Electrical - Directorate General of Employment & Training

Electrical - Directorate General of Employment & Training

Electrical - Directorate General of Employment & Training

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Course Curricula<br />

for<br />

Short Term Courses based on<br />

Modular Employable Skills (MES)<br />

in<br />

ELECTRICAL Sector<br />

DIRECTORATE GENERAL OF EMPLOYMENT AND TRAINING<br />

MINISTRY OF LABOUR & EMPLOYMENT<br />

GOVERNMENT OF INDIA

Course Curricula for Short Term Courses based on Modular<br />

Employable Skills (MES) in the <strong>Electrical</strong> Sector<br />

CONTENTS<br />

1. Background ................................................................................................................... 2<br />

2. Frame Work for Skill Development based on Modular Employable Skills ..................... 2<br />

3. Age <strong>of</strong> Participants ......................................................................................................... 3<br />

4. Curriculum Development Process .................................................................................. 3<br />

5. Development <strong>of</strong> Core Competencies ............................................................................. 3<br />

6. Duration <strong>of</strong> the Programmes .......................................................................................... 4<br />

7. Pathways to acquire Qualification .................................................................................. 4<br />

8. Methodology .................................................................................................................. 5<br />

9. Instructional Media Packages ........................................................................................ 5<br />

10. Assessment ................................................................................................................... 5<br />

11. Certificate ...................................................................................................................... 5<br />

12. Course Matrix ................................................................................................................ 6<br />

13. Module ........................................................................................................................... 7<br />

14. Basic <strong>Electrical</strong> <strong>Training</strong> ................................................................................................. 7<br />

15. Repair <strong>of</strong> Home Appliance ............................................................................................. 9<br />

16. House Wiring ............................................................................................................... 11<br />

17. Electronic Choke & CFL Assembling ........................................................................... 13<br />

18. Transformer Winding ................................................................................................... 14<br />

19. Armature Winding ........................................................................................................ 15<br />

20. Rewinding <strong>of</strong> AC/DC Motors ........................................................................................ 16<br />

21. Repair <strong>of</strong> <strong>Electrical</strong> Power Tools .................................................................................. 17<br />

22. Maintenance <strong>of</strong> Batteries ............................................................................................. 19<br />

23. List <strong>of</strong> Expert/Trade Committee Members .................................................................... 20<br />

1

Skill Development based on Modular Employable Skills (MES)<br />

Background<br />

The need for giving emphasis on the Skill Development, especially for the less<br />

educated, poor and out <strong>of</strong> school youth has been highlighted in various forums. The skill<br />

level and educational attainment <strong>of</strong> the work force determines the productivity, income levels<br />

as well as the adaptability <strong>of</strong> the working class in changing environment. Large percentage<br />

<strong>of</strong> population in India is living below poverty line. One <strong>of</strong> the important causes is lower<br />

percentage <strong>of</strong> skilled persons in the workforce<br />

The skill development at present is taking place mostly in the informal way, i.e.<br />

persons acquire skill at the work-place when they help their parents, relatives and employers<br />

etc. Such persons do not have a formal certificate and thus earn lower wages and are<br />

exploited by employers. They have come through informal system due to socio-economic<br />

circumstances <strong>of</strong> the family and the compulsions <strong>of</strong> earning a livelihood rather than<br />

attending a formal course. While their productivity is low, their contribution to the national<br />

GDP cannot be ignored. If the country can create a system <strong>of</strong> certification which not only<br />

recognizes their skills but also provides education and training in a mode that suits their<br />

economic compulsions, it will not only benefit the workforce to earn a decent living but also<br />

contribute to the national economy by better productivity <strong>of</strong> this workforce.<br />

Another related problem to be tackled is large number <strong>of</strong> students drop outs (About<br />

63% <strong>of</strong> the school students drop out at different stages before reaching Class-X).<br />

Frame work for Skill Development based on ‘Modular Employable Skills (MES)’<br />

Very few opportunities for skill development are available for the above referred<br />

groups (out <strong>of</strong> school youth & existing workers especially in the informal sector). Most <strong>of</strong> the<br />

existing Skill Development programmes are long term in nature. Poor and less educated<br />

persons can not afford long term training programmes due to higher entry qualifications,<br />

opportunity cost etc. Therefore, a new frame work for Skill Development for the Informal<br />

Sector has been evolved by the DGET to address to the above mentioned problems. The<br />

key features <strong>of</strong> the new frame work for skill development are:<br />

Demand driven Short term training courses based on modular employable skills<br />

decided in consultation with Industry<br />

Flexible delivery mechanism (part time, weekends, full time)<br />

Different levels <strong>of</strong> programmes (Foundation level as well as skill upgradation) to meet<br />

demands <strong>of</strong> various target groups<br />

Central Government will facilitate and promote training while Vocational <strong>Training</strong> (VT)<br />

Providers under the Govt. and Private Sector will provide training<br />

Optimum utilisation <strong>of</strong> existing infrastructure to make training cost effective.<br />

Testing <strong>of</strong> skills <strong>of</strong> trainees by independent assessing bodies who would not be<br />

involved in conduct <strong>of</strong> the training programme, to ensure that it is done impartially.<br />

Testing & certification <strong>of</strong> prior learning (skills <strong>of</strong> persons acquired informally)<br />

2

The Short Term courses would be based on „Modular Employable Skills (MES)‟.<br />

The concept for the MES is :<br />

<br />

<br />

<br />

<br />

<br />

Identification <strong>of</strong> „minimum skills set‟ which is sufficient to get an employment in the labour<br />

market.<br />

It allows skills upgradation, multiskilling, multi entry and exit, vertical mobility and life long<br />

learning opportunities in a flexible manner.<br />

It also allows recognition <strong>of</strong> prior learning (certification <strong>of</strong> skills acquired informally)<br />

effectively.<br />

The modules in a sector when grouped together could lead to a qualification equivalent<br />

to National Trade Certificate or higher.<br />

Courses could be available from level 1 to level 3 in different vocations depending upon<br />

the need <strong>of</strong> the employer organisations.<br />

MES would benefit different target groups like :<br />

o Workers seeking certification <strong>of</strong> their skills acquired informally<br />

o workers seeking skill upgradation<br />

o early school drop-outs and unemployed<br />

o previously child labour and their familly<br />

Age <strong>of</strong> participants<br />

The minimum age limit for persons to take part in the scheme is 14 years but there is<br />

no upper age limit.<br />

Curriculum Development Process<br />

Following procedure is used for developing course curricula<br />

• Identification <strong>of</strong> Employable Skills set in a sector based on division <strong>of</strong> work in the labour<br />

market.<br />

• Development <strong>of</strong> training modules corresponding to skills set identified so as to provide<br />

training for specific & fit for purpose<br />

• Organization <strong>of</strong> modules in to a Course Matrix indicating vertical and horizontal mobility.<br />

The course matrix depicts pictorially relation among various modules, pre requisites for<br />

higher level modules and how one can progress from one level to another.<br />

• Development <strong>of</strong> detailed curriculum and vetting by a trade committee and by the NCVT<br />

(Close involvement <strong>of</strong> Employers Organizations, State Governments, experts, vocational<br />

training providers and other stake holders is ensured at each stages).<br />

Development <strong>of</strong> Core Competencies<br />

Possession <strong>of</strong> proper attitudes is one <strong>of</strong> the most important attribute <strong>of</strong> a competent person.<br />

