Rolling bearings in electric motors and generators

Rolling bearings in electric motors and generators

Rolling bearings in electric motors and generators

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

www.bergab.ru Берг АБ bergab@ya.ru Тел. (495)-228-06-21, факс (495) 223-3071<br />

6 Failure modes <strong>and</strong> corrective actions<br />

Insufficient bear<strong>in</strong>g load/Other damage<br />

Insufficient bear<strong>in</strong>g load<br />

Other damage<br />

When a motor runs without a load,<br />

there is an immense risk that the <strong>bear<strong>in</strong>gs</strong><br />

will become damaged, s<strong>in</strong>ce they<br />

always need to have a m<strong>in</strong>imum load<br />

to function well. The damage will<br />

appear as smear<strong>in</strong>g on the roll<strong>in</strong>g<br />

elements <strong>and</strong> raceways.<br />

It takes time for the <strong>in</strong>itial damage<br />

to develop to such an extent that the<br />

bear<strong>in</strong>g damage can be detected.<br />

Corrective action<br />

Make sure to apply an external load<br />

to the <strong>bear<strong>in</strong>gs</strong>. It is most important to<br />

remember this when us<strong>in</strong>g cyl<strong>in</strong>drical<br />

roller <strong>bear<strong>in</strong>gs</strong>, s<strong>in</strong>ce they are typically<br />

used to accommodate heavier loads.<br />

This does not apply to preloaded<br />

<strong>bear<strong>in</strong>gs</strong> (➔ section “Preload<strong>in</strong>g with<br />

spr<strong>in</strong>gs” on page 47).<br />

Overload from mount<strong>in</strong>g errors<br />

Incorrect mount<strong>in</strong>g methods can significantly<br />

reduce bear<strong>in</strong>g service life.<br />

Damage caused by <strong>in</strong>correct mount<strong>in</strong>g<br />

frequently appears as equally spaced<br />

<strong>in</strong>dentations where the roll<strong>in</strong>g elements<br />

were pushed <strong>in</strong>to the raceways. Over<br />

time, flak<strong>in</strong>g is likely to start from these<br />

<strong>in</strong>dentations (➔ fig 15 ).<br />

These <strong>in</strong>dentations are usually<br />

formed when the mount<strong>in</strong>g force is<br />

applied to the wrong bear<strong>in</strong>g r<strong>in</strong>g <strong>and</strong><br />

the force is transmitted through the<br />

roll<strong>in</strong>g elements; or when a hammer or<br />

similar tool is used to mount a component,<br />

such as a shaft pulley, sprocket<br />

or coupl<strong>in</strong>g.<br />

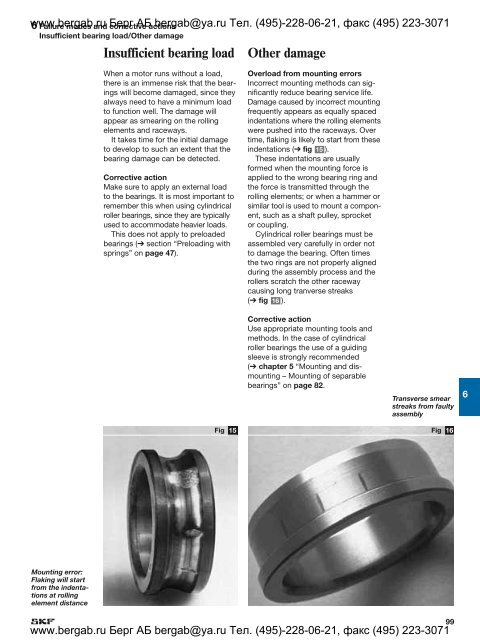

Cyl<strong>in</strong>drical roller <strong>bear<strong>in</strong>gs</strong> must be<br />

assembled very carefully <strong>in</strong> order not<br />

to damage the bear<strong>in</strong>g. Often times<br />

the two r<strong>in</strong>gs are not properly aligned<br />

dur<strong>in</strong>g the assembly process <strong>and</strong> the<br />

rollers scratch the other raceway<br />

caus<strong>in</strong>g long tranverse streaks<br />

(➔ fig 16 ).<br />

Corrective action<br />

Use appropriate mount<strong>in</strong>g tools <strong>and</strong><br />

methods. In the case of cyl<strong>in</strong>drical<br />

roller <strong>bear<strong>in</strong>gs</strong> the use of a guid<strong>in</strong>g<br />

sleeve is strongly recommended<br />

(➔ chapter 5 “Mount<strong>in</strong>g <strong>and</strong> dismount<strong>in</strong>g<br />

– Mount<strong>in</strong>g of separable<br />

<strong>bear<strong>in</strong>gs</strong>” on page 82.<br />

Transverse smear<br />

streaks from faulty<br />

assembly<br />

6<br />

Fig<br />

15<br />

Fig<br />

16<br />

Mount<strong>in</strong>g error:<br />

Flak<strong>in</strong>g will start<br />

from the <strong>in</strong>dentations<br />

at roll<strong>in</strong>g<br />

element distance<br />

www.bergab.ru Берг АБ bergab@ya.ru Тел. (495)-228-06-21, факс (495) 223-3071<br />

99