specifications - Dunn County

specifications - Dunn County

specifications - Dunn County

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

SPECIFICATIONS<br />

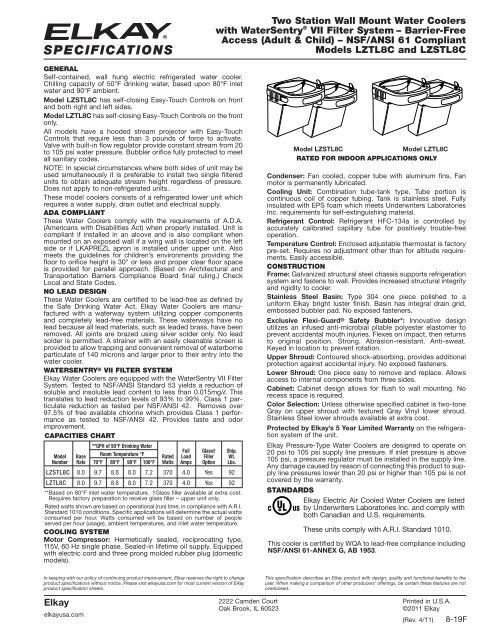

Two Station Wall Mount Water Coolers<br />

with WaterSentry ® VII Filter System – Barrier-Free<br />

Access (Adult & Child) – NSF/ANSI 61 Compliant<br />

Models LZTL8C and LZSTL8C<br />

GENERAL<br />

Self-contained, wall hung electric refrigerated water cooler.<br />

Chilling capacity of 50°F drinking water, based upon 80°F inlet<br />

water and 90°F ambient.<br />

Model LZSTL8C has self-closing Easy-Touch Controls on front<br />

and both right and left sides.<br />

Model LZTL8C has self-closing Easy-Touch Controls on the front<br />

only.<br />

All models have a hooded stream projector with Easy-Touch<br />

Controls that require less than 3 pounds of force to activate.<br />

Valve with built-in flow regulator provide constant stream from 20<br />

to 105 psi water pressure. Bubbler orifice fully protected to meet<br />

all sanitary codes.<br />

NOTE: In special circumstances where both sides of unit may be<br />

used simultaneously it is preferable to install two single filtered<br />

units to obtain adequate stream height regardless of pressure.<br />

Does not apply to non-refrigerated units.<br />

These model coolers consists of a refrigerated lower unit which<br />

requires a water supply, drain outlet and electrical supply.<br />

ADA COMPLIANT<br />

These Water Coolers comply with the requirements of A.D.A.<br />

(Americans with Disabilities Act) when properly installed. Unit is<br />

compliant if installed in an alcove and is also compliant when<br />

mounted on an exposed wall if a wing wall is located on the left<br />

side or if LKAPREZL apron is installed under upper unit. Also<br />

meets the guidelines for children’s environments providing the<br />

floor to orifice height is 30" or less and proper clear floor space<br />

is provided for parallel approach. (Based on Architectural and<br />

Transportation Barriers Compliance Board final ruling.) Check<br />

Local and State Codes.<br />

NO LEAD DESIGN<br />

These Water Coolers are certified to be lead-free as defined by<br />

the Safe Drinking Water Act. Elkay Water Coolers are manufactured<br />

with a waterway system utilizing copper components<br />

and completely lead-free materials. These waterways have no<br />

lead because all lead materials, such as leaded brass, have been<br />

removed. All joints are brazed using silver solder only. No lead<br />

solder is permitted. A strainer with an easily cleanable screen is<br />

provided to allow trapping and convenient removal of waterborne<br />

particulate of 140 microns and larger prior to their entry into the<br />

water cooler.<br />

WATERSENTRY ® VII FILTER SYSTEM<br />

Elkay Water Coolers are equipped with the WaterSentry VII Filter<br />

System. Tested to NSF/ANSI Standard 53 yields a reduction of<br />

soluble and insoluble lead content to less than 0.015mg/l. This<br />

translates to lead reduction levels of 93% to 99%. Class 1 particulate<br />

reduction as tested per NSF/ANSI 42. Removes over<br />

97.5% of free available chlorine which provides Class 1 performance<br />

as tested to NSF/ANSI 42. Provides taste and odor<br />

improvement.<br />

CAPACITIES CHART<br />

**GPH of 50°F Drinking Water<br />

Full Glass† Ship.<br />

Model Base<br />

Room Temperature °F<br />

Rated Load Filler Wt.<br />

Number Rate 70°F 80°F 90°F 100°F Watts Amps Option Lbs.<br />

LZSTL8C 8.0 9.7 8.8 8.0 7.2 370 4.0 Yes 92<br />

LZTL8C 8.0 9.7 8.8 8.0 7.2 370 4.0 Yes 92<br />

**Based on 80°F inlet water temperature. †Glass filler available at extra cost.<br />

Requires factory preparation to receive glass filler – upper unit only.<br />

Rated watts shown are based on operational (run) time, in compliance with A.R.I.<br />

Standard 1010 conditions. Specific applications will determine the actual watts<br />

consumed per hour. Watts consumed will be based on number of people<br />

served per hour (usage), ambient temperatures, and inlet water temperature.<br />

COOLING SYSTEM<br />

Motor Compressor: Hermetically sealed, reciprocating type,<br />

115V, 60 Hz single phase. Sealed-in lifetime oil supply. Equipped<br />

with electric cord and three prong molded rubber plug (domestic<br />

models).<br />

Model LZSTL8C<br />

Model LZTL8C<br />

RATED FOR INDOOR APPLICATIONS ONLY<br />

Condenser: Fan cooled, copper tube with aluminum fins. Fan<br />

motor is permanently lubricated.<br />

Cooling Unit: Combination tube-tank type. Tube portion is<br />

continuous coil of copper tubing. Tank is stainless steel. Fully<br />

insulated with EPS foam which meets Underwriters Laboratories<br />

Inc. requirements for self-extinguishing material.<br />

Refrigerant Control: Refrigerant HFC-134a is controlled by<br />

accurately calibrated capillary tube for positively trouble-free<br />

operation.<br />

Temperature Control: Enclosed adjustable thermostat is factory<br />

pre-set. Requires no adjustment other than for altitude requirements.<br />

Easily accessible.<br />

CONSTRUCTION<br />

Frame: Galvanized structural steel chassis supports refrigeration<br />

system and fastens to wall. Provides increased structural integrity<br />

and rigidity to cooler.<br />

Stainless Steel Basin: Type 304 one piece polished to a<br />

uniform Elkay bright luster finish. Basin has integral drain grid,<br />

embossed bubbler pad. No exposed fasteners.<br />

Exclusive Flexi-Guard ® Safety Bubbler*: Innovative design<br />

utilizes an infused anti-microbial pliable polyester elastomer to<br />

prevent accidental mouth injuries. Flexes on impact, then returns<br />

to original position. Strong. Abrasion-resistant. Anti-sweat.<br />

Keyed in loca tion to prevent rotation.<br />

Upper Shroud: Contoured shock-absorbing, provides additional<br />

protection against accidental injury. No exposed fasteners.<br />

Lower Shroud: One piece easy to remove and replace. Allows<br />

access to internal components from three sides.<br />

Cabinet: Cabinet design allows for flush to wall mounting. No<br />

recess space is required.<br />

Color Selection: Unless otherwise specified cabinet is two-tone<br />

Gray on upper shroud with textured Gray Vinyl lower shroud.<br />

Stainless Steel lower shrouds available at extra cost.<br />

Protected by Elkay’s 5 Year Limited Warranty on the refrigeration<br />

system of the unit.<br />

Elkay Pressure-Type Water Coolers are designed to operate on<br />

20 psi to 105 psi supply line pressure. If inlet pressure is above<br />

105 psi, a pressure regulator must be installed in the supply line.<br />

Any damage caused by reason of connecting this product to supply<br />

line pressures lower than 20 psi or higher than 105 psi is not<br />

covered by the warranty.<br />

STANDARDS<br />

Elkay Electric Air Cooled Water Coolers are listed<br />

by Underwriters Laboratories Inc. and comply with<br />

both Canadian and U.S. requirements.<br />

These units comply with A.R.I. Standard 1010.<br />

This cooler is certified by WQA to lead-free compliance including<br />

NSF/ANSI 61-ANNEX G, AB 1953.<br />

In keeping with our policy of continuing product improvement, Elkay reserves the right to change<br />

product <strong>specifications</strong> without notice. Please visit elkayusa.com for most current version of Elkay<br />

product specification sheets.<br />

Elkay<br />

elkayusa.com<br />

2222 Camden Court<br />

Oak Brook, IL 60523<br />

This specification describes an Elkay product with design, quality and functional benefits to the<br />

user. When making a comparison of other producers’ offerings, be certain these features are not<br />

overlooked.<br />

Printed in U.S.A.<br />

©2011 Elkay<br />

(Rev. 4/11) 8-19F

INSURE PROPER VENTILATION BY MAINTAINING 6" (152mm) MINIMUM CLEARANCE FROM CABINET LOUVERS TO WALL.<br />

F = 7/16 BOLT HOLES FOR FASTENING UNIT TO WALL<br />

D = ELECTRICAL SUPPLY (3) WIRE RECESSED BOX DUPLEX OUTLET<br />

C = 1-1/2 TRAP NOT FURNISHED<br />

FROM WALL<br />

B = RECOMMENDED LOCATION OUT IN. 2 STUB DRAIN DRAIN. NOMINAL 1-1/2" ACCOMODATE TO OUTLET WASTE FOR<br />

OUT MAXIMUM (76mm) 3" WALL.<br />

FROM<br />

WATER RECOMMENDED = A TUBE.<br />

COPPER UNPLATED O.D. 3/8 ACCEPT TO FURNISHED (NOT VALVE SHUT-OFF LOCATION. SUPPLY<br />

LEGEND<br />

VIEW<br />

SIDE VIEW<br />

FRONT<br />

Two Station Wall Mount Water Coolers<br />

with WaterSentry ® VII Filter System – Barrier-Free<br />

Access (Adult & Child) – NSF/ANSI 61 Compliant<br />

Models LZTL8C and LZSTL8C<br />

ROUGH-IN DIMENSIONS<br />

WaterSentry ® VII Filter System<br />

OPERATION OF QUICK CONNECT FITTINGS<br />

SIMPLY PUSH IN<br />

TUBE TO ATTACH<br />

TUBE IS SECURED<br />

IN POSITION<br />

PUSH IN COLLET<br />

TO RELEASE TUBE<br />

IMPORTANT!<br />

INSTALLER PLEASE NOTE:<br />

This water cooler has been designed and built to provide water to the<br />

user which has not been altered by materials in the cooler waterways.<br />

The grounding of electrical equipment such as telephone, computers,<br />

etc., to water lines is a common procedure. This grounding may be<br />

in the building but may also occur away from the building. This grounding<br />

can cause electrical feedback into a water cooler creating an electrolysis<br />

which creates a metallic taste or causes an increase in the metal content<br />

of the water. This condition is avoidable by installing the cooler using the<br />