Without proper attitudes, the performance <strong>of</strong> a person gets adversely affected. Hence,<br />

systematic efforts will be made to develop attitudes during the training programme.<br />

The trainees deal with men, materials and machines. They handle sophisticated tools and<br />

instruments. Positive attitudes have to be developed in the trainees by properly guiding<br />

3

them and setting up examples <strong>of</strong> good attitudes by demonstrated behaviors and by the<br />

environment provided during training.<br />

Some important core competencies to be developed are:<br />

1. Safety consciousness and safe working practices<br />

2. Care <strong>of</strong> equipment and tools<br />

3. Punctuality, discipline and honesty<br />

4. Concern for quality<br />

5. Respect for rules and regulations<br />

6. Concern for health and hygiene<br />

7. Cordial relationship and Cooperation with co-workers and team Work<br />

8. Positive attitude and behavior<br />

9. Responsibility and accountability<br />

10. Learn continously<br />

11. Communication Skills<br />

12. Concern for environment and waste disposal<br />

Following competencies should also be developed during level-II and higher courses:<br />

1. Ability for planning, organizing and coordinating<br />

2. Creative thinking, problem solving and decision making<br />

3. Leadership<br />

4. Ability to bear stress<br />

5. Negotiation<br />

Duration <strong>of</strong> the Programmes<br />

Time taken to gain the qualification will vary according to the pathway taken and will be kept<br />

very flexible for persons with different backgrounds and experience. Duration has been<br />

prescribed in hours in the curriculum <strong>of</strong> individual module, which are based on the content<br />

and requirements <strong>of</strong> a MES Module. However, some persons may take more time than the<br />

prescribed time. They should be provided reasonable time to complete the course.<br />

Pathways to acquire Qualification:<br />

Access to the qualification could be through:<br />

• An approved training programme; Or<br />

• A combination <strong>of</strong> an approved training programme plus recognition <strong>of</strong> prior<br />

learning including credit transfer; Or<br />

• The recognition <strong>of</strong> prior learning that provides evidence <strong>of</strong> the achievement <strong>of</strong><br />

the competencies for the qualification.<br />

4

Methodology<br />

The training methods to be used should be appropriate to the development <strong>of</strong> competencies.<br />

The focus <strong>of</strong> the programme is on “performing” and not on “Knowing”. Lecturing will be<br />

restricted to the minimum necessary and emphasis to be given for „hands on training‟.<br />

The training methods will be individual centered to make each person a competent one.<br />

Opportunities for individual work will be provided. The learning process will be continuously<br />

monitored and feedback will be provided on individual basis.<br />

Demonstrations using different models, audio visual aids and equipment will be used<br />

intensively.<br />

Instructional Media Packages<br />

In order to maintain quality <strong>of</strong> training uniformly all over the country, instructional media<br />

packages (IMPs) will be developed by the National Instructional Media Institute (NIMI),<br />

Chennai.<br />

Assessment<br />

DGE&T will appoint assessing bodies to assess the competencies <strong>of</strong> the trained persons.<br />

The assessing body will be an independent agency, which will not be involved in conducting<br />

the training programmes. This, in turn, will ensure quality <strong>of</strong> training and credibility <strong>of</strong> the<br />

scheme. Keeping in view the target <strong>of</strong> providing training/testing <strong>of</strong> one million persons<br />

through out the country and to avoid monopoly, more than one assessing bodies will be<br />

appointed for a sector or an area.<br />

Certificate<br />

Successful persons will be awarded certificates issued by National Council for Vocational<br />

<strong>Training</strong> (NCVT).<br />

5

Course Matrix<br />

Proposed Course Outline/ Pathway<br />

Repair <strong>of</strong><br />

Home<br />

Appliance<br />

House<br />

Wiring<br />

<strong>Electrical</strong><br />

choke &<br />

CFL<br />

assembling<br />

Transformer<br />

Winding<br />

Armature<br />

Winding<br />

Repair <strong>of</strong><br />

AC/DC<br />

Motors<br />

Repair <strong>of</strong><br />

<strong>Electrical</strong><br />

Power Tools<br />

Maintenance<br />

<strong>of</strong><br />

Batteries.<br />

Power Transmission line<br />

Tower Erection<br />

Basic <strong>Electrical</strong> <strong>Training</strong><br />

Power Transmission Line<br />

Stringing<br />

6

MODULES<br />

Basic <strong>Electrical</strong> <strong>Training</strong><br />

Name<br />

: Basic <strong>Electrical</strong> <strong>Training</strong><br />

Sector<br />

: <strong>Electrical</strong><br />

Code<br />

: ELE101<br />

Entry Qualification<br />

: 5th Standard & 14 years and Above<br />

Duration<br />

: 120 Hrs<br />

Terminal competency: The participant will be able to<br />

State what is an accident, the probable causes and safe attitude<br />

Rescue a person who is in contact with a live wire<br />

Understand the general safety <strong>of</strong> Tools and Equipments<br />

Describe electricity, conductor, insulator, voltage, current, resistance, P.D., and inter<br />

relation between Voltage, Current, and Resistance etc.<br />

Connect volt meter, watt meter, ammeter, energy meter, multimeter, materials in<br />

simple electric circuits and measure the units.<br />

Do various connections like series, parallel etc.<br />

Explain the difference between AC & DC<br />

Describe the purpose <strong>of</strong> Earthing and Types <strong>of</strong> Earthing.<br />

Course contents:<br />

Underpinning Knowledge (Theory<br />

Practical Competencies<br />

Safety practice –<br />

Safety practices – lifting and handling.<br />

o Lifting and handling loads.<br />

o Heavy Equipments<br />

Safety practice –<br />

Safety practices – Fire fighting<br />

o Fire extinguishers<br />

o Types <strong>of</strong> fire extinguishers<br />

<strong>General</strong> safety <strong>of</strong> tools and equipments Nature <strong>of</strong> working <strong>of</strong> tools and<br />

equipments.<br />

<strong>Electrical</strong> safety<br />

<strong>Electrical</strong> safety practice<br />

o Rescue a person who is in contact<br />

with live wire.<br />

o Rescue a person who is in contact<br />

with live wire.<br />

o Treat a person for electric<br />

shock/injury.<br />

o Treat a person for electric<br />

shock/injury.<br />

Introduction to Electricity<br />

Prepare Terminations<br />

Conductors and types <strong>of</strong> conductors<br />

o Skinning Different types <strong>of</strong> cable<br />

Insulators and types <strong>of</strong> insulators<br />

ends<br />

Crimping & crimping tool<br />

o Make various joints in cable<br />

Soldering<br />

o Crimping cable ends.<br />

o Soldering the cable lugs<br />

Define simple electrical terms like voltage,<br />

current, resistance and their units.<br />

Simple electrical connections using<br />

resistance, voltmeter, and ammeter,<br />

multimeter<br />

Simple series and parallel circuits Connecting number <strong>of</strong> lamps in series<br />

connection.<br />

Connecting number <strong>of</strong> lamps in parallel<br />

connection.<br />

Direct current and testing the polarity<br />

Testing the polarity <strong>of</strong> DC supply.<br />

Alternating current and identifying phase,<br />

neutral and earth terminals<br />

Identification <strong>of</strong> phase and neutral in single<br />

phase supply<br />

Purpose <strong>of</strong> Earthing<br />

Carry out <strong>of</strong> pipe earthing<br />

Types <strong>of</strong> Earthing.<br />

Carry out <strong>of</strong> plate earthing<br />

o Pipe Earthing<br />

o Plate Earthing<br />

Simple house wiring circuit. Repairing <strong>of</strong> house wiring faults.

