Prospekt Mailing Stretch hood - Beumer.com

Prospekt Mailing Stretch hood - Beumer.com

Prospekt Mailing Stretch hood - Beumer.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

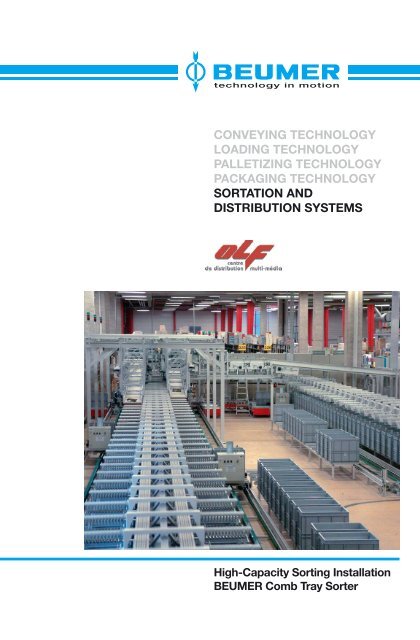

CONVEYING TECHNOLOGY<br />

LOADING TECHNOLOGY<br />

PALLETIZING TECHNOLOGY<br />

PACKAGING TECHNOLOGY<br />

SORTATION AND<br />

DISTRIBUTION SYSTEMS<br />

High-Capacity Sorting Installation<br />

BEUMER Comb Tray Sorter

BEUMER High-Capacity Sortation Technology<br />

in Operation at OLF<br />

OLF, part of the Payot Naville<br />

Distribution Holding Company, is the<br />

Swiss market leader for the distribution<br />

of books, maps and multimedia<br />

products in French, English and<br />

German, efficiently expediting<br />

delivery from the publisher to the<br />

reader.<br />

Located in the heart of Switzerland,<br />

OLF is able to handle shipments<br />

to all European countries, making it<br />

a reliable partner for book stores,<br />

discount stores and specialty shops<br />

in Switzerland as well as for over<br />

1,200 international publishers.<br />

By constantly improving their<br />

logistics facilities, OLF is able to<br />

successfully meet both market<br />

requirements and customers’<br />

expectations.<br />

To allow the customer to focus on<br />

their own <strong>com</strong>mercial activities,<br />

OLF provides third party logistics<br />

services which include:<br />

Data exchange between stores<br />

and the OLF logistics center<br />

via electronic data exchange<br />

Stock level based order generation<br />

Recording of orders through OLF<br />

Labeling as per customer<br />

specifications<br />

Shipping items using customer<br />

specific packaging<br />

Online order confirmation<br />

Electronic invoice/packing list<br />

delivery

BEUMER’s Comb Tray Sorter – a Key Component<br />

for Modern Warehouse Management Systems<br />

BEUMER’s sorter system assures<br />

reliable and consistent performance<br />

of OLF’s distribution center.<br />

Some of the key features of the<br />

system are:<br />

high sorting capacity<br />

accurate tracking of the articles<br />

grouping of back orders<br />

customer specific price and<br />

barcode labeling<br />

printing of shipping documents.<br />

Feeding lines<br />

The feeding lines consist of label<br />

print and apply stations and conveyors<br />

that gently transport the labeled<br />

articles to the BEUMER Comb<br />

Tray Sorter. The labeling stations<br />

are able to both singulate stacked<br />

product as well as to handle single<br />

articles. The articles are identified<br />

by barcode and labeled individually<br />

for each customer. The print data<br />

of the labels are transmitted in real<br />

time to the labeling stations by the<br />

BEUMER Sorting System (BeSS).<br />

The BEUMER Comb Tray Sorter<br />

The BEUMER Comb Tray Sorter<br />

is based on the modular, proven<br />

design of BEUMER’s Tilt Tray Sorter.<br />

The tilting element has been<br />

replaced by a pair of <strong>com</strong>b trays<br />

which are placed to the left and<br />

right side of the carriage. By means<br />

of a pneumatically activated brush,<br />

the product is swept off the <strong>com</strong>b<br />

tray and drops into the tote below.<br />

The system is driven by the<br />

BEUMER Sorter Control (BSC)<br />

and the BEUMER Sorting System<br />

(BeSS), connected via network to<br />

the warehouse management<br />

system (WMS).<br />

Tote Replenishment and<br />

Retrieval System<br />

Each destination of the BEUMER<br />

Comb Tray Sorter consists of a tote<br />

which - when the order is <strong>com</strong>plete -<br />

is automatically replaced by a<br />

