Simatic - Programming with STEP7 - Process Control and ...

Simatic - Programming with STEP7 - Process Control and ...

Simatic - Programming with STEP7 - Process Control and ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

s<br />

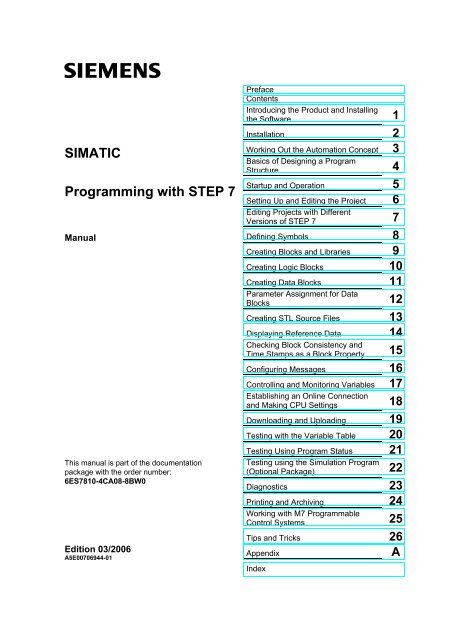

SIMATIC<br />

<strong>Programming</strong> <strong>with</strong> STEP 7<br />

Manual<br />

This manual is part of the documentation<br />

package <strong>with</strong> the order number:<br />

6ES7810-4CA08-8BW0<br />

Edition 03/2006<br />

A5E00706944-01<br />

Preface<br />

Contents<br />

Introducing the Product <strong>and</strong> Installing<br />

the Software 1<br />

Installation 2<br />

Working Out the Automation Concept 3<br />

Basics of Designing a Program<br />

Structure 4<br />

Startup <strong>and</strong> Operation 5<br />

Setting Up <strong>and</strong> Editing the Project 6<br />

Editing Projects <strong>with</strong> Different<br />

Versions of STEP 7 7<br />

Defining Symbols 8<br />

Creating Blocks <strong>and</strong> Libraries 9<br />

Creating Logic Blocks 10<br />

Creating Data Blocks 11<br />

Parameter Assignment for Data<br />

Blocks 12<br />

Creating STL Source Files 13<br />

Displaying Reference Data 14<br />

Checking Block Consistency <strong>and</strong><br />

Time Stamps as a Block Property 15<br />

Configuring Messages 16<br />

<strong>Control</strong>ling <strong>and</strong> Monitoring Variables 17<br />

Establishing an Online Connection<br />

<strong>and</strong> Making CPU Settings 18<br />

Downloading <strong>and</strong> Uploading 19<br />

Testing <strong>with</strong> the Variable Table 20<br />

Testing Using Program Status 21<br />

Testing using the Simulation Program<br />

(Optional Package) 22<br />

Diagnostics 23<br />

Printing <strong>and</strong> Archiving 24<br />

Working <strong>with</strong> M7 Programmable<br />

<strong>Control</strong> Systems 25<br />

Tips <strong>and</strong> Tricks 26<br />

Appendix<br />

Index<br />

A

Safety Guidelines<br />

This manual contains notices you have to observe in order to ensure your personal safety, as well as to<br />

prevent damage to property. The notices referring to your personal safety are highlighted in the manual<br />

by a safety alert symbol, notices referring to property damage only have no safety alert symbol. The<br />

notices shown below are graded according to the degree of danger.<br />

!<br />

!<br />

!<br />

Danger<br />

indicates that death or severe personal injury will result if proper precautions are not taken.<br />

Warning<br />

indicates that death or severe personal injury may result if proper precautions are not taken.<br />

Caution<br />

<strong>with</strong> a safety alert symbol indicates that minor personal injury can result if proper precautions are not<br />

taken.<br />

Caution<br />

<strong>with</strong>out a safety alert symbol indicates that property damage can result if proper precautions are not<br />

taken.<br />

Qualified Personnel<br />

Prescribed Usage<br />

Notice<br />

indicates that an unintended result or situation can occur if the corresponding notice is not taken into<br />

account.<br />

If more than one degree of danger is present, the warning notice representing the highest degree of<br />

danger will be used. A notice warning of injury to persons <strong>with</strong> a safety alert symbol may also include a<br />

warning relating to property damage.<br />

The device/system may only be set up <strong>and</strong> used in conjunction <strong>with</strong> this documentation. Commissioning<br />

<strong>and</strong> operation of a device/system may only be performed by qualified personnel. Within the context of<br />

the safety notices in this documentation qualified persons are defined as persons who are authorized to<br />

commission, ground <strong>and</strong> label devices, systems <strong>and</strong> circuits in accordance <strong>with</strong> established safety<br />

practices <strong>and</strong> st<strong>and</strong>ards.<br />

Note the following:<br />

!<br />

Warning<br />

This device <strong>and</strong> its components may only be used for the applications described in the catalog or the<br />

technical description, <strong>and</strong> only in connection <strong>with</strong> devices or components from other manufacturers<br />

which have been approved or recommended by Siemens.<br />

Correct, reliable operation of the product requires proper transport, storage, positioning <strong>and</strong> assembly<br />

as well as careful operation <strong>and</strong> maintenance.<br />

Trademarks<br />

All names identified by ® are registered trademarks of the Siemens AG.<br />

The remaining trademarks in this publication may be trademarks whose use by third parties for their<br />

own purposes could violate the rights of the owner.<br />

Disclaimer of Liability<br />

We have reviewed the contents of this publication to ensure consistency <strong>with</strong> the hardware <strong>and</strong><br />

software described. Since variance cannot be precluded entirely, we cannot guarantee full consistency.<br />