Tools and Equipments:<br />

1. Connector, 6”<br />

2. Screw Driver 8” 10”, 12”<br />

3. Cutting Pliers 6”, 8”<br />

4. Neon Tester<br />

5. Heavy Duty Screw Driver10”, 12”<br />

6. Nose Pliers 6”<br />

7. Crimping tool<br />

8. Volt meter 0-600 V (MC Type)<br />

9. Volt meter 0-600 V (MI Type)<br />

10. Ammeter 0-5 (MC Type)<br />

11. Ammeter 0-5 (MI Type)<br />

12. Watt meter 0-2.5KW<br />

13. Energy meter 0-10A,240V<br />

14. Multimeter<br />

15. Megger 500V<br />

16. Line Tester<br />

17. Types <strong>of</strong> fire extinguishers<br />

18. Common tools used in electrical field.<br />

19. Soldering iron 25W, 250V<br />

8

Repair <strong>of</strong> Home Appliance<br />

Name<br />

Sector<br />

Code<br />

Entry Qualification<br />

: Repair <strong>of</strong> Home Appliance<br />

: <strong>Electrical</strong><br />

: ELE202<br />

: 8 th Standard 14 years and Above<br />

MES Modules on Basic <strong>Electrical</strong> <strong>Training</strong><br />

Duration<br />

: 120 Hrs<br />

Terminal competency : The participant will be able to<br />

1. Observe the safety precautions while working<br />

2. Test line cord for continuity with test lamp/multimeter<br />

3. Prepare a heating element for a heater as required specification.<br />

4. Replace the old element for heater, kettle, non –automatic electronic<br />

iron, room heaters etc., with a new one<br />

5. Dismantle and reassemble an electric iron, heater, kettle,<br />

room heater, toaster, hair dryer, mixie etc.<br />

6. Install a ceiling fan and the regulator.<br />

7. Check a fluorescent lamp chock, starter and install it.<br />

Course contents:<br />

Underpinning Knowledge (Theory<br />

Practical Competencies<br />

Safety precaution Safety precaution<br />

Install, service and repair all kinds <strong>of</strong> electrical<br />

home appliances<br />

<strong>General</strong> repair <strong>of</strong> heating iron, kettle,<br />

ceiling fan, table fan, washing machine<br />

etc.,<br />

Test the fan capacitors.<br />

Clean and lubricate the bearing <strong>of</strong> ceiling<br />

and table fan, and check the speed.<br />

Regulator <strong>of</strong> both fan.<br />

Repair and rectification <strong>of</strong> an automatic electric<br />

iron, servicing and repairing <strong>of</strong> mixer, ceiling and<br />

Measure the insulation resistance between<br />

the terminals and body <strong>of</strong> the appliance<br />

table fan.<br />

Check the oscillator mechanisms <strong>of</strong> table<br />

fan<br />

Assemble and install a fluorescent6 lamp. Select the fuse size according to the load <strong>of</strong><br />

Thermostat heat controls <strong>of</strong> Automatic electric iron,<br />

steam iron, spray irons.<br />

Understand home appliances like heater, iron, kettle<br />

ceiling fan, table fan, washing machine etc.<br />

<br />

circuit<br />

Dismantle and reassemble automatic iron,<br />

ceiling fn table fan cooking range, storage<br />

heater, washing machines, and wet<br />

grinders etc.<br />

Maintenance <strong>of</strong> decorative serial lamp for a<br />

required supply voltage<br />

Assemble, connect and install a twin fluorescent<br />

lamp with accessories<br />

Repair and service technique <strong>of</strong> cooking range,<br />

storage water heater, washing machines, wet<br />

grinders. Replace the heating element in a soldering.<br />

<br />

<br />

<br />

<br />

Determine the number <strong>of</strong> lamps to be<br />

connected in series for particular supply<br />

voltage for making decorative serial lamp.<br />

Check the internal connections <strong>of</strong> cooking<br />

range selector switch and circuits.<br />

connections in different temperature<br />

arrangements<br />

Check the simple mechanical timer, small<br />

water pump <strong>of</strong> washing machines and<br />

regular service and faults.<br />

Repair <strong>of</strong> house wiring.<br />

9

Tools and Equipments:<br />

1. Electric Heater<br />

2. Electric Iron<br />

3. Electric Kettle<br />

4. Ceiling Fan<br />

5. Table Fan<br />

6. Washing Machine<br />

7. Automatic Iron<br />

8. Cooking Range<br />

9. Storage Heater<br />

10. Wet Grinder<br />

11. Connector, 6”<br />

12. Screw Driver 8” 10”, 12”<br />

13. Cutting Pliers 6”, 8”<br />

14. Neon Tester<br />

15. Heavy Duty Screw Driver10”, 12”<br />

16. Nose Pliers 6”<br />

17. Soldering iron<br />

18. Multimeter<br />

10

House wiring<br />

Name<br />

Sector<br />

Code<br />

Entry Qualification<br />

Duration<br />

Terminal competency:<br />

: House wiring<br />

: <strong>Electrical</strong><br />

: ELE203<br />

: 8 th Standard 14 years and Above<br />

MES Modules on Basic <strong>Electrical</strong> <strong>Training</strong><br />

:120 hrs<br />

The participant will be able to<br />

1. Observe the safety precautions while working<br />

2. List <strong>of</strong> necessary hand tools and their uses<br />

3. Cater and maintenance <strong>of</strong> wiring tools<br />

4. Draw and describe simple electrical circuits.<br />

5. Understand the different system <strong>of</strong> wiring used for domestic<br />

installation.<br />

6. Understand the necessity <strong>of</strong> good earthing in an electrical<br />

installation.<br />

7. Do the domestic installation testing before energizing a domestic<br />

installation.<br />

Course Contents:<br />

Underpinning Knowledge (Theory Practical Competencies<br />

Safety precaution Safety precaution<br />

Safety equipments that should be available<br />

with an electrician working on line<br />

electrical instillation.<br />

Common hand tools, their uses,<br />

care and maintenance.<br />

ISI rules related to wiring (<strong>General</strong>) Identify the wiring accessories as<br />

