fiber products

fiber products

fiber products

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

You must welcome change as the rule but not as your ruler.<br />

The year 2000<br />

— Denis Waitley<br />

was a year of change – significant change for The Siemon Company and for our industry.<br />

The tremendous global demand for Siemon <strong>products</strong> has resulted in the expansion and reorganization of Siemon Company<br />

resources to better serve our customers. From manufacturing to shipping to engineering, Siemon employees have spent the<br />

year 2000 adapting how we design, manufacture, and deliver our <strong>products</strong>. Externally the rapid acceleration and extent of<br />

mergers, acquisitions, and spin-offs continues to change the landscape of our industry. The rate of churn has created an<br />

unsettled and uncertain environment across the industry in many organizations. As the Siemon Company begins its 98th year<br />

of business, I can assure you that we intend to remain an independent family owned enterprise.<br />

In today’s hectic business climate the only constant is change. During our 98 years in business the company has<br />

reinvented itself many times. At the turn of the 20th century we were a small start-up serving the needs of the fledgling<br />

telecommunications industry. Over the years The Siemon Company has anticipated<br />

change and adapted to meet the needs of our customers. Today we have evolved<br />

into a global supplier of cabling systems for the internet generation.<br />

It is better to excel in any<br />

single art than to arrive only at mediocrity in several.<br />

We are specialists at<br />

— Pliny The Younger<br />

The Siemon Company. We make cabling systems. By delivering superior <strong>products</strong> we have earned a<br />

reputation for innovation and value around the world. We have also developed a new program to ensure our most popular<br />

items are always in stock at a Siemon distributor. We call it our FOCUS program. FOCUS items are the cabling <strong>products</strong> and<br />

tools most frequently used by Siemon Certified Installers . Throughout this catalog you will notice <strong>products</strong> highlighted with<br />

SM<br />

this logo . Individual FOCUS items will be highlighted in red. These items should always be readily available from<br />

your Siemon distributor. If not, contact our Customer Service Department, and we will help you find a stocking location.<br />

Another useful tool for identifying and ordering the most popular Siemon <strong>products</strong> is our Recommended Stock Package.<br />

Please look for it at the very end of this catalog. We encourage all Siemon distributors to stock the items listed there.<br />

The Siemon Company has always been known as a technology leader. Our goal for 2001 is to have our reputation for<br />

service match the performance of our <strong>products</strong>.<br />

Carl N. Siemon<br />

President, The Siemon Company

Fiber Products 1.0<br />

Fiber<br />

Products<br />

PERFORMANCE MARKINGS<br />

Meets category 3 and class C requirements of ISO/IEC 11801<br />

(including amendments A.1 & A.2), ANSI/TIA/EIA-568-A (including<br />

addenda A-1, A-2 & A-3) and TSB67. Requirements are specified<br />

to an upper frequency limit of 16 MHz.<br />

Meets category 5 and class D requirements and recommendations of<br />

ISO/IEC 11801 (including amendments A.1 & A.2), ANSI/TIA/EIA-568-A<br />

(including addenda A-1, A-2, A-3 & A-4), TSB67 and TSB95.<br />

Requirements are specified to an upper frequency limit of 100 MHz.<br />

This classification is a superset of .<br />

Meets category 5e and additional class D requirements of amendment<br />

2 of ISO/IEC 11801, and addendum 5 to ANSI/TIA/EIA-568-A.<br />

Requirements are specified to an upper frequency limit of 100 MHz.<br />

This classification is a superset of .<br />

Performance exceeds draft category 6 and class E specifications under<br />

development for edition 2 of ISO/IEC 11801 and TIA PN-3727.<br />

Requirements are specified to an upper frequency limit of 250 MHz.<br />

This classification is a superset of .<br />

Performance exceeds draft category 7 and class F specifications under<br />

development for edition 2 of ISO/IEC 11801. Requirements are<br />

specified to an upper frequency limit of 600 MHz. This classification<br />

is an electrical superset of .<br />

SAFETY MARKINGS<br />

Communications Circuit Accessory Listed per Underwriters Laboratories<br />

Standard UL 1863 or Secondary Protectors for Communications<br />

Circuits Listed per Underwriters Laboratories Standard UL 497A, or<br />

non-metallic surface raceway and fittings Listed per UL 5A.<br />

Certification by Underwriters Laboratories to United States Standards<br />

and C22.2 Canadian Telecommunications Standards.<br />

Certification by the Canadian Standards Association to C22.2 Canadian<br />

Telecommunications Standards.<br />

Electromagnetic Compatibility according to Article 10 of European<br />

Council Directive 89/336/EEC.<br />

ORDERING INFORMATION<br />

<br />

FOCUS <strong>products</strong> are the most popular Siemon <strong>products</strong> and<br />

should always be readily available at your local Siemon distributor.<br />

FOCUS <strong>products</strong> are identified by the FOCUS symbol and are also<br />

distinguished with red text. If a FOCUS item is not available at<br />

your local distributor, please contact Siemon Customer Service for<br />

prompt resolution.<br />

Bulk project packs are the most economical and environmentally friendly<br />

way to purchase <strong>products</strong> for large projects. Less packaging means fewer<br />

packages to open and less waste to clean up, which saves time and<br />

money. Bulk pack <strong>products</strong> are identified by the bulk pack symbol.<br />

ISO 9001, 9002 and 14001<br />

Work Area 2.0<br />

Shielded Products 3.0<br />

Modular Patching 4.0<br />

Racks and Cable Management 5.0<br />

Patch Cords, Plugs and Cable 6.0<br />

S210 Products 7.0<br />

S110 Products 8.0<br />

S66 Products 9.0<br />

Protection 10.0<br />

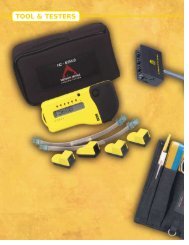

Tools and Testers 11.0<br />

Standards Overview 12.0<br />

Application Guide 13.0<br />

Installation Practices 14.0<br />

Glossary 15.0<br />

Index 16.0<br />

Work Area<br />

Shielded<br />

Products<br />

Modular<br />

Patching<br />

Racks & Cable Patch Cords,<br />

Management Plugs & Cable<br />

S210<br />

Products<br />

S110<br />

Products<br />

S66<br />

Products<br />

Protection<br />

Tools &<br />

Testers<br />

Standards<br />

Overview<br />

Application<br />

Guide<br />

Installation<br />

Practices<br />

Glossary Index

Product Innovation<br />

The Siemon Company is committed to leading the industry in<br />

development of the highest performance cabling <strong>products</strong> available. In<br />

1998 Siemon was the first manufacturer to offer a category 6<br />

solution. The TERA connector was released in 1999, making it the<br />

first commercially available, standards recognized category 7<br />

connector. Last year we were the first major manufacturer to offer<br />

two different small form factor <strong>fiber</strong> connectors – the MT-RJ and the<br />

LC. Our commitment to product innovation is evident in the<br />

resources we allocate to research and development. In fact, The<br />

Siemon Company spends a higher percentage of revenue on R&D<br />

than either IBM or Hewlett Packard.<br />

Quality<br />

The Siemon Company is driven by our commitment to quality,<br />

which has resulted in ISO 9001, ISO 9002, and ISO 14001<br />

certification. We look at quality from two perspectives: internal and<br />

external. We complete vigorous internal assessments to ensure that<br />

we are performing within the scope of our plan.<br />

Through a program of operator ownership all employees are<br />

responsible for the quality of their own work – and have the<br />

authority to control it. We practice procedures to make sure that<br />

the customer is happy the first time, all the time.<br />

Service and Support<br />

Our <strong>products</strong> are only as good as the people who stand behind<br />

them. The Siemon Company is dedicated to offering our customers<br />

the best product support available. Our highly trained Technical<br />

Support Department is available for product and installation<br />

assistance. Many of our Technical Support staff are BICSI RCDD<br />

or RCDD/LAN Specialist certified – a designation for individuals<br />

who demonstrate expertise in the design, integration, and<br />

implementation of telecommunications transport systems and their<br />

related infrastructure components. Our commitment extends to the<br />

field as well. Every Siemon Certified Installer SM<br />

is required to attend<br />

a rigorous week long training course covering standards, installation<br />

practices and system design. Our installers must also attend<br />

recertification classes every two years.<br />

A large staff of knowledgeable Customer Service Representatives<br />

is available to assist with orders for customers around the world.<br />

When you purchase Siemon <strong>products</strong>, you can rest assured that<br />

you’ll receive the highest level of support available.

Certified<br />

Installers SM<br />

Siemon Certified Installers SM<br />

(CIs) provide the necessary<br />

link between Siemon<br />

<strong>products</strong> and completed<br />

installations by designing,<br />

installing, and maintaining<br />

Siemon Cabling Systems.<br />

CIs also ensure that the<br />

cabling solution is compliant<br />

with our extended warranty<br />

requirements. By utilizing<br />

Siemon CIs, multi-site and<br />

multi-national customers can<br />

be assured of consistent<br />

quality and performance of<br />

their installed cabling system<br />

anywhere in the world.<br />

Consultant/<br />

Architect Program<br />

The Siemon Consultant/<br />

Architect Program was<br />

developed to meet the<br />

specific needs of consultants,<br />

architectural firms and<br />

electrical engineering<br />

companies. It focuses on<br />

the design of the Siemon<br />

Cabling System ® and<br />

provides up-to-date, factual<br />

information on the latest<br />

industry standards and<br />

high-quality Siemon<br />

<strong>products</strong> that support<br />

today’s demands for high<br />

bandwidth and emerging<br />

technologies.<br />

Project<br />

Assistance Program<br />

Through our global network<br />

of certified designers and<br />

installers, the Siemon Project<br />

Assistance Program provides<br />

its clients with a process<br />

that ensures successful<br />

telecommunications cabling<br />

projects, from concept<br />

through implementation.By<br />

leveraging Siemon internal<br />

resources and the resources<br />

of our worldwide allies, the<br />

Siemon Project Assistance<br />

Team becomes the primary<br />

contact for all your<br />

structured cabling needs.<br />

World Class Training<br />

All Siemon design and<br />

installation programs are<br />

supported by extensive<br />

educational services. The<br />

Siemon Cabling System ®<br />

Training Program is based<br />

on the latest industry<br />

standards and was developed<br />

by our engineering<br />

department. It is the only<br />

ISO 9001 approved training<br />

program in the industry that<br />

is accredited by BICSI.<br />

The Siemon Company is<br />

committed to providing its<br />

certified designers, installers,<br />

and consultants with the<br />

most comprehensive and<br />

effective training programs<br />

in the world.