However, the information in this publication is reviewed regularly <strong>and</strong> any necessary corrections are<br />

included in subsequent editions.<br />

Siemens AG<br />

Automation <strong>and</strong> Drives<br />

Postfach 4848<br />

90437 NÜRNBERG<br />

GERMANY<br />

A5E00706944-01<br />

03/2006<br />

Copyright © Siemens AG 2006<br />

Technical data subject to change

Preface<br />

Purpose<br />

This manual provides a complete overview of programming <strong>with</strong> STEP 7. It is<br />

designed to support you when installing <strong>and</strong> commissioning the software. It<br />

explains how to proceed when creating programs <strong>and</strong> describes the components of<br />

user programs.<br />

The manual is intended for people who are involved in carrying out control tasks<br />

using STEP 7 <strong>and</strong> SIMATIC S7 automation systems.<br />

We recommend that you familiarize yourself <strong>with</strong> the examples in the manual<br />

"Working <strong>with</strong> STEP 7 V5.4, Getting Started." These examples provide an easy<br />

introduction to the topic "<strong>Programming</strong> <strong>with</strong> STEP 7."<br />

Basic Knowledge Required<br />

In order to underst<strong>and</strong> this manual, general knowledge of automation technology is<br />

required.<br />

In addition, you must be familiar <strong>with</strong> using computers or PC-similar tools (for<br />

example, programming devices) <strong>with</strong> the MS Windows 2000 Professional,<br />

MS Windows XP Professional or MS Windows Server 2003 operating system.<br />

Scope of the Manual<br />

This manual is valid for release 5.4 of the STEP 7 programming software package.<br />

You can find the latest information on the service packs:<br />

• in the "readme.wri" file<br />

• in the updated STEP 7 online help.<br />

The topic "What's new?" in the online help offers an excellent introduction <strong>and</strong><br />

overview of the newest STEP 7 innovations.<br />

<strong>Programming</strong> <strong>with</strong> STEP 7<br />

A5E00706944-01<br />

iii

Preface<br />

STEP 7 Documentation Packages<br />

This manual is part of the documentation package "STEP 7 Basic Information.“<br />

The following table displays an overview of the STEP 7 documentation:<br />

Documentation Purpose Order Number<br />

STEP 7 Basic Information <strong>with</strong><br />

Basic information for technical 6ES7810-4CA08-8BW0<br />

• Working <strong>with</strong> STEP 7,<br />

personnel describing the methods<br />

Getting Started Manual<br />

of implementing control tasks <strong>with</strong><br />

STEP 7 <strong>and</strong> the S7-300/400<br />

• <strong>Programming</strong> <strong>with</strong> STEP 7<br />

programmable controllers.<br />

• Configuring Hardware <strong>and</strong><br />

Communication Connections,<br />

STEP 7<br />

• From S5 to S7, Converter Manual<br />

STEP 7 Reference <strong>with</strong><br />

• Ladder Logic (LAD) / Function Block<br />

Diagram (FDB) / Statement List (STL)<br />

for S7-300/400 manuals<br />

• St<strong>and</strong>ard <strong>and</strong> System Function<br />

for S7-300/400<br />

Volume 1 <strong>and</strong> Volume 2<br />

Provides reference information<br />

<strong>and</strong> describes the programming<br />

languages LAD, FBD <strong>and</strong> STL,<br />

<strong>and</strong> st<strong>and</strong>ard <strong>and</strong> system function<br />

extending the scope of the<br />

STEP 7 basic information.<br />

6ES7810-4CA08-8BW1<br />

Online Helps Purpose Order Number<br />

Help on STEP 7<br />

Basic information on<br />

programming <strong>and</strong> configuring<br />

hardware <strong>with</strong> STEP 7 in the form<br />

of an online help.<br />

Part of the STEP 7<br />

St<strong>and</strong>ard software.<br />

Reference helps on AWL/KOP/FUP<br />

Reference help on SFBs/SFCs<br />

Reference help on Organization Blocks<br />

Context-sensitive reference<br />

information.<br />

Part of the STEP 7<br />

St<strong>and</strong>ard software.<br />

iv<br />

<strong>Programming</strong> <strong>with</strong> STEP 7<br />

A5E00706944-01

Preface<br />

Further Support<br />

If you have any technical questions, please get in touch <strong>with</strong> your Siemens<br />

representative or responsible agent.<br />

You will find your contact person at:<br />

http://www.siemens.com/automation/partner<br />

You will find a guide to the technical documentation offered for the individual<br />

SIMATIC Products <strong>and</strong> Systems here at:<br />

http://www.siemens.com/simatic-tech-doku-portal<br />

The online catalog <strong>and</strong> order system is found under:<br />

http://mall.automation.siemens.com/<br />

Training Centers<br />

Siemens offers a number of training courses to familiarize you <strong>with</strong> the SIMATIC<br />

S7 automation system. Please contact your regional training center or our central<br />

training center in D 90327 Nuremberg, Germany for details:<br />

Telephone: +49 (911) 895-3200.<br />

Internet: http://www.sitrain.com<br />

Technical Support<br />

You can reach the Technical Support for all A&D products<br />

• Via the Web formula for the Support Request<br />

http://www.siemens.com/automation/support-request<br />

• Phone: + 49 180 5050 222<br />

• Fax: + 49 180 5050 223<br />

Additional information about our Technical Support can be found on the Internet<br />

pages http://www.siemens.com/automation/service<br />

Service & Support on the Internet<br />

In addition to our documentation, we offer our Know-how online on the internet at:<br />

http://www.siemens.com/automation/service&support<br />

where you will find the following:<br />

• The newsletter, which constantly provides you <strong>with</strong> up-to-date information on<br />

your products.<br />

• The right documents via our Search function in Service & Support.<br />

• A forum, where users <strong>and</strong> experts from all over the world exchange their<br />

experiences.<br />

• Your local representative for Automation & Drives.<br />

• Information on field service, repairs, spare parts <strong>and</strong> more under "Services".<br />