per symbols.<br />

Introduction to electricity<br />

Make simple twist joints<br />

Conductor & Insulator.<br />

Joints in <strong>Electrical</strong> Conductor<br />

Make married joint in stranded<br />

conductors.<br />

Make tee joint in stranded<br />

conductor.<br />

Diagram and systems used in domestic<br />

wiring installation<br />

Prepare T.W Board for fixing<br />

Flush type accessories.<br />

Make the wiring layout for a bed<br />

room <strong>of</strong> a house with 6 points.<br />

Carryout the wiring in PVC casing<br />

and capping as per layout.<br />

Earthing – Types.<br />

Earthing domestic installation<br />

I E rule for Energy meter Installation.<br />

<br />

<br />

<br />

Carryout pipe earthing pipe<br />

earthing as per I E rule.<br />

Prepare are mount energy meter<br />

board<br />

Carryout domestic installation<br />

testing<br />

11

Tools & Equipemnts:<br />

1. Screw Driver 8” 10”, 12”<br />

2. Combination Pliers 6”, 8”<br />

3. Neon Tester<br />

4. Round Nose Plier 15 cm<br />

5. Electrician Knife 10 cm<br />

6. Heavy Duty Screw Driver10”, 12”<br />

7. Nose Pliers 6”<br />

8. B.P.Hammer 1/2Kg,1/4Kg<br />

9. Cold Chisel 15 cm<br />

10. Tri Square 30 cm<br />

11. Fermer chisel 14cm,20cm,25cm<br />

12. Pocker 15cm<br />

13. Power drilling Machine 6 mm<br />

14. Hacksaw 30 cm<br />

15. Wire shipper 10 cm<br />

16. Measuring tape 5 meters<br />

12

Electronic Choke & CFL assembling<br />

Name<br />

: Electronic Choke & CFL assembling<br />

Sector<br />

: <strong>Electrical</strong><br />

Code<br />

: ELE204<br />

Entry Qualification<br />

: 8 th Standard 14 years and Above<br />

MES Modules on Basic <strong>Electrical</strong> <strong>Training</strong><br />

Duration<br />

: 120 hrs<br />

Terminal Competency The participant will be able to<br />

1. Observe the safety precautions while working<br />

2. Tell the resistance valve by seeing the colour coded resister and<br />

verify with the multimeter<br />

3. List the names <strong>of</strong> the Electronic components used in the circuit.<br />

4. Insert the components as per layout <strong>of</strong> PCB<br />

5. Solder the components.<br />

6. Taking the input and output leads.<br />

7. Test the assembled circuit.<br />

Course Contents:<br />

Underpinning Knowledge (Theory Practical Competencies<br />

Safety Precaution<br />

Safety Precaution<br />

Colour code <strong>of</strong> carbon resistors<br />

Practicing the color coded resistor valve<br />

then verifying with the miltimeter.<br />

Familiarization with different Electronic<br />

components used like capacitor, transistor,<br />

diode, choke coil etc.,<br />

Study the components symbol as per<br />

diagram<br />

Interpret the components as per circuit and<br />

laying the components on PCB<br />

Testing <strong>of</strong> assembled PCB<br />

Tools & Equipment:<br />

1 Soldering iron 25W, 230V<br />

2 Neon tester<br />

3 Multimeter<br />

4 Combination Plier.<br />

5 Nose plier<br />

6 Wire stripper<br />

7 Electrician Knife.<br />

Testing <strong>of</strong> different types <strong>of</strong> Electronic<br />

components.<br />

Practicing the symbol components as per<br />

diagram/circuit/<br />

Lay the components as per layout then<br />

soldering on PCB<br />

Trouble shooting if any on assembled<br />

circuit<br />

13

Transformer Winding<br />

Name<br />

: Transformer Winding<br />

Sector<br />

: <strong>Electrical</strong><br />

Code<br />

: ELE205<br />

Entry Qualification<br />

: 8th Standard 14 years and Above<br />

MES Modules on Basic <strong>Electrical</strong> <strong>Training</strong><br />

Duration<br />

120 hrs<br />

Terminal competency<br />

The Participant will be able to<br />

1. Dismantle the transformer cores<br />

2. Measure and also determine the size <strong>of</strong> winding wire for primary and secondary<br />

3. Take the dimensions <strong>of</strong> a bobbin and prepare the bobbin from suitable materials<br />

4. Wind the primary and secondary winding layer by layer.<br />

5. Stack the cores and fasten them<br />

6. Test the transformer for insulation, transformation ratio and performance<br />

Underpinning Knowledge (Theory Practical Competencies<br />

Safety precautions Safety precautions<br />

Identification <strong>of</strong> phase and neutral in<br />

single-phase A/C. supply,<br />

Testing the supply using test lamp<br />

with different wattage lamps.<br />

Test a single-phase transformer for its<br />

continuity and insulation.<br />

Take the dimensions <strong>of</strong> a bobbin<br />

and prepare the bobbin from<br />

Measuring a enameled winding wire with<br />

Std wire gauge.<br />

<br />

suitable materials<br />

Measure and also determine the size<br />

<strong>of</strong> winding wire for primary and<br />

secondary<br />

Wind/rewind a small transformer Dismantle /reassemble the<br />

transformer cores<br />

Wind the primary and secondary<br />

winding layer by layer.<br />

Use & Operation <strong>of</strong> hand operated and<br />

motorized coil winding machine.<br />

Impregnation Varnish after testing the<br />

transformer – its advantages.<br />

Tools and equipments:<br />

<br />

<br />

Familiarization and operation with<br />

the motorized coil winding machine<br />

– <strong>General</strong> maintenance to be done<br />

Test the transformer for insulation,<br />

transformation ratio and<br />

performance<br />

1 Screw Driver 8” 10”, 12”<br />

2 Cutting Plier 6”, 8”<br />

3. Neon Tester<br />

4. Heavy Duty Screw Driver10”, 12”<br />

5. Nose Plier 6”<br />

6. Standard Wire Gauge<br />

7. Motorized coil winding machine<br />

8. Hand operated coil winding machine<br />

14

Armature winding<br />

Name<br />

: Armature winding<br />

Sector<br />

: <strong>Electrical</strong><br />

Code<br />

: ELE206<br />

Entry Qualification<br />

: 8th Standard 14 years and Above<br />

MES Modules on Basic <strong>Electrical</strong> <strong>Training</strong><br />

Duration<br />

: 120 hrs<br />

Terminal Competency: The participant will be able to<br />

1. Observe the safety precautions while working<br />

2. Check and test the armature.<br />

3. Strip the old winding from the armature<br />

4. Record the winding data<br />

5. Prepare the armature for rewinding<br />

6. Wind the coils by hand insulate them<br />

7. Solder the leads to the commentator raisers.<br />

8. Varnish the armature winding.<br />

9. Understand end connection, electrical and distinguishing start and finish <strong>of</strong> each<br />

Underpinning Knowledge (Theory<br />

Practical Competencies<br />

Safety precautions Safety precautions<br />

Type <strong>of</strong> winding like lap and wave winding Study the parts <strong>of</strong> armature.<br />

Introduction to armature winding<br />

Check and test the armature.<br />

Method <strong>of</strong> dismantling the burnt winding wire. Strip the old winding from the armature<br />