proper materials as shown below.<br />

NOTICE<br />

This water cooler must be connected to the water supply using a dielectric<br />

coupling. The cooler is furnished with a non-metallic strainer<br />

which meets this requirement.<br />

The drain trap which is provided by the installer should also be plastic to<br />

completely isolate the cooler from the building plumbing system.<br />

A B C<br />

PUSHING TUBE IN BEFORE<br />

PULLING IT OUT HELPS TO<br />

RELEASE TUBE<br />

FRONT VIEW<br />

RATED FOR INDOOR APPLICATIONS ONLY<br />

SIDE VIEW<br />

LEGEND<br />

A = RECOMMENDED WATER SUPPLY LOCATION. SHUT-OFF VALVE (NOT FURNISHED TO ACCEPT 3/8 O.D. UNPLATED COPPER TUBE.<br />

3" (76mm) MAXIMUM OUT FROM WALL.<br />

B = RECOMMENDED LOCATION FOR WASTE OUTLET TO ACCOMODATE 1-1/2" NOMINAL DRAIN. DRAIN STUB 2 IN. OUT FROM WALL<br />

C = 1-1/2 TRAP NOT FURNISHED<br />

D = ELECTRICAL SUPPLY (3) WIRE RECESSED BOX DUPLEX OUTLET<br />

F = 7/16 BOLT HOLES FOR FASTENING UNIT TO WALL<br />

INSURE PROPER VENTILATION BY MAINTAINING 6" (152mm) MINIMUM CLEARANCE FROM CABINET LOUVERS TO WALL.<br />

Elkay<br />

8-19F (Rev. 4/11)<br />

2222 Camden Court<br />

Oak Brook, IL 60523<br />

elkayusa.com<br />

Printed in U.S.A.<br />

©2011 Elkay

PRODUCT FEATURES<br />

• Complete filtered cooler and bottle filling<br />

station in a consolidated space saving ADAcompliant<br />

design<br />

• Sanitary, no-touch, sensor activation with<br />

automatic 30-second shut-off timer<br />

• WaterSentry ® Plus 3000 gallon filter included<br />

• Flexi-Guard ® StreamSaver Bubbler<br />

• Silver Ion anti-microbial protection<br />

• Quick fill rate is 1.1 gpm for refrigerated units<br />

and 1.5 gpm for non-refrigerated units<br />

• Laminar flow provides minimal splash<br />

• Real drain system eliminates standing water<br />

• Visual user interface display includes:<br />

• Filter Monitor indicating when replacement<br />

is necessary<br />

• Green Ticker counting the quantity of 16<br />

oz. bottles saved from the landfill for nonrefrigerated<br />

units and 12 oz. bottles for<br />

refrigerated units<br />

Unit shall provide 8.0 gph of 50 0 F water at 90 0 F<br />

ambient and 80 0 F inlet water. Bottle filling unit<br />

shall include an electronic sensor for no-touch<br />

activation with an automatic 30-second shut-off<br />

timer. Shall provide 1.1-1.5* gpm flow rate with<br />

laminar flow to minimize splashing. Shall include<br />

antimicrobial protected plastic components to<br />

prevent mold and mildew. Cooler unit shall have<br />

pushbar activation and water-efficient Stream-<br />

Saver bubbler. Shall include the WaterSentry®<br />

Plus filter, certified to NSF/ANSI 42 and 53 for<br />

lead reduction, with visual monitor to indicate<br />

when replacement is necessary. Bottle Filling<br />

unit shall meet ADA guidelines for parallel approach.<br />

Cooler shall meet ADA guidelines for<br />

frontal or parallel approach. Unit shall be leadfree<br />

design which meets Safe Drinking Water Act<br />

and is certified to NSF/ANSI 61 and California<br />

AB1953. Unit shall be certified to UL399 and<br />

CAN/CSA 22.2 No. 120.<br />

EZH2O T M System<br />

Cooler/Bottle Filling Station<br />

Models LZS8WS and LZSTL(R)8WS<br />

IMAGES<br />

Model LZS8WSLK shown.<br />

Includes Single Filtered<br />

Cooler with Bottle Filling<br />

Station.<br />

¨ Vandal-resistant StreamSaver Bubbler<br />

¨ 51300C Replacement filter<br />

Model LZSTL8WSLK<br />

shown. Includes Bi-Level<br />

Filtered Cooler with<br />

Bottle Filling Station<br />

¨ 51300C_3PK Replacement filter 3-pack<br />

¨ 36292C Receptacle Adaptor Plug<br />

OPTIONAL ACCESSORIES<br />

Ideal for use in:<br />

• Educational facilities<br />

• Healthcare facilities<br />

• Sport and fitness centers<br />

• Airports<br />

• Office buildings<br />

• Other commercial buildings<br />

SUGGESTED SPECIFICATION<br />

*Fill rate may vary slightly depending on existing refrigeration systems in the field<br />

2222 Camden Court<br />

Oak Brook, IL 60523<br />

Phone: 630-572-3192<br />

Web: Elkayusa.com<br />

APPLICATIONS<br />

Third Party Certified to:<br />

• UL399 and CAN/CSA 22.2 No. 120<br />

• Lead-free compliance including<br />

NSF/ANSI 61 and CA AB1953<br />

In keeping with our policy of continuing product improvement, Elkay reserves the right to change <strong>specifications</strong><br />

without notice.<br />

Please visit elkayusa.com for the most current version.<br />

© 2010 Elkay<br />

14-57C (4/2010)

Job Name: ________________________________________<br />

Date: __________________________________ Qty: ______<br />

Page 2<br />

EZH2O is designed to fit on an EZ Cooler which is properly<br />

installed per the EZ Spec Sheet rough-in design.<br />

*Rated for Indoor Use Only<br />

ELKAY®<br />

ROUGH-IN DIMENSIONS<br />

Single Cooler Installation<br />

Bi-Level Cooler Installation<br />

Installation Notes:<br />

• Unit will mount on bracket attached to wall by 6 holes (as shown above)<br />

• Water and electrical will connect thru a hole punched into basin.<br />

Basin will be pre-punched.<br />

• Refer to page 3 for single EZ rough-in.<br />

• Refer to page 4 for bi-level EZ rough-in.<br />

Contact Info (Name, Phone, Email): _____________________<br />

__________________________________________________<br />

__________________________________________________<br />

Approval for Manufacture Signature and Date:<br />

__________________________________________________<br />

Specifications and measurements are subject to change<br />

without notification.<br />

Please visit elkayusa.com for most current version.<br />

2222 Camden Court<br />

Oak Brook, IL 60523<br />

Phone: 630-572-3192<br />

Web: Elkayusa.com<br />

Models LZS8WS<br />

and LZSTL8WS

Page 3<br />

*Rated for Indoor Use Only<br />

ELKAY®<br />

ROUGH-IN DIMENSIONS<br />

*Reduce Height By 3” For Installation Of Children’s ADA Cooler<br />

LEGEND:<br />

A = Recommended Water Supply Location 3/8 O.D. Unplated Copper Tube Connect Stub With Shut-Off (By Others) - 3” (76mm)<br />

Maximum Out From Wall.<br />

B = Recommended Location For Waste Outlet To Accommodate 1-1/2” Nominal Drain. Drain Stub 2” Out From Wall.<br />

C = 1-1/2” Trap (Not Furnished)<br />

D = Electrical Supply (3) Wire Recessed Box Duplex Outlet<br />

E = Insure proper ventilation by maintaining 6” (152mm) minimum clearance from cabinet louvers to wall.<br />

F = 7/16” Bolt Holes For Fastening Unit To Wall<br />

Specifications and measurements are subject to change<br />

without notification.<br />

Please visit elkayusa.com for most current version.<br />

2222 Camden Court<br />

Oak Brook, IL 60523<br />

Phone: 630-572-3192<br />

Web: Elkayusa.com<br />

EZ Style Single Level<br />

Cooler Installation

*Reduce Height By 3” For Installation Of Children’s ADA Cooler<br />

LEGEND:<br />

A = Recommended Water Supply Location 3/8 O.D. Unplated Copper Tube Connect Stub With Shut-Off (By Others) - 3” (76mm)<br />

Maximum Out From Wall.<br />

B = Recommended Location For Waste Outlet To Accommodate 1-1/2” Nominal Drain. Drain Stub 2” Out From Wall.<br />

C = 1-1/2” Trap (Not Furnished)<br />

D = Electrical Supply (3) Wire Recessed Box Duplex Outlet<br />

E = Insure proper ventilation by maintaining 6” (152mm) minimum clearance from cabinet louvers to wall.<br />

F = 7/16” Bolt Holes For Fastening Unit To Wall<br />

Page 4<br />

*Rated for Indoor Use Only<br />

ELKAY®<br />

ROUGH-IN DIMENSIONS<br />

Specifications and measurements are subject to change<br />

without notification.<br />

Please visit elkayusa.com for most current version.<br />

2222 Camden Court<br />

Oak Brook, IL 60523<br />

Phone: 630-572-3192<br />

Web: Elkayusa.com<br />

EZ Style Bi-Level<br />

Cooler Installation

®<br />

Z415B<br />

BODY ASSEMBLY<br />

W/ "TYPE B" STRAINER<br />

SPECIFICATION SHEET<br />

TAG _______<br />

Dimensional Data (inches and [ mm ]) are Subject to Manufacturing Tolerances and Change Without Notice<br />

