Whiting Refinery Modernization Project - Indiana Logistics

Whiting Refinery Modernization Project - Indiana Logistics

Whiting Refinery Modernization Project - Indiana Logistics

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

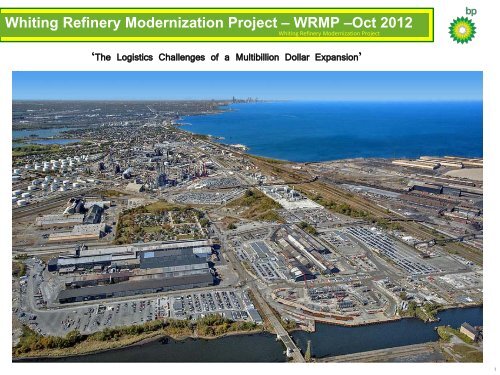

<strong>Whiting</strong> <strong>Refinery</strong> <strong>Modernization</strong> <strong>Project</strong> – WRMP –Oct 2012<br />

<strong>Whiting</strong> <strong>Refinery</strong> <strong>Modernization</strong> <strong>Project</strong><br />

‘The <strong>Logistics</strong> Challenges of a Multibillion Dollar Expansion’<br />

1

BP <strong>Whiting</strong> Business Overview<br />

<strong>Whiting</strong> <strong>Refinery</strong> <strong>Modernization</strong> <strong>Project</strong><br />

• The refinery began operation in 1890<br />

• The 6 th largest refinery in the U.S.<br />

with 413,000 barrels per day of crude<br />

distillation capacity<br />

• Supplied by a network of pipelines<br />

that provides access to 3 distinct<br />

crude markets<br />

• Over 15 millions gallons per day of<br />

transportation fuels produced and<br />

shipped via 8 pipelines<br />

• Transportation fuel marketed at a<br />

network of terminals across 8 states<br />

• One of the largest producers of<br />

asphalt in the U. S.<br />

• Other products distributed across<br />

the country by pipeline, truck, rail<br />

and barge<br />

• Existing refinery employs about<br />

1,850 BP employs plus contractors<br />

for capital projects, TARs, etc.<br />

2

WRMP competitively repositions <strong>Whiting</strong> <strong>Refinery</strong><br />

<strong>Whiting</strong> <strong>Refinery</strong> <strong>Modernization</strong> <strong>Project</strong><br />

• Modernizes the <strong>Whiting</strong> <strong>Refinery</strong> with world scale assets<br />

• Processes incremental heavy sour and high TAN crude as substitute for<br />

light, sweet crude<br />

• Selective debottlenecking of fuels production<br />

Status<br />

• Completion is during second half of 2013<br />

• Greater than 75% complete with on-site construction<br />

• 28 million hours worked without a day-away from-work injury<br />

3

Key Aspects of the <strong>Project</strong><br />

<strong>Whiting</strong> <strong>Refinery</strong> <strong>Modernization</strong> <strong>Project</strong><br />

BP Confidential 4<br />

4

12 Pipestill<br />

<strong>Whiting</strong> <strong>Refinery</strong> <strong>Modernization</strong> <strong>Project</strong><br />

New Vacuum Tower<br />

One of the worlds’ largest<br />

New Crude Tower<br />

Old Crude and Vacuum Towers<br />

Super Module at dock area<br />

5

12 Pipestill<br />

<strong>Whiting</strong> <strong>Refinery</strong> <strong>Modernization</strong> <strong>Project</strong><br />

August 2011<br />

October 2012<br />

• All modules and major equipment set<br />

6

Coker<br />

<strong>Whiting</strong> <strong>Refinery</strong> <strong>Modernization</strong> <strong>Project</strong><br />

August 2011<br />

August 2012<br />

• All modules and major equipment set<br />

7

Gas Oil Hydro-Treater<br />

<strong>Whiting</strong> <strong>Refinery</strong> <strong>Modernization</strong> <strong>Project</strong><br />

August 2011<br />

August 2012<br />

•All modules and major equipment set<br />

8

Sulfur Recovery Facilities<br />

<strong>Whiting</strong> <strong>Refinery</strong> <strong>Modernization</strong> <strong>Project</strong><br />

August 2011<br />

August 2012<br />

9

OSBL Facilities<br />

<strong>Whiting</strong> <strong>Refinery</strong> <strong>Modernization</strong> <strong>Project</strong><br />

Overall OSBL Scope<br />

• Several OSBL sub-projects significantly modernize the<br />

refinery<br />

OSBL Cooling Tower #8<br />

• 90,000 gallons per minute of water circulation<br />

10

Coker gantry crane and holding barn<br />

<strong>Whiting</strong> <strong>Refinery</strong> <strong>Modernization</strong> <strong>Project</strong><br />

Fully automated Coker gantry crane<br />

Coke barn holding 5 days product produced at 6,000 tons/day<br />

11

<strong>Logistics</strong> Challenges on a Mega <strong>Project</strong> Scale<br />

