2.4.3 Initial type test of the approved product by a recognised inspection agency<br />

Within the limits of the initial type test, the requirements specified in DIN EN 12115, DIN EN 14420-1<br />

and in the "<strong>Approval</strong> Principles for Leak Detectors suited for use with Double-walled Pipelines" issued<br />

by the German Institute for Construction Engineering (DIBt) of August 1994, the <strong>Technical</strong> Regulations<br />

for Combustible Liquids (TRbF 131-2), in DIN EN 12266-1/2, DIN 3771-34 and DIN ISO 1817 have to<br />

be met. Once the results of the tests performed on samples from the current production underlying the<br />

<strong>General</strong> <strong>Technical</strong> <strong>Approval</strong> have been furnished, these will replace those obtained in the course of the<br />

initial type-testing procedure.<br />

EN ISO 1402:1996-09<br />

Rubber and plastics hoses and hose assemblies - Hydrostatic testing

DIBt<br />

<strong>General</strong> <strong>Technical</strong> <strong>Approval</strong> Page 7 of 8 | 27 July 2009<br />

Z-65.25-220<br />

3 Design-related provisions<br />

(1) The utilisation of the flexible double-walled pipe and the associated intermediate layer is limited to<br />

the types of water-hazardous liquids of the suitability category A listed in the chemical resistance chart<br />

specified on the supplementary sheet 1 to DIN EN 12115 12 as suitable for use with the corresponding<br />

material. The approved product may also be used for the conveyance of other types of waterhazardous<br />

liquids if proof has been furnished that, if handled at the provided temperatures, these<br />

liquids meet the requirements specified in the <strong>Technical</strong> Regulations for Combustible Liquids (TRbF)<br />

131, part 2, No. 5.4.<br />

(2) To ensure the flexible double-walled pipe is monitored as required, the vacuum leak detector<br />

admitted for use with the related type of liquid specified in the <strong>Technical</strong> Description 13 is to be<br />

connected. Regarding the connection and operation of the vacuum leak detector, the instructions<br />

contained in the <strong>Technical</strong> Descriptions need to be followed and adhered to.<br />

(3) When using the product in exceptional cases for suction operations as admitted in below section 4,<br />

par. (7), the vacuum leak detector must be temporarily put out of operation.<br />

4 Utilisation-related provisions<br />

(1) The approved product is to be used in compliance with the specifications set out in the "<strong>Technical</strong><br />

Description". Only specialised companies within the meaning of § 19, par. I, of the German Water<br />

Management Act (WHG) may be charged with the installation, maintenance and repair and/or cleaning<br />

of the approved product. They need to possess the knowledge required for the installation of leak<br />

detectors in compliance with the TRbF 503 (directive concerning the supervision of the installation of<br />

leak detectors, version dated May 1987) and must have been trained by the applicant. This training is<br />

to be repeated annually. Each time after an inspection of the leak detector, the expert charged with<br />

doing this work must issue a corresponding installation and test certificate.<br />

(2) No specialised companies need to be charged with the execution of the works and activities<br />

specified in above sub-section (1), if they, as an exception under German Federal State Law, are<br />

exempted from the obligation to register as certified specialists or if the manufacturer of the approved<br />

product carries out these works and/or activities using his own qualified staff. In such a case, the<br />

application of the occupational safety and health requirements remains unaffected.<br />

(3) Leak detection systems working on the vacuum principle only may be connected to the flexible<br />

jacketed pipe. In the case of a leakage, the leak detector must be able to withstand overpressures of up<br />

to 10bar or must trigger automatic (self-acting) shut-off valves (magnetic valves, f. ex.) to prevent its<br />

components from being exposed to inadmissible pressure levels.<br />

(4) The vacuum leak detector must comply with the applicable legal provisions and its suitability for<br />

use with the flexible double-walled pipe within the scope of application it has been designed for must<br />

have been proven. At the latest when reaching a negative pressure of -325mbar, the vacuum leak<br />

detector must trigger an alarm. Once such an alarm is triggerd, the leak detector must deactivate the<br />

vacuum pump to discontinue the vacuuming procedure.<br />

(5) The liquids provided for being transferred must not have a tendency to thicken or to separate solid<br />

materials and their kinematic viscosity should not exceed 5000cSt at +4°C.<br />

Supplementary sheet 1 to<br />

12 DIN EN 12115:2001-05 Rubber and thermoplastics hoses and hose assemblies for liquid or gaseous chemicals -<br />

Specification;<br />

13<br />

<strong>Technical</strong> Description of the double-walled hose line manufactured by the applicant as examined by TÜV-Nord<br />

Systems GmbH & Co. KG on June 19, 2009.

DIBt<br />

<strong>General</strong> <strong>Technical</strong> <strong>Approval</strong> Page 8 of 8 | 27 July 2009<br />

Z-65.25-220<br />

(6) The flexible double-walled pipe must, at one of its ends, be provided with a nozzle for the<br />

connection of the leak detector. The other end of the flexible double-walled pipe needs to be provided<br />

with a control-screw that allows to check if the leak detection medium can pass freely.<br />

(7) Only in exceptional cases may the flexible double-walled pipe be used for suction operations. This<br />

is admissible if, as specified in DIN EN 12115, the possible negative suction pressure with respect to<br />

the actually applied hose, suffices to ensure the vacuum stability in an acceptable manner.<br />

