WASHING SOAP INTRODUCTION Soap is the traditional ... - smallB

WASHING SOAP INTRODUCTION Soap is the traditional ... - smallB

WASHING SOAP INTRODUCTION Soap is the traditional ... - smallB

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>WASHING</strong> <strong>SOAP</strong><br />

<strong>INTRODUCTION</strong><br />

<strong>Soap</strong> <strong>is</strong> <strong>the</strong> <strong>traditional</strong> washing compound made from oil fats and caustic alkali. One can say<br />

a detergent <strong>is</strong> <strong>the</strong> one that cleans any surface. Syn<strong>the</strong>tic detergent <strong>is</strong> quite different from<br />

o<strong>the</strong>r kinds of detergent. More foam <strong>is</strong> produced with such kind of detergents, moreover,<br />

<strong>the</strong>re <strong>is</strong> less tension created on <strong>the</strong> dirty surface yet emulsification takes places and <strong>the</strong><br />

detergent niters <strong>the</strong> surface much faster. Th<strong>is</strong> <strong>is</strong> <strong>the</strong> reason why <strong>the</strong> cleaning process <strong>is</strong> fast.<br />

<strong>Soap</strong> <strong>is</strong> surfactant used in conjunction with water for washing and cleaning that h<strong>is</strong>torically<br />

comes in solid bars but also in <strong>the</strong> form of a thick liquid, especially from soap d<strong>is</strong>pensers in<br />

public washrooms. <strong>Soap</strong> are useful for cleaning because soap molecules.<br />

Hand made soap differs from industrial soap in that, usually, an excess of fat <strong>is</strong> used to<br />

consume <strong>the</strong> alkali (super fatting), and in that <strong>the</strong> glycerin <strong>is</strong> not removed.<br />

ABOUT THE PRODUCT<br />

<strong>Soap</strong> <strong>is</strong> an item of daily necessity as cleaning agent. It <strong>is</strong> mass consumer item in both rural<br />

and urban areas. <strong>Soap</strong> may be divided into toilet soap and washing soap. In <strong>the</strong> toilet soap<br />

market, new product innovation such as liquid soap, soap-free syn<strong>the</strong>tic detergents and nowash<br />

soap have taken an increasing share of <strong>the</strong> market from <strong>traditional</strong> soap bars. While<br />

<strong>the</strong>re are large companies manufacturing soap including toilet and washing soap, it <strong>is</strong> an<br />

ideal product to manufacture in SSI sector.<br />

MARKET POTENTIAL<br />

The soap market <strong>is</strong> divided into true soaps (a combination of fat and caustic materials) and<br />

non-soapy detergents (largely petroleum by-products). The market for soap products largely<br />

mature in developed markets and d<strong>is</strong>play stagnant growth. The growth potential in<br />

developing countries <strong>is</strong> huge. The per capita consumption of soap in India <strong>is</strong> about 1.75 kg.<br />

per year On th<strong>is</strong> bas<strong>is</strong>, <strong>the</strong> demand for laundry washing soap in north-eastern region <strong>is</strong><br />

estimated at 6825 tonne per year. Keeping in view <strong>the</strong> demand potential and a number of<br />

establ<strong>is</strong>hed brand, as well as local manufacturer in <strong>the</strong> market, <strong>the</strong>re <strong>is</strong> still shortfall in <strong>the</strong><br />

ex<strong>is</strong>ting market. The market for washing soap <strong>is</strong> encouraging even in remote areas People<br />

can now willing to use washing soap as <strong>the</strong>y are recognizing importance of cleaning. A<br />

number of soap making unit may come up to meet <strong>the</strong> shortage in <strong>the</strong> regional market.<br />

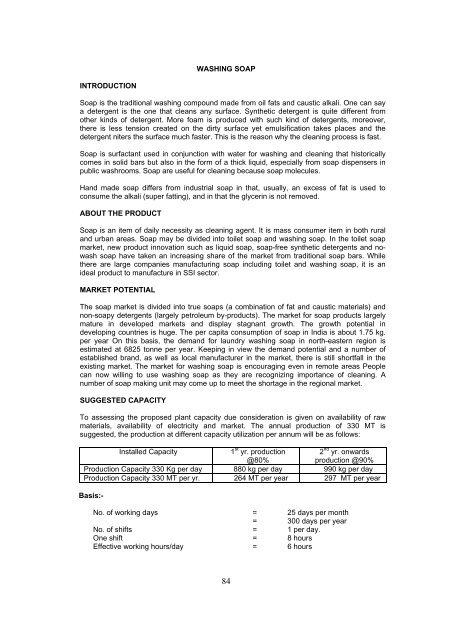

SUGGESTED CAPACITY<br />

To assessing <strong>the</strong> proposed plant capacity due consideration <strong>is</strong> given on availability of raw<br />

materials, availability of electricity and market. The annual production of 330 MT <strong>is</strong><br />

suggested, <strong>the</strong> production at different capacity utilization per annum will be as follows:<br />