<strong>Programming</strong> <strong>with</strong> STEP 7<br />

A5E00706944-01<br />

v

Preface<br />

vi<br />

<strong>Programming</strong> <strong>with</strong> STEP 7<br />

A5E00706944-01

Contents<br />

1 Introducing the Product <strong>and</strong> Installing the Software 1-1<br />

1.1 Overview of STEP 7 ......................................................................................... 1-1<br />

1.2 The STEP 7 St<strong>and</strong>ard Package ....................................................................... 1-6<br />

1.3 What's New in STEP 7, Version 5.4? ............................................................. 1-11<br />

1.4 Extended Uses of the STEP 7 St<strong>and</strong>ard Package ......................................... 1-14<br />

1.4.1 Engineering Tools........................................................................................... 1-15<br />

1.4.2 Run-Time Software......................................................................................... 1-17<br />

1.4.3 Human Machine Interface............................................................................... 1-19<br />

2 Installation 2-1<br />

2.1 Automation License Manager........................................................................... 2-1<br />

2.1.1 User Rights Through The Automation License Manager ................................. 2-1<br />

2.1.2 Installing the Automation License Manager...................................................... 2-4<br />

2.1.3 Guidelines for H<strong>and</strong>ling License Keys.............................................................. 2-5<br />

2.2 Installing STEP 7 .............................................................................................. 2-6<br />

2.2.1 Installation Procedure....................................................................................... 2-8<br />

2.2.2 Setting the PG/PC Interface ........................................................................... 2-11<br />

2.3 Uninstalling STEP 7........................................................................................ 2-13<br />

3 Working Out the Automation Concept 3-1<br />

3.1 Basic Procedure for Planning an Automation Project ...................................... 3-1<br />

3.2 Dividing the <strong>Process</strong> into Tasks <strong>and</strong> Areas...................................................... 3-2<br />

3.3 Describing the Individual Functional Areas ...................................................... 3-4<br />

3.4 Listing Inputs, Outputs, <strong>and</strong> In/Outs ................................................................. 3-6<br />

3.5 Creating an I/O Diagram for the Motors ........................................................... 3-6<br />

3.6 Creating an I/O Diagram for the Valves............................................................ 3-7<br />

3.7 Establishing the Safety Requirements.............................................................. 3-8<br />

3.8 Describing the Required Operator Displays <strong>and</strong> <strong>Control</strong>s................................ 3-9<br />

3.9 Creating a Configuration Diagram .................................................................. 3-10<br />

4 Basics of Designing a Program Structure 4-1<br />

4.1 Programs in a CPU........................................................................................... 4-1<br />

4.2 Blocks in the User Program.............................................................................. 4-2<br />

4.2.1 Organization Blocks <strong>and</strong> Program Structure .................................................... 4-3<br />

4.2.2 Call Hierarchy in the User Program.................................................................. 4-9<br />

4.2.3 Block Types .................................................................................................... 4-11<br />

4.2.3.1 Organization Block for Cyclic Program <strong>Process</strong>ing (OB1) ............................. 4-11<br />

4.2.3.2 Functions (FC) ................................................................................................ 4-16<br />

4.2.3.3 Function Blocks (FB) ...................................................................................... 4-17<br />

4.2.3.4 Instance Data Blocks...................................................................................... 4-20<br />

4.2.3.5 Shared Data Blocks (DB)................................................................................ 4-23<br />

4.2.3.6 System Function Blocks (SFB) <strong>and</strong> System Functions (SFC) ....................... 4-24<br />

<strong>Programming</strong> <strong>with</strong> STEP 7<br />

A5E00706944-01<br />

vii

Contents<br />

4.2.4 Organization Blocks for Interrupt-Driven Program <strong>Process</strong>ing....................... 4-26<br />

4.2.4.1 Time-of-Day Interrupt Organization Blocks (OB10 to OB17) ......................... 4-26<br />

4.2.4.2 Time-Delay Interrupt Organization Blocks (OB20 to OB23)........................... 4-28<br />

4.2.4.3 Cyclic Interrupt Organization Blocks (OB30 to OB38).................................... 4-29<br />

4.2.4.4 Hardware Interrupt Organization Blocks (OB40 to OB47).............................. 4-31<br />

4.2.4.5 Startup Organization Blocks (OB100 / OB101 / OB102)................................ 4-32<br />

4.2.4.6 Background Organization Block (OB90)......................................................... 4-34<br />

4.2.4.7 Error H<strong>and</strong>ling Organization Blocks (OB70 to OB87 / OB121 to OB122)...... 4-36<br />

5 Startup <strong>and</strong> Operation 5-1<br />

5.1 Starting STEP 7 ................................................................................................ 5-1<br />

5.2 Starting STEP 7 <strong>with</strong> Default Start Parameters................................................ 5-3<br />

5.3 Calling the Help Functions................................................................................ 5-5<br />

5.4 Objects <strong>and</strong> Object Hierarchy........................................................................... 5-6<br />

5.4.1 Project Object ................................................................................................... 5-8<br />

5.4.2 Library Object ................................................................................................... 5-9<br />

5.4.3 Station Object ................................................................................................. 5-10<br />

5.4.4 Programmable Module Object........................................................................ 5-12<br />

5.4.5 S7/M7 Program Object ................................................................................... 5-14<br />

5.4.6 Block Folder Object ........................................................................................ 5-16<br />

5.4.7 Source File Folder Object............................................................................... 5-19<br />

5.4.8 S7/M7 Program <strong>with</strong>out a Station or CPU...................................................... 5-20<br />

5.5 User Interface <strong>and</strong> Operation ......................................................................... 5-21<br />

5.5.1 Operating Philosophy ..................................................................................... 5-21<br />

5.5.2 Window Arrangement ..................................................................................... 5-22<br />

5.5.3 Elements in Dialog Boxes............................................................................... 5-23<br />

5.5.4 Creating <strong>and</strong> Managing Objects ..................................................................... 5-24<br />