Dimensions In Inches<br />

ENGINEERING SPECIFICATION: ZURN ZN415B<br />

Floor and shower drain, Dura-Coated cast iron body with bottom outlet, combination invertible membrane clamp and adjustable collar<br />

with seepage slots and "TYPE B" polished nickel bronze, light-duty strainer.<br />

OPTIONS (Check/specify appropriate options)<br />

PIPE SIZE (Specify size/type) OUTLET 'E' BODY HT. DIM.<br />

2 thru 4 [51 thru 102] _____ IC Inside Caulk 3-7/8 [98]<br />

2 thru 4 [51 thru 102] _____ IG Inside Gasket 3-7/8 [98]<br />

2 [51] _____ IP Threaded 2-3/8 [60]<br />

3 [76] _____ IP Threaded 2-5/8 [67]<br />

4 [102] _____ IP Threaded 2-7/8 [73]<br />

6 [152] _____ IP Threaded 2-3/4 [70]<br />

2 thru 4 [51 thru 102] _____ NH No-Hub 3-7/8 [98]<br />

2 thru 4 [51 thru 102] _____ NL Neo-Loc 3-3/4 [95]<br />

PREFIXES<br />

___ ZB D.C.C.I. Body Assembly w/ Polished Bronze Top<br />

___ ZN D.C.C.I. Body Assembly w/ Polished Nickel Bronze Top*<br />

SUFFIXES<br />

___ -AA All Acid Resisting Epoxy<br />

___ -SR Stabilizer Ring<br />

___ -AR Acid Resisting Epoxy Coated Cast Iron<br />

___ -TC Neo-Loc Test Cap Gasket (2-4 [51-102] NL Outlet Only)<br />

___ -C Clamp Collar for -90 Side Outlet Body<br />

___ -U 1 - 3 [25 - 76] High Extension Adapter<br />

___ -CP Chrome-Plated Bronze Top<br />

___ -DC Debris Cover (Field Assembled)<br />

___ -DP Decorative Polished Top<br />

___ -V<br />

___ -VP<br />

___ -W<br />

Backwater Valve<br />

Vandal-Proof Secured Top<br />

Winter Closure Plug<br />

___ -EF 3/8 [16] Extension Frame<br />

___ -Y Sediment Bucket<br />

___ -G Galvanized Cast Iron<br />

___ -4 4 [102] Diameter Funnel (Z328)<br />

___ -HD Heavy-Duty Slotted Grate (ZN 5 [127] & 6 [152] Sizes Only)<br />

___ -OF Oval Funnel (Z329-7) (6 - 10 [152 - 254] Strainers Only)<br />

___ -P Trap Primer Connection (Specify 1/2 [13] or 3/4 [19])<br />

___ -SA Stabilizer Assembly (See Z1035)<br />

___ -SQ Stabilizer Q-Deck (See Z1035-Q)<br />

*REGULARLY FURNISHED UNLESS OTHERWISE SPECIFIED<br />

___ -18<br />

___ -90<br />

REV. P<br />

Approx.<br />

Wt. Lbs.<br />

[kg]<br />

Leveling Ring (See Z400-18)<br />

90° Threaded Side Outlet Body Assembly<br />

(2 [51], 3 [76] Only)<br />

DWG. NO. 58789<br />

Strainer<br />

Open Area<br />

Sq. In. [cm 2 ]<br />

A B Strainer<br />

K<br />

K'<br />

Pipe Size Dia. Min. Max. Min. Max.<br />

2-3 [51-76] 5 [127] 1 [25] 1-1/2 [38] 1-3/32 [28] 2-1/4 [57] 11 [5] 8 [52]<br />

2-3-4 [51-76-102] 6 [152] 1 [25] 1-25/32 [45] 1-13/32 [36] 2-17/32 [64] 13 [6] 9 [58]<br />

2-3-4 [51-76-102] 7 [178] 1 [25] 2-1/8 [54] 1-23/32 [44] 2-7/8 [73] 14 [6] 12 [77]<br />

3-4 [76-102] 8 [203] 1-5/32 [30] 2-1/8 [54] 1-3/4 [44] 2-7/8 [73] 16 [7] 18 [116]<br />

6 [152] 8 [203] 1-5/32 [30] 2-1/8 [54] 1-3/4 [44] 2-7/8 [73] 18 [8] 18 [116]<br />

6 [152] 10 [254] 1-7/16 [37] 2-1/2 [64] 2 [51] 3-1/4 [83] 22 [10] 26 [168]<br />

DATE: 06/20/11 C.N. NO. 121440<br />

PRODUCT NO. Z415B<br />

ZURN INDUSTRIES, LLC ♦ SPECIFICATION DRAINAGE OPERATION ♦ 1801 Pittsburgh Ave. ♦ Erie, PA 16514<br />

Phone: 814/455-0921 ♦ Fax: 814/454-7929 ♦ World Wide Web: www.zurn.com<br />

In Canada: ZURN INDUSTRIES LIMITED ♦ 3544 Nashua Drive ♦ Mississauga, Ontario L4V1L2 ♦ Phone: 905/405-8272 Fax: 905/405-1292

Features<br />

• Vitreous china<br />

• Wall-mount<br />

• With hanger<br />

• With overflow<br />

• Drilled for concealed arm carrier<br />

• Optional soap dispenser hole on left (-L) or right (-R)<br />

• 8″ (203 mm) centers, 4″ (102 mm), centers or single<br />

hole<br />

• 21-1/4″ (540 mm) x 18-1/8″ (460 mm)<br />

Codes/Standards Applicable<br />

Specified model meets or exceeds the following:<br />

• ADA<br />

• ICC/ANSI A117.1<br />

• CSA B651<br />

• OBC<br />

• ASME A112.19.2/CSA B45.1<br />

Specified Model<br />

WALL-MOUNT LAVATORY<br />

K-2005<br />

ALSO K-2006, K-2007<br />

ADA<br />

KINGSTONTM<br />

CSA B651<br />

OBC<br />

Colors/Finishes<br />

• 0: White<br />

• Other: Refer to Price Book for additional colors/finishes<br />

Accessories<br />

• CP: Polished Chrome<br />

• Other: Refer to Price Book for additional colors/finishes<br />

Model Description Colors/Finishes<br />

K-2005 Lavatory with 4″ (102 mm) centers less soap dispenser hole ❑ 0 ❑ Other_____<br />

K-2005-L Lavatory with 4″ (102 mm) centers with soap dispenser hole on left ❑ 0 ❑ Other_____<br />

K-2005-R Lavatory with 4″ (102 mm) centers with soap dispenser hole on right ❑ 0 ❑ Other_____<br />

K-2006 Lavatory with 8″ (203 mm) centers less soap dispenser hole ❑ 0 ❑ Other_____<br />

K-2007 Lavatory with single hole less soap dispenser hole ❑ 0 ❑ Other_____<br />

K-2007-L Lavatory with single hole with soap dispenser hole on left ❑ 0 ❑ Other_____<br />

K-2007-R Lavatory with single hole with soap dispenser hole on right ❑ 0 ❑ Other_____<br />

Recommended Accessories<br />

K-8998 P-Trap ❑ CP ❑ Other_____<br />

Product Specification<br />

Lavatory shall be made of vitreous china. The lavatory shall be 21-1/4″ (540 mm) in length and 18-1/8″ (460 mm) in width.<br />

Lavatory shall be wall-mounted with hangers. Lavatory shall have 8″ (203 mm) centers (K-2006), 4″ (102 mm) centers (K-2005),<br />

or single hole (K-2007). Lavatory shall have overflow. Lavatory shall be drilled for concealed arm carrier. Lavatory shall have<br />

optional soap dispenser hole left (-L) or right (-R). Lavatory shall be Kohler Model K-______-______-______.<br />

Page 1 of 2<br />

116611-4-CL<br />

USA/Canada: 1-800-4KOHLER<br />

(1-800-456-4537)<br />

www.kohler.com

KINGSTONTM<br />

Technical Information<br />

Fixture*:<br />

Basin area 16″ (406 mm) x 10″ (254 mm)<br />

Water depth 3-1/8″ (79 mm)<br />

Drain hole Ø 1-3/4″ (44 mm)<br />

* Approximate measurements for comparison only.<br />

Installation Notes<br />

Install this product according to the installation guide.<br />

Will comply with ADA when installed per Section 606<br />

Lavatories of the Act.<br />

Will comply with CSA B651 when installed per Clause 4.3.3<br />

of the standard.<br />

Will comply with OBC when installed per Clause 3.8.3.11.<br />

Holes K-2005 K-2006 K-2007<br />

Spout Ø 1-1/4″<br />

(32 mm)<br />

Ø 1-3/8″<br />

(35 mm)<br />

Ø 1-3/8″<br />

(35 mm)<br />

Faucet Ø 1-1/4″<br />

(32 mm)<br />

Ø 1-3/8″<br />

(35 mm)<br />

Soap<br />

dispenser<br />

Ø 1-1/4″<br />

(32 mm)<br />

Ø 1-1/4″<br />

(32 mm)<br />

Included components:<br />

Hanger 64839<br />

Concealed Arm<br />

Hole Location<br />

K-2006<br />

1/2" (13 mm) 2" (51 mm)<br />

4" (102 mm) 3-3/4" (95 mm)<br />

4" (102 mm)<br />

Faucet Holes<br />

13-3/4"<br />

(349 mm)<br />

8-1/2"<br />

(216 mm)<br />

Ø 1-1/4" (32 mm)<br />

Leveling Screw<br />

Hole<br />

33<br />

(845 mm)<br />

8-3/8"<br />

(213 mm)<br />

Leveling<br />

Screw Slot<br />

18-1/8"<br />

(460 mm)<br />

17-1/4" (438 mm) Ø 1-1/4" (32 mm)<br />

Locking Device<br />

21-1/4" (540 mm) Hole<br />

8-1/4" (210 mm)<br />

12"<br />

(305 mm)<br />

5" (127 mm)<br />

3/8"<br />

Hot<br />

29-1/8"<br />

(740 mm)<br />

1-1/4" OD<br />

4" (102 mm)<br />

Standard Installation<br />

4-3/8" 7-1/4"<br />

(111 mm) (184 mm)<br />

3/8" Cold<br />

12-7/8"<br />

(327 mm)<br />

34"<br />

(864 mm)<br />

Max<br />

27"<br />

(686 mm)<br />

Min<br />

4-1/4"<br />

(108 mm)<br />

31"<br />

(787 mm)<br />

4-1/4"<br />

(108 mm)<br />

18-1/8" (460 mm)<br />

8"<br />

(203 mm)<br />

Min<br />

9"<br />

(229 mm)<br />

Min<br />

Recommended ADA Installation<br />

K-2005<br />

-L 4" (102 mm) -R<br />

4-1/2" (114 mm)<br />

K-2007<br />

4-3/8" (111 mm)<br />

-L -R<br />

9"<br />

(229 mm)<br />

6"<br />

(152 mm)<br />

Max<br />

3-3/4"<br />

(95 mm)<br />

3-3/4"<br />

(95 mm)<br />

KINGSTONTM WALL-MOUNT LAVATORY<br />

Page2of2<br />

116611-4-CL<br />

Product Diagram

Battery Powered Hand Washing Faucet<br />

EBF-85<br />

u<br />

Description<br />

Battery Powered, Sensor Activated Electronic Hand Washing Faucet for tempered or hot/cold<br />