Terminology used in winding like pole pitch Record the winding data<br />

coid pitch back and front pitch progressive and<br />

retrogressive winding etc.<br />

A/C/DC armature winding. Prepare the armature for rewinding<br />

Preparation <strong>of</strong> winding data for given armature. Wind the coils by hand insulate<br />

them<br />

Connection <strong>of</strong> armature leads on<br />

raiser.<br />

Preparation <strong>of</strong> winding table , connection<br />

diagram, winding diagram for given armature.<br />

Understand end connection,<br />

electrical and distinguishing start<br />

Impregnation methods <strong>of</strong> armature after<br />

rewinding and testing.<br />

Tools and equipments:<br />

1. Screw Driver 8” 10”, 12”<br />

2. Cutting Plier 6”, 8”<br />

3. Neon Tester<br />

4. Heavy Duty Screw Driver10”, 12”<br />

5. Nose Plier 6”<br />

6. Standard Wire Gauge<br />

7. Motorized coil winding machine<br />

8. Hand operated coil winding machine<br />

9. Grumbler<br />

10. Multimeter<br />

<br />

and finish <strong>of</strong> each<br />

Varnish the armature winding<br />

15

Rewinding <strong>of</strong> AC/DC Motor<br />

Name<br />

:Rewinding <strong>of</strong> AC/DC Motor<br />

Sector<br />

:<strong>Electrical</strong><br />

Code<br />

: ELE207<br />

Entry Qualification : 8th Standard 14 years and Above<br />

MES Modules on Basic <strong>Electrical</strong> <strong>Training</strong><br />

Duration<br />

: 120 hrs<br />

Terminal Competency<br />

The participant will be able to<br />

1. Observe the safety precautions while working<br />

2. List the materials used for motor winding<br />

3. Method <strong>of</strong> stripping the old winding and preparing the winding former and coils<br />

4. Prepare the winding former and the coils<br />

5. Wind the coils for starting and running winding<br />

6. Method <strong>of</strong> inserting coil in the slots.<br />

Course contents:<br />

Underpinning Knowledge (Theory<br />

Safety Precaution<br />

Practical Competencies<br />

Safety Precaution<br />

knowledge about Single phase and 3-phase supply. List the conducting and<br />

insulating materials used in<br />

Introduction to re-winding<br />

Insulating material used<br />

Terminology used in single phase and three phase<br />

winding like pole pitch coil pitch etc.,<br />

<br />

<br />

motor winding<br />

Testing the motor before<br />

declaring for rewinding<br />

Prepare the winding former<br />

and the coils<br />

Method <strong>of</strong> stripping the old winding and preparing<br />

the winding former and the coils.<br />

Preparation <strong>of</strong> winding data for given Motor.<br />

Procedure followed for re-winding <strong>of</strong> all kind <strong>of</strong><br />

electric motors like single phase A./C. motors, pump<br />

motors, ceiling fan motors, table fan motors,<br />

washing machine motors etc.<br />

Various methods used <strong>of</strong> inserting coil into the slots.<br />

Preparation <strong>of</strong> winding table , connection diagram,<br />

winding diagram for given Motor.<br />

Test to be done after re-winding-impregnation<br />

methods <strong>of</strong> winding<br />

Tools & Equipment:<br />

1. Screw Driver 8” 10”, 12”<br />

2. Cutting Plier 6”, 8”<br />

3. Neon Tester<br />

4. Heavy Duty Screw Driver10”, 12”<br />

5. Nose Plier 6”<br />

6. Standard Wire Gauge<br />

7. Motorized coil winding machine<br />

8. Hand operated coil winding machine<br />

Method <strong>of</strong> stripping the old winding<br />

and preparing the winding former and<br />

the coils<br />

Method <strong>of</strong> inserting coil in the slots.<br />

<br />

Making end connections<br />

Testing the motor after rewinding<br />

<br />

Impregnation methods <strong>of</strong><br />

winding<br />

16

Repair <strong>of</strong> <strong>Electrical</strong> Power Tools<br />

Name<br />

Sector:<br />

Code<br />

Entry Qualification<br />

: Repair <strong>of</strong> <strong>Electrical</strong> Power Tools<br />

: <strong>Electrical</strong><br />

: ELE208<br />

: 5th Standard 14 years and Above<br />

MES Modules on Basic <strong>Electrical</strong> <strong>Training</strong><br />

: 120 Hrs.<br />

Participants will be able to do<br />

1. Observe the safety precautions while working<br />

2. The maintenance and troubleshooting techniques <strong>of</strong> single – phase motors<br />

3. <strong>General</strong> maintenance procedures and tests that should be conducted on the main<br />

parts.<br />

4. Identify the motor leads that are tagged or color coded according to the standardized<br />

color code.<br />

5. Trouble shoots capacitor motors and how to work safely with capacitors in order to<br />

avoid electrical shock.<br />

6. Determine which <strong>of</strong> the specific parts to check when the motor fails to start.<br />

7. Identify the symptoms <strong>of</strong> trouble in universal motors.<br />

8. Repair <strong>of</strong> hand drilling machine, marble cutter, heavy duty mini grinder,<br />

sander/polishers, blower, heavy duty cutter and portable cut<strong>of</strong>f saw.<br />

9. Dismantling and reassembling <strong>of</strong> single phase motor.<br />

10. Use diagnostic table to help in troubleshooting motor in plant<br />

Duration<br />

Terminal Competency:<br />

Course content:<br />

Underpinning Knowledge (Theory<br />

Safety precautions<br />

Classification <strong>of</strong> single phase motors – parts,<br />

construction and working <strong>of</strong> single phase<br />

motors<br />

Classification <strong>of</strong> electrical power tools as per<br />

their application like hand drilling machine,<br />

angle grinder, rotary hammer, sander/polisher,<br />

blower, heavy duty cutter, portable cut <strong>of</strong>f saw<br />

etc.,<br />

Trouble shooting technique in electrical power<br />

tools – like insulation testing armature defects,<br />

field winding, stator winding defects, noisy<br />

operation bearing problem, carbon brush<br />

changing, turning the commutator surface.<br />

Symptoms and causes <strong>of</strong> motor troubles –<br />

preventive and breakdown maintenance.<br />

Practical Competencies<br />

Safety precautions<br />

Dismantling and reassembling <strong>of</strong> single<br />

phase motors like permanent capacitor,<br />

capacitor start induction run, capacitor<br />

start capacitor run, Universal motors.<br />

Dismantling and reassembling <strong>of</strong><br />

electrical power tools used like hand<br />

drilling machine, angle grinder, rotary<br />

hammer, marble cutter , heavy duty mini<br />

grinder, sander/polisher, blower , heavy<br />

duty cutter, portable cut <strong>of</strong>f saw etc.,<br />

Trouble shooting in hand tools testing <strong>of</strong><br />

insulation, armature defects, capacitor testing,<br />

carbon brush replacing after bedding – testing the<br />

protective devices.<br />

<br />

Preventive maintenance <strong>of</strong> hand tools,<br />

overhauling, changing defective parts<br />

etc.,<br />

Tools and equipments:<br />

17

1. Screw Driver 8” 10”, 12”<br />

2. Cutting Pliers 6”, 8”<br />

3. Neon Tester<br />

4. Heavy Duty Screw Driver10”, 12”<br />

5. Nose Pliers 6”, 8”<br />

6. DE Spanner Set 8 Nos.<br />

7. Pipe Wrench 22mm<br />

8. 13mm two speed driller<br />

9. 100mm Heavy duty mini Grinder<br />

10. 150mm Straight Grinder<br />

11. Dual speed flexible grinder<br />

12. 180mm Sander/Polisher<br />

13. Blower<br />

14. Heavy duty Cutter<br />

15. Portable cut-<strong>of</strong>f saw<br />

18

Maintenance <strong>of</strong> Batteries<br />

Name<br />

Sector<br />

Code<br />

Entry Qualification<br />

: Maintenance <strong>of</strong> Batteries<br />

: <strong>Electrical</strong><br />

: ELE209<br />

: 8 th Standard 14 years and Above<br />

MES Modules on Basic <strong>Electrical</strong> <strong>Training</strong><br />

: 60 hrs<br />

Duration<br />

Terminal Competency:<br />

The participants will be able to:<br />

1. Observe the safety precautions while working<br />

2. Preparation <strong>of</strong> electrolyte<br />

3. Preparation <strong>of</strong> cells and arrangements <strong>of</strong> cells<br />

4. Assembling <strong>of</strong> battery<br />

5. Charging / recharging <strong>of</strong> battery<br />

6. Care and preventive maintenance <strong>of</strong> battery<br />

Course Content:<br />

Underpinning Knowledge (Theory Practical Competencies<br />

Safety precautions Safety precautions<br />

Construction a lead acid battery Preparation <strong>of</strong> electrolyte<br />