5.5.5 Selecting Objects in a Dialog Box .................................................................. 5-29<br />

5.5.6 Session Memory ............................................................................................. 5-30<br />

5.5.7 Changing the Window Arrangement............................................................... 5-31<br />

5.5.8 Saving <strong>and</strong> Restoring the Window Arrangement ........................................... 5-31<br />

5.6 Keyboard Operation........................................................................................ 5-32<br />

5.6.1 Key Combinations for Menu Comm<strong>and</strong>s........................................................ 5-32<br />

5.6.2 Key Combinations for Moving the Cursor....................................................... 5-34<br />

5.6.3 Key Combinations for Selecting Text ............................................................. 5-36<br />

5.6.4 Key Combinations for Access to Online Help................................................. 5-36<br />

5.6.5 Key Combinations for Toggling between Windows ........................................ 5-37<br />

6 Setting Up <strong>and</strong> Editing the Project 6-1<br />

6.1 Project Structure ............................................................................................... 6-1<br />

6.2 What You Should Know About Access Protection ........................................... 6-2<br />

6.3 What You Should Know About The Change Log ............................................. 6-4<br />

6.4 Using Foreign-Language Character Sets......................................................... 6-5<br />

6.5 Setting the MS Windows Language ................................................................. 6-8<br />

6.6 Setting Up a Project.......................................................................................... 6-9<br />

6.6.1 Creating a Project............................................................................................. 6-9<br />

6.6.2 Inserting Stations ............................................................................................ 6-11<br />

6.6.3 Inserting an S7/M7 Program........................................................................... 6-12<br />

6.7 Editing a Project.............................................................................................. 6-14<br />

6.7.1 Checking Projects for Software Packages Used............................................ 6-15<br />

viii<br />

<strong>Programming</strong> <strong>with</strong> STEP 7<br />

A5E00706944-01

Contents<br />

6.8 Managing Multilingual Texts ........................................................................... 6-15<br />

6.8.1 Types of Multilingual Texts ............................................................................. 6-17<br />

6.8.2 Structure of the Export File............................................................................. 6-18<br />

6.8.3 Managing User Texts Whose Language Font is Not Installed ....................... 6-19<br />

6.8.4 Information on the Log File............................................................................. 6-20<br />

6.8.5 Optimizing the Source for Translation ............................................................ 6-21<br />

6.8.6 Optimizing the Translation <strong>Process</strong>................................................................ 6-22<br />

6.9 Micro Memory Card (MMC) as a Data Carrier................................................ 6-23<br />

6.9.1 What You Should Know About Micro Memory Cards (MMC)......................... 6-23<br />

6.9.2 Using a Micro Memory Card as a Data Carrier .............................................. 6-25<br />

6.9.3 Memory Card File ........................................................................................... 6-25<br />

6.9.4 Storing Project Data on a Micro Memory Card (MMC)................................... 6-26<br />

7 Editing Projects <strong>with</strong> Different Versions of STEP 7 7-1<br />

7.1 Editing Version 2 Projects <strong>and</strong> Libraries........................................................... 7-1<br />

7.2 Exp<strong>and</strong>ing DP Slaves That Were Created <strong>with</strong><br />

Previous Versions of STEP 7 ........................................................................... 7-1<br />

7.3 Editing Current Configurations <strong>with</strong> Previous Versions of STEP 7 .................. 7-3<br />

7.4 Appending SIMATIC PC Configurations of Previous Versions ........................ 7-4<br />

7.5 Displaying Modules Configured <strong>with</strong> Later STEP 7 Versions<br />

or Optional Packages ....................................................................................... 7-6<br />

8 Defining Symbols 8-1<br />

8.1 Absolute <strong>and</strong> Symbolic Addressing .................................................................. 8-1<br />

8.2 Shared <strong>and</strong> Local Symbols............................................................................... 8-3<br />

8.3 Displaying Shared or Local Symbols................................................................ 8-4<br />

8.4 Setting the Address Priority (Symbolic/Absolute)............................................. 8-5<br />

8.5 Symbol Table for Shared Symbols ................................................................... 8-9<br />

8.5.1 Structure <strong>and</strong> Components of the Symbol Table ............................................. 8-9<br />

8.5.2 Addresses <strong>and</strong> Data Types Permitted in the Symbol Table........................... 8-11<br />

8.5.3 Incomplete <strong>and</strong> Non-Unique Symbols in the Symbol Table........................... 8-12<br />

8.6 Entering Shared Symbols............................................................................... 8-13<br />

8.6.1 General Tips on Entering Symbols................................................................. 8-13<br />

8.6.2 Entering Single Shared Symbols in a Dialog Box .......................................... 8-14<br />

8.6.3 Entering Multiple Shared Symbols in the Symbol Table ................................ 8-15<br />

8.6.4 Using Upper <strong>and</strong> Lower Case for Symbols .................................................... 8-16<br />

8.6.5 Exporting <strong>and</strong> Importing Symbol Tables......................................................... 8-18<br />

8.6.6 File Formats for Importing/Exporting a Symbol Table .................................... 8-18<br />

8.6.7 Editing Areas in Symbol Tables...................................................................... 8-21<br />

9 Creating Blocks <strong>and</strong> Libraries 9-1<br />

9.1 Selecting an Editing Method............................................................................. 9-1<br />

9.2 Selecting the <strong>Programming</strong> Language ............................................................. 9-2<br />

9.2.1 Ladder Logic <strong>Programming</strong> Language (LAD)................................................... 9-4<br />

9.2.2 Function Block Diagram <strong>Programming</strong> Language (FBD)................................. 9-5<br />

9.2.3 Statement List <strong>Programming</strong> Language (STL)................................................. 9-6<br />

9.2.4 S7 SCL <strong>Programming</strong> Language...................................................................... 9-7<br />