Installed Capacity<br />

1 st yr. production<br />

@80%<br />

2 nd yr. onwards<br />

production @90%<br />

Production Capacity 330 Kg per day 880 kg per day 990 kg per day<br />

Production Capacity 330 MT per yr. 264 MT per year 297 MT per year<br />

Bas<strong>is</strong>:-<br />

No. of working days = 25 days per month<br />

= 300 days per year<br />

No. of shifts = 1 per day.<br />

One shift = 8 hours<br />

Effective working hours/day = 6 hours<br />

84

INFRASTRUCTURE REQUIREMENT<br />

The main Infrastructural facilities required are:<br />

Covered shed area (processing hall/storages/office)<br />

Power requirement<br />

Water Requirement<br />

700 sq. ft.<br />

5 kw.<br />

1500 ltrs/day<br />

RAW MATERIALS<br />

The main raw materials required are hard or non-edible oils/fats, caustic soda and sodium<br />

silicate. Packing materials/paper wrappers/cartoons are required for packaging. Hard oils<br />

includes unrefined rice bran oil, neem oil, cotton seed oil, castor oil, sal seed oil, niger seed oil<br />

and minor oils of tree origin. There <strong>is</strong> some production of sal seed, niger seed and cotton seed in<br />

north-east but <strong>the</strong>re <strong>is</strong> no significant production of <strong>the</strong>ir oils. However <strong>the</strong> hard oils caustic soda,<br />

sodium silicates and o<strong>the</strong>r consumables are easily available from <strong>the</strong> local dealer.<br />

SUGGESTED LOCATION<br />

Washing soap projects should be located near urban or semi urban areas of NEr including sikkim<br />

surrounded by available market for raw materials, skilled manpower and as well as market for<br />

end product, location for setting up of washing soap making unit should be based on well<br />

developed road connectivity.<br />

RODUCTION PROCESS (STEP WISE)<br />

The major process steps for manufacture of washing soap are:<br />

Heating of oil/fat in a pan at approximately 70 0 C.<br />

Adding of caustic soda solution of required concentration in oil in small quantities at a Time<br />

Saponification of <strong>the</strong> mixture for 1 to 2 hours under hours under controlled heat by gradually<br />

thickening and finally assuming <strong>the</strong> shiny translucent surface, free from froth.<br />

Completion of saponification and boiling.<br />

Addition of builders and fillers like sodium silicate, soap stone, colours and perfumes etc.<br />

Cooling of soap charge and transferring to <strong>the</strong> cooling frames for setting.<br />

Cutting <strong>the</strong> bars, stamping and packing.<br />

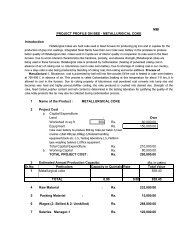

PROJECT ECONOMICS<br />

Total Capital Requirement;<br />

The total capital requirement including fixed capital and working capital <strong>is</strong> estimated at Rs 14.02<br />

lakhs as follows. Of th<strong>is</strong>, <strong>the</strong> project cost compr<strong>is</strong>ing fixed capital and margin money on working<br />

capital <strong>is</strong> Rs.10.92 lakhs.<br />

A. Fixed Capital (Rs. in lakhs)<br />

Land<br />

on rent<br />

Land Development Cost 1.00<br />

Building /Civil works:<br />

i) Work shed 400 sq.ft 2.40<br />

ii) Office/Store 300 sq.ft. 1.80<br />

iii) Toilet/Bathroom/Cemented<br />

open space, Drainage facilities<br />

etc. 0.80<br />

Plant & Machinery 1.50<br />

M<strong>is</strong>c. Fixed Assets 1.00<br />

(Water arrangement/Overhead<br />

reservoir/pump set/power<br />

line connection/water & electrical<br />

fittings/office equipment)<br />

Preliminary & Pre-operative Expenses 0.50<br />

Contingency prov<strong>is</strong>ion 0.40<br />

Total 9.40<br />

85

B. Working Capital:<br />

Raw materials/consumables & 15 days 1.60<br />

Packing materialls<br />

Working expenses 1 month 0.50<br />

Fin<strong>is</strong>hed goods 10 days 1.35<br />

Receivable 7 days 1.17<br />

4.62<br />

Note: Working capital to be financed as –<br />

Margin Money : 1.52<br />

Bank Finance : 3.10<br />

4.62<br />

Means of Finance:<br />

The project cost of Rs.10.92 lakhs may be financed as under:<br />

Promoter’s Equity(25%) : 2.72 Lakhs<br />

Term Loan(75%) : 8.20 Lakhs<br />

10.92 Lakhs<br />

Operating Expenses<br />

The annual operating expenses are estimated as under:<br />

(Rs. in Lakhs)<br />

Raw materials/consumables 32.00<br />

Packing materials & Printed levels<br />

Wages & Salaries 5.41<br />

Utilities 0.40<br />

Repair & Maintenance 0.10<br />

Admin<strong>is</strong>trative Overhead 0.20<br />

Selling expenses 10% on sales 5.28<br />

Depreciation 0.45<br />

Interest 1.48<br />

-------------<br />

45.32<br />

------------<br />

Sales Turn Over<br />

The average ex-factory selling price of washing soap <strong>is</strong> in range of Rs. 20,000 to 21,000 per<br />