water operation.<br />

u<br />

Flow Rate<br />

£0.5 gpm/1.9 Lpm Vandal Resistant Spray Head<br />

(See Accessories for other Spray Head options)<br />

u<br />

Specifications<br />

ADA Compliant, Battery Powered, Sensor Activated, Chrome Plated Brass Hand Washing Faucet<br />

with the following features:<br />

• Splash-proof Circuit Control Module<br />

• Fiber Optic, Automatic, Self-adaptive Sensing<br />

• Isolated Latching Solenoid Operator, isolates magnetic components from water contact<br />

• Audible Tone Low Battery Indicator<br />

• Serviceable Filtered Solenoid Valve<br />

• Bak-Chek ® Tee for Hot/Cold Supply<br />

• Trim Plate with Anti-Rotation Pin (specify 4” or 8”)<br />

• Vandal Resistant Spray Head with Pressure Compensating Flow Control<br />

• Polypropylene Optic Cable Protection<br />

• Includes four (4) C-size Alkaline Batteries<br />

u<br />

u<br />

Variations<br />

(Add suffix to Model Number for inclusion with Faucet)<br />

• Trim Plate (must be specified)<br />

£ -4 Trim Plate for 4” Centerset Sink<br />

£ -8 Trim Plate for 8” Centerset Sink<br />

• Temperature Mixing Valves (optional)<br />

£ ADM Above Deck Mechanical Mixing Valve<br />

£ BDM Below Deck Mechanical Mixing Valve<br />

£ BDT Below Deck Thermostatic Mixing Valve<br />

Bak-Chek ® Tee not required or provided when a Temperature Mixing Valve is included with the<br />

faucet.<br />

Consult Factory for Finish Variations<br />

Accessories (Specify separately)<br />

• Vandal Resistant Spray Heads<br />

£ ETF-1027-A 2.2 gpm/8.3 Lpm Laminar Flow Spray Head<br />

(recommended for medical applications)<br />

£ ETF-1022-A 2.2 gpm/8.3 Lpm Aerator<br />

• Grid Strainer<br />

£ ETF-460-A Chrome Plated Brass Grid Strainer w/1¼” Outlet Tube<br />

See OPTIMA Accessories Section of the Sloan Catalog for a complete listing of OPTIMA Faucet<br />

Accessories and Variations.<br />

u<br />

u<br />

u<br />

u<br />

u<br />

u<br />

ADA Compliant<br />

Automatic<br />

The Sloan OPTIMA Plus ® EBF-85 Battery Powered, Electronic Hand<br />

Washing Faucet operates by means of an adaptive infrared sensor that<br />

is linked to the faucet by a fiber optic cable. Once the user’s hands<br />

enter the sensor’s effective range, the Solenoid activates the water flow.<br />

Tempered water flows from the Faucet until hands are moved away.<br />

The Faucet then automatically shuts off.<br />

Hygienic<br />

The ultimate in sanitary protection — there are no handles to turn or<br />

buttons to push. Helps to control the spread of infectious diseases.<br />

Economical<br />

Automatic operation provides water usage savings over other faucet<br />

devices. Reduces maintenance and operation costs. Self-adaptive<br />

Range Adjustment makes installation quick and easy. Battery operation<br />

ideal for Retrofit installations.<br />

Warranty<br />

3 year (limited)<br />

Compliant to:<br />

ASME A112.18.1-2005/CSA B125.1-05<br />

ISO/IEC 17025<br />

This product may<br />

contribute to<br />

LEED credits.<br />

See details on LEED<br />

calculation worksheet.<br />

This space for Architect/Engineer approval<br />

Job Name<br />

Model Specified<br />

Date<br />

Quantity<br />

Variations Specified<br />

Customer/Wholesaler<br />

Contractor<br />

Architect<br />

Optima Plus EBF-85 S.S. — Rev. 2 (09/10)<br />

The information contained in this document is subject to change without notice.

EBF-85<br />

FAUCET DIMENSIONS<br />

(Shown with 4” Trim Plate)<br />

u<br />

u<br />

Description<br />

Battery Powered, Sensor Activated Electronic Hand Washing Faucet for tempered or<br />

hot/cold water operation.<br />

Flow Rate<br />

£0.5 gpm/1.9 Lpm Vandal Resistant Spray Head<br />

(See Accessories for other Spray Head options)<br />

ELECTRICAL SPECIFICATIONS<br />

u<br />

u<br />

Control Circuit<br />

6 VDC — Operates on four (4)<br />

alkaline C-size batteries. Self-adaptive<br />

Range Adjustment, Audible<br />

Troubleshooting and Low Battery<br />

Indicator. Fiber Optic Cable between<br />

Electronic Module and Faucet keeps<br />

all electronic signals below the sink.<br />

Battery Life<br />

2 years at 8,000 cycles/month<br />

u<br />

u<br />

OPTIMA ® Sensor Range<br />

Nominal: 4”- 5” (102 mm - 127 mm)<br />

Self-adaptive Zone: 2” - 8”<br />

(51 mm - 203 mm) — Faucet selfadjustment<br />

range within this zone<br />

dependent upon depth and reflectivity of<br />

basin.<br />

Solenoid Valve<br />

Low Energy Latching Solenoid with Selfcleaning<br />

By-pass and Integral Clean Out<br />

Strainer Filter.<br />

u<br />

u<br />

Time Out Adjustment Settings<br />

30 seconds — The Faucet Time out Setting determines the maximum time the<br />

faucet will run upon continuous detection. The EBF-85 is factory set at the 30<br />

second time out. Consult factory for time out settings to meet individual<br />

application requirements.<br />

Maximum Distance Control Module may be Installed from Spout<br />

30” (762 mm)<br />

OPERATION<br />

1. Continuous, invisible light<br />

beams are emitted from the<br />

OPTIMA ® Sensor. Fiber optic<br />

cables transmit the light from<br />

the circuit to the spout.<br />

2. The faucet is activated by<br />

placing hands beneath the<br />

spray head, thus activating the<br />

Solenoid Valve. Tempered<br />

water flows for as long as<br />

hands continue to stay within<br />

the Sensor’s range (30 second<br />

automatic shut off).<br />

3. When hands are removed,<br />

the water flow automatically<br />

stops. The faucet is then<br />

ready for the next user.<br />

EBF-85 Faucet with Bak-Chek ® Tee<br />

for Hot and Cold Water Supply<br />

(shown with 4” trim plate)<br />

EBF-85 Faucet with ADM Variation Mixing<br />

Valve for Hot and Cold Water Supply<br />

(shown with 8” trim plate)<br />

EBF-85 Faucet with BDM and BDT Variation Mixing<br />

Valves for Hot and Cold Water Supply<br />

(shown with 4” trim plate)<br />

SLOAN VALVE COMPANY • 10500 SEYMOUR AVENUE • FRANKLIN PARK, IL 60131<br />

Phone: 1-800-982-5839 or 1-847-671-4300 • Fax: 1-800-447-8329 or 1-847-671-4380 • www.sloanvalve.com<br />

Copyright © 2010 Sloan Valve Company Optima Plus EBF-85 S.S. — Rev. 2 (09/10)

Features<br />

• Vitreous china<br />

• Drop-in<br />

• Single-hole<br />

• ADA compliant when installed in a 21″ (533 mm)<br />

minimum depth countertop<br />

• Optional soap dispenser hole on left (-L) or right (-R)<br />

• With or without overflow<br />

• 20-1/4″ (514 mm) x 17-1/2″ (445 mm)<br />

Codes/Standards Applicable<br />

Specified model meets or exceeds the following:<br />

• ADA<br />

• ICC/ANSI A117.1<br />

• CSA B651<br />

• OBC<br />

• ASME A112.19.2/CSA B45.1<br />

Specified Model<br />

COUNTERTOP BATHROOM SINK<br />

K-2196<br />

ADA<br />

CSA B651<br />

OBC<br />

Colors/Finishes<br />

• 0: White<br />

• Other: Refer to Price Book for additional colors/finishes<br />

Accessories<br />

• CP: Polished Chrome<br />

PENNINGTON ®<br />

Model Description Colors/Finishes<br />

K-2196-1N Single-hole drilling; less overflow ❑ 0 ❑ Other_____<br />

K-2196-1K Single-hole drilling; less overflow; with soap dispenser hole on right ❑ 0 ❑ Other_____<br />

K-2196-1F Single-hole drilling; less overflow; with soap dispenser hole on left ❑ 0 ❑ Other_____<br />

K-2196-1 Single-hole drilling; with overflow; less soap dispenser hole ❑ 0 ❑ Other_____<br />

K-2196-1L Single-hole drilling; with overflow; with soap dispenser hole on left ❑ 0 ❑ Other_____<br />

K-2196-1R Single-hole drilling; with overflow; with soap dispenser hole on right ❑ 0 ❑ Other_____<br />

Recommended Accessories<br />

K-8998 P-Trap ❑ CP<br />

Product Specification<br />

The drop-in bathroom sink shall be made of vitreous china. Bathroom sink shall be 20-1/4″ (514 mm) in length, and 17-1/2″ (445<br />

mm) in width. Bathroom sink shall have single-hole drilling (-1). Bathroom sink shall be ADA compliant when installed in a 21″<br />