Commercial – Industrial<br />

BASF<br />

BEIJING NATIONAL WEALTH PLAZA<br />

CIBA GEIGY<br />

CINCINNATI MILACRON<br />

CON EDISON<br />

DOW CHEMICAL<br />

EDS<br />

EXXON<br />

FORD MOTOR COMPANY<br />

GENERAL ELECTRIC<br />

GENERAL MOTORS<br />

GEORGIA PACIFIC<br />

HUNDAI ELECTRONICS<br />

IMATION<br />

INGERSOL RAND<br />

JD EDWARDS<br />

JOHNSON & JOHNSON<br />

KUALA LUMPUR CITY CENTER<br />

MERCK<br />

MICROSOFT<br />

MOTOROLA<br />

NESTLÉ<br />

OLIN<br />

RAY-O-VAC<br />

RAYTHEON<br />

SALT PALACE CONVENTION CENTER<br />

SEAGATE MALAYSIA<br />

SINO CHEMICAL GROUP<br />

SONY<br />

SYDNEY HARBOUR CASINO<br />

Education<br />

BAYLOR COLLEGE OF MEDICINE<br />

BOSTON COLLEGE<br />

DARTMOUTH COLLEGE<br />

EMORY UNIVERSITY<br />

GEORGETOWN UNIVERSITY<br />

HARVARD UNIVERSITY<br />

OXFORD UNIVERSITY<br />

SEATTLE UNIVERSITY<br />

THOMAS JEFFERSON LIBRARY<br />

UNIVERSITY OF MADRID<br />

UNIVERSITY OF MEXICO<br />

UNIVERSITY OF PENNSYLVANIA<br />

UNIVERSITY OF TECHNOLOGY SYDNEY<br />

UNIVERSITY OF UTAH<br />

WASHINGTON AND LEE UNIVERSITY<br />

YALE UNIVERSITY<br />

Finance<br />

AMERICAN EXPRESS<br />

BANK OF CHINA<br />

BANK OF NEW YORK<br />

BANK ONE<br />

Finance (cont’d)<br />

BEIJING FINANCIAL BUREAU<br />

BLUE CROSS BLUE SHIELD<br />

BMW FINANCIAL SERVICES<br />

CENTER BANK<br />

CHARLES SCHWAB<br />

COMMONWEALTH BANK<br />

CZECH NATIONAL BANK<br />

DELOITTE & TOUCHE<br />

DEUTSCH BANK<br />

DONALDSON, LUFKIN & JENRETTE<br />

ERNST & YOUNG<br />

GOLDMAN SACHS<br />

HSBC<br />

MASTERCARD INTERNATIONAL<br />

MERRILL LYNCH<br />

NASDAQ<br />

NATIONAL RESERVE BANK<br />

NATIONAL WESTMINSTER BANK<br />

PACIFICORP<br />

PRICEWATERHOUSECOOPERS<br />

PROGRESSIVE INSURANCE<br />

TULLET & TOKYO FOREX<br />

Government<br />

BEIJING WATER AUTHORITY<br />

CITY OF WESTMINSTER<br />

CIVIL AVIATION SAFETY AUTHORITY<br />

IRS<br />

JOB CORP<br />

NATIONAL WEALTH CENTER<br />

NEW SOUTH WALES POLICE<br />

PARLIAMENT HOUSE AUSTRALIA<br />

SCOTTISH HYDRO ELECTRIC<br />

UNITED NATIONS<br />

U.S. DEPARTMENT OF ENERGY<br />

U.S. FEDERAL COURT SYSTEM<br />

U.S. POST OFFICE<br />

Medical<br />

BAYLOR MEDICAL CENTER<br />

CHILDREN’S HOSPITAL PHILADELPHIA<br />

CLINIC LEICESTER ROYAL INFIRMARY<br />

DEACONESS MEDICAL CENTER<br />

DEKALB MEDICAL CENTER<br />

GEMS METROPOLITAN FAMILY HEALTH<br />

IMPERIAL CANCER RESEARCH FUND<br />

KAISER PERMANENTE—KAISER KOOLAU<br />

MAYO CLINIC<br />

MERCK<br />

PRINCETON MEDICAL CENTER<br />

SACRED HEART MEDICAL CENTER<br />

SALISBURY HEALTH AUTHORITY<br />

YALE–NEW HAVEN HOSPITAL<br />

Retail<br />

ACE HARDWARE<br />

ADVANCED AUTOPARTS<br />

ALBERTSONS<br />

AMAZON.COM<br />

CLOPAY<br />

FEDERATED STORES<br />

HOLLYWOOD VIDEO<br />

J.CREW<br />

K-MART<br />

NIEMAN MARCUS<br />

SEARS<br />

SOTHEBY’S<br />

STAPLES<br />

TOYS “R” US<br />

WALGREENS<br />

WAL-MART<br />

Telecommunications<br />

AT&T<br />

CABLETRON<br />

CELLULAR ONE<br />

CSC AUSTRALIA PTY LTD.<br />

GENERAL DATACOMM<br />

HBO<br />

HEWLETT PACKARD<br />

HONEYWELL<br />

IBM<br />

MCI WORLDCOM<br />

MITEL<br />

MOTOROLA<br />

NEC<br />

NOKIA<br />

NORTEL NETWORKS<br />

SHANGHAI TELEPHONE INSTITUTE<br />

SIEMENS BUSINESS COMMUNICATIONS<br />

SPRINT<br />

UNISYS<br />

U.S. WEST<br />

Transportation<br />

DALLAS INTERNATIONAL AIRPORT<br />

DHL<br />

FEDERAL AVIATION ADMINISTRATION<br />

JAPAN TOURIST BUREAU<br />

LONG ISLAND RAILROAD<br />

MALAYSIAN AIRLINES<br />

MINISTRY OF RAILWAYS<br />

PORT AUTHORITY OF NEW YORK<br />

SOUTHWEST AIRLINES<br />

TORONTO AIRPORT<br />

UNITED AIRLINES<br />

UPS

The Siemon Company is committed to developing new and<br />

innovative cabling <strong>products</strong> that offer exceptional value to our<br />

customers worldwide. Our engineering R&D staff is currently<br />

working on a variety of exciting new <strong>products</strong> that will continue<br />

to lead the industry in performance, functionality, and ease of use.<br />

A few of the <strong>products</strong> in development are listed here. For the<br />

latest information on new product releases, please watch for our<br />

monthly new product updates. If you aren’t on our mailing list,<br />

we encourage you to complete and return the fax-back form at<br />

the back of this catalog so we may inform you of the latest<br />

product releases. You may also visit our web site for our<br />

most current product information.<br />

Industrial Product Line<br />

To meet the unique requirements of harsh<br />

industrial environments, Siemon is developing a<br />

complete line of industrial Ethernet <strong>products</strong>.<br />

Siemon will offer two grades of industrial <strong>products</strong><br />

that are based on the widely accepted RJ45<br />

connector design.<br />

Siemon’s industrial hardened connector is designed<br />

to meet the most stringent IEC IP (International<br />

Protection) specifications for resistance to moisture,<br />

dust, corrosion, EMI/RFI, vibration and shock.<br />

These rugged <strong>products</strong> are best suited for heavy manufacturing<br />

environments where Ethernet is required. They are also ideal for nonmanufacturing<br />

environments, such as marine, chemical processing, and<br />

petroleum refineries, where heavy resistance to water, chemicals and<br />

high temperatures is required.<br />

For less demanding environments, Siemon will release a line of<br />

<strong>products</strong> designed to protect connections from moderate exposure to<br />

contaminants and temperature variations. These <strong>products</strong> will meet less<br />

stringent IP requirements and will be best suited to applications such as<br />

food services, hospitals and light manufacturing.<br />

Bright White MAX Modules<br />

and Mounting Hardware<br />

Due to popular demand, Siemon will<br />

soon offer MAX modules and a<br />

variety of MAX work area mounting<br />

solutions in bright white. Bright white<br />

will be the ideal color choice for many<br />

work area applications.<br />

Shielded TERA 1-Pair Plug<br />

A shielded 1-pair TERA plug is<br />

planned for release this year. The plug<br />

can be used with TERA outlets to<br />

serve voice, fax or broadband video<br />

applications. Up to four simultaneous<br />

applications can be provided for from<br />

a single TERA outlet. A combination<br />

of 2-pair and 1-pair plugs can<br />

also be used to serve a<br />

combination of data,<br />

voice and video<br />

from a single<br />

outlet.