9.2.5 S7-GRAPH <strong>Programming</strong> Language (Sequential <strong>Control</strong>) .............................. 9-8<br />

9.2.6 S7 HiGraph <strong>Programming</strong> Language (State Graph) ........................................ 9-9<br />

9.2.7 S7 CFC <strong>Programming</strong> Language ................................................................... 9-10<br />

9.3 Creating Blocks............................................................................................... 9-11<br />

9.3.1 Blocks Folder .................................................................................................. 9-11<br />

9.3.2 User-Defined Data Types (UDT) .................................................................... 9-12<br />

9.3.3 Block Properties.............................................................................................. 9-13<br />

9.3.4 Displaying Block Lengths................................................................................ 9-15<br />

9.3.5 Comparing Blocks........................................................................................... 9-16<br />

9.3.6 Rewiring.......................................................................................................... 9-19<br />

<strong>Programming</strong> <strong>with</strong> STEP 7<br />

A5E00706944-01<br />

ix

Contents<br />

9.3.7 Attributes for Blocks <strong>and</strong> Parameters ............................................................. 9-19<br />

9.4 Working <strong>with</strong> Libraries .................................................................................... 9-20<br />

9.4.1 Hierarchical Structure of Libraries .................................................................. 9-22<br />

9.4.2 Overview of the St<strong>and</strong>ard Libraries ................................................................ 9-22<br />

10 Creating Logic Blocks 10-1<br />

10.1 Basics of Creating Logic Blocks ..................................................................... 10-1<br />

10.1.1 Structure of the Program Editor Window........................................................ 10-1<br />

10.1.2 Basic Procedure for Creating Logic Blocks .................................................... 10-3<br />

10.1.3 Default Settings for the LAD/STL/FBD Program Editor.................................. 10-4<br />

10.1.4 Access Rights to Blocks <strong>and</strong> Source Files ..................................................... 10-4<br />

10.1.5 Instructions from the Program Elements Table .............................................. 10-5<br />

10.2 Editing the Variable Declaration ..................................................................... 10-6<br />

10.2.1 Using the Variable Declaration in Logic Blocks.............................................. 10-6<br />

10.2.2 Interaction Between The Variable Detail View And The Instruction List ........ 10-8<br />

10.2.3 Structure of the Variable Declaration Window................................................ 10-9<br />

10.3 Multiple Instances in the Variable Declaration ............................................. 10-10<br />

10.3.1 Using Multiple Instances............................................................................... 10-10<br />

10.3.2 Rules for Declaring Multiple Instances ......................................................... 10-11<br />

10.3.3 Entering a Multiple Instance in the Variable Declaration Window................ 10-11<br />

10.4 General Notes on Entering Statements <strong>and</strong> Comments .............................. 10-12<br />

10.4.1 Structure of the Code Section ...................................................................... 10-12<br />

10.4.2 Procedure for Entering Statements .............................................................. 10-13<br />

10.4.3 Entering Shared Symbols in a Program ....................................................... 10-14<br />

10.4.4 Title <strong>and</strong> Comments for Blocks <strong>and</strong> Networks ............................................. 10-15<br />

10.4.5 Entering Block Comments <strong>and</strong> Network Comments .................................... 10-16<br />

10.4.6 Working <strong>with</strong> Network Templates ................................................................. 10-17<br />

10.4.7 Search Function for Errors in the Code Section........................................... 10-18<br />

10.5 Editing LAD Elements in the Code Section .................................................. 10-19<br />

10.5.1 Settings for Ladder Logic <strong>Programming</strong>....................................................... 10-19<br />

10.5.2 Rules for Entering Ladder Logic Elements................................................... 10-19<br />

10.5.3 Illegal Logic Operations in Ladder ................................................................ 10-22<br />

10.6 Editing FBD Elements in the Code Section.................................................. 10-23<br />

10.6.1 Settings for Function Block Diagram <strong>Programming</strong> ..................................... 10-23<br />

10.6.2 Rules for Entering FBD Elements................................................................. 10-24<br />

10.7 Editing STL Statements in the Code Section ............................................... 10-26<br />

10.7.1 Settings for Statement List <strong>Programming</strong>..................................................... 10-26<br />

10.7.2 Rules for Entering STL Statements .............................................................. 10-26<br />

10.8 Updating Block Calls..................................................................................... 10-27<br />

10.8.1 Changing Interfaces...................................................................................... 10-28<br />

10.9 Saving Logic Blocks...................................................................................... 10-29<br />

11 Creating Data Blocks 11-1<br />

11.1 Basic Information on Creating Data Blocks.................................................... 11-1<br />

11.2 Declaration View of Data Blocks .................................................................... 11-2<br />

11.3 Data View of Data Blocks ............................................................................... 11-3<br />

11.4 Editing <strong>and</strong> Saving Data Blocks ..................................................................... 11-4<br />

11.4.1 Entering the Data Structure of Shared Data Blocks ....................................... 11-4<br />

11.4.2 Entering <strong>and</strong> Displaying the Data Structure<br />

of Data Blocks Referencing an FB (Instance DBs) ........................................ 11-5<br />

11.4.3 Entering the Data Structure of User-Defined Data Types (UDT) ................... 11-7<br />

11.4.4 Entering <strong>and</strong> Displaying the Structure of Data Blocks Referencing a UDT.... 11-8<br />

11.4.5 Editing Data Values in the Data View............................................................. 11-9<br />

11.4.6 Resetting Data Values to their Initial Values .................................................. 11-9<br />

11.4.7 Saving Data Blocks....................................................................................... 11-10<br />

x<br />

<strong>Programming</strong> <strong>with</strong> STEP 7<br />

A5E00706944-01

Contents<br />

12 Parameter Assignment for Data Blocks 12-1<br />

12.1 Assigning Parameters to Technological Functions ........................................ 12-2<br />

13 Creating STL Source Files 13-1<br />

13.1 Basic Information on <strong>Programming</strong> in STL Source Files................................ 13-1<br />

13.2 Rules for <strong>Programming</strong> in STL Source Files .................................................. 13-2<br />

