rtf model - CML Distribution

rtf model - CML Distribution

rtf model - CML Distribution

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

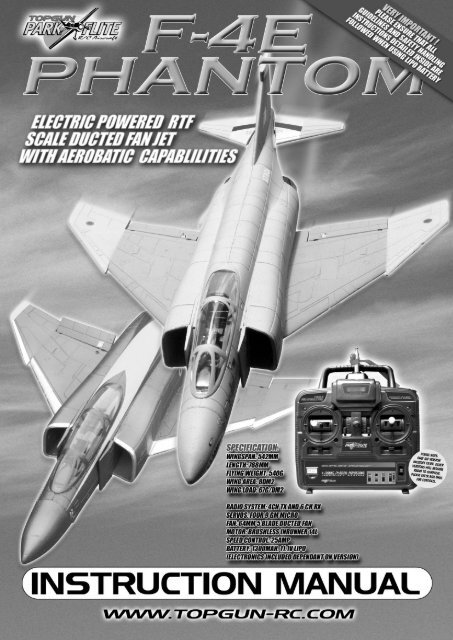

F-4E Phantom<br />

RTF MODEL<br />

Congratulations on purchasing the Top Gun F-4E Phantom RTF<br />

INSTRUCTION MANUAL<br />

Top Gun Park Flite are proud to present this high performance<br />

ducted fan sport scale <strong>model</strong> of the F4 Phantom. Supplied in<br />

three versions, TGP0200 is a Ready to Fly package with<br />

transmitter, receiver, LiPo flight battery and charger, TGP0201 is<br />

an Almost Ready to Fly package without transmitter and<br />

receiver and TGP0202 is an Airframe only with ducted fan and<br />

motor.<br />

This <strong>model</strong> has been designed with the utmost care and<br />

attention to detail to produce a light weight, strong, and<br />

realistic looking <strong>model</strong> aeroplane with excellent flying<br />

characteristics.<br />

We feel that this <strong>model</strong> emulates the style, performance and<br />

character of its full size counterpart.<br />

This <strong>model</strong> is a high performance miniature aircraft that allows<br />

intermediate to advanced <strong>model</strong> pilots to perform both scale<br />

and aerobatic manoeuvers. The light weight, large wing area<br />

and powerful ducted fan motor assembly allow the <strong>model</strong> to fly<br />

both fast and slow, with high speed rolls and tight turns while<br />

maintaining full control.<br />

These instructions assume a reasonable level of competence<br />

for both building and flying and we recommend that the <strong>model</strong><br />

is flown at a recognised club with frequency control measures<br />

and suitable third party insurance.<br />

The owner – pilot of this <strong>model</strong> should take note of regulations,<br />