How to keep lead acid battery health. Preparation <strong>of</strong> cells and<br />

arrangements <strong>of</strong> cells<br />

Recharging <strong>of</strong> battery, Assembling <strong>of</strong> battery<br />

Check the condition <strong>of</strong> battery, reading <strong>of</strong><br />

hydrometer, preparation <strong>of</strong> electrolyte and<br />

chemical effect.<br />

Battery chargers and its application<br />

precautions to be taken while operation.<br />

<br />

<br />

Charging / recharging <strong>of</strong> battery<br />

Care and preventive maintenance <strong>of</strong><br />

battery<br />

Tools and equipments:<br />

1. Screw Driver 8” 10”, 12”<br />

2. Cutting Pliers 6”, 8”<br />

3. Neon Tester<br />

4. Heavy Duty Screw Driver10”, 12”<br />

5. Nose Pliers 6”<br />

6. Hydrometer<br />

7. High Discharge Tester<br />

8. Battery charger<br />

19

List <strong>of</strong> Expert/Trade Committee Members<br />

CURRICULUM DEVELOPMENT FOR SHORT TERM COURSES BASED ON<br />

MODULAR EMPLOYABLE SKILLS<br />

SECTOR/AREA:<br />

<strong>Electrical</strong><br />

Sl. Name & designation<br />

Remarks<br />

S/shri<br />

1 V.M.Rao, Director, ATI (V), Hyderabad Chairman<br />

2 S.Mastan, Sr.Manager, Midhani, Hydesrabad Member<br />

3 S.N.Pille, Chief Executive, S.N.Engineers, Hyderabad Member<br />

4 I.Nagaraju, RC All.Tech.Power Systems PVt.Ltd, Hyd Member<br />

5 H.Somasundram, Director, ATI EPI, R’pur, Hyderabad Member<br />

6 S.Chatterjee, JDT, ATI (V), Hyd Member<br />

7 G.Despande, T.O, RDAT, Hyderabad Member<br />

8 E.Balakrishna, DDT, ATI(V), Hyd Member<br />

9 A.Venkateswara rao, -do- Member<br />

10 V.V.Subba Rao, -do- Member<br />

11 P.K.Srivastava, ADT, -do- Member<br />

12 K.Kesavan, T.O, -do- Member<br />

13 S.Venugopalan, TO, -do- Member<br />

file name : MES-electrical Aug 2007<br />

20

Course Curriculum<br />

Under<br />

SKILL DEVELOPMENT INITIATIVE SCHEME (SDIS)<br />

Based on<br />

Modular Employable Skills (MES)<br />

On<br />

Designed in<br />

January 2011<br />

Government <strong>of</strong> India<br />

Ministry <strong>of</strong> Labour & <strong>Employment</strong><br />

<strong>Directorate</strong> <strong>General</strong> <strong>of</strong> <strong>Employment</strong> & <strong>Training</strong><br />

Course Curriculum under Skill Development Initiative Scheme (SDIS)<br />

based on Modular Employable Skills (MES)<br />

21

CONTENTS<br />

1. List <strong>of</strong> members attended the Trade Committee Meeting…………………………...... 3<br />

2. Background ................................................................................................................. 4<br />

3. Frame Work for Skill Development based on Modular Employable Skills .................. 4<br />

4. Introduction… …………………………………………………………………………..…... 5<br />

5. Age <strong>of</strong> Participants ...................................................................................................... 5<br />

6. Curriculum Development Process................................................................................ 5<br />

7. Development <strong>of</strong> Core Competencies ...........................................................................6<br />

8. Duration <strong>of</strong> the Programmes................................................................................... ….6<br />

9. Pathways to acquire Qualification ................................................................................6<br />

10. Methodology ..............................................................................................................6<br />

11. Instructional Media Packages ....................................................................................7<br />

12. Assessment............................................................................................................... .7<br />

13. Certificate ...................................................................................................................7<br />

14. Course Matrix ...........................................................................................................8<br />

a) Level - I – Module - 2 … Power Transmission Line Tower Erection…………………. 9<br />

b) Level - I – Module - 3 … Power Transmission Line Stringing………………………. 12<br />

22

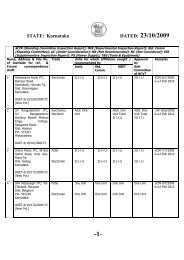

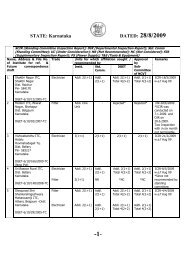

List <strong>of</strong> members attended the Trade Committee Meeting for designing the course curriculum under<br />

Skill Development Initiative Scheme (SDIS) based on Modular Employable Skills (MES) on The Module <strong>of</strong><br />

in the <strong>Electrical</strong> Sector held on 28th JANUARY 2011 at power Grid Corporation, Kolkata<br />

Shri Anil Kumar, Director In Charge, C.S.T.A.R.I., Kolkata.<br />

Sl. Name and Designation<br />

Organization<br />

Remarks<br />

No. S/Shri<br />

1 Ravi P. Singh, Executive Director Power Grid Corporation, Kolkata Chairman<br />

2 Anil Kumar, Director In Charge CSTARI, Kolkata Member<br />

3 Chetan verma, <strong>General</strong> Manager Power Grid Corporation, Gurgaon Member<br />

(HRD)<br />

4 P.L.Ghosh, Assistant <strong>General</strong> Manager Kalpataru Power Transmission Ltd., Member<br />

Kolkata<br />

5 A.K.Jain, Chief Engineer Damodar valley Corpn., Kolkata Member<br />

6 Yatindra Dwivedi, Chief Manager Power Grid Corporation, Gurgaon Member<br />

(HRD)<br />

7 Bhaskar Sarathy, Manager Larsen & Toubro, Chennai Member<br />

8 Devendra Burade, Manager (Human Jyoti Stringing Ltd., Delhi<br />

Member<br />

Resource)<br />

9 Goutam Banerjee, Senior Engineer West Bengal State Electricity<br />

Member<br />

(Project)<br />

Transmission corpn. Ltd., Kolkata<br />

10 P.Das Sharma, Chief Engineer West Bengal State Electricity<br />

Member<br />

(Project)<br />

Transmission corpn. Ltd., Kolkata<br />

11 Jacob Verghese, Dev. Manager KEC, Nagpur Member<br />

12 Prakash Bose, Manager Kalpataru Power Transmission Ltd., Member<br />

Kolkata<br />

13 Virendra Kumar, Deputy Manager Power Grid Corporation, Kolkata Member<br />

14 Sanjay Kumar, Dy. Director <strong>of</strong> Trg. Regional <strong>Directorate</strong> <strong>of</strong> Apprenticeship Member<br />

