REFINERY NEWS May 2012

REFINERY NEWS May 2012

REFINERY NEWS May 2012

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

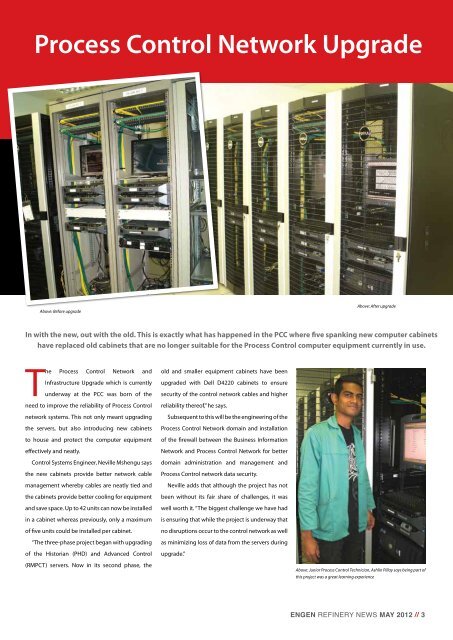

Process Control Network Upgrade<br />

Above: Before upgrade<br />

Above: After upgrade<br />

In with the new, out with the old. This is exactly what has happened in the PCC where five spanking new computer cabinets<br />

have replaced old cabinets that are no longer suitable for the Process Control computer equipment currently in use.<br />

The Process Control Network and<br />

Infrastructure Upgrade which is currently<br />

underway at the PCC was born of the<br />

need to improve the reliability of Process Control<br />

network systems. This not only meant upgrading<br />

the servers, but also introducing new cabinets<br />

to house and protect the computer equipment<br />

effectively and neatly.<br />

Control Systems Engineer, Neville Mshengu says<br />

the new cabinets provide better network cable<br />

management whereby cables are neatly tied and<br />

the cabinets provide better cooling for equipment<br />

and save space. Up to 42 units can now be installed<br />

in a cabinet whereas previously, only a maximum<br />

of five units could be installed per cabinet.<br />

“The three-phase project began with upgrading<br />

of the Historian (PHD) and Advanced Control<br />

old and smaller equipment cabinets have been<br />

upgraded with Dell D4220 cabinets to ensure<br />

security of the control network cables and higher<br />

reliability thereof,” he says.<br />

Subsequent to this will be the engineering of the<br />

Process Control Network domain and installation<br />

of the firewall between the Business Information<br />

Network and Process Control Network for better<br />

domain administration and management and<br />

Process Control network data security.<br />

Neville adds that although the project has not<br />

been without its fair share of challenges, it was<br />

well worth it. “The biggest challenge we have had<br />

is ensuring that while the project is underway that<br />

no disruptions occur to the control network as well<br />

as minimizing loss of data from the servers during<br />

upgrade.”<br />

(RMPCT) servers. Now in its second phase, the<br />

Above: Junior Process Control Technician, Ashlin Pillay says being part of<br />

this project was a great learning experience<br />

engen Refinery news <strong>May</strong> <strong>2012</strong> // 3