Fiber<br />

Products<br />

Work Area<br />

FIBER PRODUCTS<br />

Shielded<br />

Products<br />

RACK MOUNT<br />

INTERCONNECT<br />

CENTER (RIC)<br />

(pages 1.6 – 1.7)<br />

WALL MOUNT<br />

INTERCONNECT<br />

CENTER (SWIC3)<br />

(pages 1.8 – 1.9)<br />

FIBER<br />

CONNECT PANEL<br />

(FCP3)<br />

(page 1.10)<br />

FIBER<br />

MANAGEMENT<br />

TRAY (FMT)<br />

(page 1.11)<br />

Index<br />

Patch Cords,<br />

Plugs and<br />

Cable<br />

S210<br />

Products<br />

S110<br />

Products<br />

S66<br />

Products<br />

Protection<br />

Tools<br />

and<br />

Testers<br />

Standards<br />

Overview<br />

Application<br />

Guide<br />

Glossary<br />

Installation<br />

Practices<br />

Racks and<br />

Cable<br />

Management<br />

Modular<br />

Patching<br />

Product High density, High density, High density, low profile, High density, use with<br />

Applications low-to-high <strong>fiber</strong> count, low-to-medium <strong>fiber</strong> count, economical enclosure CT ® or MAX patch panels<br />

feature-rich rack mounting wall mount ideal for low <strong>fiber</strong> count, to accommodate <strong>fiber</strong> or<br />

solution rack mount applications mixed media applications<br />

Mounting Space 2-4 RMS Wall 1 RMS 1-3 RMS<br />

Capacity 6-144 <strong>fiber</strong>s 4-48 <strong>fiber</strong>s 6-36 <strong>fiber</strong>s 2-96 <strong>fiber</strong>s<br />

(ST, SC, FC, LC)<br />

Capacity 12-288 <strong>fiber</strong>s 12-96 <strong>fiber</strong>s 12-72 <strong>fiber</strong>s 2-96 <strong>fiber</strong>s<br />

(MT-RJ)<br />

Adapters Quick-Pack Quick-Pack Quick-Pack CT ® Couplers or<br />

Adapter Plates Adapter Plates Adapter Plates MAX Modules<br />

Adapter Types ST, SC, FC, MT-RJ, LC, ST, SC, FC, MT-RJ, LC, ST, SC, FC, MT-RJ, LC, ST, SC, FC, MT-RJ, LC,<br />

Hybrid ST/SC Hybrid ST/SC Hybrid ST/SC Hybrid ST/SC<br />

Adapter Multimode Multimode Multimode Multimode<br />

Performance & Singlemode & Singlemode & Singlemode & Singlemode<br />

Colors Black, White Black, White Black Black<br />

Note: 1 RMS = 44.5mm (1.75 in.)<br />

1•0<br />

T H E S I E M O N . C O M P A N Y

Fiber<br />

Products<br />

Work Area<br />

Shielded<br />

Products<br />

Modular<br />

Patching<br />

Racks and<br />

Cable<br />

Management<br />

Patch Cords,<br />

Plugs and<br />

Cable<br />

S210<br />

Products<br />

S110<br />

Products<br />

S66<br />

Products<br />

Protection<br />

Tools<br />

and<br />

Testers<br />

Standards<br />

Overview<br />

Application<br />

Guide<br />

Installation<br />

Practices<br />

SIEMON ENGINEERS ON MT-RJ PRODUCTS<br />

The Siemon Engineering team<br />

had three primary goals for<br />

our MT-RJ solution — provide<br />

the best possible product,<br />

make it installer-friendly, and<br />

ensure compatibility with as<br />

many existing Siemon <strong>products</strong><br />

as possible.<br />

Our connector design provides high performance and quick<br />

installation time. Siemon MT-RJ connectors have factory<br />

polished stubs — just prep the <strong>fiber</strong>, insert into the connector<br />

and crimp to complete the termination. Our R&D lab spent<br />

many hours validating the performance of the connector prior<br />

to release to ensure it consistently yields superior insertion loss<br />

numbers, typically 0.30 dB. The feedback from our customers<br />

has been very positive on the connector’s reliability,<br />

performance and ease of use.<br />

We also realized from the start that the MT-RJ would be very<br />

popular for <strong>fiber</strong>-to-the-desk applications. However, customer<br />

feedback told us that people did not want to use bulky<br />

faceplates or “<strong>fiber</strong>-only” work area mounting solutions. With<br />

that in mind, we designed our MT-RJ adapters to be compatible<br />

with nearly all of our work area <strong>products</strong>. Siemon MT-RJ<br />

adapters fit right alongside our copper outlets in our existing<br />

faceplates, surface mount boxes and more.<br />

We’re still continuing to expand our MT-RJ product line as<br />

well. We completed the release of our 50/125µm MT-RJ<br />

<strong>products</strong> last year and this year we introduced new, higher<br />

density adapter plates. Our 12-adapter plate (24-ports) doubles<br />

the density of the solution we offered last year. Our team isn’t<br />

done yet. Look for additional improvements and <strong>fiber</strong> <strong>products</strong><br />

from us in the future.<br />

SECTION CONTENTS<br />

MT-RJ Products. . . . . . . . . . . . . . . . . . . . . . 1.2 – 1.3<br />

MT-RJ Adapter Products . . . . . . . . . . . . . . . . . . . . 1.3<br />

MT-RJ Jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . 1.3<br />

MT-RJ Field-Installable Connectors . . . . . . . . . . . . . 1.3<br />

LC Products. . . . . . . . . . . . . . . . . . . . . . . . 1.4 – 1.5<br />

LC Adapter Products . . . . . . . . . . . . . . . . . . . . . . 1.5<br />

LC Jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5<br />

LC Field-Installable Connectors . . . . . . . . . . . . . . . 1.5<br />

Rack Mount Interconnect Center<br />

(RIC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.6 – 1.7<br />

Fiber Storage Center (FSC) . . . . . . . . . . . . . . . . . . 1.7<br />

Wall Mount Interconnect Center<br />

(SWIC3) . . . . . . . . . . . . . . . . . . . . . . . . . . 1.8 – 1.9<br />

Mini Wall Mount Interconnect Center<br />

(MINI-SWIC3) . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.9<br />

Fiber Connect Panel (FCP3). . . . . . . . . . . . . . . . . 1.10<br />

Fiber Management Tray (FMT) . . . . . . . . . . . . . . . 1.11<br />

Flat Quick-Pack Adapter Plates . . . . . . . . . . . . . 1.12<br />

Splice Trays . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.13<br />

Compression Fittings . . . . . . . . . . . . . . . . . . . . . 1.13<br />

Compression Fitting Conversion Kits . . . . . . . . . . . 1.13<br />

Bend Radius Guide . . . . . . . . . . . . . . . . . . . . . . 1.13<br />

Plug and Play Fiber Products . . . . . . . . . . 1.14 – 1.15<br />

Plug and Play Modules . . . . . . . . . . . . . . . . . . . 1.15<br />

Plug and Play Reel and Extender System . . . . . . . 1.15<br />

ST and SC Fiber Cable Assemblies:<br />

Jumpers and Pigtails . . . . . . . . . . . . . . . . . . . . . 1.16<br />

ST and SC Connectors . . . . . . . . . . . . . . . . . . . . 1.17<br />

Lightspeed Termination Products . . . . . . . 1.18 – 1.19<br />

Automated Fiber Polisher . . . . . . . . . . . . . . . . . . 1.18<br />

Lightspeed ST and SC Fiber Termination Kits. . . . . 1.19<br />

LC Fiber Termination Upgrade Kit . . . . . . . . . . . . 1.19<br />

MT-RJ Fiber Termination Kit . . . . . . . . . . . . . . . . 1.19<br />

Index<br />

Glossary<br />

1•1<br />

T H E S I E M O N . C O M P A N Y

Index<br />

Work Area<br />

Shielded<br />

Products<br />

Tools<br />

and<br />

Testers<br />

Modular<br />

Patching<br />

S110<br />

Products<br />

Fiber<br />

Products<br />

MT-RJ PRODUCTS<br />

TYPICAL INSERTION LOSS FOR MULTIMODE<br />

CONNECTORS IS 0.3dB, WELL BELOW THE<br />

0.75 dB MAXIMUM ALLOWED BY<br />

TIA/EIA-568-A AND ISO/IEC 11801<br />

SIEMON MT-RJ ADAPTER<br />

PRODUCTS ARE COMPATIBLE WITH<br />

VIRTUALLY ALL SIEMON WORK AREA<br />

MOUNTING SOLUTIONS<br />

Racks and<br />

Cable<br />

Management<br />

Patch Cords,<br />

Plugs and<br />

Cable<br />

S210<br />

Products<br />

HINGED LATCH<br />

Ever reversed polarity on a duplex<br />

<strong>fiber</strong> termination? Siemon’s hinged<br />

latch allows you to correct the<br />

mistake. Simply defeat the<br />

integrated latch, turn the<br />

connector upside down, and insert<br />

into adapter.<br />

JUMPER COMBINATIONS AVAILABLE<br />

IN MT-RJ TO MT-RJ, MT-RJ<br />

TO SC AND MT-RJ TO ST<br />

CONNECTORS AND JUMPERS<br />

ARE AVAILABLE IN 62.5/125µM<br />

AND 50/125µM OPTIONS<br />

HIGHER DENSITY – MT-RJ CONNECTORS<br />

S66<br />

Products<br />

Protection<br />

SIDE STACKABLE<br />

High-density MT-RJ MAX <br />

modules fit along side copper<br />

and multimedia outlets offering<br />

high density and a clean<br />

appearance for <strong>fiber</strong> to the desk<br />

applications.<br />

ARE ABOUT THE SIZE OF A STANDARD<br />

“RJ” STYLE JACK AND ABOUT 1/3 THE<br />

SIZE OF AN SC DUPLEX CONNECTOR<br />

USE THE SIEMON MT-RJ FIELD<br />

TERMINATION KIT TO TERMINATE<br />

CONNECTORS IN THE FIELD<br />

Standards<br />

Overview<br />

Application<br />

Guide<br />

Installation<br />

Practices<br />

Glossary<br />

FAST TERMINATION<br />

Proven no epoxy/no polish<br />

termination method greatly reduces<br />

installation time.<br />

SIEMON MT-RJ HIGHLIGHTS<br />

Siemon provides a complete line of MT-RJ Small Form Factor (SFF)<br />

interconnect <strong>products</strong> — providing the utmost in versatility and performance.<br />

Siemon MT-RJ MAX Modules, CT ® Couplers and FOB bezels are compatible<br />

with our faceplates, Fiber Outlet Boxes, and Surface Mount Boxes, enabling<br />

a wide variety of work area options. MT-RJ Quick-Pack Adapter Plates can be<br />

used in our popular rack and wall mount <strong>fiber</strong> enclosures. Connectors utilize<br />

a proven no epoxy/no polish termination method, providing optimum<br />

installation flexibility.<br />

1•2<br />

T H E S I E M O N . C O M P A N Y

Fiber<br />

Products<br />

Work Area<br />

Shielded<br />

Products<br />

Modular<br />

Patching<br />

MT-RJ ADAPTER PRODUCTS<br />

No one offers a wider variety of MT-RJ solutions for the work area. Siemon MT-RJ adapter <strong>products</strong> are compatible with<br />

our current line of MAX , CT ® Coupler and Fiber Outlet Box (FOB) <strong>products</strong>, allowing a mix of copper and <strong>fiber</strong> outlets<br />

in a single faceplate. Modular furniture, SM ® Surface Mount Boxes, and Multi-user Telecommunications Outlet<br />

