ITP Metal Casting: 2002 Metal Casting Industry of the Future ...

ITP Metal Casting: 2002 Metal Casting Industry of the Future ...

ITP Metal Casting: 2002 Metal Casting Industry of the Future ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

elements on <strong>the</strong> properties <strong>of</strong> <strong>the</strong> die cast product. This permits a tailoring <strong>of</strong> alloy compositions to<br />

optimize die castings for specific applications. Die casters have utilized <strong>the</strong> information to improve heat<br />

sinks by enhancing <strong>the</strong> <strong>the</strong>rmal capability <strong>of</strong> an alloy and to increase <strong>the</strong> strength <strong>of</strong> an alloy. The<br />

increased strength led to reduced section thickness and 7% less alloy needed per casting. For more<br />

information about <strong>the</strong> publication, please visit http://www.diecasting.org/.<br />

• RSP Tooling – The Rapid Solidification Process (RSP TM ) was developed at <strong>the</strong> Idaho National<br />

Engineering and Environmental Laboratory under grants from DOE. This process is designed to allow die<br />

casters to build production tooling in <strong>the</strong> time it usually takes to make prototype<br />

tooling. The RSP TM Tooling process makes high quality production tooling from<br />

virtually any existing tooling metal, for any tooling process. The technique<br />

eliminates <strong>the</strong> need for any CNC milling, sink EDM, benching, polishing,<br />

engraving and heat treatment. An early application <strong>of</strong> <strong>the</strong> technology was <strong>the</strong><br />

production <strong>of</strong> low-carbon steel strip, <strong>the</strong> industry’s highest volume commodity. A<br />

major advantage <strong>of</strong> using <strong>the</strong> RSP TM for producing strip is <strong>the</strong> significant<br />

reduction in energy use. Producing <strong>the</strong> strip directly from <strong>the</strong> molten metal with<br />

accuracy would eliminate <strong>the</strong> need for hot rolling unit operations, saving time, As-deposited H13 tool steel<br />

money, and energy. The invention received an R&D 100 Award in 1998 and <strong>the</strong> die for die casting<br />

Federal Laboratory Consortium Award in 2001. In <strong>2002</strong>, RSP TM applications.<br />

Tooling, LLC<br />

was formed to design, build, use, and sell machines that manufacture tooling using this process. To learn<br />

more, please visit http://www.oit.doe.gov/metalcast/factsheets/csu_rsp_tooling.pdf.<br />

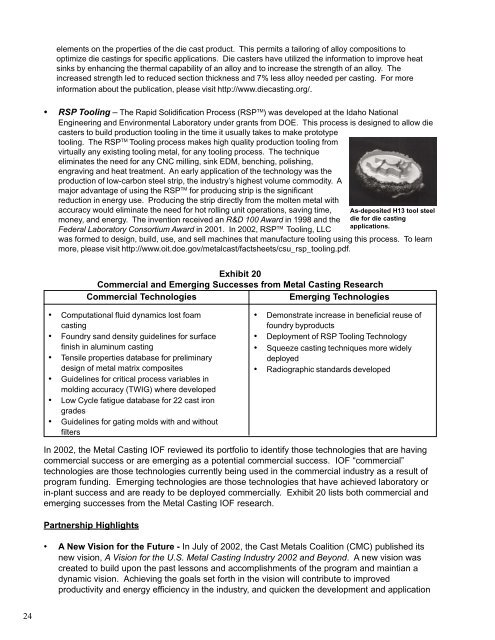

Exhibit 20<br />

Commercial and Emerging Successes from <strong>Metal</strong> <strong>Casting</strong> Research<br />

Commercial Technologies<br />

Emerging Technologies<br />

• Computational fluid dynamics lost foam<br />

casting<br />

• Foundry sand density guidelines for surface<br />

finish in aluminum casting<br />

• Tensile properties database for preliminary<br />

design <strong>of</strong> metal matrix composites<br />

• Guidelines for critical process variables in<br />

molding accuracy (TWIG) where developed<br />

• Low Cycle fatigue database for 22 cast iron<br />

grades<br />

• Guidelines for gating molds with and without<br />

filters<br />

• Demonstrate increase in beneficial reuse <strong>of</strong><br />

foundry byproducts<br />

• Deployment <strong>of</strong> RSP Tooling Technology<br />

• Squeeze casting techniques more widely<br />

deployed<br />

• Radiographic standards developed<br />

In <strong>2002</strong>, <strong>the</strong> <strong>Metal</strong> <strong>Casting</strong> IOF reviewed its portfolio to identify those technologies that are having<br />

commercial success or are emerging as a potential commercial success. IOF “commercial”<br />

technologies are those technologies currently being used in <strong>the</strong> commercial industry as a result <strong>of</strong><br />

program funding. Emerging technologies are those technologies that have achieved laboratory or<br />

in-plant success and are ready to be deployed commercially. Exhibit 20 lists both commercial and<br />

emerging successes from <strong>the</strong> <strong>Metal</strong> <strong>Casting</strong> IOF research.<br />

Partnership Highlights<br />

• A New Vision for <strong>the</strong> <strong>Future</strong> - In July <strong>of</strong> <strong>2002</strong>, <strong>the</strong> Cast <strong>Metal</strong>s Coalition (CMC) published its<br />

new vision, A Vision for <strong>the</strong> U.S. <strong>Metal</strong> <strong>Casting</strong> <strong>Industry</strong> <strong>2002</strong> and Beyond. A new vision was<br />

created to build upon <strong>the</strong> past lessons and accomplishments <strong>of</strong> <strong>the</strong> program and maintian a<br />

dynamic vision. Achieving <strong>the</strong> goals set forth in <strong>the</strong> vision will contribute to improved<br />

productivity and energy efficiency in <strong>the</strong> industry, and quicken <strong>the</strong> development and application<br />

24