Manual GATOR Mini-Saw

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

EN<br />

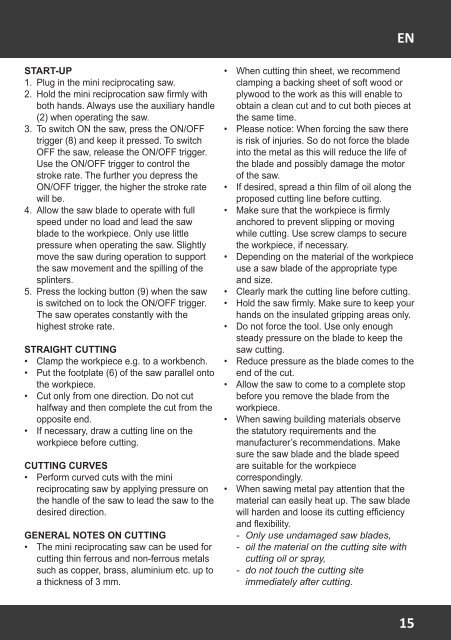

START-UP<br />

1. Plug in the mini reciprocating saw.<br />

2. Hold the mini reciprocation saw firmly with<br />

both hands. Always use the auxiliary handle<br />

(2) when operating the saw.<br />

3. To switch ON the saw, press the ON/OFF<br />

trigger (8) and keep it pressed. To switch<br />

OFF the saw, release the ON/OFF trigger.<br />

Use the ON/OFF trigger to control the<br />

stroke rate. The further you depress the<br />

ON/OFF trigger, the higher the stroke rate<br />

will be.<br />

4. Allow the saw blade to operate with full<br />

speed under no load and lead the saw<br />

blade to the workpiece. Only use little<br />

pressure when operating the saw. Slightly<br />

move the saw during operation to support<br />

the saw movement and the spilling of the<br />

splinters.<br />

5. Press the locking button (9) when the saw<br />

is switched on to lock the ON/OFF trigger.<br />

The saw operates constantly with the<br />

highest stroke rate.<br />

STRAIGHT CUTTING<br />

• Clamp the workpiece e.g. to a workbench.<br />

• Put the footplate (6) of the saw parallel onto<br />

the workpiece.<br />

• Cut only from one direction. Do not cut<br />

halfway and then complete the cut from the<br />

opposite end.<br />

• If necessary, draw a cutting line on the<br />

workpiece before cutting.<br />

CUTTING CURVES<br />

• Perform curved cuts with the mini<br />

reciprocating saw by applying pressure on<br />

the handle of the saw to lead the saw to the<br />

desired direction.<br />

GENERAL NOTES ON CUTTING<br />

• The mini reciprocating saw can be used for<br />

cutting thin ferrous and non-ferrous metals<br />

such as copper, brass, aluminium etc. up to<br />

a thickness of 3 mm.<br />

• When cutting thin sheet, we recommend<br />

clamping a backing sheet of soft wood or<br />

plywood to the work as this will enable to<br />

obtain a clean cut and to cut both pieces at<br />

the same time.<br />

• Please notice: When forcing the saw there<br />

is risk of injuries. So do not force the blade<br />

into the metal as this will reduce the life of<br />

the blade and possibly damage the motor<br />

of the saw.<br />

• If desired, spread a thin film of oil along the<br />

proposed cutting line before cutting.<br />

• Make sure that the workpiece is firmly<br />

anchored to prevent slipping or moving<br />

while cutting. Use screw clamps to secure<br />

the workpiece, if necessary.<br />

• Depending on the material of the workpiece<br />

use a saw blade of the appropriate type<br />

and size.<br />

• Clearly mark the cutting line before cutting.<br />

• Hold the saw firmly. Make sure to keep your<br />

hands on the insulated gripping areas only.<br />

• Do not force the tool. Use only enough<br />

steady pressure on the blade to keep the<br />

saw cutting.<br />

• Reduce pressure as the blade comes to the<br />

end of the cut.<br />

• Allow the saw to come to a complete stop<br />

before you remove the blade from the<br />

workpiece.<br />

• When sawing building materials observe<br />

the statutory requirements and the<br />

manufacturer’s recommendations. Make<br />

sure the saw blade and the blade speed<br />

are suitable for the workpiece<br />

correspondingly.<br />

• When sawing metal pay attention that the<br />

material can easily heat up. The saw blade<br />

will harden and loose its cutting efficiency<br />

and flexibility.<br />

- Only use undamaged saw blades,<br />

- oil the material on the cutting site with<br />

cutting oil or spray,<br />

- do not touch the cutting site<br />

immediately after cutting.<br />

15<br />

7061234 Ma # 1112-16.indd 15 16-12-11 13:31