Assemblies (MuTOA) solutions are also available.<br />

Siemon also provides a complete, cost effective MT-RJ solution for the telecommunications room. Our MT-RJ<br />

Quick-Pack adapter plates fit into our existing line of rack and wall mount enclosures. A variety of MT-RJ jumpers<br />

(shown below) are also available for patching to active equipment.<br />

Racks and<br />

Cable<br />

Management<br />

MT-RJ CT ® COUPLERS<br />

See page 2.6<br />

MT-RJ MAX MODULES<br />

See page 2.18<br />

MT-RJ FOB BEZELS<br />

See page 2.29<br />

MT-RJ QUICK-PACK <br />

ADAPTER PLATES<br />

See page 1.12<br />

Patch Cords,<br />

Plugs and<br />

Cable<br />

Note: For MT-RJ SM ® Surface Mount Box compatibility, see page 2.34<br />

S210<br />

Products<br />

S110<br />

Products<br />

MT-RJ JUMPERS<br />

Siemon MT-RJ jumpers are factory-terminated and 100% optically tested to assure<br />

optimum performance. Jumpers comply with TIA/EIA-568-A and ISO/IEC 11801<br />

<strong>fiber</strong> performance specifications and are available in MT-RJ to MT-RJ and hybrid<br />

MT-RJ to SC and ST options.<br />

S66<br />

Products<br />

Protection<br />

Tools<br />

and<br />

Testers<br />

PART#<br />

DESCRIPTION<br />

FJ2R-MTMT(X)MM-(XX). . . . . . MT-RJ to MT-RJ jumper, multimode (62.5/125 or 50/125µm)<br />

FJ2R-MTSA(X)MM-(XX) . . . . . . MT-RJ to ST jumper, multimode (62.5/125 or 50/125µm)<br />

FJ2R-MTSC(X)MM-(XX) . . . . . . MT-RJ to SC jumper, multimode (62.5/125 or 50/125µm)<br />

Use (X) to specify <strong>fiber</strong> type:<br />

6 = 62.5/125µm MM (gray jacket), 5 = 50/125 µm MM (orange jacket)<br />

Use (XX) to specify cable length: 01 = 1m (3.3 ft.), 03 = 3m (9.8 ft.), 05 = 5m (16.4 ft.)<br />

Notes: All jumpers are manufactured from OFNR riser grade cable that meets UL 1666<br />

Insertion loss = 0.30dB typical; return loss = 20dB minimum<br />

Custom lengths available upon request.<br />

Contact Customer Service Department for more information.<br />

Standards<br />

Overview<br />

Application<br />

Guide<br />

Installation<br />

Practices<br />

Glossary<br />

MT-RJ FIELD-INSTALLABLE CONNECTORS<br />

Siemon MT-RJ connectors pack all the benefits of duplex <strong>fiber</strong> optic performance into a compact<br />

“RJ” style design. Terminations are quick and easy, utilizing a proven no epoxy/no polish method.<br />

Siemon MT-RJ connectors feature two <strong>fiber</strong>s factory-terminated to the ferrule with protruding stubs<br />

engaged within a pre-installed splice mechanism. Just prep the cable and insert the <strong>fiber</strong>s into the<br />

connecter to complete termination. No epoxy or polish is necessary.<br />

PART #<br />

DESCRIPTION<br />

FC2-MT6MM . . . . . . . . . . . . . . MT-RJ duplex connector with pins (male), multimode 62.5/125µm<br />

FC2-MT5MM . . . . . . . . . . . . . . MT-RJ duplex connector with pins (male), multimode 50/125µm<br />

Note: Siemon MT-RJ connectors are compatible with 3.0mm round duplex jacketed or buffered <strong>fiber</strong> cables<br />

Index<br />

MT-RJ TERMINATION KIT PAGE 1.19<br />

1•3<br />

T H E S I E M O N . C O M P A N Y

Index<br />

Glossary<br />

Work Area<br />

Racks and<br />

Cable<br />

Management<br />

Patch Cords,<br />

Plugs and<br />

Cable<br />

Tools<br />

and<br />

Testers<br />

S110<br />

Products<br />

Modular<br />

Patching<br />

Shielded<br />

Products<br />

Fiber<br />

Products<br />

LC PRODUCTS<br />

S210<br />

Products<br />

HIGHER DENSITY<br />

LC connectors are about half the<br />

size of SC duplex connectors,<br />

providing greater density.<br />

FACTORY TERMINATED LC DUPLEX<br />

JUMPERS COMPLY WITH TIA/EIA 568-A<br />

AND ISO/IEC 11801 FIBER<br />

PERFORMANCE SPECIFICATIONS<br />

SIMPLEX LC CONNECTORS TERMINATE<br />

BUFFERED FIBER WHICH HELPS<br />

MAINTAIN PROPER BEND RADIUS<br />

REQUIREMENTS IN TIGHT SPACES<br />

ALL SIEMON LC ADAPTERS ARE “UNIVERSAL”<br />

AND SUPPORT EITHER SINGLEMODE OR<br />

MULTIMODE APPLICATIONS<br />

S66<br />

Products<br />

Protection<br />

PERFORMANCE AND VARIETY<br />

Siemon offers a full line of high<br />

performance singlemode and<br />

multimode LC <strong>products</strong> providing a<br />

complete solution for any<br />

installation.<br />

JUMPER COMBINATIONS<br />

AVAILABLE INCLUDE LC TO LC,<br />

LC TO SC, AND LC TO ST<br />

Standards<br />

Overview<br />

Application<br />

Guide<br />

Installation<br />

Practices<br />

FAST TERMINATION<br />

LC multimode connectors<br />

terminate in just 2 minutes using<br />

our LightSpeed Termination Kit<br />

(with LC upgrade kit) greatly<br />

reducing installation time.<br />

THE SIEMON LC SYSTEM HIGHLIGHTS<br />

Siemon LC <strong>products</strong> offer all the benefits of SC and ST connections in a Small<br />

Form Factor (SFF), high-density design. LC adapter <strong>products</strong> are compatible<br />

with our popular MAX, CT ® , FOB, and SM ® work area and telecommunications<br />

room <strong>products</strong>, providing a wide variety of installation options. LC connectors<br />

take just 2 minutes to terminate, using the Siemon LightSpeed Termination<br />

Kit. Both multimode solutions and singlemode <strong>products</strong> are available.<br />

1•4<br />

T H E S I E M O N . C O M P A N Y

Fiber<br />

Products<br />

Work Area<br />

Shielded<br />

Products<br />

Modular<br />

Patching<br />

LC ADAPTER PRODUCTS<br />

No one offers a wider variety of LC solutions for the work area. Siemon LC adapter <strong>products</strong> are compatible with our<br />

current line of MAX , CT ® Coupler, and Fiber Outlet Box (FOB) <strong>products</strong>, allowing a mix of copper and <strong>fiber</strong> outlets<br />

in a single faceplate. Modular furniture, SM ® Surface Mount Boxes, and Multi-user Telecommunications Outlet<br />

Assemblies (MuTOA) solutions are also available.<br />

Siemon also provides a complete, cost-effective LC solution for the telecommunications room. LC Quick-Pack <br />

Adapter Plates fit into our existing line of rack and wall mount enclosures. A variety of multimode and singlemode<br />

LC jumpers (shown below) are available for patching to active equipment.<br />

Racks and<br />

Cable<br />

Management<br />

Patch Cords,<br />

Plugs and<br />

Cable<br />

LC CT ® COUPLERS<br />

See page 2.6<br />

LC MAX MODULES<br />

See page 2.18<br />

LC FOB BEZELS<br />

See page 2.29<br />

LC SM ® BEZELS<br />

See page 2.34<br />

LC QUICK-PACK <br />

ADAPTER PLATES<br />

See page 1.12<br />

S210<br />

Products<br />

S110<br />

Products<br />

S66<br />

Products<br />

Protection<br />

Tools<br />

and<br />

Testers<br />

LC JUMPERS<br />

Siemon LC jumpers are factory terminated and polished, assuring optimum performance. LC jumpers are<br />

guaranteed to meet TIA/EIA-568-A and ISO/IEC 11801 <strong>fiber</strong> performance specifications, and are available in<br />

LC to LC and hybrid LC to SC and ST options. Both multimode and singlemode jumpers are available.<br />

DUPLEX<br />

FJ2-LCLC(X)MM-(XX) . . . . . . . . LC to LC multimode, 50/125 or 62.5/125µm<br />

FJ2-LCULCU-(XX) . . . . . . . . . . . LC to LC singlemode<br />

FJ2-LCSA(X)MM-(XX) . . . . . . . . LC to ST multimode, 50/125 or 62.5/125µm<br />

FJ2-LCUSAU-(XX) . . . . . . . . . . . LC to ST singlemode<br />

FJ2-LCSC(X)MM-(XX) . . . . . . . . LC to SC multimode, 50/125 or 62.5/125µm<br />

FJ2-LCUSCU-(XX) . . . . . . . . . . . LC to SC singlemode<br />

SIMPLEX<br />

FJ1-LCULCU-(XX) . . . . . . . . . . . LC to LC singlemode<br />

FJ1-LCUSAU-(XX) . . . . . . . . . . . LC to ST singlemode<br />

FJ1-LCUSCU-(XX) . . . . . . . . . . . LC to SC singlemode<br />

Use (X) to specify multimode <strong>fiber</strong> type:<br />

6 = 62.5/125µm <strong>fiber</strong> (gray jacket); 5 = 50/125µm <strong>fiber</strong> (orange jacket)<br />

Use (XX) to specify cable length:<br />

01 = 1m (3.3 ft.), 03 = 3m (9.8 ft.), 05 = 5m (16.4 ft.)<br />

Notes: Multimode performance: 0.30dB typical insertion loss; 25dB typical return loss;<br />

Singlemode performance: 0.30dB typical insertion loss; 55dB minimum return loss;<br />

