CO/1VT Series â Adhesion to PC, ABS - Kraiburg TPE

CO/1VT Series â Adhesion to PC, ABS - Kraiburg TPE

CO/1VT Series â Adhesion to PC, ABS - Kraiburg TPE

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

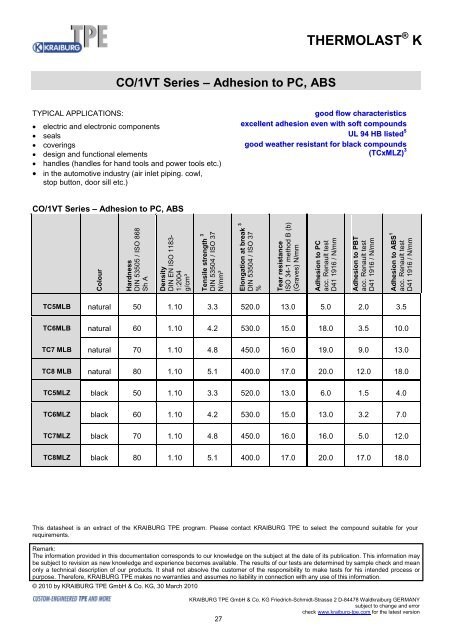

Colour<br />

Hardness<br />

DIN 53505 / ISO 868<br />

Sh A<br />

Density<br />

DIN EN ISO 1183-<br />

1:2004<br />

g/cm³<br />

Tensile strength 3<br />

DIN 53504 / ISO 37<br />

N/mm²<br />

Elongation at break 3<br />

DIN 53504 / ISO 37<br />

%<br />

Tear resistance<br />

ISO 34-1 method B (b)<br />

(Graves) N/mm<br />

<strong>Adhesion</strong> <strong>to</strong> <strong>PC</strong><br />

acc. Renault test<br />

D41 1916 / N/mm<br />

<strong>Adhesion</strong> <strong>to</strong> PBT<br />

acc. Renault test<br />

D41 1916 / N/mm<br />

<strong>Adhesion</strong> <strong>to</strong> <strong>ABS</strong> 1<br />

acc. Renault test<br />

D41 1916 / N/mm<br />

THERMOLAST ® K<br />

<strong>CO</strong>/<strong>1VT</strong> <strong>Series</strong> – <strong>Adhesion</strong> <strong>to</strong> <strong>PC</strong>, <strong>ABS</strong><br />

TYPICAL APPLICATIONS:<br />

electric and electronic components<br />

seals<br />

coverings<br />

design and functional elements<br />

handles (handles for hand <strong>to</strong>ols and power <strong>to</strong>ols etc.)<br />

in the au<strong>to</strong>motive industry (air inlet piping. cowl,<br />

s<strong>to</strong>p but<strong>to</strong>n, door sill etc.)<br />

good flow characteristics<br />

excellent adhesion even with soft compounds<br />

UL 94 HB listed 5<br />

good weather resistant for black compounds<br />

(TCxMLZ) 3<br />

<strong>CO</strong>/<strong>1VT</strong> <strong>Series</strong> – <strong>Adhesion</strong> <strong>to</strong> <strong>PC</strong>, <strong>ABS</strong><br />

TC5MLB natural 50 1.10 3.3 520.0 13.0 5.0 2.0 3.5<br />

TC6MLB natural 60 1.10 4.2 530.0 15.0 18.0 3.5 10.0<br />

TC7 MLB natural 70 1.10 4.8 450.0 16.0 19.0 9.0 13.0<br />

TC8 MLB natural 80 1.10 5.1 400.0 17.0 20.0 12.0 18.0<br />

TC5MLZ black 50 1.10 3.3 520.0 13.0 6.0 1.5 4.0<br />

TC6MLZ black 60 1.10 4.2 530.0 15.0 13.0 3.2 7.0<br />

TC7MLZ black 70 1.10 4.8 450.0 16.0 16.0 5.0 12.0<br />

TC8MLZ black 80 1.10 5.1 400.0 17.0 20.0 17.0 18.0<br />

This datasheet is an extract of the KRAIBURG <strong>TPE</strong> program. Please contact KRAIBURG <strong>TPE</strong> <strong>to</strong> select the compound suitable for your<br />