13.2.1 Rules for Entering Statements in STL Source Files ....................................... 13-2<br />

13.2.2 Rules for Declaring Variables in STL Source Files ........................................ 13-3<br />

13.2.3 Rules for Block Order in STL Source Files..................................................... 13-4<br />

13.2.4 Rules for Setting System Attributes in STL Source Files ............................... 13-4<br />

13.2.5 Rules for Setting Block Properties in STL Source Files ................................. 13-5<br />

13.2.6 Permitted Block Properties for Each Block Type............................................ 13-7<br />

13.3 Structure of Blocks in STL Source Files......................................................... 13-7<br />

13.3.1 Structure of Logic Blocks in STL Source Files ............................................... 13-8<br />

13.3.2 Structure of Data Blocks in STL Source Files ................................................ 13-9<br />

13.3.3 Structure of User-Defined Data Types in STL Source Files........................... 13-9<br />

13.4 Syntax <strong>and</strong> Formats for Blocks in STL Source Files .................................... 13-10<br />

13.4.1 Format Table of Organization Blocks ........................................................... 13-10<br />

13.4.2 Format Table of Function Blocks.................................................................. 13-11<br />

13.4.3 Format Table of Functions............................................................................ 13-12<br />

13.4.4 Format Table of Data Blocks ........................................................................ 13-13<br />

13.5 Creating STL Source Files ........................................................................... 13-14<br />

13.5.1 Creating STL Source Files ........................................................................... 13-14<br />

13.5.2 Editing S7 Source Files ................................................................................ 13-14<br />

13.5.3 Setting The Layout of Source Code Text ..................................................... 13-15<br />

13.5.4 Inserting Block Templates in STL Source Files............................................ 13-15<br />

13.5.5 Inserting the Contents of Other STL Source Files........................................ 13-15<br />

13.5.6 Inserting Source Code from Existing Blocks in STL Source Files................ 13-16<br />

13.5.7 Inserting External Source Files..................................................................... 13-16<br />

13.5.8 Generating STL Source Files from Blocks ................................................... 13-17<br />

13.5.9 Importing Source Files.................................................................................. 13-17<br />

13.5.10 Exporting Source Files.................................................................................. 13-18<br />

13.6 Saving <strong>and</strong> Compiling STL Source Files <strong>and</strong> Executing<br />

a Consistency Check.................................................................................... 13-19<br />

13.6.1 Saving STL Source Files .............................................................................. 13-19<br />

13.6.2 Checking Consistency in STL Source Files.................................................. 13-19<br />

13.6.3 Debugging STL Source Files........................................................................ 13-19<br />

13.6.4 Compiling STL Source Files ......................................................................... 13-20<br />

13.7 Examples of STL Source Files ..................................................................... 13-21<br />

13.7.1 Examples of Declaring Variables in STL Source Files ................................. 13-21<br />

13.7.2 Example of Organization Blocks in STL Source Files .................................. 13-22<br />

13.7.3 Example of Functions in STL Source Files................................................... 13-23<br />

13.7.4 Example of Function Blocks in STL Source Files......................................... 13-25<br />

13.7.5 Example of Data Blocks in STL Source Files............................................... 13-27<br />

13.7.6 Example of User-Defined Data Types in STL Source Files ......................... 13-28<br />

14 Displaying Reference Data 14-1<br />

14.1 Overview of the Available Reference Data..................................................... 14-1<br />

14.1.1 Cross-Reference List...................................................................................... 14-2<br />

14.1.2 Program Structure .......................................................................................... 14-4<br />

14.1.3 Assignment List .............................................................................................. 14-6<br />

14.1.4 Unused Symbols............................................................................................. 14-8<br />

14.1.5 Addresses Without Symbols........................................................................... 14-9<br />

14.1.6 Displaying Block Information for LAD, FBD, <strong>and</strong> STL .................................... 14-9<br />

<strong>Programming</strong> <strong>with</strong> STEP 7<br />

A5E00706944-01<br />

xi

Contents<br />

14.2 Working <strong>with</strong> Reference Data....................................................................... 14-10<br />

14.2.1 Ways of Displaying Reference Data............................................................. 14-10<br />

14.2.2 Displaying Lists in Additional Working Windows .......................................... 14-10<br />

14.2.3 Generating <strong>and</strong> Displaying Reference Data................................................. 14-11<br />

14.2.4 Finding Address Locations in the Program Quickly...................................... 14-12<br />

14.2.5 Example of Working <strong>with</strong> Address Locations ............................................... 14-13<br />

15 Checking Block Consistency <strong>and</strong> Time Stamps as a Block Property 15-1<br />

15.1 Checking Block Consistency .......................................................................... 15-1<br />

15.2 Time Stamps as a Block Property <strong>and</strong> Time Stamp Conflicts........................ 15-3<br />

15.3 Time Stamps in Logic Blocks ......................................................................... 15-4<br />

15.4 Time Stamps in Shared Data Blocks.............................................................. 15-5<br />

15.5 Time Stamps in Instance Data Blocks............................................................ 15-5<br />

15.6 Time Stamps in UDTs <strong>and</strong> Data Blocks Derived from UDTs ......................... 15-6<br />

15.7 Correcting the Interfaces in a Function, Function Block, or UDT ................... 15-6<br />

15.8 Avoiding Errors when Calling Blocks.............................................................. 15-7<br />

16 Configuring Messages 16-1<br />

16.1 The Message Concept.................................................................................... 16-1<br />

16.1.1 What Are the Different Messaging Methods?................................................. 16-1<br />

16.1.2 Choosing a Messaging Method ...................................................................... 16-3<br />

16.1.3 SIMATIC Components.................................................................................... 16-5<br />

16.1.4 Parts of a Message......................................................................................... 16-5<br />