and local bylaws before flying this aircraft.<br />

Please take time to read through these instructions before<br />

commencing assembly. We list operations in order of works to<br />

reduce the risk of damage during assembly.<br />

PLEASE READ THROUGH ALL WARNINGS AND<br />

GUIDELINES FOR LIPO HANDLING AT THE<br />

BACK OF THE MANUAL BEFORE USE.<br />

An 11.1V 1300 mAh lithium polymer (LiPo) battery and charger<br />

is included as part of this package and these cells must be<br />

operated with care to prevent the risk of fire.<br />

LiPo Batteries are soft cased and can be easily damaged by<br />

sharp items, puncturing of the soft casing can cause fires and<br />

we recommend that they are stored and handled carefully.<br />

Use only a LiPo rated charger, set to a maximum of 3 cells<br />

(11.1v) and no more than 1 amp charge current.<br />

Remove battery from the aircraft and charge on a non<br />

flammable, non conductive surface<br />

Due to continual and ongoing product development the parts<br />

shown in the manual may differ from those supplied.<br />

2

KIT CONTENTS AND DESCRIPTION (DEPENDANT ON VERSION)<br />

(RTF contents pictured)<br />

1. Fuselage with ducted fan, motor, Electronic<br />

Speed Control (ESC) receiver, elevator servo<br />

and steering servo with pushrods.<br />

2. Fuselage nosecone section<br />

3. Clear cockpit canopy.<br />

4. Two wing panels with factory hinged ailerons<br />

and aileron servos installed<br />

5. Two horizontal stabiliser panels<br />

6. Elevator joiner assembly.<br />

7. Vertical stabiliser-fin<br />

8. Main undercarriage and nose gear assemblies<br />

with wheels and mounting hardware<br />

9. Four function fully proportional 35Mhz<br />

transmitter<br />

10. Pushrods, control horns, linkage and fixing<br />

hardware<br />

11. Tube of adhesive<br />

12. LiPo Battery 3 cell 11.1V 1300 mAh (15c)<br />

13. Mains power 3 cell LiPo charger<br />

14. Self adhesive decals.<br />

SPECIFICATIONS<br />

Specifications<br />

Wing span 542mm (21.34”)<br />

Length 788mm (31”)<br />

Wing Area 8Dm_ (124 sq inches)<br />

Weight<br />

Radio<br />

Motor<br />

WARNING<br />

540 g (19 Ounces)<br />

4 function 35Mhz PPM<br />

4 Qty micro servos<br />

25 Amp brushless ESC<br />

Brushless in runner<br />

5 blade 64mm ducted fan<br />

11.1v 1300mAh LiPo battery<br />

This R/C aircraft is not a toy and can<br />

result in serious bodily harm, injury and<br />

property damage if misused.<br />

Fly only in open areas and at preferably<br />

BMFA recognised clubs and sites.<br />

3

SECTION 1: KIT CONTENTS AND DESCRIPTION<br />

MAIN FUSELAGE ASSEMBLY.<br />

Supplied complete with ducted<br />

fan unit using high performance<br />

brushless in runner motor.<br />

25Amp Electronic Speed Control<br />

(ESC) pre-wired to motor with<br />

extended leads to forward<br />

battery box and hinged cover.<br />

35mhz 6 channel receiver<br />

installed inside hidden<br />

compartment and pre-wired to<br />

aileron, steering and elevator<br />

servo.<br />

Built in grip for hand launching.<br />

Nose Cone<br />

Clear vacuum formed canopy<br />

Wing Panels, supplied as two<br />

halves.<br />

Each wing half includes factory<br />

hinged aileron pre-drilled ready<br />

to receive control horn.<br />

Wing underside has<br />

undercarriage fixing plate and<br />

factory fitted aileron servo.<br />

4

Two horizontal stabiliser panels pre-drilled ready to<br />

receive control horn.<br />

Main Undercarriage and nose gear units.<br />

Two sets of lightweight wheels fixed onto wire<br />

torque rod undercarriage.<br />

Four clamp plates and 8 fixing screws for securing<br />

to wing plates.<br />

Nose gear steering arm is factory installed in<br />

Note left and right panels are identified by joiner<br />

recess on lower face only.<br />

Horizontal stabiliser joiners with fixing screws.<br />

Control horn with clamp connector, backplate and<br />

fixing screws<br />

Elevator push rod.<br />

fuselage.4 function fully proportional 35Mhz<br />

transmitter.<br />

Vertical stabiliser-fin.<br />

Available on 5 alternate 35 MHz frequencies.<br />

5

Aileron pushrods, control horns, and fixing<br />

hardware.<br />

Two short pushrods with clevis connector.<br />

ADHESIVE<br />

5ml tube of foam safe adhesive.<br />

Note pierce end of tube with pin in screw on lid.<br />

Two Control horns with back plates and four fixing<br />

screws.<br />

SECTION 2: BATTERY AND CHARGER<br />

BATTERY AND CHARGER<br />

WARNING<br />

(items may differ from<br />

contents)<br />

BATTERY AND CHARGER<br />

11.1V (3 cell) 1300mAh (C) LiPo Battery rated at<br />

15C max discharge. Fitted with 3.5mm gold plug<br />

and socket.<br />

12v Lipo Balance charger. Easy to use automatic<br />

Lithium Polymer charger for 2-3 cell packs.<br />

A lithium polymer (LiPo) battery rated at 15C<br />

(19.5A) discharge and fast charger is included<br />

as part of this package, these cells must be<br />