<strong>Training</strong> (ER), Kolkata<br />

15 L.K.Mukherjee, Dy. Director <strong>of</strong> Trg. CSTARI, Kolkata Member<br />

16 Dr. Soumen Basu, Dy. Director <strong>Directorate</strong> <strong>of</strong> Industrial <strong>Training</strong>, Member<br />

West Bengal<br />

17 Subrata Das, Asst. Director <strong>Directorate</strong> <strong>of</strong> Industrial <strong>Training</strong>, Member<br />

West Bengal<br />

18 Ashoke Rarhi, Asst.Director <strong>of</strong> Trg. CSTARI, Kolkata Member<br />

19 R. N. Manna, <strong>Training</strong> Officer CSTARI, Kolkata Member<br />

20 Raj Kumar Roy, Instructor (Elect.) Industrial <strong>Training</strong> Institute, Kalyani Member<br />

21 Biswajit Show, Instructor (Elect.) Industrial <strong>Training</strong> Institute, Tollygaunge,<br />

Kolkata<br />

Member<br />

23

LEVEL – I<br />

Module Name: Power Transmission Line Tower Erection<br />

Sector:<br />

<strong>Electrical</strong><br />

Code: ELE 110<br />

Entry Qualification: Ability to read and write, no handicap, physically fit to climb towers, should not<br />

be colour blind.<br />

Age:<br />

Minimum Age: 18 Years, Maximum Age: 25 years<br />

Duration:<br />

470 Hrs<br />

Terminal competency: The participant will be able to<br />

Understand erection procedure and erect the tower with tools and procedures while<br />

observing the safety precautions<br />

Course Contents:<br />

Underpinning Knowledge (Theory)<br />

1. Elementary details about Transmission line<br />

foundation works (Audio Visual(AV))<br />

Survey<br />

Pits marking<br />

Excavation<br />

Stub setting/ earthing<br />

2. Transmission Line Towers (AV)<br />

Type <strong>of</strong> Towers including ULEs (Unequal Leg<br />

Extensions) details<br />

Structural Drawings and Bill <strong>of</strong> Material<br />

Markings and identification <strong>of</strong> Tower Parts<br />

Loading, unloading and stacking <strong>of</strong> Tower<br />

Materials<br />

3. Environmental Impact<br />

Awareness about environmental impact<br />

ROW issues<br />

Damage Control<br />

4. Introduction to Tools and Plans related to Tower<br />

erection<br />

Identification<br />

Up-keeping<br />

Proper uses (AV)<br />

Detailed description <strong>of</strong> derricks (AV)<br />

Do’s and Don’t<br />

Testing its Healthiness<br />

Important Parts <strong>of</strong> Towers and its fitting sequence<br />

Communication sets<br />

5. Personal Protection Equipments (PPE’s)<br />

Identification<br />

Up-keeping<br />

Proper uses (AV)<br />

Practical Competencies<br />

Elementary practical skills for Pits<br />

marking, excavation and stubsetting/earthing<br />

through Audio visual<br />

on Tower Foundation, Transmission<br />

Line Survey<br />

Identifying types <strong>of</strong> towers(for<br />

various voltage levels) through Audio<br />

Visual inputs, reading structural<br />

drawings & bill <strong>of</strong> material,<br />

identification <strong>of</strong> tower parts and<br />

stacking <strong>of</strong> Tower material<br />

Practical ways to handle tower parts<br />

and material in order to minimize<br />

environmental impact/damage,<br />

straight line use <strong>of</strong> tractors<br />

Practical use <strong>of</strong> Tools and Plans for<br />

Tower erection including testing <strong>of</strong><br />

T&Ps<br />

Practical use <strong>of</strong> Personal Protection<br />

Equipments(PPEs) for Tower erection<br />

24

Do’s and Don’t<br />

Testing its Healthiness and identification <strong>of</strong> faulty<br />

PPEs<br />

6. Field Quality Plan and Procedures<br />

Standard field quality plans and procedures<br />

o Visual checking <strong>of</strong> materials for Stacking,<br />

Cleanliness, Galvanizing, Damages,<br />

completeness<br />

o Sequence <strong>of</strong> erection, checking for<br />

completeness, tightening <strong>of</strong> nuts and bolts,<br />

Tack welding etc.<br />

Quality associated with erection works.<br />

7. Erection Procedures (AV)<br />

Staking <strong>of</strong> Pieces at Site and ensuring availability<br />

<strong>of</strong> full material.<br />

Ground Assembly<br />

Hosting <strong>of</strong> derricks<br />

Identification <strong>of</strong> proper size and quantity <strong>of</strong> Bolts<br />

and Nuts<br />

Detailed erection process (step by step)<br />

8. Safety in Erection (AV)<br />

Safety procedures<br />

First Aid arrangements<br />

Handling <strong>of</strong> emergency situations<br />

Proper display & markings <strong>of</strong> safety procedure and<br />

details.<br />

9. S<strong>of</strong>t Skills<br />

Emotional contents (AV)<br />

Team Work<br />

Communication skill<br />

Discipline & punctuality<br />

Positive attitude and behavior<br />

10. Practical Field <strong>Training</strong><br />

Actual climbing on tower with tools and<br />

procedures<br />

Field demonstration on safety during erection<br />

Erection <strong>of</strong> tower (step by step) in control<br />

environment<br />

11. Site Visits<br />

Practical demonstration<br />

12. Recapturing, practical demonstration, appraisal<br />

and validation<br />

Ensuring quality associated with<br />

Tower erection works and ensuring<br />

Field Quality Plan and Procedures<br />

Practical experience for checking<br />

material availability for Tower<br />

erection, stacking <strong>of</strong> pieces, ground<br />

assembly, hoisting <strong>of</strong> derricks, proper<br />

use <strong>of</strong> pulleys/winches, balancing<br />

while lifting the material,<br />

anchoring/guying angle <strong>of</strong> derrick<br />

poles, kinds <strong>of</strong> knots <strong>of</strong> ropes, use <strong>of</strong><br />

proper bolts and nuts and step-wise<br />

erection procedure, Special<br />

arrangements to be used for various<br />

crossings (River, Power line, National<br />

Highway, Railway).<br />

Safe working on the site and ensuring<br />

adherence to safety procedures<br />

Observing discipline and punctuality<br />

on work, keeping and promoting<br />

positive attitude, maintaining good<br />

interpersonal relationship and working<br />

in team<br />

Full erection <strong>of</strong> Power Transmission<br />

Line Tower observing safety<br />

procedures<br />

Gaining practical competencies<br />

through observation <strong>of</strong> actual tower<br />

erection at construction site<br />

Recapturing practical competencies<br />

acquired and learning by performance<br />

during appraisal<br />

25

Tools & Equipments(Power Transmission Line Tower Erection):<br />

1. Winch(Manual/Motorized) – 1 No.<br />

2. Ginpole( 1 No.)/Derrick( 2 Nos.)<br />

3. Polypropylene rope- 10 bundles <strong>of</strong> 220 mtrs.<br />

4. Single/Four sheave pulley- 4 nos. each<br />

5. Crow bars, spanners, hammers, hooks, slings- 4 nos. each<br />

6. Torque wrench- 4 nos.<br />

7. Safety equipment viz. safety helmets, safety belts, first aid box, Fall Arrestors – as per<br />

requirement( at least one each)<br />

8. Audio-visual Aids.- 1 set<br />

9. Slings, D-shackle, wire rope(12 mm)- 4 nos. each<br />

26

LEVEL – I<br />

Module Name: Power Transmission Line Stringing<br />

Sector:<br />

<strong>Electrical</strong><br />

Code: ELE 111<br />

Entry Qualification: Ability to read and write, no handicap, physically fit to climb towers, should not<br />