(533 mm) minimum depth countertop. Bathroom sink shall feature optional soap dispenser hole (-L, left or -R, right). Bathroom<br />

sink shall be Kohler Model K-2196-_______-______.<br />

Page 1 of 2<br />

113805-4-DG<br />

USA/Canada: 1-800-4KOHLER<br />

(1-800-456-4537)<br />

www.kohler.com

PENNINGTON ®<br />

Technical Information<br />

Fixture*:<br />

Basin area 16″ (406 mm) x 11″ (279 mm)<br />

Water depth 4″ (102 mm)<br />

Drain hole Ø 1-3/4″ (44 mm)<br />

*Approximate measurements for comparison only.<br />

Holes<br />

Spout<br />

Soap dispenser<br />

Ø 1-3/8″ (35 mm)<br />

Ø 1-1/4″(32 mm)<br />

Included components:<br />

Cut-out template 1002970-7<br />

Installation Notes<br />

Install this product according to the installation guide.<br />

NOTICE: Countertop manufacturer or cutter must use the<br />

cutout template provided with the product, or a current one<br />

provided by Kohler Co. (call 1-800-4KOHLER). Kohler Co. is<br />

not responsible for cutout errors when the incorrect cutout<br />

template is used.<br />

Will comply with ADA when installed per Section 606<br />

Lavatories of the Act.<br />

Will comply with CSA B651 when installed per Clause 4.3.3<br />

of the standard.<br />

Will comply with OBC when installed per Clause 3.8.3.11.<br />

6-3/4"<br />

(171 mm)<br />

10"<br />

(254 mm)<br />

3/8" Hot<br />

1-1/4"<br />

Outlet<br />

-L -R<br />

20-1/4" (514 mm)<br />

2-15/16"<br />

(75 mm)<br />

7-3/8"<br />

(187 mm)<br />

1-3/4"<br />

(44 mm)<br />

5/8" (16 mm)<br />

3/8" Cold<br />

17-1/2"<br />

(445 mm)<br />

8-1/2"<br />

(216 mm) 14-1/8"<br />

(359 mm)<br />

34"<br />

(864 mm)<br />

3"<br />

(76 mm)<br />

24" (610 mm)<br />

8"<br />

(203 mm)<br />

Min 6"<br />

(152 mm)<br />

Max<br />

27"<br />

(688 mm)<br />

Min 9"<br />

(229 mm) Min<br />

Recommended ADA Installation<br />

4" (102 mm)<br />

Standard Installation<br />

PENNINGTON ® COUNTERTOP BATHROOM SINK<br />

Page2of2<br />

113805-4-DG<br />

Product Diagram

Battery Powered Hand Washing Faucet<br />

EBF-85<br />

u<br />

Description<br />

Battery Powered, Sensor Activated Electronic Hand Washing Faucet for tempered or hot/cold<br />

water operation.<br />

u<br />

Flow Rate<br />

£0.5 gpm/1.9 Lpm Vandal Resistant Spray Head<br />

(See Accessories for other Spray Head options)<br />

u<br />

Specifications<br />

ADA Compliant, Battery Powered, Sensor Activated, Chrome Plated Brass Hand Washing Faucet<br />

with the following features:<br />

• Splash-proof Circuit Control Module<br />

• Fiber Optic, Automatic, Self-adaptive Sensing<br />

• Isolated Latching Solenoid Operator, isolates magnetic components from water contact<br />

• Audible Tone Low Battery Indicator<br />

• Serviceable Filtered Solenoid Valve<br />

• Bak-Chek ® Tee for Hot/Cold Supply<br />

• Trim Plate with Anti-Rotation Pin (specify 4” or 8”)<br />

• Vandal Resistant Spray Head with Pressure Compensating Flow Control<br />

• Polypropylene Optic Cable Protection<br />

• Includes four (4) C-size Alkaline Batteries<br />

u<br />

u<br />

Variations<br />

(Add suffix to Model Number for inclusion with Faucet)<br />

• Trim Plate (must be specified)<br />

£ -4 Trim Plate for 4” Centerset Sink<br />

£ -8 Trim Plate for 8” Centerset Sink<br />

• Temperature Mixing Valves (optional)<br />

£ ADM Above Deck Mechanical Mixing Valve<br />

£ BDM Below Deck Mechanical Mixing Valve<br />

£ BDT Below Deck Thermostatic Mixing Valve<br />

Bak-Chek ® Tee not required or provided when a Temperature Mixing Valve is included with the<br />

faucet.<br />

Consult Factory for Finish Variations<br />

Accessories (Specify separately)<br />

• Vandal Resistant Spray Heads<br />

£ ETF-1027-A 2.2 gpm/8.3 Lpm Laminar Flow Spray Head<br />

(recommended for medical applications)<br />

£ ETF-1022-A 2.2 gpm/8.3 Lpm Aerator<br />

• Grid Strainer<br />

£ ETF-460-A Chrome Plated Brass Grid Strainer w/1¼” Outlet Tube<br />

See OPTIMA Accessories Section of the Sloan Catalog for a complete listing of OPTIMA Faucet<br />

Accessories and Variations.<br />

u<br />

u<br />

u<br />

u<br />

u<br />

u<br />

ADA Compliant<br />

Automatic<br />

The Sloan OPTIMA Plus ® EBF-85 Battery Powered, Electronic Hand<br />

Washing Faucet operates by means of an adaptive infrared sensor that<br />

is linked to the faucet by a fiber optic cable. Once the user’s hands<br />

enter the sensor’s effective range, the Solenoid activates the water flow.<br />

Tempered water flows from the Faucet until hands are moved away.<br />

The Faucet then automatically shuts off.<br />

Hygienic<br />

The ultimate in sanitary protection — there are no handles to turn or<br />

buttons to push. Helps to control the spread of infectious diseases.<br />

Economical<br />

Automatic operation provides water usage savings over other faucet<br />

devices. Reduces maintenance and operation costs. Self-adaptive<br />

Range Adjustment makes installation quick and easy. Battery operation<br />

ideal for Retrofit installations.<br />

Warranty<br />

3 year (limited)<br />

Compliant to:<br />

ASME A112.18.1-2005/CSA B125.1-05<br />

ISO/IEC 17025<br />

This product may<br />

contribute to<br />

LEED credits.<br />

See details on LEED<br />

calculation worksheet.<br />

This space for Architect/Engineer approval<br />

Job Name<br />

Model Specified<br />

Date<br />

Quantity<br />

Variations Specified<br />

Customer/Wholesaler<br />

Contractor<br />

Architect<br />

Optima Plus EBF-85 S.S. — Rev. 2 (09/10)<br />

The information contained in this document is subject to change without notice.

EBF-85<br />

FAUCET DIMENSIONS<br />

(Shown with 4” Trim Plate)<br />

u<br />

u<br />

Description<br />

Battery Powered, Sensor Activated Electronic Hand Washing Faucet for tempered or<br />

hot/cold water operation.<br />

Flow Rate<br />

£0.5 gpm/1.9 Lpm Vandal Resistant Spray Head<br />

(See Accessories for other Spray Head options)<br />

ELECTRICAL SPECIFICATIONS<br />

u<br />

u<br />

Control Circuit<br />

6 VDC — Operates on four (4)<br />

alkaline C-size batteries. Self-adaptive<br />

Range Adjustment, Audible<br />

Troubleshooting and Low Battery<br />

Indicator. Fiber Optic Cable between<br />

Electronic Module and Faucet keeps<br />

all electronic signals below the sink.<br />

Battery Life<br />

2 years at 8,000 cycles/month<br />

u<br />

u<br />

OPTIMA ® Sensor Range<br />

Nominal: 4”- 5” (102 mm - 127 mm)<br />

Self-adaptive Zone: 2” - 8”<br />

(51 mm - 203 mm) — Faucet selfadjustment<br />

range within this zone<br />

dependent upon depth and reflectivity of<br />

basin.<br />

Solenoid Valve<br />

Low Energy Latching Solenoid with Selfcleaning<br />

By-pass and Integral Clean Out<br />

Strainer Filter.<br />

u<br />

u<br />

Time Out Adjustment Settings<br />

30 seconds — The Faucet Time out Setting determines the maximum time the<br />

faucet will run upon continuous detection. The EBF-85 is factory set at the 30<br />

second time out. Consult factory for time out settings to meet individual<br />

application requirements.<br />

Maximum Distance Control Module may be Installed from Spout<br />

30” (762 mm)<br />

OPERATION<br />

1. Continuous, invisible light<br />

beams are emitted from the<br />

OPTIMA ® Sensor. Fiber optic<br />

cables transmit the light from<br />

the circuit to the spout.<br />

2. The faucet is activated by<br />

placing hands beneath the<br />

spray head, thus activating the<br />

Solenoid Valve. Tempered<br />

water flows for as long as<br />

hands continue to stay within<br />

the Sensor’s range (30 second<br />

automatic shut off).<br />

3. When hands are removed,<br />

the water flow automatically<br />

stops. The faucet is then<br />

ready for the next user.<br />

EBF-85 Faucet with Bak-Chek ® Tee<br />

for Hot and Cold Water Supply<br />

(shown with 4” trim plate)<br />

EBF-85 Faucet with ADM Variation Mixing<br />

Valve for Hot and Cold Water Supply<br />

(shown with 8” trim plate)<br />

EBF-85 Faucet with BDM and BDT Variation Mixing<br />

Valves for Hot and Cold Water Supply<br />

(shown with 4” trim plate)<br />

SLOAN VALVE COMPANY • 10500 SEYMOUR AVENUE • FRANKLIN PARK, IL 60131<br />

Phone: 1-800-982-5839 or 1-847-671-4300 • Fax: 1-800-447-8329 or 1-847-671-4380 • www.sloanvalve.com<br />

Copyright © 2010 Sloan Valve Company Optima Plus EBF-85 S.S. — Rev. 2 (09/10)