high-speed tote replenishment and<br />

retrieval system.<br />

Each tote has a unique barcode<br />

(“license plate”) assigned to the<br />

corresponding order.<br />

If the BSC initiates a tote exchange,<br />

the full tote is replaced with an<br />

empty one and conveyed by a railguided<br />

vehicle for further transport<br />

to the packing stations.<br />

The BEUMER Comb Tray<br />

Sorter’s most impressive<br />

features:<br />

gentle article handling<br />

sturdy design<br />

highly efficient handling of flat<br />

products<br />

gentle discharge of all products<br />

low maintenance carriages<br />

low maintenance and low wear<br />

linear motor drives<br />

low noise operation<br />

modular design

Technical data:<br />

Sorted Items: Books, maps and multimedia products<br />

Destinations: 201<br />

Destination type: Totes with spring loaded bottom<br />

Sorter speed: 1.4 m/s<br />

Sorter capacity: 12,600 trays per hour<br />

Peak capacity: 10,800 items per hour (under ideal conditions,<br />

the feeding lines are limited to 3,600 items per hour)<br />

Induction capacity: max. 3,600 items per hour, for each induction<br />

Labeling lines: max. 3,600 items per hour with automatic unstacking and labeling<br />

Tote staging: 4 loading and unloading vehicles for feeding and discharging of the<br />

tote destinations; repack desks, printer and dispenser for packing slips<br />

Controls: BSC (BEUMER Sorter Control) by Industrial PLC with distributed I/O<br />

BeSS (BEUMER Sorting System) by HP-ProLiant with RAID 1 function,<br />

software Windows 2000 Professional,<br />

BeOS (BEUMER Operator System) for visualization and customerspecific<br />

sorting functions<br />

Sorter Destinations<br />

Document Printer / Dispenser<br />

The information contained in this this brochure merely serves as as a non-binding description of our products products and and is without without guarantee.<br />

Binding information, in particular relating to to capacity data and suitability suitability for specific specific applications, can only be provided within the framework of of concrete inquiries. inquiries. E510 0707<br />

BEUMER Maschinenfabrik<br />

GmbH & Co. KG<br />

Postfach 12 54<br />

D - 59267 Beckum/Germany<br />

Tel.: +49 - (0) 25 21 - 24 0<br />

Fax: +49 - (0) 25 21 - 24 280<br />

E-Mail: BEUMER@BEUMER.<strong>com</strong><br />

Internet: www.BEUMER.<strong>com</strong><br />

Tote Replenishment & Retrieval System<br />

Future Destinations<br />

Pack Stations<br />

BEUMER Corporation<br />

Branchburg, NJ 08876/ USA<br />

Tel.: +1 (732) 560-8222<br />

Fax: +1 (732) 563-0905<br />

BEUMER Ltda.<br />

Campinas - SP/Brazil<br />

Tel.: +55 (0) 19-3243-1700<br />

Fax: +55 (0) 19-3242-1411<br />

Empty Tote Storage<br />

Special Handling Workstations<br />

BEUMER S.a.r.l.<br />

St. Ouen L’Aumone/France<br />

Tel.: +33 (0) 1-3464-2520<br />

Fax: +33 (0) 1-3037-6883<br />

Full Tote Take-Away<br />

Conveyor<br />

BEUMER Technology India<br />

Private Limited • Mumbai /India<br />

Tel.: +91 (0) 22-2577-2874<br />

Fax: +91 (0) 22-2577-2876<br />

Overhead Induction Lines<br />

Asia Representative Office<br />

of BEUMER • Bangkok/Thailand<br />

Ph.: +66 (0) 2731-7190<br />

Fax: +66 (0) 2731-7194<br />

��������������<br />

��������������<br />

���� ����<br />

����� +86 (0) 21-6921-3788<br />

����� +86 (0) 21-6921-3628<br />

BEUMER<br />

Comb Tray<br />

Sorter<br />

Australian Representative Office<br />

of BEUMER • North Ryde / Australia<br />

Ph.: +61(0) 2-9889-5561<br />

Fax: +61(0) 2-9889-5562<br />

OOO BEUMER<br />

Moscow/Russia<br />

Tel.: +7 495-945 2818<br />

Fax: +7 495-945 0641<br />

Label<br />

Print & Apply<br />

Stations