requirements.<br />

Remark:<br />

The information provided in this documentation corresponds <strong>to</strong> our knowledge on the subject at the date of its publication. This information may<br />

be subject <strong>to</strong> revision as new knowledge and experience becomes available. The results of our tests are determined by sample check and mean<br />

only a technical description of our products. It shall not absolve the cus<strong>to</strong>mer of the responsibility <strong>to</strong> make tests for his intended process or<br />

purpose. Therefore, KRAIBURG <strong>TPE</strong> makes no warranties and assumes no liability in connection with any use of this information.<br />

© 2010 by KRAIBURG <strong>TPE</strong> GmbH & Co. KG, 30 March 2010<br />

KRAIBURG <strong>TPE</strong> GmbH & Co. KG Friedrich-Schmidt-Strasse 2 D-84478 Waldkraiburg GERMANY<br />

subject <strong>to</strong> change and error<br />

check www.kraiburg-tpe.com for the latest version<br />

27

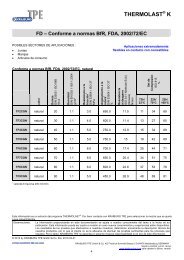

THERMOLAST ® K<br />

<strong>CO</strong>/<strong>1VT</strong> <strong>Series</strong> – <strong>Adhesion</strong> <strong>to</strong> <strong>PC</strong>, <strong>ABS</strong><br />

<strong>CO</strong>/<strong>1VT</strong> <strong>Series</strong> – <strong>Adhesion</strong> <strong>to</strong> <strong>PC</strong>, <strong>ABS</strong> - especially low hardness<br />

TC3MSB natural 32 1.10 1.5 500.0 9.0 4.5 1.5 2.0<br />

TC4MSB natural 40 1.10 2.3 560.0 10.0 5.0 1.0 2.0<br />

TC3MSZ black 32 1.10 1.5 500.0 9.0 12.0 1.5 4.0<br />

TC4MSZ black 40 1.10 2.3 560.0 10.0 12.0 1.0 3.0<br />

1 The adhesion quality is very much depending on the mold design, product geometry as the processing parameters.<br />

KRAIBURG <strong>TPE</strong> assists you pleasantly<br />

2 Tested under artificial weathering according <strong>to</strong> DIN EN ISO 4892-2. The black compounds (TCxMLZ) are weather resistant up <strong>to</strong> 2200 MJ/m 2 ,<br />

which is equal <strong>to</strong> 1.1 year outdoor expose in central Europe<br />

3 Deviating from ISO 37 standard test piece S2 is tested with a traverse speed of 200 mm/min.<br />

4 Not valid for TC3MSB, TC4MSB, TC3MSZ, TC4MSZ<br />

This datasheet is an extract of the KRAIBURG <strong>TPE</strong> program. Please contact KRAIBURG <strong>TPE</strong> <strong>to</strong> select the compound suitable for your<br />

requirements.<br />

Remark:<br />

The information provided in this documentation corresponds <strong>to</strong> our knowledge on the subject at the date of its publication. This information may<br />

be subject <strong>to</strong> revision as new knowledge and experience becomes available. The results of our tests are determined by sample check and mean<br />

only a technical description of our products. It shall not absolve the cus<strong>to</strong>mer of the responsibility <strong>to</strong> make tests for his intended process or<br />

purpose. Therefore, KRAIBURG <strong>TPE</strong> makes no warranties and assumes no liability in connection with any use of this information.<br />