SPECIFICATIONS<br />

GENERAL<br />

Highest quality sink formed of #18 (1.2mm) gauge, type 304<br />

(18-8) nickel bearing stainless steel. Top mount.<br />

DESIGN FEATURES<br />

Bowl Depths: 6-1/8" (156mm) (BLR[Q]1560), 7-1/8" (181mm)<br />

(all others).<br />

Coved Corners: 1-3/4" (44mm) vertical and horizontal radius.<br />

Bowl and Faucet Deck Recess: 3/16" (5mm) below outside<br />

edge of sink.<br />

Finish: Exposed surfaces are hand blended to a lustrous satin<br />

finish.<br />

Underside: Fully undercoated to dampen sound and reduce<br />

condensation.<br />

These sinks comply with ASME A112.19.3-2008/CSA B45.4-08.<br />

These sinks are listed by the International Association<br />

of Plumbing and Mechanical Officials as meeting the<br />

require ments of the Uniform Plumbing Code.<br />

Gourmet Sink<br />

and Sink Packages<br />

Model BLH15C<br />

Model BLR(Q)151<br />

SINK PACKAGES<br />

BLH15C Package includes:<br />

(1) BLR15 Sink.<br />

(1) LKDA2438 Faucet.<br />

(1) LK36 Basket strainer.<br />

BLR150C Package includes:<br />

(1) BLR15 Sink.<br />

(1) LKD2223 Faucet.<br />

(1) LK36 Basket strainer.<br />

OTHER<br />

Drain Openings: 3-1/2" (89mm) (BLR[Q]1516), 2" (51mm) (all<br />

others).<br />

NOTE: Unless otherwise specified, sink is furnished with 1 faucet<br />

hole as shown.<br />

Model BLR150C<br />

OPTIONAL ACCESSORIES<br />

Bottom Grid: LKWBG12090SS (BLH15C, BLR150C, BLR[Q]15,<br />

BLR[Q]1560).<br />

Cutting Board: CB912.<br />

Drains: LK36 (BLH15C, BLR150C, BLR[Q]15, BLR[Q]1560), LK99<br />

(BLR[Q]1516).<br />

Installation hardware for thicker countertops: LK363 (up to<br />

1-1/2" [38mm] thick); LK463 (up to 2-1/2" [66mm] thick).<br />

Rinsing Basket: LKWRB1209SS.<br />

Utensil Caddy for Rinsing Basket: LKWUCSS.<br />

SEE OTHER SIDE FOR PRODUCT DIMENSIONS.<br />

In keeping with our policy of continuing product improvement, Elkay reserves the right to change<br />

product <strong>specifications</strong> without notice. Please visit elkayusa.com for most current version of Elkay<br />

product specification sheets.<br />

This specification describes an Elkay product with design, quality and functional benefits to the<br />

user. When making a comparison of other producers’ offerings, be certain these features are not<br />

overlooked.<br />

Elkay<br />

elkayusa.com<br />

2222 Camden Court<br />

Oak Brook, IL 60523<br />

Printed in U.S.A.<br />

©2008 Elkay<br />

(Rev. 12/08) 1-3E

Gourmet Sink<br />

and Sink Packages<br />

SPECIFICATIONS<br />

SINK DIMENSIONS*<br />

Cutout in<br />

No. of 1 1 /4"<br />

Overall<br />

Inside Bowl<br />

Countertop<br />

(32mm) or 1 1 /2"<br />

U-Channel Quick-Clip ® (11 /2" [38mm]<br />

(38mm) Dia. Minimum<br />

Model<br />

Model<br />

L W L W D Radius Corners)<br />

Drain Faucet Holes Cabinet<br />

Number Number A B C D E L W Opening 4" (102mm) Centers Size<br />

BLH15C – 15 15 12 9 1 /4 7 1 /8 14 3 /8 14 3 /8 2 3 18<br />

(381mm) (381mm) (305mm) (235mm) (181mm) (365mm) (365mm) (51mm)<br />

(457mm)<br />

BLR150C – 15 15 12 9 1 /4 7 1 /8 14 3 /8 14 3 /8 2 1 18<br />

(381mm) (381mm) (305mm) (235mm) (181mm) (365mm) (365mm) (51mm)<br />

(457mm)<br />

BLR15 BLRQ15 15 15 12 9 1 /4 7 1 /8 14 3 /8 14 3 /8 2 1, 2, MR2 or 3 18<br />

(381mm) (381mm) (305mm) (235mm) (181mm) (365mm) (365mm) (51mm)<br />

(457mm)<br />

BLR1516 BLRQ1516 15 15 12 9 1 /4 7 1 /8 14 3 /8 14 3 /8 3 1 ⁄2 1, 2, MR2 or 3 18<br />

(381mm) (381mm) (305mm) (235mm) (181mm) (365mm) (365mm) (89mm)<br />

(457mm)<br />

BLR1560 BLRQ1560 15 15 12 9 1 /4 6 1 /8 14 3 /8 14 3 /8 2 1, 2, MR2 or 3 18<br />

(381mm) (381mm) (305mm) (235mm) (156mm) (365mm) (365mm) (51mm)<br />

(457mm)<br />

*Length is left to right. Width is front to back.<br />

HOLE DRILLING<br />

CONFIGURATIONS<br />

1<br />

(1-1/4" [32mm] diameter)<br />

1-3/4"R (44mm)<br />

D<br />

B<br />

4"<br />

(102mm)<br />

C<br />

A<br />

2<br />

(1-1/4" [32mm] diameter)<br />

4"<br />

(102mm)<br />

1-3/4"R (44mm)<br />

Model BLR151 Illustrated<br />

E<br />

MR2<br />

(1-1/2" [38mm] diameter)<br />

4"<br />

4"<br />

(102mm) (102mm)<br />

3<br />

(1-1/2" [38mm] diameter)<br />

U-Channel Type Mounting System<br />

Quick-Clip ® Mounting System<br />

Elkay<br />

1-3E (Rev. 12/08)<br />

2222 Camden Court<br />

Oak Brook, IL 60523<br />

elkayusa.com<br />

Printed in U.S.A.<br />

©2008 Elkay

MECHANICAL FAUCETS<br />

895-317CP<br />

Manual and Metering Faucets<br />

Product Type<br />

___________________________________________________<br />

Deck Mounted 4" Fixed Centers Hot and Cold Water Sink<br />

Faucet<br />

Features & Specifications<br />

___________________________________________________<br />

• 4" Fixed Centers<br />

• 3 1/2" Rigid / Swing Gooseneck Spout<br />

• 2.2 GPM (8.3 L/min) Aerator<br />

• 4" Wristblade Handle<br />

• Quaturn Compression Operating Cartridge<br />

• 1/2" NPSM Supply Inlets and Coupling Nut for 3/8" or 1/2"<br />

Flexible Riser<br />

• CFNow! Item Ships in 5 Days<br />

Performance Specification<br />

___________________________________________________<br />

• Rated Operating Pressure: 20-125 PSI<br />

• Rated Operating Temperature: 40-140ºF<br />

Job Name ________________________________________________<br />

Item Number _____________________________________________<br />

Section/Tag ______________________________________________<br />

Model Specified ___________________________________________<br />

Architect _________________________________________________<br />

Engineer _________________________________________________<br />

Contractor ________________________________________________<br />

[ ] Submitted as Shown [ ] Submitted with Variations<br />

Date _____________________________________________________<br />

Warranty<br />

___________________________________________________<br />

• Lifetime Limited Faucet Warranty<br />

• 5-Year Limited Cartridge Warranty<br />

• 1-Year Limited Finish Warranty<br />

Codes & Standards<br />

___________________________________________________<br />

• ASME A112.18.1/CSA B125.1<br />

• Certified to NSF/ANSI 61, Section 9 by CSA<br />

• ADA ANSI/ICC A117.1<br />

Last Revision: 01/23/2012 • Date Printed: 02/10/2013 • Product <strong>specifications</strong> subject to change without notice<br />

2100 South Clearwater Drive<br />

Des Plaines, IL<br />

P: 847/803-5000<br />

F: 847/803-5454<br />

Technical: 800/TEC-TRUE<br />

www.chicagofaucets.com

895-317CP<br />

Manual and Metering Faucets<br />

Architect/Engineer Specification<br />

________________________________________________________________________________________________________<br />

Chicago Faucets No. 895-317CP, Deck Mounted 4" Fixed Centers Hot and Cold Water Sink Faucet, Chrome Plated solid brass construction. 3<br />

1/2" Center to Center Rigid / Swing Gooseneck Spout. 2.2 GPM (8.3 L/min) Pressure Compensating Softflo Aerator. 4" Metal Wristblade<br />

handle(s) with Sixteen Point Tapered Broach and Secured Blue and Red Buttons. Quaturn rebuildable compression cartridge, opens and<br />

closes 90°, closes with water pressure, features square tapered stem. 1/2" NPSM Supply Inlets and Coupling Nut for 3/8" or 1/2" Flexible Riser.<br />

This product meets ADA ANSI/ICC A117.1 requirements and is tested and certified to industry standards: ASME A112.18.1/CSA B125.1, and<br />

Certified to NSF/ANSI 61, Section 9 by CSA.<br />

Operation and Maintenance<br />

________________________________________________________________________________________________________<br />

Installation should be in accordance with local plumbing codes. Flush all pipes thoroughly before installation. After installation,<br />

remove spout outlet or flow control and flush faucet thoroughly to clear any debris. Care should be taken when cleaning the<br />

product. Do not use abrasive cleaners, chemicals or solvents as they can result in surface damage. Use mild soap and warm<br />

water for cleaning and protecting the life of Chicago Faucet products. For specific operation and maintenance refer to the<br />

installation instructions and repair parts documents that are located at www.chicagofaucets.com.<br />

Chicago Faucets, member of the Geberit Group, is the leading brand of commercial faucets and fittings in the United States,<br />

offering a complete range of products for schools, laboratories, hospitals, office buildings, food service, airports and sport facilities.<br />

Call 1.800.TECTRUE or 1.847.803.5000 Option 1 for installation or other technical assistance.<br />

Last Revision: 01/23/2012 • Date Printed: 02/10/2013 • Product <strong>specifications</strong> subject to change without notice<br />