operated with care to prevent the risk of fire.<br />

LiPo Batteries are soft cased and can be easily<br />

damaged by sharp items, puncturing of the soft<br />

casing can cause fires and we recommend that<br />

they are stored and handled carefully.<br />

Use only the supplied balance charger or a LiPo<br />

rated charger set to a maximum of 3 cells<br />

(11.1v) and less than 1 amp charge current.<br />

Remove battery from the aircraft and charge on<br />

a non flammable, non conductive surface<br />

6

SECTION 3: TRANSMITTER<br />

The FM4DP is a fully proportional 4 function 35Mhz<br />

transmitter.<br />

The kit includes a high performance 11.1V (3 cell)<br />

1300mAh LiPo Battery rated at 20C (19.5 amp) max<br />

discharge.<br />

The kit includes a high performance 11.1V (3 cell)<br />

1300mAh LiPo Battery rated at 20C (19.5 amp) max<br />

discharge.<br />

This must be charged using the dedicated 12v DC<br />

input 0.8 Amp output fast charger and connecting<br />

lead.<br />

Connect the crocodile lead connectors to a 12V DC<br />

power source (a 12V car battery is ideal), ensuring<br />

that correct polarity is observed. Red is positive (+)<br />

and Black is Negative (-).<br />

Connect the lead into the matching socket of the<br />

battery charger and the Red LED will illuminate.<br />

Push the white balance plug of the battery into the<br />

matching charger output socket to commence<br />

charging.<br />

The green LED illuminates to confirm charging and<br />

switches off when the charge is complete<br />

A full charge will take between 1 and 2 hours.<br />

The transmitter is supplied in a Mode 2<br />

configuration. Mode 2 is also known as Throttle<br />

Left.<br />

The left stick controls Throttle and rudder<br />

movement.<br />

The right stick controls aileron and elevator<br />

movement.<br />

Battery state is indicated by a green and red bank<br />

of coloured LED.<br />

A flashing red LED and audible alarm indicates<br />

dangerously low voltage. The <strong>model</strong> should be<br />

landed immediately to replace batteries before all<br />

control is lost.<br />

Frequency control is by removable crystal, The<br />

transmitter frequency is identified on the crystal<br />

holder located on the front of the transmitter.<br />

CHARGE IN A TIN AND AWAY FROM COMBUSTABLE<br />

MATERIAL. DO NOT CHARGE UNATTENDED. GO TO<br />

REAR OF MANUAL FOR FURTHER GUIDES<br />

7

8 off AA size dry cells or high capacity Nimh<br />

batteries (not included) must be inserted before<br />

operation.<br />

Remove the rear cover and install batteries into the<br />

battery tray as directed by the moulded in polarity<br />

(+ & -) markings.<br />

A small panel of four small slide switches is set on<br />

the front panel of the transmitter.<br />

These are electronic servo reversing switches and<br />

should be adjusted to give the correct control<br />

surface deflections relative to stick movements.<br />

SECTION 4: ASSEMBLY<br />

Locate the main fuselage assembly and nose cone<br />

and dry fit together ensuring that the parts locate<br />

together.<br />

Insert undercarriage into mounting plate located in<br />

the wing panels and fix in place with saddles and<br />

four self tapping screws.<br />

Note wheel is located outwards towards rear of the<br />

wing.<br />

Position the nose wheel assembly over the collet in<br />

the forward fuselage.<br />

The flat machined in the wire should align with the<br />

grub screw with the coil facing forward.<br />

Insert wire in collet and tighten grub screw with<br />

Allen key.<br />

Apply adhesive to the contact faces and press firmly<br />

together<br />

Wipe off any excess adhesive and allow to dry.<br />

Locate the main undercarriage assemblies, clamp<br />

plates and fixing screws.<br />

8

Locate the control horns and fixings.<br />

Position the control horn over the recess moulded in<br />

the aileron<br />

Ensure that horn is on the bottom surface and apply<br />

a drop of adhesive before pressing in place.<br />

Fix in place with two screws and backplate.<br />

Locate the aileron pushrods<br />

Locate the two horizontal stabiliser panels, elevator<br />

joiners and fixing screws.<br />

Position the joiners the recess moulded in the<br />

elevator panels. The spikes will key into the foam.<br />

Ensure that joiner is on the bottom surface of both<br />

panels and apply adhesive before pressing in place.<br />

Wipe off excess adhesive and allow to dry before<br />

proceeding further.<br />

Connect Z-bend of short pushrod to outer hole of<br />

servo arm.<br />

Clip clevis connector into hole in horn furthest from<br />

aileron surface.<br />

Locate the vertical stabiliser-Fin and test fit onto<br />

rear of fuselage.<br />

Apply adhesive to the contact faces and press firmly<br />

together and use pins or tape to hold in place.<br />

Wipe off any excess adhesive and allow to dry.<br />

9

Remove excess length of pushrod with wire<br />

cutters.<br />

