Micro-D - Cinch Connectors

Micro-D - Cinch Connectors

Micro-D - Cinch Connectors

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Connector Performance Specifications<br />

Property Requirement Test Method<br />

Current Rating<br />

3 amp maximum<br />

Dielectric Withstanding Voltage:<br />

Sea level 900 VAC MIL-STD-1344, Method 3001<br />

70,000 Feet 300 VAC<br />

Contact Resistance 8 milliohms maxiumum MIL-STD--202, Method 307<br />

Low Level Contact Resistance 32 milliohms maximum MIL-STD-1344, Method 3002<br />

Insulation Resistance 5000 megohms minimum MIL-STD-1344, method 3003<br />

Magnetic Permeability 2.0 µ maximum ASTM A342<br />

Mating Force (10 ounces max) X (# of contacts) MIL-DTL-83513<br />

Unmating Force (0.5 ounces min) X (# of contacts) MIL-DTL-83513<br />

Contact Retention 5 pounds minimum MIL-STD-1344, Method 2007<br />

Operating Temperature -55 o C. to +150 o C.<br />

Durability 500 mating cycles minimum MIL-DTL-83513, Para. 4.5.16<br />

Salt Spray (Corrosion) 48 hours MIL-STD-1344, Method 2004, Condition E<br />

Outgassing 1.0% Total Mass Loss (TML) SP-R-0022 (NASA) or ASTM E595<br />

0.1% total volatile<br />

Condensible Material (TVCM)<br />

Crimp Tensile Stength:<br />

Wire Type M22759/11 5 pounds minimum MIL-DTL-83513, Para. 4.5.20<br />

Wire Type M22759/33<br />

10 pounds minimum<br />

Fluid Immersion Perchloroethelyne, 2 hours MIL-DTL-83513, Para. 7.5.18<br />

Lubricating Oil (MIL-L-23649), 20 hrs.<br />

Coolanol 25, 1 hour<br />

Shock 50G’s MIL-STD-1344, Method 2004, Condition E<br />

Vibration 20G’s MIL-STD-1344, Method 2005, Condition IV

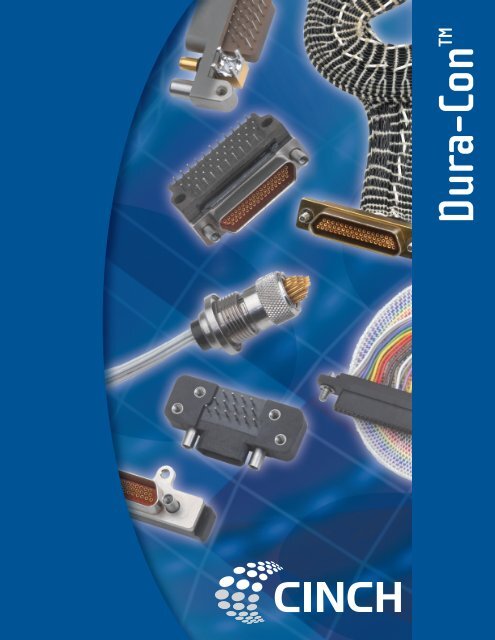

<strong>Micro</strong> D <strong>Connectors</strong><br />

Connector Performance Specifications<br />

Weight and Space<br />

Property Requirement Test Method<br />

Current Dense Rating centerline spacing and 3 lightweight amp maximumaterials make Dura-Con the<br />

ideal connector where weight and space must be kept to a minimum while<br />

Dielectric Withstanding Voltage:<br />

maintaining maximum reliability.<br />

Sea level 900 VAC MIL-STD-1344, Method 3001<br />

Shock and Vibration<br />

70,000 Feet 300 VAC<br />

The <strong>Cinch</strong> Dura-Con contact, due to its low mass, provides electrical continuity<br />

Contact under Resistance extreme conditions of shock 8 milliohms and vibration. maxiumum MIL-STD--202, Method 307<br />

High Reliability Twist Pin Contact<br />

Low Level Contact Resistance 32 milliohms maximum MIL-STD-1344, Method 3002<br />

Insulation The heart Resistance of the Dura-Con system 5000 is megohms the twist minimum pin contact. This MIL-STD-1344, contact is made method from 3003<br />

a precision miniature spring cable with a welded tip. The expanded cable creates a<br />

Magnetic Permeability 2.0 µ maximum ASTM A342<br />

helix of seven spring members around the pin maintaining contact with the socket no<br />

Mating matter Force what radial forces are applied. (10 ounces This max) spring X (# of contacts) cable can withstand MIL-DTL-83513 many flex<br />

cycles without exhibiting any evidence of metal fatigue. Reliable mating is further<br />

Unmating Force (0.5 ounces min) X (# of contacts) MIL-DTL-83513<br />

ensured by protecting the pin contact in a tightly controlled recessed cavity.<br />

Contact Retention 5 pounds minimum MIL-STD-1344, Method 2007<br />

Operating Temperature -55 o C. to +150 o C.<br />

Durability 500 mating cycles minimum MIL-DTL-83513, Para. 4.5.16<br />

Salt Spray (Corrosion) 48 hours MIL-STD-1344, Method 2004, Condition E<br />

Applications<br />

Outgassing 1.0% Total Mass Loss (TML) SP-R-0022 (NASA) or ASTM E595<br />

<strong>Cinch</strong> Dura-Con connectors are MIL-DTL-83513 qualified and are used in<br />

0.1% total volatile<br />

missile systems, avionics, radar, minefield, space defense and many other military<br />

applications where reliability is Condensible crucial. This Material highly (TVCM) adaptable design has also seen<br />

many commercial applications including medical, telecommunications, computer,<br />

Crimp Tensile Stength:<br />

down-hole and transportation.<br />

Wire Type M22759/11 5 pounds minimum MIL-DTL-83513, Para. 4.5.20<br />

Termination Options<br />

Wire Type M22759/33 10 pounds minimum<br />

Insulated Wire – Available in 24 to 30 gauge wire at custom lengths<br />

Fluid specified Immersion by the customer. Perchloroethelyne, 2 hours MIL-DTL-83513, Para. 7.5.18<br />

Lubricating Oil (MIL-L-23649), 20 hrs.<br />

Uninsulated Wire – Allows greater flexibility when installing the connector.<br />

Available in 24 to 28 gauge wire. Coolanol 25, 1 hour<br />

Shock 50G’s MIL-STD-1344, Method 2004, Condition E<br />

Solder Cups – Used in applications that require the lowest contact<br />

Vibration resistance and require termination 20G’s by the customer.<br />

MIL-STD-1344, Method 2005, Condition IV<br />

Metal Sh<br />

n<br />

n<br />

n<br />

MIL-D<br />

Availa<br />

High s<br />

n Ideal fo<br />

n<br />

n<br />

Moistu<br />

Availa<br />

Plastic S<br />

n<br />

n<br />

n<br />

n<br />

n<br />

MIL-D<br />

Availa<br />

Econo<br />

Smalle<br />

Conne<br />

Printed<br />

n<br />

n<br />

n<br />

n<br />

MIL-D<br />

Availa<br />

For us<br />

Three<br />

<strong>Micro</strong> Ed<br />

n<br />

n<br />

n<br />

n<br />

Availa<br />

184 po<br />

Design<br />

Meets<br />

Connect<br />

n<br />

n<br />

n<br />

Availa<br />

Reduc<br />

Conne<br />

<strong>Micro</strong>m<br />

n<br />

n<br />

n<br />

Provid<br />

Availa<br />

Guide

2006<br />

MILAERO-505/03.06