be colour blind.<br />

Age :<br />

Minimum Age: 18 Years, Maximum Age: 25 years<br />

Duration:<br />

470 Hrs<br />

Terminal competency: The participant will be able to<br />

Understand stringing procedure and perform stringing work with tools and<br />

procedures while observing the safety precautions<br />

Course Contents:<br />

Underpinning Knowledge (Theory)<br />

1. Elementary details <strong>of</strong> foundation and Tower<br />

stringing (AV)<br />

Type <strong>of</strong> Tower (Tension and suspension)<br />

Survey<br />

Pits marking<br />

Excavation<br />

Stub setting/ earthling<br />

Type <strong>of</strong> Towers including ULEs (Unequal<br />

Leg Extensions) details<br />

2. Pre-check <strong>of</strong> erected tower (AV)<br />

Missing members<br />

Tightening<br />

3. T&P associated with Stringing works (AV)<br />

Insulator hoisting<br />

Hardware fitting<br />

Stringing<br />

4. Personal Protection Equipments (PPE’s)<br />

Identification<br />

Proper uses<br />

Up-keeping<br />

Do’s and Don’t<br />

Testing its Healthiness<br />

5. Identification <strong>of</strong> materials (AV)<br />

Insulator type<br />

Fittings and rollers<br />

Drum schedules<br />

Do’s and Don’t<br />

6. Field Quality Plan and Procedures related<br />

to stringing<br />

Standard field quality plan and procedures<br />

a. Insulators- Visual check for<br />

Practical Competencies<br />

Elementary practical skills for Pits marking,<br />

excavation and stub-setting/earthling through<br />

Audio visual on Tower Foundation and<br />

stringing, Identifying types <strong>of</strong> towers and<br />

Transmission Line Survey<br />

Checking <strong>of</strong> erected tower before stringing<br />

Practical use <strong>of</strong> Tools and Plans for Power<br />

Transmission Line Stringing<br />

Practical use <strong>of</strong> Personal Protection<br />

Equipments(PPEs) for Power Transmission<br />

Line Stringing<br />

Identification and proper use <strong>of</strong> materials<br />

related to Stringing work<br />

Ensuring quality associated with Tower<br />

erection works and ensuring Field Quality Plan<br />

and Procedures<br />

27

cleanliness/glazing/cracks/white spots,<br />

IR Value<br />

b. Visual checking <strong>of</strong> conductor drums<br />

etc.<br />

c. During stringing- Conductor/earthwirescratch/cut<br />

check, repair sleeve,<br />

midspan joints etc.<br />

d. After stringing- check for clearances,<br />

jumpering, copper bond, placement <strong>of</strong><br />

spacer/damper<br />

Quality associated with works<br />

7. Stringing procedures (AV)<br />

Placement <strong>of</strong> TSE and Drums<br />

Guys <strong>of</strong> TSE and Tower<br />

Paying out <strong>of</strong> Pilot wire<br />

Paying out <strong>of</strong> Earth Wire<br />

Paying out <strong>of</strong> Conductors<br />

Use <strong>of</strong> MSCJ<br />

Rough sagging<br />

Procedures and precautions for<br />

arrangements for various crossings.<br />

Important earthing arrangements for Power<br />

Line crossings (LT & HT)<br />

Final sagging<br />

Clipping, spacing, jumpering<br />

Important safety aspects<br />

Do’s and Don’t<br />

Removal <strong>of</strong> clamps and connectors<br />

8. Safety in Stringing<br />

Safety procedures (AV)<br />

First Aid arrangements<br />

Handling <strong>of</strong> emergency situations<br />

Proper display & markings for safety<br />

procedures and guidelines<br />

9. S<strong>of</strong>t Skills<br />

Emotional contents (AV)<br />

Team Work<br />

Communication<br />

Discipline & punctuality<br />

Positive attitude and behavior<br />

10. Practical Field <strong>Training</strong><br />

Actual stringing in control environment.<br />

Field demonstration on safety during<br />

stringing work<br />

11. Site Visits<br />

Demonstration <strong>of</strong> actual string work<br />

12. Recapturing, practical demonstration,<br />

appraisal and validation<br />

Practical experience for Power Transmission<br />

Line Stringing such as placement <strong>of</strong> TSE &<br />

Drums, use <strong>of</strong> Guys & MSCJ, paying out <strong>of</strong><br />

Pilot wire/Earth wire/ conductors, rough/final<br />

sagging, clipping/spacing/jumpering, special<br />

arrangements required for various crossings<br />

(River, Power line, National Highway,<br />

Railway) etc.<br />

Safe working on the site and ensuring<br />

adherence to safety procedures<br />

Observing discipline and punctuality on work,<br />

keeping and promoting positive attitude,<br />

maintaining good interpersonal relationship and<br />

working in team<br />

Stringing <strong>of</strong> Power Transmission Line<br />

observing safety procedures<br />

Gaining practical competencies through<br />

observation <strong>of</strong> actual Stringing at construction<br />

site<br />

Recapturing practical competencies acquired<br />

and learning by performance during appraisal<br />

28

Tools & Equipments (Power Transmission Line Stringing):<br />

1. Running block for conductor-bundle – 1 no.<br />

2. Head board- 1 no.<br />

3. Pilot wire- Sample piece<br />

4. Ground roller- 1 no.<br />

5. Pulling grips- 1 no.<br />

6. Drum mounting jack for conductor drum- 1 set<br />

7. Hydraulic compression machine with suitable capacity with die sets- at site<br />

8. Four sheave pulley- 1 set<br />

9. Conductor lifting tackle- 1 set<br />

10. Come-along clamp for conductor & earthwire – 1 no each<br />

11. Winch – motorized/manual – at site<br />

12. Trifor- at site<br />

13. Hydraulic wire cutter – at site<br />

14. Wire rope – sample piece<br />

15. Polypropylene rope (suitable dia) - sample pieces<br />

16. Sag board – 1 set<br />

17. Megger – 1 no.<br />

18. Theodolite – 1 no.<br />

19. Twin bundle suspension fitting and Tension fitting – 1 set<br />

20. Insulators- 4 nos. each type<br />

21. Flags- samples<br />

22. Binocular- 1 no.<br />

23. Hammers, Spanners, Slings, Hecksaw- 1 each<br />

24. Torque wrench- 1 no.<br />

25. Turn-buckle- 1 no. sample<br />

26. Vernier Caliper- 1 no.<br />

27. Audio Visual Aid- 1 set<br />

28. Safety equipment viz. safety helmets, safety belts, first aid box – as per requirement<br />

( at least one each)<br />

29