<strong>Whiting</strong> <strong>Refinery</strong> <strong>Modernization</strong> <strong>Project</strong><br />

Construction Statistics<br />

• 800 modules and vessels<br />

• 1,200 pieces of equipment<br />

• 380 miles of pipe<br />

• 50,000 tons of steel<br />

• 1325 miles of wire and cable (distance from Chicago to Santa Fe, NM)<br />

• 15,000 concrete truck deliveries<br />

• 95,000 truckload deliveries<br />

• 14,000 piles to be driven<br />

• 200 material deliveries per day<br />

• 9,000+ Staff/Craft on ‘One <strong>Whiting</strong>’ site at peak<br />

12

Key Material and <strong>Logistics</strong> Pattern<br />

<strong>Whiting</strong> <strong>Refinery</strong> <strong>Modernization</strong> <strong>Project</strong><br />

<strong>Whiting</strong> <strong>Refinery</strong><strong>Modernization</strong> <strong>Project</strong><br />

Foster<br />

Wheeler<br />

(EPC)<br />

COKER<br />

AG&P<br />

(Modules)<br />

Philippines<br />

International<br />

Shipment<br />

(Jumbo via<br />

Foster<br />

Wheeler)<br />

Jacobs<br />

(EPC)<br />

_________________________<br />

Sulfur (SRC)<br />

JAT (Jacobs)<br />

(Modules)<br />

Charleston, SC<br />

Fluor<br />

(EPC)<br />

________________________<br />

GOHT<br />

________________________<br />

OSBL<br />

________________________<br />

12 PS<br />

Dii<br />

(Modules)<br />

Louisiana<br />

Barges<br />

Mammoet<br />

Mammoet<br />

Site<br />

Placement<br />

Truck & Rail<br />

Non-Modular Material/Equipment<br />

Major<br />

Engineering<br />

Equipment<br />

International<br />

Shipment<br />

Mammoet to point of<br />

final <strong>Whiting</strong> location<br />

All Equipment is FAS

<strong>Logistics</strong> – Global to Last Mile<br />

<strong>Whiting</strong> <strong>Refinery</strong> <strong>Modernization</strong> <strong>Project</strong><br />

• Vessels<br />

− USA<br />

− Spain<br />

− Italy<br />

− Germany<br />

− Japan<br />

− Korea<br />

• Shipped by<br />

− Jumbo Ship<br />

− Ocean Barge<br />

− Lake Barge<br />

− Hopper Barge<br />

− Freight<br />

− Rail<br />

14

<strong>Logistics</strong> – Global to Last Mile<br />

<strong>Whiting</strong> <strong>Refinery</strong> <strong>Modernization</strong> <strong>Project</strong><br />

• Modules – 600<br />

− New Iberia, La<br />

− Goose Creek, SC<br />

− Batangas, Phillipines<br />

• Shipped by<br />

− Jumbo Ship<br />

− Ocean Barge<br />

− Lake Barge<br />

− Deck Barge<br />

− Hopper barge<br />

15

Shipping Offloads – Vessels / Modules<br />

<strong>Whiting</strong> <strong>Refinery</strong> <strong>Modernization</strong> <strong>Project</strong><br />

• Via St Lawrence Seaway and<br />

Great Lakes<br />

− Montreal, Canada<br />

− Port of <strong>Indiana</strong><br />

− IPMT Dock Facility<br />

• Via Mississippi and Illinois Rivers<br />

− Port Allen, SC<br />

− New Iberia, La<br />

− IPMT Dock Facility<br />

16

12 PS Vacuum Tower on Deck Barge<br />

<strong>Whiting</strong> <strong>Refinery</strong> <strong>Modernization</strong> <strong>Project</strong>

IPMT Dock Facility<br />

<strong>Whiting</strong> <strong>Refinery</strong> <strong>Modernization</strong> <strong>Project</strong><br />

• 2 Heavy Lift Berths and a Roll On / Roll-Off Ramp<br />

− 400T crane for Hopper Barge offloads and SPMT Transporters for Deck Barge Roll Offs<br />

18

IPMT Dock Facility–N–54 Acres, S–17+ Acres w/Roll Off Ramp – Aug 2008<br />

<strong>Whiting</strong> <strong>Refinery</strong> <strong>Modernization</strong> <strong>Project</strong><br />

19

IPMT Dock Facility – N – 54 Acres, S – 17+ Acres w/Roll Off Ramp – Nov 2010<br />

<strong>Whiting</strong> <strong>Refinery</strong> <strong>Modernization</strong> <strong>Project</strong><br />

20

IPMT Dock Facility – N – 54 Acres, S – 17 Acres w/Roll Off Ramp – OCT 2012<br />

<strong>Whiting</strong> <strong>Refinery</strong> <strong>Modernization</strong> <strong>Project</strong>

Engineering, Review and 3 rd Party Asssurance<br />

<strong>Whiting</strong> <strong>Refinery</strong> <strong>Modernization</strong> <strong>Project</strong><br />