Test fit the two horizontal stabiliser panels.<br />

The joiners pass through a tube at the rear of the<br />

fuselage.<br />

The panels should be angled downwards. (anhedral)<br />

Fit the two fixing screws to lock the joiner in place.<br />

Test fit the two wing panels on to the fuselage<br />

Apply adhesive to the contact faces on the wing and<br />

fuselage and press firmly together use pins or tape<br />

to hold in place.<br />

Wipe off any excess adhesive and allow to dry.<br />

Repeat procedure for the other wing panel.<br />

SECTION 5: FINAL SET UP<br />

Locate the elevator pushrod, control horn, fixings<br />

and backplate.<br />

position the control horn on the moulded recess on<br />

the elevator in line with the servo arm and fix in<br />

place with screws and backplate.<br />

Insert the pushrod through the clamp connectors in<br />

the servo arm and control horn.<br />

WARNING<br />

With the battery connected and the <strong>model</strong><br />

switched on the motor is live. The Electronic<br />

speed controller (ESC) will go through its start<br />

up procedure and will emit a series of beeps<br />

while it configures throttle positions. The<br />

motor could start unexpectedly and we<br />

recommend that the <strong>model</strong> is restrained during<br />

handling.<br />

Ensure that transmitter is switched on with throttle<br />

down and all trims central.<br />

Open the hinged battery bay door by turning the<br />

catches.<br />

Insert into the battery and ensure that battery and<br />

ESC leads project out of the aperture.<br />

Connect the battery and ESC leads together<br />

Red-red and Black-Black and close the battery<br />

cover using the catches to lock it in place.<br />

Align elevators with mould line in fuselage and<br />

gently tighten connectors until the controls are<br />

checked.<br />

Uncoil the receiver aerial and fully extend to hang<br />

off the rear of the aircraft.<br />

10

Adjust aileron surfaces if required by unclipping the<br />

pushrod clevis connectors and winding in or out to<br />

suit.<br />

The steering servo and elevators can also be<br />

adjusted on the clamp connectors.<br />

Ensure that trims and sticks are central, loosen<br />

clamp screw and tighten down firmly when<br />

centralized.<br />

Run the aircraft along a smooth surface to confirm<br />

the steering is central.<br />

When happy with the nose wheel alignment apply a<br />

few drops of adhesive around the canopy frame and<br />

press in place. 5.3<br />

CHECK THE BALANCE.<br />

Check that all controls operate in the correct<br />

manner and that all control surfaces are level.<br />

The <strong>model</strong> should sit level or slightly nose down<br />

when supported upside down from a point 85mm<br />

back from the point where the wing leading edge<br />

joins the fuselage. This corresponds to a point<br />

midway along the top surface air brakes panel line.<br />

DO NOT ATTEMPT TO FLY WITH A REARWARD<br />

BALANCE POINT<br />

85mm<br />

11

SECTION 6: FIRST FLIGHT<br />

BEFORE THE TEST FLIGHT<br />

On completion of the <strong>model</strong> take time to test the<br />

<strong>model</strong> in the workshop.<br />

Switch on the transmitter,<br />

connect the battery and<br />

double check that all<br />

surfaces operate in the<br />

correct manner without<br />

stalled servos.<br />

Check for adequate range<br />

with and without motor<br />

running.<br />

If everything is okay, take it to the flying field and<br />

rig it up again.<br />

Always follow the frequency control procedures of<br />

your local flying site and ensure that you have<br />

adequate third party insurance cover.<br />

Repeat the full pre flight inspection before flying.<br />

12<br />

FLYING<br />

WARNING<br />

Do not advance the throttle unless the <strong>model</strong> is<br />

restrained. With the powerful motor-fan<br />

combination producing up to 500g of thrust, the<br />

<strong>model</strong> will accelerate across a smooth surface<br />

very quickly.<br />

The F4 Phantom is capable of 5 to 10 minute flight<br />

times and can R.O.G (Rise Off Ground) from smooth<br />

metalled runways or very closely cut grass. A hand<br />

launch will be required If flying from normal grass<br />

or without undercarriage. .<br />

It is aerobatic and able to<br />

perform loops and rolls<br />

but due to its light weight<br />

it should not be flown in<br />

wind greater than 10mph.<br />

Control throws set during<br />

assembly will produce a<br />

<strong>model</strong> capable of flying<br />

smooth scale like performance and medium to high<br />

speed aerobatic manoeuvers.<br />

The control surface movements can be increased by<br />

moving the clevis connectors nearer to the control<br />

surfaces.<br />

To reduce movements move the pushrod<br />

connections nearer to the servo on the output arms<br />

and further out along the control surfaces horns.<br />

ENJOY YOURSELF BUT ALWAYS FLY SAFE!