16.1.5 Which Message Blocks Are Available? .......................................................... 16-6<br />

16.1.6 Formal Parameters, System Attributes, <strong>and</strong> Message Blocks ....................... 16-8<br />

16.1.7 Message Type <strong>and</strong> Messages........................................................................ 16-9<br />

16.1.8 How to Generate an STL Source File from Message-Type Blocks.............. 16-10<br />

16.1.9 Assigning Message Numbers....................................................................... 16-10<br />

16.1.10 Differences Between Project-Oriented <strong>and</strong> CPU-Oriented Assignment of<br />

Message Numbers........................................................................................ 16-11<br />

16.1.11 Options for Modifying the Message Number Assignment of a Project......... 16-11<br />

16.2 Project-Oriented Message Configuration ..................................................... 16-12<br />

16.2.1 How to Assign Project-Oriented Message Numbers .................................... 16-12<br />

16.2.2 Assigning <strong>and</strong> Editing Block-Related Messages .......................................... 16-12<br />

16.2.2.1 How to Create Block-Related Messages (Project-Oriented)........................ 16-13<br />

16.2.2.2 How to Edit Block-Related Messages (Project-Oriented)............................. 16-16<br />

16.2.2.3 How to Configure PCS 7 Messages (Project-Oriented) ............................... 16-16<br />

16.2.3 Assigning <strong>and</strong> Editing Symbol-Related Messages....................................... 16-18<br />

16.2.3.1 How to Assign <strong>and</strong> Edit Symbol-Related Messages (Project-Oriented) ...... 16-18<br />

16.2.4 Creating <strong>and</strong> Editing User-Defined Diagnostic Messages ........................... 16-19<br />

16.3 CPU-Oriented Message Configuration......................................................... 16-20<br />

16.3.1 How to Assign CPU-Oriented Message Numbers........................................ 16-20<br />

16.3.2 Assigning <strong>and</strong> Editing Block-Related Messages .......................................... 16-21<br />

16.3.2.1 How to Create Block-Related Messages (CPU-Oriented)............................ 16-21<br />

16.3.2.2 How to Edit Block-Related Messages (CPU-Oriented) ................................ 16-24<br />

16.3.2.3 How to Configure PCS 7 Messages (CPU-Oriented)................................... 16-25<br />

16.3.3 Assigning <strong>and</strong> Editing Symbol-Related Messages....................................... 16-26<br />

16.3.3.1 How to Assign <strong>and</strong> Edit Symbol-Related Messages (CPU-Oriented) .......... 16-26<br />

16.3.4 Assigning <strong>and</strong> Editing User-Specific Diagnostic Messages ......................... 16-27<br />

16.4 Tips for Editing Messages ............................................................................ 16-28<br />

16.4.1 Adding Associated Values to Messages ...................................................... 16-28<br />

16.4.2 Integrating Texts from Text Libraries into Messages ................................... 16-30<br />

16.4.3 Deleting Associated Values.......................................................................... 16-31<br />

16.5 Translating <strong>and</strong> Editing Operator Related Texts .......................................... 16-32<br />

16.5.1 Translating <strong>and</strong> Editing User Texts .............................................................. 16-32<br />

xii<br />

<strong>Programming</strong> <strong>with</strong> STEP 7<br />

A5E00706944-01

Contents<br />

16.6 Translating <strong>and</strong> Editing Text Libraries .......................................................... 16-34<br />

16.6.1 User Text Libraries ....................................................................................... 16-34<br />

16.6.2 Creating User Text Libraries......................................................................... 16-34<br />

16.6.3 How to Edit User Text Libraries.................................................................... 16-35<br />

16.6.4 System Text Libraries................................................................................... 16-36<br />

16.6.5 Translating Text Libraries ............................................................................. 16-36<br />

16.7 Transferring Message Configuration Data to the Programmable <strong>Control</strong>ler 16-38<br />

16.8 Displaying CPU Messages <strong>and</strong> User-Defined Diagnostic Messages .......... 16-39<br />

16.8.1 Configuring CPU Messages ......................................................................... 16-42<br />

16.8.2 Displaying Stored CPU Messages ............................................................... 16-42<br />

16.9 Configuring the 'Reporting of System Errors' ............................................... 16-43<br />

16.9.1 Supported Components <strong>and</strong> Functional Scope............................................ 16-45<br />

16.9.2 Settings for "Report System Error" ............................................................... 16-48<br />

16.9.3 Generating Blocks for Reporting System Errors .......................................... 16-49<br />

16.9.4 Generated FB, DB ........................................................................................ 16-49<br />

16.9.5 Creating Foreign-Language Message Texts in 'Report System Error'......... 16-51<br />

17 <strong>Control</strong>ling <strong>and</strong> Monitoring Variables 17-1<br />

17.1 Configuring Variables for Operator <strong>Control</strong> <strong>and</strong> Monitoring ........................... 17-1<br />

17.2 Configuring Operator <strong>Control</strong> <strong>and</strong> Monitoring Attributes<br />

<strong>with</strong> Statement List, Ladder Logic, <strong>and</strong> Function Block Diagram................... 17-3<br />

17.3 Configuring Operator <strong>Control</strong> <strong>and</strong> Monitoring Attributes<br />

via the Symbol Table ...................................................................................... 17-4<br />

17.4 Changing Operator <strong>Control</strong> <strong>and</strong> Monitoring Attributes <strong>with</strong> CFC ................... 17-5<br />

17.5 Transferring Configuration Data to the<br />

Operator Interface Programmable <strong>Control</strong>ler ................................................. 17-6<br />