All jumpers and pigtails are manufactured using OFNR riser grade cable<br />

that meets UL 1666;<br />

All connectors include ceramic ferrules.<br />

Standards<br />

Overview<br />

Application<br />

Guide<br />

Installation<br />

Practices<br />

Glossary<br />

LC FIELD-INSTALLABLE CONNECTORS<br />

Siemon LC connectors pack all the benefits of duplex <strong>fiber</strong> optic performance into a compact<br />

“RJ” style design. LC connectors are compatible with a wide variety of Siemon work area and<br />

telecommunications room solutions. Siemon LC connectors are field-installable, using the<br />

easy, fast, reliable LightSpeed termination system. LC multimode connectors terminate either<br />

62.5/125 or 50/125µm <strong>fiber</strong>.<br />

MULTIMODE<br />

FC1-LC-MM-B80. . . . . . . . . . . . LC Simplex connector, multimode, buffered <strong>fiber</strong>, beige boot<br />

FC2-LC-MM-J80. . . . . . . . . . . . LC Duplex connector, multimode, jacketed <strong>fiber</strong>, beige boot<br />

SINGLEMODE<br />

FC1-LC-SM-B02 . . . . . . . . . . . . LC Simplex connector, singlemode, buffered <strong>fiber</strong>, white boot<br />

FC1-LC-SM-J02 . . . . . . . . . . . . LC Simplex connector, singlemode, jacketed <strong>fiber</strong>, white boot<br />

Index<br />

LIGHTSPEED TERMINATION KIT PAGE 1.19, LC UPGRADE KIT PAGE 1.19<br />

1•5<br />

T H E S I E M O N . C O M P A N Y

Fiber<br />

Products<br />

Work Area<br />

RACK MOUNT INTERCONNECT CENTER (RIC)<br />

S66<br />

Products<br />

S110<br />

Products<br />

Modular<br />

Patching<br />

Racks and<br />

Cable<br />

Management<br />

Shielded<br />

Products<br />

Patch Cords,<br />

Plugs and<br />

Cable<br />

S210<br />

Products<br />

SLIDING TRAY<br />

Tray slides out the front or the rear<br />

for optimum adapter/connector<br />

access. The tray latches in center<br />

position to prevent it from moving<br />

while mating and de-mating<br />

connectors.<br />

Protection<br />

Tools<br />

and<br />

Testers<br />

Standards<br />

Overview<br />

INTEGRATED LATCHES<br />

Enable easy snap-in installation<br />

and one-finger removal of adapter<br />

plates.<br />

RUGGED 12 GAUGE<br />

ALUMINUM ALLOY<br />

CONSTRUCTION COATED<br />

WITH DURABLE PAINT<br />

FINISH<br />

INCLUDES A FRONT AND<br />

REAR LOCKING CLASP TO<br />

SECURE DOORS IN CLOSED<br />

POSITION<br />

FRONT LABELING PANEL<br />

CAN BE EASILY REMOVED<br />

VIA TWO SNAP LATCHES<br />

FOR MAXIMUM ACCESS<br />

TO CONNECTIONS<br />

SPRING LOADED QUICK-<br />

RELEASE HINGES ENABLE<br />

EASY REMOVAL OF FRONT<br />

AND REAR DOORS, BUT<br />

ONLY WHEN HINGES ARE<br />

DEFEATED, PREVENTING<br />

MISPLACED OR DAMAGED<br />

DOORS<br />

PLENTY OF SPACE AT THE<br />

FRONT TO ACCESS AND<br />

ORGANIZE FIBER<br />

Application<br />

Guide<br />

Installation<br />

Practices<br />

Glossary<br />

Index<br />

ROTATING GROMMETS<br />

Facilitates loading and retaining<br />

jumpers while minimizing<br />

microbending stress when utilizing<br />

the sliding tray.<br />

RIC HIGHLIGHTS<br />

The Siemon Rack Mount Interconnect Center has always been known for<br />

its superior <strong>fiber</strong> management capabilities and high quality. This year Siemon<br />

has made two important enhancements to the RIC product line. Maximum <strong>fiber</strong><br />

capacity has been doubled with the introduction of our new 12-adapter<br />

(24 <strong>fiber</strong>) MT-RJ Quick-Pack adapter plates. Additionally, the entire RIC<br />

product line has been redesigned to accept flat Quick-Pack adapter plates,<br />

eliminating the need to order or stock two different types of adapter plates<br />

(flat and angled).<br />

1•6<br />

T H E S I E M O N . C O M P A N Y

S66<br />

Products<br />

S110<br />

Products<br />

Work Area<br />

Racks and<br />

Cable<br />

Management<br />

Patch Cords,<br />

Plugs and<br />

Cable<br />

S210<br />

Products<br />

Modular<br />

Patching<br />

Shielded<br />

Products<br />

Fiber<br />

Products<br />

RACK MOUNT INTERCONNECT CENTER (RIC)<br />

Siemon RIC24-F, 36-F and 48-F enclosures have been redesigned to work with flat Quick-Pack adapter plates, simplifying ordering and stocking.<br />

Angled adapter plates are still available for compatibility with existing installations. Contact Siemon Customer Service for ordering details.<br />

PART #<br />

DESCRIPTION<br />

RIC24-F-(XX) . . . . . . . . . . . . 24/48/96-port Rack Mount Interconnect Center,<br />

2 RMS<br />

height: 86.6mm (3.41 in.);<br />

width: 432mm (17.00 in.);<br />

depth: 380mm (14.95 in.)<br />

PART #<br />

DESCRIPTION<br />

RIC36-F-(XX) . . . . . . . . . . . . 36/72/144-port Rack Mount Interconnect Center,<br />

2 RMS<br />

height: 86.6mm (3.41 in.);<br />

width: 432mm (17.00 in.);<br />

depth: 380mm (14.95 in.)<br />

Protection<br />

RIC48-F-(XX) . . . . . . . . . . . . 48/96/192-port Rack Mount Interconnect Center,<br />

3 RMS<br />

height: 133mm (5.25 in.);<br />

width: 432mm (17.00 in.);<br />

depth: 380mm (14.95 in.)<br />

RIC72-F-(XX) . . . . . . . . . . . . 72/144/288-port Rack Mount Interconnect Center,<br />

4 RMS<br />

height: 178mm (7.00 in.);<br />

width: 432mm (17.00 in.);<br />

depth: 380mm (14.95 in.)<br />

Tools<br />

and<br />

Testers<br />

Standards<br />

Overview<br />

Note: 1 RMS = 44.5mm (1.75 in.)<br />

Use (XX) to specify color: 01 = black, 02 = white<br />

Note: All RIC <strong>products</strong> include laser-printable labels*, cable ties, rack-mounting hardware, and pre-installed <strong>fiber</strong> management clips<br />

New RIC enclosures are not compatible with angled adapter plates.<br />

*Visit our web site or contact our Technical Support Department for labeling software.<br />

QUICK-PACK ADAPTER PLATES PAGE 1.12, SPLICE TRAYS PAGE 1.13, BEND RADIUS GUIDE PAGE 1.13<br />

Application<br />

Guide<br />

Installation<br />

Practices<br />

Glossary<br />

Index<br />

FIBER STORAGE CENTER<br />

The Siemon 3 RMS rack mount Fiber Storage Center (FSC) is typically utilized in tandem<br />

with a Rack Mount Interconnect Center (RIC). Fiber jumpers exiting the front of the RIC<br />

are routed into the FSC to store slack. The <strong>fiber</strong> management is simple but effective, and<br />

is mounted on a tray that slides out the front for easy access to the storage area.<br />

PART #<br />

DESCRIPTION<br />

FSC3-(XX) . . . . . . . . . . . . . . . . . Fiber Storage Center, 3 RMS<br />

height: 133mm (5.25 in.);<br />

width: 432mm (17.00 in.);<br />

depth: 380mm (14.95 in.)<br />

Note: 1 RMS = 44.5mm (1.75 in.)<br />

Use (XX) to specify color: 01 = black, 02 = white<br />

1•7<br />

T H E S I E M O N . C O M P A N Y

Fiber<br />

Products<br />

Work Area<br />

WALL MOUNT INTERCONNECT CENTER (SWIC3)<br />

Standards<br />

Overview<br />

Patch Cords,<br />

Plugs and<br />

Cable<br />

S210<br />

Products<br />

S110<br />

Products<br />

Racks and<br />

Cable<br />

Management<br />

Modular<br />

Patching<br />

Shielded<br />

Products<br />

EASY ACCESS<br />

Doors on enclosures and jumper<br />

guard swing open a full 180° to<br />

provide complete front and side<br />

access.<br />

S66<br />

Products<br />

Protection<br />

Tools<br />

and<br />

Testers<br />

DUAL-LEVEL FIBER MANAGERS<br />

Incorporates two independent<br />

levels of storage to enable the<br />

<strong>fiber</strong> to be routed at levels that<br />

correspond to the adapters.<br />

CONVENIENT LABELING<br />

SYSTEM INCLUDES<br />

REMOVABLE CLEAR<br />

LABEL HOLDERS FOR<br />

STORING AND<br />

PROTECTING FIBER<br />

DOCUMENTATION<br />

DOORS ON<br />

ENCLOSURE AND<br />

JUMPER GUARD CAN<br />

BE ORDERED WITH<br />

INDEPENDENT KEY<br />

LOCK OR LATCHING<br />

OPTIONS<br />

OPTIONAL SPLICE TRAY<br />

BRACKET AVAILABLE<br />

FOR MOUNTING<br />

MULTIPLE SPLICE<br />

TRAYS<br />

QUICK-PACK <br />

ADAPTER PLATES ARE<br />

AVAILABLE WITH SC,<br />

ST, FC, MT-RJ, OR LC<br />

ADAPTERS<br />

DUST-PROOFING<br />

GROMMETS INCLUDED<br />

INTEGRATED HINGED<br />

FIBER GUARD<br />

PROVIDES JUMPER<br />

PROTECTION AND<br />

MANAGEMENT<br />

Application<br />

Guide<br />

Installation<br />

Practices<br />

Glossary<br />

Index<br />

SNAP-IN ADAPTER PLATES<br />

Utilizes same Quick-Pack adapter<br />

plates as RIC enclosures with<br />

integrated latches for snap-in<br />

installation and one finger<br />

removal.<br />

SWIC3 HIGHLIGHTS<br />

The Wall Mount Interconnect Center (SWIC3) is a cost-effective <strong>fiber</strong><br />

enclosure designed to manage and connect up to 96 <strong>fiber</strong>s. The low-profile,<br />

compact design makes it ideal for telecommunications closets or other<br />

installation areas where wall space is at a premium. The adapter mounting<br />

method is standardized via the utilization of the same snap-in Quick-Pack <br />

adapter plates used in our family of Rack Mount Interconnect Centers (RICs).<br />