ADDENDUM<br />

REMOVAL OF UNDERCARRIAGE<br />

For an improved in flight performance and<br />

appearance the tricycle undercarriage can be<br />

removed.<br />

Removal of the undercarriage assemblies reduces<br />

both the weight and drag of the <strong>model</strong> increasing<br />

the power to weight ratio and top speed, the wing<br />

loading also drops slightly which improves<br />

manoeuvrability.<br />

The decision should not be taken lightly though.<br />

Without an undercarriage the <strong>model</strong> must be hand<br />

launched firmly into wind and belly landings will be<br />

the norm.<br />

While the aircraft can be built without<br />

undercarriage, we recommend that the <strong>model</strong> is<br />

assembled and flown with wheels initially to allow<br />

time to familiarise with the aircrafts performance.<br />

While the main wheels and nose gear can easily be<br />

removed and replaced, removal of the nose wheel<br />

steering servo requires ‘minor surgery’.<br />

Removal of the main gears is a simple task<br />

involving removal of the fixing screws, clamp plates<br />

and formed undercarriage assemblies. Similarly the<br />

nose wheel is removed by removing the grubscrew<br />

and pulling the wire out of the collet.<br />

To remove the steering servo slide a thin <strong>model</strong>ling<br />

blade between the canopy and fuselage to break the<br />

glue joints and remove the canopy<br />

Disconnect the nose gear steering servo from the<br />

receiver.<br />

Disconnect the steering push rod and slide a thin<br />

<strong>model</strong>ling blade between the servo and fuselage to<br />

break the glue joints. Remove the servo<br />

Refit the canopy with a few drops of adhesive.<br />

With the main wheels removed the moulded in grip<br />

beneath the fuselage provides an ideal finger and<br />

thumb hold for hand launching.<br />

13

IMPORTANT SAFETY INSTRUCTIONS AND WARNINGS – READ BEFORE USE<br />

• Lithium Polymer batteries can be volatile. Whilst some of the instances listed below are rare, they can occur and it is<br />

important for you to be aware of how to handle such situations. Failure to read and follow the below instructions may<br />

result in fire, personal injury and damage to property if charged or used improperly.<br />

• Top Gun Park Flite, its distributors or retailers assume no liability for failures to comply with these warnings and safety<br />

guidelines.<br />

• By using this battery, the buyer assumes all risks associated with lithium batteries. If you do not agree with these<br />

conditions, return the battery immediately before use.<br />

• The final use and preparation of the battery pack is ultimately beyond our control and those of our representatives and<br />

retaillers. Your decision to use this product incorporates your agreement that you have read and understood the safety<br />

precautions listed below and on each battery pack, and that you agree to accept full responsibility for any injury, loss or<br />

damage resulting from all circumstances surrounding your use or misuse of this product.<br />

GENERAL GUIDELINES AND WARNINGS<br />

1) Only use the supplied specific Lithium Polymer charger. Do not use a NiMH or NiCd charger - Failure to do so may a cause fire, which<br />

may result in personal injury and property damage.<br />

2) Never charge batteries unattended. When charging LiPo batteries you should always remain in constant observation to monitor the<br />

charging process and react to potential problems that may occur.<br />

4) If at any time you witness a battery starting to balloon or swell up, discontinue charging process immediately, disconnect the battery<br />

and observe it in a safe place for approximately 15 minutes. This may cause the battery to leak, and the reaction with air may cause the<br />

chemicals to ignite, resulting in fire.<br />

5) Since delayed chemical reaction can occur, it is best to observe the battery as a safety precaution. Battery observation should occur in a<br />

safe area outside of any building or vehicle and away from any combustible material.<br />