tonne. Assuming a net ex-factory price of Rs. 20,000 per tonne, <strong>the</strong> annual sales realization for<br />

264 MT of soap <strong>is</strong> estimated to be Rs.52.80.<br />

Profitability:<br />

Based on <strong>the</strong> sales realization and <strong>the</strong> operating expenses, <strong>the</strong> profit would be Rs. 7.48 lakhs per<br />

year. Th<strong>is</strong> works out to a return on capital investment of 53 %. The unit would break-even at<br />

about 40% of <strong>the</strong> capacity.<br />

Break Even Analys<strong>is</strong><br />

A. Variable Cost: (Rs. in Lakhs)<br />

Raw Materials/Consumables & 32.00<br />

Packing Materials<br />

Utilities 0.40<br />

Selling Expenses 5.28<br />

-------<br />

37.68<br />

-------<br />

B. Semi-Variable Cost: (Rs. in Lakhs)<br />

Wages & Salaries 5.41<br />

Repair & Maintenance 0.10<br />

Admin<strong>is</strong>trative Overhead 0.20<br />

Depreciation 0.45<br />

Interest 1.48<br />

7.64<br />

86

C. Sales Real<strong>is</strong>ation: Rs. 52.80 Lakhs<br />

D. Contribution Rs. 15.12 Lakhs<br />

E. Break Even Point (B/D X 80% (capacity Utilization) 40%<br />

Machinery & Equipment:<br />

The main equipment required are –<br />

i) <strong>Soap</strong> making pan : 2 Nos.<br />

ii) <strong>Soap</strong> cooling frames : 4 Nos.<br />

iii) Cutting machine with table : 1 No.<br />

iv) Stamping press with one set block : 1 No.<br />

v) Stirrer : 4 Nos.<br />

vi) Storage drums, buckets,<br />

weighing scales etc. : set.<br />

Raw Materials/Consumable/Packaging materials (Annually):<br />

Manpower:<br />

Highlights:<br />

Category<br />

Item Quantity Rates Annual (Rs in lakh)<br />

1. Rice Brand Oil 100 MT 19,000/MT 19.00<br />

2. Caustic Soda 50 MT 15,000/MT 7.50<br />

3. Sodium Silicate 100 MT 4,000/MT 4.00<br />

4. Packing materials/ L.S. -- 1.50<br />

O<strong>the</strong>r consumables<br />

TOTAL 32.00<br />

No.of<br />

person<br />

Salary per<br />

person per<br />

month(Rs)<br />

Monthly Requirement<br />

(Rs )<br />

Superv<strong>is</strong>or/Accountant 1 6000 6000<br />

Skilled worker 1 6000 6000<br />

Semi-Skilled workers 2 5000 10000<br />

Unskilled workers 3 3000 9000<br />

Sales personnel 2 5000 10000<br />

Total Manpower Cost 41,000<br />

Salary Bill Rs 4.92 Lakhs + Benefits @ 10% annually i.e. Rs 0.49<br />

Total Annual Salary Bill : Rs 5.41 Lakh.<br />

The major highlights of <strong>the</strong> project are as follows:<br />

Total Capital requirement Rs. 14.02 lakhs<br />

Promoter’s contribution Rs. 2.72 lakhs<br />

Annual Sales realization Rs. 52.80 lakhs<br />

Annual Operating Expenses Rs. 45.32 lakhs<br />

Annual Profit Rs. 7.48 lakhs<br />

Return on sales 14%<br />

Break-even point 40%<br />

No. of person employed 9<br />

87

Address of Plant of Machineries suppliers<br />

M/S Corporated Engineers,<br />

7, Chittaranjan Avenue,<br />

Kolkata<br />

M/S Jai Bharat Engineering works,<br />

Lal Kuan,<br />

Delhi.<br />

M/S Munshi & Co Pvt. Ltd.<br />

181-183 Bapu Khote Street,<br />

Pydhonie,<br />

Mumbai-400003<br />

Supplier of chemicals/consumables<br />

M/S Assam Essence Supply & Co.<br />

Lalsing Mansion (2 nd Floor)<br />

A.T. Road,<br />

Guwahati-781 001<br />

88