This year all Siemon <strong>fiber</strong> enclosures, including the SWIC3, have been<br />

modified to accept just flat Quick-Pack adapter plates, simplifying ordering<br />

and eliminating the need to stock two different types of plates.<br />

1•8<br />

T H E S I E M O N . C O M P A N Y

Tools<br />

and<br />

Testers<br />

Work Area<br />

Shielded<br />

Products<br />

Modular<br />

Patching<br />

Racks and<br />

Cable<br />

Management<br />

Patch Cords,<br />

Plugs and<br />

Cable<br />

S210<br />

Products<br />

S110<br />

Products<br />

S66<br />

Products<br />

Protection<br />

Fiber<br />

Products<br />

WALL MOUNT INTERCONNECT CENTER (SWIC3)<br />

Siemon SWIC3 enclosures have been redesigned to work with flat Quick-Pack adapter plates, simplifying ordering and stocking. Please note this new<br />

design is not compatible with angled adapter plates. Angled adapter plates are still available for compatibility with existing installations. Contact<br />

Siemon Customer Service for ordering details.<br />

PART #<br />

DESCRIPTION<br />

SWIC3-(X)-(XX) . . . . . . . . . . . . . 24/48/96-port Wall Mount Interconnect Center. Includes dual-level <strong>fiber</strong><br />

managers, port designation labels and removable pocket, dust-proofing<br />

grommets, strain relief hardware, cable ties, and mounting hardware.<br />

height: 311mm (12.25 in);<br />

width: 311mm (12.25 in);<br />

depth: 82.6mm (3.25 in)<br />

Use 1st (X) to specify type of lock on the enclosure: A = key lock A, C = thumb-turn latch<br />

Use 2nd (XX) to specify color: 01 = black, 02 = white<br />

PART #<br />

DESCRIPTION<br />

SWIC3G-(X)(X)-(XX). . . . . . . . . . 24/48/96-port Wall Mount Interconnect Center with integrated jumper guard.<br />

Includes dual-level <strong>fiber</strong> managers, port designation labels and<br />

removable pocket, dust-proofing grommets, strain relief hardware,<br />

cable ties, and mounting hardware.<br />

height: 311mm (12.25 in);<br />

width: 406mm (16 in);<br />

depth: 82.6mm (3.25 in)<br />

Use 1st (X) to specify type of lock on the enclosure (left) door: A = key lock A, C = thumb-turn latch<br />

Use 2nd (X) to specify type of lock on the guard (right) door:A = key lock A, B = key lock B, C = thumb-turn latch<br />

Use (XX) to specify color: 01 = black, 02 = white<br />

Note: New SWIC3 <strong>products</strong> are only compatible with flat Quick-Pack adapter plates<br />

PART #<br />

DESCRIPTION<br />

TRAY-B-(XX) . . . . . . . . . . . . . . . Bracket for mounting splice trays to SWIC3 base<br />

Use (XX) to specify color: 01 = black, 02 = white<br />

FIBER ADAPTER PLATES PAGE 1.12, SPLICE TRAYS PAGE 1.13, BEND RADIUS GUIDE PAGE 1.13<br />

Standards<br />

Overview<br />

Application<br />

Guide<br />

Installation<br />

Practices<br />

Glossary<br />

Index<br />

MINI WALL MOUNT INTERCONNECT CENTER (MINI-SWIC3)<br />

The Mini-SWIC3 enables the economical interconnection of <strong>fiber</strong> in locations where wall space is<br />

limited while still providing many of the popular, installer-friendly features of the SWIC3. By accepting<br />

two flat Quick-Pack adapter plates, the MINI-SWIC3 can accommodate from 6–48 <strong>fiber</strong>s. Also included<br />

are dust-proofing grommets to provide protection from contaminants and bend radius guides to ensure<br />

optimal storage of <strong>fiber</strong> slack.<br />

PART #<br />

DESCRIPTION<br />

SWIC3-M-(XX) . . . . . . . . . . . . . 6/24/48-port Mini Wall Mount Interconnect Center<br />

height: 218.4mm (8.6 in.);<br />

width: 185.4mm (7.3 in.);<br />

depth: 82.6mm (3.25 in.)<br />

Use (XX) to specify color: 01 = black, 02 = white<br />

Note: The MINI-SWIC3 is only compatible with flat Quick-Pack adapter plates.<br />

1•9<br />

T H E S I E M O N . C O M P A N Y

Work Area<br />

Racks and<br />

Cable<br />

Management<br />

Modular<br />

Patching<br />

Fiber<br />

Products<br />

FIBER CONNECT<br />

PANEL (FCP3)<br />

OPTIONAL SPLICE TRAYS CAN BE<br />

Shielded<br />

Products<br />

HIGH DENSITY<br />

FCP3 enclosures accommodate up<br />

to 72 <strong>fiber</strong>s in only 1 RMS on a 19<br />

inch rack.<br />

LANCED TABS PROVIDE CONVENIENT<br />

CABLE ANCHOR POINTS FOR<br />

INCOMING JACKETED CABLES<br />

MOUNTED TO MANAGE AND PROTECT<br />

EITHER MECHANICAL OR FUSION SPLICES<br />

Patch Cords,<br />

Plugs and<br />

Cable<br />

S210<br />

Products<br />

SLIDING TRAY<br />

The FCP3-DWR (drawer version)<br />

features a tray that slides out from<br />

the front or rear, providing easy<br />

access to <strong>fiber</strong> connections even<br />

on fully loaded racks.<br />

FRONT FIBER CLIPS MANAGE<br />

UP TO 36 DUPLEX FIBER JUMPERS<br />

(72 FIBERS TOTAL)<br />

REAR FIBER CLIPS MANAGE<br />

CABLE SLACK WHILE<br />

MAINTAINING MINIMUM BEND<br />

RADIUS REQUIREMENTS<br />

S110<br />

Products<br />

LABEL HOLDER PROTECTS FIBER JUMPERS<br />

AND IS READILY REMOVABLE VIA RELEASE OF<br />

FACTORY-INSTALLED SNAP-LATCHES<br />

S66<br />

Products<br />

Protection<br />

Tools<br />

and<br />

Testers<br />

Standards<br />

Overview<br />

FIBER CONNECT PANEL (FCP3) HIGHLIGHTS<br />

The Fiber Connect Panel (FCP3-DWR and FCP3-RACK) rack mount enclosures<br />

economically connect, protect, and manage up to 72 <strong>fiber</strong>s within one Rack<br />

Mount Space (RMS). The FCP3 has been redesigned this year to accept the<br />

same flat Quick-Pack adapter plates used in our Rack and Wall Mount<br />

Interconnect Centers. The FCP3-DWR makes access to the connections easy<br />

via a tray that slides out the front or the rear.<br />

Application<br />

Guide<br />

QUICK-PACK ADAPTER PLATES PAGE 1.12, SPLICE TRAYS PAGE 1.13,<br />

COMPRESSION FITTINGS PAGE 1.13<br />

Installation<br />

Practices<br />

Glossary<br />

Index<br />

PART #<br />

DESCRIPTION<br />

FCP3-DWR . . . . . . . . . . . . . . . . 6- to 72-port Fiber Connect Panel with sliding tray.<br />

Includes mounting brackets, housing/tray, <strong>fiber</strong> managers, grommets,<br />

label holders, and labels<br />

height: 43.2mm (1.7 in.);<br />

width: 482.6mm (19.0 in.);<br />

depth: 355.6mm (14.0 in.)<br />

FCP3-RACK. . . . . . . . . . . . . . . . 6- to 72-port Fiber Connect Panel with fixed tray.<br />

Includes mounting brackets, housing/cover, <strong>fiber</strong> managers and grommet<br />