6) Wire lead shorts can cause fire! If you accidentally short the wires, the battery must be placed in a safe area for observation for<br />

approximately 15 minutes. Additionally, if a short occurs and contact is made with metal (such as rings on your hand), severe injuries<br />

may occur due to the conductibility of electric current.<br />

7) A battery can still ignite even after 10 minutes.<br />

8) In the event of a crash, you must remove battery for observation and place in a safe open area away from any combustible material for<br />

approximately 15 minutes.<br />

11) Never store or charge battery pack inside your car in extreme temperatures, since extreme temperature could ignite fire.<br />

CHARGING PROCESS<br />

1) Never charge batteries unattended.<br />

2) Charge in an isolated area, away from any flammable materials and inside a closed tin or lipo charge sack. In the unlikely event that the<br />

battery may fail and ignite, this procedure will ensure that a possible battery fire is contained and limiting any possible damage.<br />

3) Let battery cool down to ambient temperature before charging.<br />

DISCHARGE<br />

Ensure that you adhere to the warning beeps on your transmitter and land the <strong>model</strong> accordingly. Do not fly until the battery is completely<br />

discharged as damage will occur.<br />

STORAGE & TRANSPORTATION<br />

1) Store battery at room temperature between 40 and 80 degrees F for best results.<br />

2) Do not expose battery pack to direct sunlight (heat) for extended periods.<br />

3) When transporting or temporarily storing in a vehicle, temperature range should be greater than 20 degrees F but no more than 150<br />

degrees F.<br />

4) Storing battery at temperatures greater than 170 degrees F for extended periods of time (more than 2 hours) may cause damage to<br />

battery and possible fire.<br />

BATTERY LIFE<br />

Batteries that lose 20% of their capacity must be removed from service and disposed of properly. Discharge the battery to 3V/Cell, making sure<br />

output wires are insulated, then wrap battery in a bag for disposal.<br />

PRODUCT WARRANTY<br />

Product warranty is limited to original defects in material and workmanship. Warranty does not cover collateral damage. Due to the nature and<br />

use of the battery there is no term warranty. Misuse, abuse, incorrect charging and other inappropriate use of this product are not covered<br />

under warranty.<br />

14

TOP GUN PARKFLITE F4 PHANTOM SPARE PARTS LIST<br />

TGP0200B F4E BLUE READY-TO-FLY EDF JET<br />

TGP0200M F4E MILITARY READY-TO-FLY EDF JET<br />

TGP0201B F4E BLUE ARTF EDF JET (NO TX/RX)<br />

TGP0201M F4E MILITARY ARTF EDF JET(NOTX/RX)<br />

TGP0202B F4E BLUE AIRFRAME ONLY EDF JET<br />

TGP0202M F4E MILITARY AIRFRAME ONLY EDF JET<br />

TGP0205B F-4E FUSELAGE (BLUE/YELL)<br />

TGP0205M F-4E FUSELAGE (MILITARY)<br />

TGP0206B F-4E WING SET (BLUE/YELL)<br />

TGP0206M F-4E WING SET (MILIATRY)<br />

TGP0207B F-4E VERTICAL WING SET (BLUE/YELL)<br />

TGP0207M F-4E VERTICAL WING SET (MILITARY)<br />

TGP0208B F-4E TAIL WING SET (BLUE/YELL)<br />

TGP0208M F-4E TAIL WING SET (MILITARY)<br />

TGP0209B F-4E PVC PARTS (BLUE/YELL)<br />

TGP0209M F-4E PVC PARTS (MILITARY)<br />

TGP0210 F-4E CONTROL ROD & PLASTIC PARTS<br />

TGP0211 F-4E LANDING GEAR<br />

TGP0512 TRANSMITTER<br />

TGP0532 INRUNNER MOTOR<br />

TGP0527 1300mah 20c 3S LIPO<br />

TGP0092 65MM DUCTED FAN UNIT<br />

TGE0001 ETRONIX 8.4G SERVO<br />

TGE0051 ETRONIX 25AMP SPEED CONTROL<br />

DISTRIBUTORS OF QUALITY MODEL & HOBBY PRODUCTS<br />

Saxon House, Saxon Business Park, Hanbury Road, Bromsgrove, Worcestershire. B60 4AD. England<br />

Tel: +44 (0) 1527 575349 Fax: + 44 (0) 1527 570536<br />

E-mail: info@cmldistribution.co.uk<br />

Web site: www.cmldistribution.co.uk<br />

15