2100 South Clearwater Drive<br />

Des Plaines, IL<br />

P: 847/803-5000<br />

F: 847/803-5454<br />

Technical: 800/TEC-TRUE<br />

www.chicagofaucets.com

®<br />

SPECIFICATIONS<br />

Celebrity ® Single Bowl Sink<br />

20 Gauge – Type 304 – Self-Rim<br />

Model DCR252210<br />

GENERAL<br />

Good quality Celebrity single bowl is seamlessly drawn of #20<br />

gauge, type 304 (18-8) nickel bearing stainless steel. Selfrimming.<br />

Exclusive trimmed corner design.<br />

DESIGN FEATURES<br />

Bowl Depth: 10".<br />

Coved Corners: 3" vertical radius, 1-3/4" horizontal radius.<br />

Bowl and Faucet Deck Recess: 3/16" total recess below outside<br />

edge of sink.<br />

Finish: Exposed surfaces are machine polished to a highlighted<br />

finish.<br />

Underside: Fully undercoated to prevent condensation and<br />

deaden sound.<br />

OTHER<br />

Drain Opening: 3-1/2".<br />

Faucet Holes: 1, 2, 3, 4 or 5, 1-1/2" faucet holes as indicated,<br />

4" center to center.<br />

NOTE: Unless otherwise specified, sink is furnished with 3 faucet<br />

holes.<br />

OPTIONAL ACCESSORIES<br />

Rinsing Baskets: LKRB2015 and LKERBSS.<br />

Cutting Board: CB1516.<br />

SINK DIMENSIONS (INCHES)*<br />

Model DCR2522103<br />

Cutout in<br />

No. of<br />

Countertop<br />

1 1 /2" Dia.<br />

(1 1 /2" Radius<br />

Faucet Minimum Ship.<br />

Model<br />

Overall Inside Bowl Corners)<br />

Holes Cabinet Wt.<br />

Number L W L W D L W 4" Center Size Lbs.<br />

DCR252210 25 22 21 15 3 /4 10 24 3 /8 21 3 /8 1, 2, 3, 4 or 5 30 14 1 /2<br />

*Length is left to right. Width is front to back.<br />

4"<br />

4"<br />

3" R<br />

22"<br />

15-3/4"<br />

25"<br />

21"<br />

1-3/4" R<br />

10"<br />

Model DCR2522103 Illustrated<br />

In keeping with our policy of continuing product improvement, Elkay reserves the right to change<br />

product <strong>specifications</strong> without notice.<br />

Elkay<br />

www.elkayusa.com<br />

ALL DIMENSIONS IN INCHES, TO CONVERT TO MILLIMETERS MULTIPLY BY 25.4.<br />

2222 Camden Court<br />

Oak Brook, IL 60523<br />

This specification describes an Elkay product with design, quality and functional benefits to the<br />

user. When making a comparison of other producers’ offerings, be certain these features are not<br />

overlooked.<br />

Printed in U.S.A.<br />

©2003 Elkay<br />

(Rev. 11/03) 1-16D

MECHANICAL FAUCETS<br />

895-317CP<br />

Manual and Metering Faucets<br />

Product Type<br />

___________________________________________________<br />

Deck Mounted 4" Fixed Centers Hot and Cold Water Sink<br />

Faucet<br />

Features & Specifications<br />

___________________________________________________<br />

• 4" Fixed Centers<br />

• 3 1/2" Rigid / Swing Gooseneck Spout<br />

• 2.2 GPM (8.3 L/min) Aerator<br />

• 4" Wristblade Handle<br />

• Quaturn Compression Operating Cartridge<br />

• 1/2" NPSM Supply Inlets and Coupling Nut for 3/8" or 1/2"<br />

Flexible Riser<br />

• CFNow! Item Ships in 5 Days<br />

Performance Specification<br />

___________________________________________________<br />

• Rated Operating Pressure: 20-125 PSI<br />

• Rated Operating Temperature: 40-140ºF<br />

Job Name ________________________________________________<br />

Item Number _____________________________________________<br />

Section/Tag ______________________________________________<br />

Model Specified ___________________________________________<br />

Architect _________________________________________________<br />

Engineer _________________________________________________<br />

Contractor ________________________________________________<br />

[ ] Submitted as Shown [ ] Submitted with Variations<br />

Date _____________________________________________________<br />

Warranty<br />

___________________________________________________<br />

• Lifetime Limited Faucet Warranty<br />

• 5-Year Limited Cartridge Warranty<br />

• 1-Year Limited Finish Warranty<br />

Codes & Standards<br />

___________________________________________________<br />

• ASME A112.18.1/CSA B125.1<br />

• Certified to NSF/ANSI 61, Section 9 by CSA<br />

• ADA ANSI/ICC A117.1<br />

Last Revision: 01/23/2012 • Date Printed: 02/10/2013 • Product <strong>specifications</strong> subject to change without notice<br />

2100 South Clearwater Drive<br />

Des Plaines, IL<br />

P: 847/803-5000<br />

F: 847/803-5454<br />

Technical: 800/TEC-TRUE<br />

www.chicagofaucets.com

895-317CP<br />

Manual and Metering Faucets<br />

Architect/Engineer Specification<br />

________________________________________________________________________________________________________<br />

Chicago Faucets No. 895-317CP, Deck Mounted 4" Fixed Centers Hot and Cold Water Sink Faucet, Chrome Plated solid brass construction. 3<br />

1/2" Center to Center Rigid / Swing Gooseneck Spout. 2.2 GPM (8.3 L/min) Pressure Compensating Softflo Aerator. 4" Metal Wristblade<br />

handle(s) with Sixteen Point Tapered Broach and Secured Blue and Red Buttons. Quaturn rebuildable compression cartridge, opens and<br />

closes 90°, closes with water pressure, features square tapered stem. 1/2" NPSM Supply Inlets and Coupling Nut for 3/8" or 1/2" Flexible Riser.<br />

This product meets ADA ANSI/ICC A117.1 requirements and is tested and certified to industry standards: ASME A112.18.1/CSA B125.1, and<br />

Certified to NSF/ANSI 61, Section 9 by CSA.<br />

Operation and Maintenance<br />

________________________________________________________________________________________________________<br />

Installation should be in accordance with local plumbing codes. Flush all pipes thoroughly before installation. After installation,<br />

remove spout outlet or flow control and flush faucet thoroughly to clear any debris. Care should be taken when cleaning the<br />

product. Do not use abrasive cleaners, chemicals or solvents as they can result in surface damage. Use mild soap and warm<br />

water for cleaning and protecting the life of Chicago Faucet products. For specific operation and maintenance refer to the<br />

installation instructions and repair parts documents that are located at www.chicagofaucets.com.<br />

Chicago Faucets, member of the Geberit Group, is the leading brand of commercial faucets and fittings in the United States,<br />

offering a complete range of products for schools, laboratories, hospitals, office buildings, food service, airports and sport facilities.<br />

Call 1.800.TECTRUE or 1.847.803.5000 Option 1 for installation or other technical assistance.<br />

Last Revision: 01/23/2012 • Date Printed: 02/10/2013 • Product <strong>specifications</strong> subject to change without notice<br />

2100 South Clearwater Drive<br />

Des Plaines, IL<br />

P: 847/803-5000<br />

F: 847/803-5454<br />

Technical: 800/TEC-TRUE<br />

www.chicagofaucets.com

METERING FAUCETS<br />

625-CP<br />

Remote Spouts and Valves<br />

Product Type<br />

___________________________________________________<br />

Hot and Cold Water Pedal Box with Short Pedals<br />

Features & Specifications<br />

___________________________________________________<br />

• Short Pedal Valves<br />

• NAIAD Metering Fast Cycle Time Closure Cartridge<br />

• Two 1/2" NPT Female Thread Inlets<br />

• 3/8" NPT Female Thread Outlet<br />

• CFNow! Item Ships in 5 Days<br />

Job Name ________________________________________________<br />

Item Number _____________________________________________<br />

Section/Tag ______________________________________________<br />

Model Specified ___________________________________________<br />

Architect _________________________________________________<br />

Engineer _________________________________________________<br />

Performance Specification<br />

___________________________________________________<br />

• Rated Operating Pressure: 20-125 PSI<br />

• Rated Operating Temperature: 40-140ºF<br />

Warranty<br />

___________________________________________________<br />

• Lifetime Limited Faucet Warranty<br />

• 5-Year Limited Cartridge Warranty<br />

• 1-Year Limited Finish Warranty<br />

Contractor ________________________________________________<br />

[ ] Submitted as Shown [ ] Submitted with Variations<br />

Date _____________________________________________________<br />

Codes & Standards<br />

___________________________________________________<br />

• ASME A112.18.1/CSA B125.1<br />

• Certified to NSF/ANSI 61, Section 9 by CSA<br />

Last Revision: 12/13/2011 • Date Printed: 02/10/2013 • Product <strong>specifications</strong> subject to change without notice<br />

2100 South Clearwater Drive<br />

Des Plaines, IL<br />

P: 847/803-5000<br />

F: 847/803-5454<br />

Technical: 800/TEC-TRUE<br />

www.chicagofaucets.com

625-CP<br />

Remote Spouts and Valves<br />

Architect/Engineer Specification<br />

________________________________________________________________________________________________________<br />

Chicago Faucets No. 625-CP, Hot and Cold Water Pedal Box with Short Pedals, Chrome Plated solid brass construction. NAIAD rebuildable<br />

self-closing metering cartridge, immediate shut-off, opens with push. Two 1/2" NPT Female Thread Inlets. 3/8" NPT Female Thread Outlet. This<br />

product is tested and certified to industry standards: ASME A112.18.1/CSA B125.1, and Certified to NSF/ANSI 61, Section 9 by CSA.<br />

Operation and Maintenance<br />

________________________________________________________________________________________________________<br />

Installation should be in accordance with local plumbing codes. Flush all pipes thoroughly before installation. After installation,<br />

remove spout outlet or flow control and flush faucet thoroughly to clear any debris. Care should be taken when cleaning the<br />

product. Do not use abrasive cleaners, chemicals or solvents as they can result in surface damage. Use mild soap and warm<br />

water for cleaning and protecting the life of Chicago Faucet products. For specific operation and maintenance refer to the<br />

installation instructions and repair parts documents that are located at www.chicagofaucets.com.<br />

Chicago Faucets, member of the Geberit Group, is the leading brand of commercial faucets and fittings in the United States,<br />

offering a complete range of products for schools, laboratories, hospitals, office buildings, food service, airports and sport facilities.<br />

Call 1.800.TECTRUE or 1.847.803.5000 Option 1 for installation or other technical assistance.<br />