height: 43.2mm (1.7 in.);<br />

width: 482.6mm (19.0 in.);<br />

depth: 241.3mm (9.5 in.)<br />

FCP3-RACK<br />

1•10<br />

T H E S I E M O N . C O M P A N Y

Patch Cords,<br />

Plugs and<br />

Cable<br />

Work Area<br />

Racks and<br />

Cable<br />

Management<br />

Fiber<br />

Products<br />

FIBER MANAGEMENT<br />

TRAY (FMT)<br />

REAR COVER SECURED BY<br />

HEAVY DUTY MAGNETS TO<br />

ENABLE KEYLESS ENTRY<br />

Shielded<br />

Products<br />

Modular<br />

Patching<br />

HIGH DENSITY<br />

The Fiber Management Tray<br />

can be used with Siemon’s<br />

MAX patch panels for higher<br />

density <strong>fiber</strong> and multimedia<br />

applications.<br />

TRAY IS 18-GAUGE<br />

STEEL WITH A<br />

BLACK FINISH THAT<br />

MATCHES CT ®<br />

AND MAX PATCH<br />

PANELS<br />

FIBER CAN BE ROUTED IN FROM<br />

THE SIDES OR REAR OF THE TRAY<br />

OUR PATENT PENDING DUAL FIBER<br />

MANAGEMENT CLIPS ARE USED TO STORE<br />

SLACK FIBERS WHILE MAINTAINING<br />

MINIMUM BEND RADIUS REQUIREMENTS<br />

S210<br />

Products<br />

S110<br />

Products<br />

FIBER ACCESS<br />

2 and 3 RMS trays include a rear<br />

hinged door to provide convenient<br />

access to <strong>fiber</strong>.<br />

EACH 2-PORT COUPLER COMES WITH A<br />

RED AND A BLUE ICON TAB AS WELL AS<br />

TWO ICON TABS TO MATCH THE COUPLER<br />

COLOR. OTHER ICON COLORS ARE<br />

AVAILABLE FOR ADDITIONAL COLOR<br />

CODING OF INDIVIDUAL PORTS<br />

CT ® OR MAX PANELS AND TRAY<br />

AVAILABLE IN 1, 2, AND 3 RMS AND<br />

WHICH ACCOMMODATE UP TO 96<br />

FIBER PORTS<br />

OPTIONAL ST, SC OR ST/SC<br />

TRANSPARENT COVER<br />

PROVIDES IMPROVED<br />

VISIBILITY DURING<br />

INSTALLATION<br />

ADAPTER COUPLERS ARE AVAILABLE<br />

IN 2- OR 4-PORT VERSIONS<br />

S66<br />

Products<br />

Protection<br />

Tools<br />

and<br />

Testers<br />

Standards<br />

Overview<br />

Application<br />

Guide<br />

Installation<br />

Practices<br />

Glossary<br />

Index<br />

ADDITIONAL FEATURES (NOT SHOWN)<br />

• THREADED ROD AND WING NUT INCLUDED TO<br />

SECURE MULTIPLE SPLICE TRAYS TO THE BASE<br />

• THE TRAY CAN BE QUICKLY ASSEMBLED TO CT ® OR<br />

MAX PANELS WITHOUT OCCUPYING ADDITIONAL<br />

RACK SPACE<br />

• STRAIN RELIEF LUGS ARE PROVIDED TO SECURE<br />

CENTRAL STRENGTH MEMBER OF FIBER CABLE<br />

FIBER MANAGEMENT TRAY (FMT) HIGHLIGHTS<br />

The family of Fiber Management Trays (FMT) are an economical solution for<br />

managing <strong>fiber</strong> cable slack and splice trays. The management trays have been<br />

designed to easily retrofit any standard 1, 2, or 3 RMS CT ® or MAX Series<br />

Patch Panel and can organize up to 96 <strong>fiber</strong>s. The tray is only 254mm (10 in.)<br />

deep, allowing it to readily fit into cabinet enclosures.<br />

CT ® PANELS PAGES 4.8 – 4.9, CT ® COUPLERS PAGES 2.2 – 2.7,<br />

MAX PANELS PAGES 4.6 – 4.7, MAX MODULES PAGES 2.14 – 2.19,<br />

FIBER SPLICE TRAYS PAGE 1.13<br />

PART # DESCRIPTION RMS HEIGHT WIDTH DEPTH<br />

CT-FMT-16-(X). . . . . . . . . . . . . . Fiber tray for 16-port CT ® Panel or MAX Panel . . . . . . . .1 . . . . . . . .43.2mm (1.7 in.) . . . . . .432mm (17 in.) . . .254mm (10 in.)<br />

CT-FMT-24-(X). . . . . . . . . . . . . . Fiber tray for 24-port CT ® Panel or MAX Panel . . . . . . . .2 . . . . . . . .86.4mm (3.4 in.) . . . . . .432mm (17 in.) . . .254mm (10 in.)<br />

CT-FMT-32-(X). . . . . . . . . . . . . . Fiber tray for 32-port CT ® Panel or MAX Panel . . . . . . . .2 . . . . . . . .86.4mm (3.4 in.) . . . . . .432mm (17 in.) . . .254mm (10 in.)<br />

CT-FMT-48-(X). . . . . . . . . . . . . . Fiber tray for 48-port CT ® Panel . . . . . . . . . . . . . . . . . . . .3 . . . . . . .129.5mm (5.1 in.) . . . . . .432mm (17 in.) . . .254mm (10 in.)<br />

FIBER MANAGEMENT TRAYS PREASSEMBLED TO CT ® PANELS<br />

CT-FMTA-16-(X) . . . . . . . . . . . . Fiber tray preassembled to a 16-port CT ® Panel . . . . . . .1 . . . . . . . .43.2mm (1.7 in.) . . . . . .432mm (17 in.) . . .254mm (10 in.)<br />

CT-FMTA-24-(X) . . . . . . . . . . . . Fiber tray preassembled to a 24-port CT ® Panel . . . . . . .2 . . . . . . . .86.4mm (3.4 in.) . . . . . .432mm (17 in.) . . .254mm (10 in.)<br />

CT-FMTA-32-(X)* . . . . . . . . . . . Fiber tray preassembled to a 32-port CT ® Panel . . . . . . .2 . . . . . . . .86.4mm (3.4 in.) . . . . . .432mm (17 in.) . . .254mm (10 in.)<br />

CT-FMTA-48-(X)* . . . . . . . . . . . Fiber tray preassembled to a 48-port CT ® Panel . . . . . . . .3 . . . . . . .129.5mm (5.1 in.) . . . . . .432mm (17 in.) . . .254mm (10 in.)<br />

Use (X) to specify inclusion of splice tray: blank = none, 1 = fusion, 2 = mechanical, 3 = fusion with sleeve<br />

*Note: for FMT’s ordered with splice trays: 16- and 24-port versions include one 24-splice tray; 32- and 48-port versions include two 24-splice trays.<br />

1•11<br />

T H E S I E M O N . C O M P A N Y

Installation<br />

Practices<br />

S66<br />

Products<br />

Patch Cords,<br />

Plugs and<br />

Cable<br />

Fiber<br />

Products<br />

Work Area<br />

Shielded<br />

Products<br />

Modular<br />

Patching<br />

FLAT QUICK-PACK ADAPTER PLATES<br />

RIC-F-SA6-(XX) . . . . . . . . . .<br />

3 duplex ST adapters<br />

(6 <strong>fiber</strong>s) and icon<br />

pockets<br />

RIC-F-SA8-(XX) . . . . . . . . . .<br />

4 duplex ST adapters<br />

(8 <strong>fiber</strong>s) and icon<br />

pockets<br />

RIC-F-SA12-(XX). . . . . . . . . .<br />

6 duplex ST adapters<br />

(12 <strong>fiber</strong>s, not shown)<br />

Note: all Siemon RIC, SWIC, MINI-SWIC and FCP3<br />

<strong>fiber</strong> enclosures have been redesigned to work<br />

exclusively with flat Quick-Pack adapter plates.<br />

Racks and<br />

Cable<br />

Management<br />

RIC-F-SC6-(XX). . . . . . . . . . .<br />

3 duplex SC adapters<br />

(6 <strong>fiber</strong>s) and icon<br />

pockets<br />

RIC-F-SC8-(XX). . . . . . . . . . .<br />

4 duplex SC adapters<br />

(8 <strong>fiber</strong>s) and icon<br />

pockets<br />

RIC-F-SC12-(XX). . . . . . . . . .<br />

6 duplex SC adapters<br />

(12 <strong>fiber</strong>s)<br />

S210<br />

Products<br />

S110<br />

Products<br />

RIC-F-MT12-(XX) . . . . . . . . .<br />

6 duplex MT-RJ adapters<br />

(12 <strong>fiber</strong>s)<br />

RIC-F-MT16-(XX) . . . . . . . . .<br />

8 duplex MT-RJ adapters<br />

(16 <strong>fiber</strong>s)<br />

RIC-F-MT24-(XX) . . . . . . . . .<br />

12 duplex MT-RJ adapters<br />

(24 <strong>fiber</strong>s)<br />

Protection<br />

Tools<br />

and<br />

Testers<br />

Standards<br />

Overview<br />

Application<br />

Guide<br />

RIC-F-AC6-(XX) . . . . . . . . . .<br />

3 duplex ST-SC adapters<br />

(6 <strong>fiber</strong>s, front side = SC)<br />

and icon pockets<br />

RIC-F-CA6-(XX) . . . . . . . . . .<br />

3 duplex SC-ST adapters<br />

(6 <strong>fiber</strong>s, front side = ST<br />

not shown)<br />

RIC-F-FC6-(XX) . . . . . . . . . . .<br />

6 FC adapters (6 <strong>fiber</strong>s)<br />

and icon pockets<br />

RIC-F-AC8-(XX) . . . . . . . . . .<br />

4 duplex ST-SC adapters<br />

(8 <strong>fiber</strong>s, front side = SC)<br />

and icon pockets<br />

RIC-F-CA8-(XX) . . . . . . . . . .<br />

4 duplex SC-ST adapters<br />

(8 <strong>fiber</strong>s, front side = ST<br />

not shown)<br />

RIC-F-FC8-(XX) . . . . . . . . . . .<br />

8 FC adapters (8 <strong>fiber</strong>s)<br />

and icon pockets<br />

RIC-F-LC(X)12-(XX) . . . . . . . .<br />

6 duplex LC adapters<br />

(12 <strong>fiber</strong>s)<br />

Use (X) to specify LC<br />

adapter color:<br />

blank = beige,<br />

U = blue<br />

RIC-F-BLNK-(XX) . . . . . . . . .<br />

Blank adapter plate<br />

Glossary<br />

Index<br />

Use (XX) to specify Adapter Plate color: 01 = black, 02 = white<br />

Add “-C” for ceramic sleeve option on SC, ST, FC, and LC <strong>fiber</strong> adapters.<br />

Each adapter plate with icon pockets includes red, blue, color-matching, and clear icons with paper labels.<br />

All adapters are “universal” to support multimode and singlemode <strong>fiber</strong> applications.<br />

Note: All Siemon RIC, SWIC3, MINI-SWIC3 and FCP3 enclosures have been redesigned to work exclusively with flat adapter plates.<br />

Angled plates are still available for existing installations. Contact our Customer Service Department for ordering information.<br />

1•12<br />

T H E S I E M O N . C O M P A N Y

Work Area<br />

Fiber<br />

Products<br />

Shielded<br />

Products<br />

Modular<br />

Patching<br />

Racks and<br />

Cable<br />

Management<br />

Patch Cords,<br />

Plugs and<br />

Cable<br />

S210<br />

Products<br />

S110<br />

Products<br />

S66<br />

Products<br />

SPLICE TRAYS<br />

These aluminum trays can be ordered with either fusion, mechanical or fusion with sleeve splice holders and<br />

come with a clear, snap-on polycarbonate cover. The standard tray holds up to 24 splices. For tight areas, a minitray<br />

is available which accommodates up to 12 splices. Trays can be stacked for high-density applications.<br />