• Major Lifts for loading, offloading, transport to site or lifting at site<br />

were<br />

− Developed by EPC or Mammoet<br />

− Stamped by <strong>Indiana</strong> PE and reviewed by Independent 3 rd party,<br />

Lowther Rolton<br />

− Witnessed by 3 rd Party Heavy Lift experts from Santis or Lowther<br />

Rolton<br />

− Reviews performed with <strong>Project</strong> Lift committees as additional<br />

assurance<br />

− Several Thousand Engineered Lifts made at site alone<br />

• <strong>Logistics</strong> required to keep engineering and paperwork flowing without<br />

impacting construction

12 PS Vacuum Tower Lift<br />

<strong>Whiting</strong> <strong>Refinery</strong> <strong>Modernization</strong> <strong>Project</strong>

Heavy Haul Road Layout<br />

<strong>Whiting</strong> <strong>Refinery</strong> <strong>Modernization</strong> <strong>Project</strong><br />

• All 34KV power lines moved<br />

underground<br />

• 138KV Transmission Lines powered<br />

down by NIPSCO for Transports<br />

over 50’ tall<br />

• Traffic Signals replaced with<br />

Swivel design<br />

• 4 K-Rated Gates installed at<br />

<strong>Refinery</strong> perimeter<br />

• New Heavy Haul roads built within<br />

refinery<br />

• Police escort from Barge facility to<br />

HH Gates<br />

• Adjacent businesses and<br />

surrounding municipalities alerted<br />

prior to Transports.

Heavy Haul Roads and Transports<br />

<strong>Whiting</strong> <strong>Refinery</strong> <strong>Modernization</strong> <strong>Project</strong><br />

• 12 PS Fractionator<br />

25

Coker Module Transport<br />

<strong>Whiting</strong> <strong>Refinery</strong> <strong>Modernization</strong> <strong>Project</strong>

Site Coordination<br />

<strong>Whiting</strong> <strong>Refinery</strong> <strong>Modernization</strong> <strong>Project</strong><br />

• Daily Meetings with Security, Emergency Response, Fire department, Pillar<br />

<strong>Logistics</strong> Leads, WBU Turnaround and <strong>Project</strong>s teams<br />

• Utilize Live Map, Monthly Aerial photos and Smart Boards to visualize and<br />

plan<br />

− Road Closures and Emergency response Impacts<br />

− Heavy Haul Transports<br />

− Major Crane Lifts and Heavy Equipment locations<br />

− Other Site Impacts due to SIMOP’s<br />

• Weekly <strong>Logistics</strong> Meeting – Longer range view<br />

− Staff and Craft Housing<br />

− Craft Parking and Bussing – 9000+ Craft at peak, 9 Parking Lots<br />

− Water distribution – 2000/day<br />

27

4 Warehouses 850K sq/ft and 13 Lay down Yards – 203 Acres<br />

<strong>Whiting</strong> <strong>Refinery</strong> <strong>Modernization</strong> <strong>Project</strong>

One <strong>Whiting</strong> Parking – 9 new Lots required<br />

<strong>Whiting</strong> <strong>Refinery</strong> <strong>Modernization</strong> <strong>Project</strong>

One <strong>Whiting</strong> Bus and Shuttle Routes/Schedule<br />

<strong>Whiting</strong> <strong>Refinery</strong> <strong>Modernization</strong> <strong>Project</strong>

One <strong>Whiting</strong> Snow Removal<br />

<strong>Whiting</strong> <strong>Refinery</strong> <strong>Modernization</strong> <strong>Project</strong>

47 Acres, H2 Plant, Standard Avenue Reroute – Aug 2008<br />

<strong>Whiting</strong> <strong>Refinery</strong> <strong>Modernization</strong> <strong>Project</strong><br />

32

47 Complex, H2 Plant, Standard Avenue Reroute – OCT 2012<br />

<strong>Whiting</strong> <strong>Refinery</strong> <strong>Modernization</strong> <strong>Project</strong>

LR13000 – 3000T Crawler Crane<br />

<strong>Whiting</strong> <strong>Refinery</strong> <strong>Modernization</strong> <strong>Project</strong><br />

• One of Largest Crawler Cranes in the<br />

World<br />

• Delivered from Germany by Jumbo<br />

Ship to Port of <strong>Indiana</strong><br />

• Offloaded in over 200 pieces<br />

• Proof Tested at 3400T<br />

• Crawler tracks over 11’ tall<br />

• Tubing on Boom and Mast is 2” Thick<br />

• Redundant State of the Art Control<br />

systems<br />

• What could you do with this crane and<br />

how would that help you?

12 PS Construction<br />

<strong>Whiting</strong> <strong>Refinery</strong> <strong>Modernization</strong> <strong>Project</strong><br />

35

Coke Drum Lifts<br />

<strong>Whiting</strong> <strong>Refinery</strong> <strong>Modernization</strong> <strong>Project</strong><br />

36