TEST REPORT

TEST REPORT

TEST REPORT

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

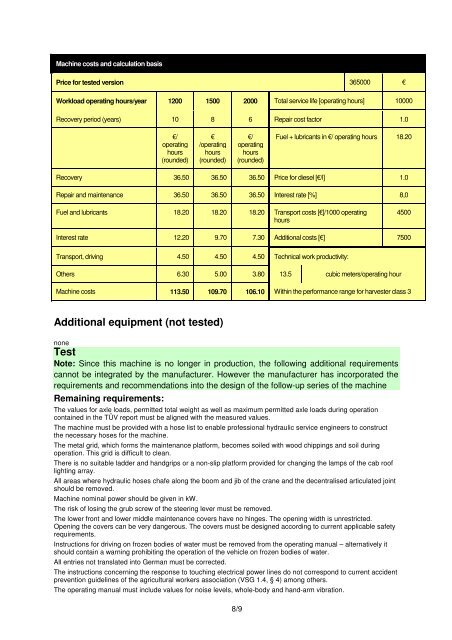

Machine costs and calculation basis<br />

Price for tested version 365000 €<br />

Workload operating hours/year 1200 1500 2000 Total service life [operating hours] 10000<br />

Recovery period (years) 10 8 6 Repair cost factor 1.0<br />

€/<br />

operating<br />

hours<br />

(rounded)<br />

€<br />

/operating<br />

hours<br />

(rounded)<br />

€/<br />

operating<br />

hours<br />

(rounded)<br />

Fuel + lubricants in €/ operating hours 18.20<br />

Recovery 36.50 36.50 36.50 Price for diesel [€/l] 1.0<br />

Repair and maintenance 36.50 36.50 36.50 Interest rate [%] 8,0<br />

Fuel and lubricants 18.20 18.20 18.20 Transport costs [€]/1000 operating<br />

hours<br />

4500<br />

Interest rate 12.20 9.70 7.30 Additional costs [€] 7500<br />

Transport, driving 4.50 4.50 4.50 Technical work productivity:<br />

Others 6.30 5.00 3.80 13.5 cubic meters/operating hour<br />

Machine costs 113.50 109.70 106.10 Within the performance range for harvester class 3<br />

Additional equipment (not tested)<br />

none<br />

Test<br />

Note: Since this machine is no longer in production, the following additional requirements<br />

cannot be integrated by the manufacturer. However the manufacturer has incorporated the<br />

requirements and recommendations into the design of the follow-up series of the machine<br />

Remaining requirements:<br />

The values for axle loads, permitted total weight as well as maximum permitted axle loads during operation<br />

contained in the TÜV report must be aligned with the measured values.<br />

The machine must be provided with a hose list to enable professional hydraulic service engineers to construct<br />

the necessary hoses for the machine.<br />

The metal grid, which forms the maintenance platform, becomes soiled with wood chippings and soil during<br />

operation. This grid is difficult to clean.<br />

There is no suitable ladder and handgrips or a non-slip platform provided for changing the lamps of the cab roof<br />

lighting array.<br />

All areas where hydraulic hoses chafe along the boom and jib of the crane and the decentralised articulated joint<br />

should be removed.<br />

Machine nominal power should be given in kW.<br />

The risk of losing the grub screw of the steering lever must be removed.<br />

The lower front and lower middle maintenance covers have no hinges. The opening width is unrestricted.<br />

Opening the covers can be very dangerous. The covers must be designed according to current applicable safety<br />

requirements.<br />

Instructions for driving on frozen bodies of water must be removed from the operating manual – alternatively it<br />

should contain a warning prohibiting the operation of the vehicle on frozen bodies of water.<br />

All entries not translated into German must be corrected.<br />

The instructions concerning the response to touching electrical power lines do not correspond to current accident<br />

prevention guidelines of the agricultural workers association (VSG 1.4, § 4) among others.<br />

The operating manual must include values for noise levels, whole-body and hand-arm vibration.<br />

8/9