STANDARD TRAY DIMENSIONS:<br />

height: 103mm (4.07 in.);<br />

width: 298mm (11.75 in.);<br />

depth: 8.13mm (0.32 in.)<br />

MINI TRAY DIMENSIONS:<br />

height: 103mm (4.07 in.);<br />

width: 179mm (7.06 in.);<br />

depth: 8.13mm (0.32 in.)<br />

PART #<br />

DESCRIPTION<br />

TRAY-(X) . . . . . . . . . . . . . . . . . . Standard <strong>fiber</strong> splice tray for up to 24 splices<br />

TRAY-M-(X). . . . . . . . . . . . . . . . Mini <strong>fiber</strong> splice tray for up to 12 splices<br />

TRAY-R-4 . . . . . . . . . . . . . . . . . Splice tray for ribbon <strong>fiber</strong> (up to 144 <strong>fiber</strong>s)<br />

Use (X) to specify type of splice holder: 1 = fusion, 2 = mechanical, 3 = fusion with sleeve<br />

Notes: Mechanical splice holders are compatible with GTE elastomeric, Siecor Camsplice ® , Norland splice and Lucent CSL.<br />

Fusion with sleeve splice holders can accommodate sleeve diameters from 1.5mm (0.059 in.) to 2mm (0.079 in.).<br />

Standard Fusion splice holders are designed for 900 micron buffered <strong>fiber</strong>s or 250 micron coated <strong>fiber</strong>s.<br />

COMPRESSION FITTINGS<br />

Compression fittings are utilized as an alternate method for securing cables to FCP3 <strong>fiber</strong><br />

enclosures. Compression fittings resist water pressure up to 70psi. Acme threads on the<br />

body prevent skipping, allowing for faster installations of lock-nuts. Polymer material<br />

resists salt water, weak acids, gasoline, alcohol, oil, greases and common solvents.<br />

PART #<br />

DESCRIPTION<br />

CF-(XX) . . . . . . . . . . . . . . . . . . . Compression fitting<br />

Use (XX) to specify size: 40 = Used for 24-<strong>fiber</strong> cable; 51 = Used for 36-<strong>fiber</strong> cable;<br />

60 = Used for 72-<strong>fiber</strong> cable; 70 = Used for 96-<strong>fiber</strong> cable<br />

Protection<br />

Tools<br />

and<br />

Testers<br />

Standards<br />

Overview<br />

Application<br />

Guide<br />

Installation<br />

Practices<br />

Glossary<br />

Index<br />

COMPRESSION FITTING CONVERSION KITS<br />

Conversion kits provide a means of securing <strong>fiber</strong> in Siemon rack and wall mount enclosures.<br />

These fittings are liquid tight up to 70 psi water pressure and resist salt water, weak acids,<br />

gasoline, alcohol, oil, grease and common solvents.<br />

PART #<br />

DESCRIPTION<br />

CF-(XX)-(X)P-(XX). . . . . . . . . . . . Compression fitting conversion kit<br />

Use first (XX) to specify cable accommodation size:<br />

40 = 24-<strong>fiber</strong> distribution cable, 51 = 36-<strong>fiber</strong> distribution cable, 60 = 72-<strong>fiber</strong> distribution cable (for RIC72<br />

enclosures only)<br />

Note: For 96-<strong>fiber</strong> distribution cable, use Siemon p/n CF-70 compression fitting and mount directly to RIC or<br />

SWIC3 enclosures.<br />

Use (X) to specify enclosure type: R = kit for RIC rack mount enclosures, S = kit for SWIC3 and SWIC3G wall<br />

mount enclosures.<br />

Use 2nd (XX) to specify color: 01 = black, 02 = white.<br />

BEND RADIUS GUIDE<br />

For use in Siemon <strong>fiber</strong> enclosures, the Bend Radius Guide (BRG2) maintains optimal<br />

<strong>fiber</strong> bend radius. No tools are required for installation. The BRG2 locks into the bottom<br />

of Siemon enclosures via a quarter-turn post on the base. The BRG2 is divided into two<br />

sections for independent management of multiple <strong>fiber</strong>s. It can also be stacked using<br />

quarter-turn post to provide additional management options.<br />

PART #<br />

DESCRIPTION<br />

BRG2-02. . . . . . . . . . . . . . . . . . Bend radius guide, white<br />

CF-(XX)-SP-01<br />

CF-(XX)-RP-01<br />

RACK MOUNT INTERCONNECT CENTER PAGES 1.6 – 1.7, WALL MOUNT INTERCONNECT CENTER PAGES 1.8 – 1.9<br />

SWIC3 with conversion kit<br />

RIC24-F with conversion kit<br />

1•13<br />

T H E S I E M O N . C O M P A N Y

Index<br />

Work Area<br />

Shielded<br />

Products<br />

Modular<br />

Patching<br />

Glossary<br />

Tools<br />

and<br />

Testers<br />

Racks and<br />

Cable<br />

Management<br />

Fiber<br />

Products<br />

PLUG AND PLAY<br />

FIBER PRODUCTS<br />

PRE-TERMINATED FIBER<br />

All <strong>fiber</strong> connections are factory<br />

terminated and tested, enabling<br />

faster installation to meet tight<br />

deadlines.<br />

CONNECTIVITY IS COMPLETED BY<br />

PLUGGING 6- OR 12-FIBER MPO<br />

CONNECTORS IN PLUG AND PLAY<br />

MODULES WHICH CAN BE SNAPPED INTO<br />

WALL OR RACK MOUNT ENCLOSURES<br />

FACTORY TERMINATION SIGNIFICANTLY<br />

REDUCES LABOR COSTS DURING INSTALLATION<br />

AND ENSURES 100% HIGH PERFORMANCE<br />

AND RELIABILITY OF THE INSTALLED SYSTEM<br />

AVAILABLE IN 50/125µM<br />

AND 62.5/125µM FIBER<br />

WITH EITHER ST OR SC<br />

INTERFACES<br />

Patch Cords,<br />

Plugs and<br />

Cable<br />

S210<br />

Products<br />

PLUG AND PLAY MODULES<br />

Modules feature integrated<br />

latches for snap-in installation and<br />

single-finger removal.<br />

SLIDE-OUT DRAWER FOR<br />

EASY FRONT ACCESS<br />

S110<br />

Products<br />

FRONT FIBER CLIPS MANAGE<br />

UP TO 18 DUPLEX FIBER<br />

JUMPERS (36 FIBERS TOTAL)<br />

NO CONNECTORS, TERMINATION<br />

KITS OR CONSUMABLES REQUIRED<br />

S66<br />

Products<br />

Protection<br />

RACK MOUNT SOLUTION<br />

Siemon’s Plug and Play modules<br />

can be used in the Fiber Connect<br />

Panel (FCP3) for a rack mount<br />

solution. See page 1.10 for the<br />

FCP3. (available in drawer or rack<br />

versions)<br />

INSTALLER-FRIENDLY SNAP-IN<br />

DESIGN ENSURES FAST AND<br />

RELIABLE INSTALLATION<br />

LABEL HOLDER PROTECTS FIBER<br />

JUMPERS AND IS READILY REMOVABLE<br />

VIA RELEASE OF SNAP-LATCHES<br />

Standards<br />

Overview<br />

Application<br />

Guide<br />

Installation<br />

Practices<br />

WALL MOUNT SOLUTION<br />

Plug and Play modules can be<br />

used in Siemon’s Wall Mount<br />

Interconnect Center (SWIC3) for<br />

a wall mount solution. See pages<br />

1.8 – 1.9 for the SWIC3.<br />

PLUG AND PLAY FIBER HIGHLIGHTS<br />

The Siemon Company introduces a solution for labor intensive <strong>fiber</strong><br />

installation and termination — the <strong>fiber</strong> Plug and Play system. This system<br />

eliminates all of the labor and logistics of standard <strong>fiber</strong> installations by<br />

providing a pre-terminated, pre-tested <strong>fiber</strong> optic connection system.<br />

1•14<br />

T H E S I E M O N . C O M P A N Y

Application<br />

Guide<br />

Protection<br />

S210<br />

Products<br />

Fiber<br />

Products<br />

Work Area<br />

Shielded<br />

Products<br />

PLUG AND PLAY MODULES<br />

The Plug and Play modules snap into Siemon wall and FCP3 rack mount enclosures to<br />

provide individual port access when transitioning from MPO connectors at the rear.<br />

The modules are factory terminated and tested for 100% guaranteed performance with either<br />

ST or SC interfaces. Installer-friendly snap-in design ensures fast and reliable installation.<br />

6- or 12-port modules are available.<br />

Modular<br />

Patching<br />

Racks and<br />

Cable<br />

Management<br />

PART #<br />

DESCRIPTION<br />

PP6-SA(X)MM-(XX). . . . . . . . . . 6-port, multimode ST Plug and Play module<br />

PP6-SC(X)MM-(XX) . . . . . . . . . . 6-port, multimode SC Plug and Play module<br />

PP12-SC(X)MM-(XX) . . . . . . . . . 12-port, multimode SC Plug and Play module<br />

Patch Cords,<br />

Plugs and<br />

Cable<br />

Use (X) to specify <strong>fiber</strong> type: 5 = 50/125µm multimode; 6 = 62.5/125µm multimode<br />

Use (XX) to specify module color: 01 = black, 02 = white<br />

12-Port<br />

SC Module<br />

6-Port<br />

ST Module<br />

PLUG AND PLAY REEL AND EXTENDER SYSTEM<br />

S110<br />

Products<br />

S66<br />

Products<br />

The cable for the Plug and Play system is provided on cable reels with 6- or 12-<strong>fiber</strong> MPO<br />

connectors on each end. The cable is available in 50/125µm or 62.5/125µm multimode riser<br />

grade <strong>fiber</strong> cable and can be ordered in any length. A cable pulling eye on one end protects<br />

the <strong>fiber</strong> during installation and facilitates fast installation. Cable extenders are also available<br />