Last Revision: 12/13/2011 • Date Printed: 02/10/2013 • Product <strong>specifications</strong> subject to change without notice<br />

2100 South Clearwater Drive<br />

Des Plaines, IL<br />

P: 847/803-5000<br />

F: 847/803-5454<br />

Technical: 800/TEC-TRUE<br />

www.chicagofaucets.com

®<br />

SPECIFICATIONS<br />

Pacemaker ® Double Bowl Hospitality Sink<br />

Models BPSR2317 and BPSRQ2317<br />

GENERAL<br />

Fine quality sink bowl seamlessly formed of #20 gauge, type<br />

304 (18-8) nickel bearing stainless steel. Self-rimming.<br />

DESIGN FEATURES<br />

Bowl Depth: 6-1/8".<br />

Coved Corners: 1-3/4" vertical and horizontal radius.<br />

Bowl and Faucet Deck Recess: 3/16" below outside edge of<br />

sink.<br />

Finish: Exposed surfaces are polished to a lustrous highlighted<br />

satin finish.<br />

Underside: Fully undercoated to dampen sound and prevent<br />

condensation.<br />

OTHER<br />

Drain Opening: 2".<br />

NOTE: Unless otherwise specified, sink is furnished with 1<br />

faucet hole as shown.<br />

These sinks comply with ANSI Standard A112.19.3M.<br />

OPTIONAL ACCESSORIES<br />

Cutting Board: CB912.<br />

SINK DIMENSIONS (INCHES)*<br />

*Length is left to right. Width is front to back.<br />

Model BPSR(Q)23171<br />

Cutout in<br />

No. of<br />

Countertop<br />

1 1 /2" Dia.<br />

U-Channel Quick-Clip ® (11 /2" Radius<br />

Faucet Minimum Ship.<br />

Model<br />

Model<br />

Overall Inside Each Bowl Corners)<br />

Holes Cabinet Wt.<br />

Number Number L W L W D L W 4" Centers Size Lbs.<br />

BPSR2317 BPSRQ2317 23 17 9 1 /4 12 6 1 /8 22 3 /8 16 3 /8 1, 2, MR2, 3 or 4 27 10 3 /4<br />

U-Channel Type Mounting System<br />

HOLE DRILLING<br />

CONFIGURATIONS<br />

1-3/4" R<br />

12"<br />

17"<br />

1<br />

4"<br />

9-1/4"<br />

23"1-1/4"<br />

9-1/4"<br />

Quick-Clip ® Mounting System<br />

2<br />

4"<br />

1-3/4" R<br />

10-1/2"<br />

6-1/8"<br />

MR2<br />

4" 4"<br />

Model BPSR23171 Illustrated<br />

3<br />

4" 4" 4"<br />

4<br />

Elkay<br />

www.elkayusa.com<br />

ALL DIMENSIONS IN INCHES, TO CONVERT TO MILLIMETERS MULTIPLY BY 25.4.<br />

In keeping with our policy of continuing product improvement, Elkay reserves the right to change<br />

product <strong>specifications</strong> without notice.<br />

2222 Camden Court<br />

Oak Brook, IL 60523<br />

This specification describes an Elkay product with design, quality and functional benefits to the<br />

user. When making a comparison of other producers’ offerings, be certain these features are not<br />

overlooked.<br />

Printed in U.S.A.<br />

©2004 Elkay<br />

(Rev. 3/04) 1-74A

Features<br />

• Metal construction<br />

• One-piece, self-contained ceramic disc valve allows<br />

both volume and temperature control<br />

• Temperature memory allows faucet to be turned on<br />

and off at any temperature setting<br />

• High-temperature limit setting for added safety<br />

• 9-1/16″ (230 mm) swing spout reach<br />

• Matching finish sidespray<br />

• Flexible supplies<br />

• Lower flow aerator options are available (refer to the<br />

Kohler Price Book)<br />

• 2.2 gpm (8.3 lpm) maximum flow rate<br />

Codes/Standards Applicable<br />

Specified model meets or exceeds the following at date of<br />

manufacture:<br />

• ADA<br />

• ASME A112.18.1/CSA B125.1<br />

• ICC/ANSI A117.1<br />

• Energy Policy Act of 2005<br />

• NSF 61<br />

• All applicable US Federal and State material<br />

regulations<br />

Specified Model<br />

Colors/Finishes<br />

FORTÉ ®<br />

KITCHEN SINK FAUCET<br />

K-10412<br />

• CP: Polished Chrome<br />

• BN: Brushed Nickel<br />

• Other: Refer to Price Book for additional colors/finishes<br />

Accessories<br />

• NA: None applicable<br />

Model Description Colors/Finishes<br />

K-10412 Kitchen sink faucet ❑ CP ❑ BN ❑ Other ____<br />

Optional Accessories<br />

1030920 Sidespray deep roughing-in kit ❑ NA<br />

Product Specification<br />

The single-handle kitchen sink faucet shall be of metal construction. Product shall have a maximum flow rate of 2.2 gallons (8.3<br />

L) per minute with lower flow aerator options available (refer to the Kohler Price Book). Product shall feature a one-piece,<br />

self-contained ceramic disc valve, which allows both volume and temperature control. Product shall feature temperature<br />

memory, allowing the faucet to be turned on and off at any temperature setting. Product shall feature a high-temperature limit<br />

setting for added safety, a 9-1/16″ (230 mm) swing spout reach, matching finish sidespray, and flexible supplies. Faucet shall<br />

be Kohler Model K-10412-___.<br />

Page 1 of 2<br />

1018338-4-E<br />

USA/Canada: 1-800-4KOHLER<br />

(1-800-456-4537)<br />

www.kohler.com

FORTÉ ®<br />

Installation Notes<br />

Install this product according to the installation guide.<br />

ADA compliant when installed to the specific requirement of<br />

the regulation.<br />

9-1/16" (230 mm)<br />

8-7/8"<br />

(225 mm)<br />

7-7/8"<br />

(200 mm)<br />

6-1/8"<br />

(156 mm)<br />

10"<br />

(254 mm)<br />

Ø 2"<br />

(51 mm)<br />

2-1/2"<br />

(64 mm)<br />

Ø 7/8"<br />

1-3/8"<br />

(35 mm)<br />

Max<br />

17"<br />

(432 mm)<br />

4"<br />

(102 mm)<br />

Cold<br />

4"<br />

(102 mm)<br />

1"<br />

(25 mm)<br />

Max<br />

Supply Hoses with 3/8"<br />

Compression Fittings<br />

FORTÉ ® KITCHEN SINK FAUCET<br />

Page2of2<br />

1018338-4-E<br />

Product Diagram

Design features:<br />

19F and 19W UTILATUB ®<br />

Laundry/Utility Tubs — Premier<br />

SEE PAGE 2 FOR A LIST OF ACCESSORIES!<br />

• High strength, one piece molded construction<br />

• Produced with Mustee’s proprietary structural thermoplastic resins<br />

and innovative cellular molding process creating extreme strength &<br />

durability<br />

• 18 Gallon capacity, extra deep 13” tub with smooth surface<br />

• Leakproof, integrally molded-in drain with stopper<br />

• Connects to standard 1-½” P or S trap<br />

• Accommodates dual-handle faucet with 4” center<br />

• Large, self-draining back shelf with retainer curb that prohibits water<br />

run-off except into tub.<br />

• Floor model includes heavy gauge steel legs with adjustable levelers<br />

• Wall model includes wall mounting bracket, side supports and<br />

mounting hardware for securing tub to concrete or stud wall<br />

• Mold and mildew-resistant components<br />

• Easy to assemble and install<br />

Code Accepted:<br />

• Color-fast white finish<br />

UTILATUB® and UTILATWIN® Laundry/Utility Tubs meet or exceed performance requirements as listed:<br />

• International Association of Plumbing and Mechanical Officials (IAPMO)® Listed<br />

• Warnock Hersey® (Canada) Listed—CSA test standards: Laundry Tray - #B45.0 and #B45.5; Drain - #B125<br />

• American National Standards Institute (ANSI)—Specification Z 124.6<br />

Specifications<br />

Colors & Models: Model Mounting H x W x D UPC<br />

White 19F Floor 34” x 20” x 24” 6 71031 00029 3<br />

White 19W Wall 34” x 20” x 24” 6 71031 00030 9<br />

MOUNTING BRACKET<br />

14 3 / 8<br />

"<br />

34"<br />

APPROX.<br />

1-1/2” LEVEL<br />

ADJUSTMENT<br />

FILLER<br />

PANELS<br />

FLOOR<br />

34"<br />

APPROX.<br />

7 1 / 2<br />

"<br />

Top View<br />

20"<br />

10"<br />

24"<br />

General: Furnish and install as shown on plans, UTILATUB®<br />

Laundry/Utility Tub model____(19F, 19W), as manufactured by E.L.<br />

Mustee & Sons, Inc. Tub shall be one-piece molded construction using<br />

structural thermoplastics with matched metal molds under extreme<br />

heat and pressure. Tub to include integrally molded drain assembly for<br />

connection to standard 1-1/2” P or S-trap, stopper and wall mounting<br />

hardware or heavy gauge steel legs with built-in levelers. 18 gallon<br />

capacity tub, 13” deep. Shall meet ANSI Specification Z 124.6. Color:<br />

White. Weight: 19F 23 lbs.; 19W 20 lbs.<br />

Floor<br />

Wall<br />

E.L. Mustee & Sons, Inc. • 5431 West 164th Street • Brook Park, OH 44142 • Phone: 216.267.3100 • Fax: 216.267.9997<br />

E-mail: info@mustee.com. • Web: www.mustee.com • Proudly made in the USA<br />

Notice: Our continuous commitment to product improvement may result in changes to product <strong>specifications</strong> without notice.<br />

Patents pending. Made and Printed in U.S.A.

19F and 19W UTILATUB ®<br />

Laundry/Utility Tub Accessories<br />

Faucet<br />

Model No.<br />

UPC<br />

93.600 6 71031 00232 7<br />

Chrome finish, 4” center set brass faucet. 7” swing spout with aerator, level handles, replaceable seats<br />

and stems. Areator or hose end.<br />

Faucet Block<br />

Model No.<br />

UPC<br />

20.600 6 71031 00031 6<br />