© 2010 by KRAIBURG <strong>TPE</strong> GmbH & Co. KG, 30 March 2010<br />

KRAIBURG <strong>TPE</strong> GmbH & Co. KG Friedrich-Schmidt-Strasse 2 D-84478 Waldkraiburg GERMANY<br />

subject <strong>to</strong> change and error<br />

check www.kraiburg-tpe.com for the latest version<br />

27

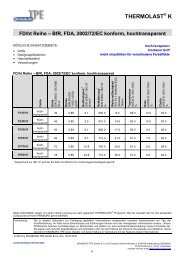

peel force (N/mm) x<br />

<strong>CO</strong>/<strong>1VT</strong> <strong>Series</strong> – <strong>Adhesion</strong> <strong>to</strong> <strong>PC</strong>, <strong>ABS</strong><br />

THERMOLAST ® K<br />

MATERIAL ADVANTAGES:<br />

excellent adhesion in coinjection moulding<br />

(depending on geometry and processing)<br />

insert moulding is possible<br />

natural compounds easy <strong>to</strong> colour<br />

tactile surface (soft <strong>to</strong>uch)<br />

good flow characteristics<br />

wide hardness range 32 – 80 Sh A<br />

UL 94 HB listed<br />

PROCESSING:<br />

processing on 2K injection moulding machines<br />

(many grades also for insert moulding)<br />

mould temperature: 40° C – 60° C<br />

low back pressure<br />

high shear force (small injection point, high injection<br />

rate etc.) is beneficial for the flow behaviour<br />

pre drying for 2 – 4 h with 60° C - 80° C is<br />

recommended<br />

processing temperature:<br />

adhesion <strong>to</strong> engineering thermoplastics<br />

180° C – 240° C (max. 250° C)<br />

high injection speed and pressure<br />

Description peel test (according <strong>to</strong> "Renault D41 1916" standard)<br />

In the below represented test setup the peel force is measured by a tensile testing machine in N/mm in dependence<br />

of the path, the upper cramp of the tensile testing machine puts back. This pass is called peel path. Therein the<br />

stretching proportion of the <strong>TPE</strong> is contained.<br />

Test piece dimensions: Thermoplastic part: 130 x 22 x 2 mm, <strong>TPE</strong> part: 130 x 20 x 2 mm.<br />

Peel test according <strong>to</strong> “Renault D41 1916“ standard<br />

test setup<br />

example diagram as result of a peel test<br />

tensile testing machine<br />

adhesion <strong>to</strong> thermoplastics<br />

10<br />

8<br />

cramp<br />

fixture<br />

<strong>TPE</strong><br />

thermoplastic<br />

flexible cramp<br />

Flexibles fixture<br />

6<br />

4<br />

2<br />

0<br />

measuring 1<br />

measuring 2<br />

measuring 3<br />

0 50 100 150<br />

peel path (mm)<br />

This datasheet is an extract of the KRAIBURG <strong>TPE</strong> program. Please contact KRAIBURG <strong>TPE</strong> <strong>to</strong> select the compound suitable for your<br />

requirements.<br />

Remark:<br />

The information provided in this documentation corresponds <strong>to</strong> our knowledge on the subject at the date of its publication. This information may<br />

be subject <strong>to</strong> revision as new knowledge and experience becomes available. The results of our tests are determined by sample check and mean<br />

only a technical description of our products. It shall not absolve the cus<strong>to</strong>mer of the responsibility <strong>to</strong> make tests for his intended process or<br />

purpose. Therefore, KRAIBURG <strong>TPE</strong> makes no warranties and assumes no liability in connection with any use of this information.<br />

© 2010 by KRAIBURG <strong>TPE</strong> GmbH & Co. KG, 30 March 2010<br />

KRAIBURG <strong>TPE</strong> GmbH & Co. KG Friedrich-Schmidt-Strasse 2 D-84478 Waldkraiburg GERMANY<br />

subject <strong>to</strong> change and error<br />

check www.kraiburg-tpe.com for the latest version<br />

27