(8) The bolts used for the fixing of the flexible double-walled pipe, including connection fittings and<br />

nipples need to be protected against accidental loosening.<br />

(9) If using the approved product for the conveyance of types of liquids, the flash point of which is<br />

below 55°C, or if using it in explosion hazardous areas, the requirements for its electrical conductivity<br />

characteristics specified in DIN EN 12115, including the guidelines issued by the employers' liability<br />

insurance association for preventing ignition hazards resulting from electrostatic charge, need to<br />

followed an complied with. The manufacturer is obliged to provide corresponding evidence. If using the<br />

metal insert of the pipe for connecting it with the hose fitting, proof is to be furnished that, while<br />

integrating the pipe into an overall system, the electrical contact between the metal inserts and the<br />

hose or pipe fitting(s) is absolutely perfect and works faultless.<br />

(10) Regarding each flexible double-walled pipe, a corresponding installation and test certificate is to<br />

be produced.<br />

5 Provisions regarding use, maintenance and care, including recurring<br />

checks and inspections<br />

(1) The applicant must include the <strong>Technical</strong> Description in his delivery.<br />

(2) The usability of the approved product is to be reconsidered and checked recurrently at reasonable<br />

intervals, but at least once every year. During the first start-up / commissioning of the flexible doublewalled<br />

pipe system and also the recurring functional checks, the unobstructedness and free passability<br />

of the monitored space between the inner and outer hose is to be checked by opening the controlscrew<br />

provided for this purpose and checking the pressure change occurring within the monitored<br />

space. It is the responsibility of the operator to decide in what manner and at what intervals the checks<br />

are to be made within the above-specified timeframe.<br />

(3) The admissible leak detectors connected to the monitored space between the inner and outer hose<br />

need to be checked in compliance with the <strong>Technical</strong> Description established for the corresponding<br />

device type.<br />

(4) All checks, inspections or tests prescribed under different laws shall remain unaffected.<br />

Eggert<br />

Certified

Pages 9 to 12 (non editable technical drawings)<br />

As for the translation of the texts on these drawings, please refer to the separately attached<br />

MS Word document or corresponding printout.

Annex 2 to the <strong>General</strong> <strong>Technical</strong> <strong>Approval</strong> No. Z-65.25-220 dated 27 July 2009<br />

<strong>Technical</strong> characteristics and materials used with combined nominal hose sizes<br />

Type name<br />

designating<br />

the combined<br />

nominal hose<br />

sizes<br />

Sizes of<br />

inner hoses<br />

Sizes of<br />

outer hoses<br />

Monitored<br />

space,<br />

volume in<br />

litres / m<br />

Design of connection<br />

and drawing No.<br />

Metals used with the fittings<br />

DWSL 1 DN 15 DN 32 0.424 With union joint Screw connections made of brass (Ms58) or stainless steel<br />

(1/2") (1 ¼") Piece list dated 29/10/2008 Pinned clamp fitting made of aluminium<br />

Drwg No. 1-2-5/1_0 Stainless steel socket (connecting piece on the hose side)<br />

DWSL 2 DN 20 DN 40 0.380 With union joint Screw connections made of brass (Ms58) or stainless steel<br />

(3/4") (1 ½") Piece list dated 29/10/2008 Pinned clamp fitting made of aluminium<br />

Drwg No. 1-2-5/1_0 Stainless steel socket (connecting piece on the hose side)<br />

DWSL 3 DN 20 DN 40 0.380 With union joint Screw connections made of brass (Ms58) or stainless steel<br />

(3/4") (1 ½") Piece list dated 29/10/2008 Screwed clamp fitting made of aluminium<br />

Drwg No. 3-4-6/1_0 Stainless steel socket (connecting piece on the hose side)<br />

DWSL 4 DN 40 DN 65 1.080 With union joint Screw connections made of brass (Ms58) or stainless steel<br />

(1 ½") (2 1/2") Piece list dated 29/10/2008 Screwed clamp fitting made of aluminium<br />

Drwg No. 3-4-6/1_0 Stainless steel socket (connecting piece on the hose side)<br />

DWSL 5 DN 40 ON 65 1.080 With union joint Screw connections made of brass (Ms58) or stainless steel<br />

(1 ½") (2 1/2") Piece list date 29/10/2008 Screwed clamp fitting, pinned, made of aluminium<br />

Drwg No. 1-2-5/1_0 Stainless steel socket (connecting piece on the hose side)<br />

DWSL 6 DN 65 DN 100 3.075 With union joint Screw connections made of brass (Ms58) or stainless steel<br />

(2 ½")<br />

")<br />

(4") Piece list dated 29/10/2008 Screwed clamp fitting made of aluminium<br />

Drwg No. 3-4-6/1_0 Stainless steel socket (connecting piece on the hose side)<br />

DWSL 7 DN 50 DN 75 0.89 With tanker coupling Made of brass (Ms58) or stainless steel<br />

DWSL 8 (2") (3") Piece list dated 18/03/2009 Screwed clamp fitting, pinned, made of stainless steel or aluminium<br />

Drwg No. 7-8NM_0 Stainless steel socket (connecting piece on the hose side)<br />

7-8/3_0<br />

7-8/2_0<br />

With flange connection<br />

Piece list dated 28/10/2008<br />

Drwg No. 7-8/F_0<br />

7-8/1_0<br />

7-8/2_0<br />

DWSL 9 DN 75 DN 100 1.075 With tanker coupling Made of brass (Ms58) or stainless steel<br />

plus<br />

DWSL 10<br />

(3") (4") Piece list dated 28/10/2008<br />

Drwg No. 9-10/VM_0<br />

Pinned clamp fitting made of stainless steel or aluminium<br />

Stainless steel socket (connecting piece on the hose side)<br />

9-10/3_0<br />

9-10/2_0<br />

With screwed flange connection<br />

Piece list dated 28/10/2008<br />

Drwg No. 9-10/F_0<br />

7-8/1_5<br />

7-8/2_0