18 Establishing an Online Connection <strong>and</strong> Making CPU Settings 18-1<br />

18.1 Establishing Online Connections.................................................................... 18-1<br />

18.1.1 Establishing an Online Connection via the "Accessible Nodes" Window....... 18-2<br />

18.1.2 Establishing an Online Connection via the Online Window of the Project ..... 18-3<br />

18.1.3 Online Access to PLCs in a Multiproject......................................................... 18-4<br />

18.1.4 Password Protection for Access to Programmable <strong>Control</strong>lers...................... 18-6<br />

18.1.5 Updating the Window Contents ...................................................................... 18-7<br />

18.2 Displaying <strong>and</strong> Changing the Operating Mode............................................... 18-8<br />

18.2.1 Displaying <strong>and</strong> Changing the Operating Mode............................................... 18-8<br />

18.3 Displaying <strong>and</strong> Setting the Time <strong>and</strong> Date ..................................................... 18-9<br />

18.3.1 CPU Clocks <strong>with</strong> Time Zone Setting <strong>and</strong> Summer/Winter Time .................... 18-9<br />

18.4 Updating the Firmware ................................................................................. 18-10<br />

18.4.1 Updating Firmware in Modules <strong>and</strong> Submodules Online ............................. 18-10<br />

19 Downloading <strong>and</strong> Uploading 19-1<br />

19.1 Downloading from the PG/PC to the Programmable <strong>Control</strong>ler..................... 19-1<br />

19.1.1 Requirements for Downloading ...................................................................... 19-1<br />

19.1.2 Differences Between Saving <strong>and</strong> Downloading Blocks.................................. 19-2<br />

19.1.3 Load Memory <strong>and</strong> Work Memory in the CPU................................................. 19-3<br />

19.1.4 Download Methods Dependent on the Load Memory .................................... 19-4<br />

19.1.5 Downloading a Program to the S7 CPU......................................................... 19-5<br />

19.1.5.1 Downloading <strong>with</strong> Project Management ......................................................... 19-5<br />

19.1.5.2 Downloading <strong>with</strong>out Project Management .................................................... 19-6<br />

19.1.5.3 Reloading Blocks in the Programmable <strong>Control</strong>ler......................................... 19-6<br />

19.1.5.4 Saving Downloaded Blocks on Integrated EPROM ....................................... 19-7<br />

19.1.5.5 Downloading via EPROM Memory Cards ...................................................... 19-7<br />

19.2 Compiling <strong>and</strong> Downloading Several Objects from the PG............................ 19-9<br />

19.2.1 Requirements for <strong>and</strong> Notes on Downloading................................................ 19-9<br />

19.2.2 Compiling <strong>and</strong> Downloading Objects............................................................ 19-11<br />

<strong>Programming</strong> <strong>with</strong> STEP 7<br />

A5E00706944-01<br />

xiii

Contents<br />

19.3 Uploading from the Programmable <strong>Control</strong>ler to the PG/PC........................ 19-13<br />

19.3.1 Uploading a Station ...................................................................................... 19-14<br />

19.3.2 Uploading Blocks from an S7 CPU............................................................... 19-15<br />

19.3.3 Editing Uploaded Blocks in the PG/PC......................................................... 19-16<br />

19.3.3.1 Editing Uploaded Blocks if the User Program is on the PG/PC ................... 19-17<br />

19.3.3.2 Editing Uploaded Blocks if the User Program is Not on the PG/PC............. 19-17<br />

19.4 Deleting on the Programmable <strong>Control</strong>ler .................................................... 19-18<br />

19.4.1 Erasing the Load/Work Memory <strong>and</strong> Resetting the CPU ............................. 19-18<br />

19.4.2 Deleting S7 Blocks on the Programmable <strong>Control</strong>ler ................................... 19-19<br />

19.5 Compressing the User Memory (RAM) ........................................................ 19-20<br />

19.5.1 Gaps in the User Memory (RAM) ................................................................. 19-20<br />

19.5.2 Compressing the Memory Contents of an S7 CPU...................................... 19-21<br />

20 Testing <strong>with</strong> the Variable Table 20-1<br />

20.1 Introduction to Testing <strong>with</strong> Variable Tables .................................................. 20-1<br />

20.2 Basic Procedure when Monitoring <strong>and</strong> Modifying <strong>with</strong> the Variable Table .... 20-2<br />

20.3 Editing <strong>and</strong> Saving Variable Tables................................................................ 20-3<br />

20.3.1 Creating <strong>and</strong> Opening a Variable Table ......................................................... 20-3<br />

20.3.2 Copying/Moving Variable Tables.................................................................... 20-3<br />

20.3.3 Saving a Variable Table.................................................................................. 20-4<br />

20.4 Entering Variables in Variable Table .............................................................. 20-4<br />

20.4.1 Inserting Addresses or Symbols in a Variable Table...................................... 20-4<br />

20.4.2 Inserting a Contiguous Address Range in a Variable Table........................... 20-6<br />

20.4.3 Inserting Modify Values .................................................................................. 20-7<br />

20.4.4 Upper Limits for Entering Timers.................................................................... 20-7<br />

20.4.5 Upper Limits for Entering Counters ................................................................ 20-8<br />

20.4.6 Inserting Comment Lines................................................................................ 20-9<br />

20.4.7 Examples ........................................................................................................ 20-9<br />

20.5 Establishing a Connection to the CPU ......................................................... 20-13<br />

20.6 Monitoring Variables..................................................................................... 20-14<br />

20.6.1 Introduction to Monitoring Variables ............................................................. 20-14<br />

20.6.2 Defining the Trigger for Monitoring Variables............................................... 20-14<br />

20.7 Modifying Variables ...................................................................................... 20-16<br />

20.7.1 Introduction to Modifying Variables .............................................................. 20-16<br />

20.7.2 Defining the Trigger for Modifying Variables ................................................ 20-17<br />

20.8 Forcing Variables.......................................................................................... 20-19<br />

20.8.1 Safety Measures When Forcing Variables ................................................... 20-19<br />

20.8.2 Introduction to Forcing Variables.................................................................. 20-20<br />

20.8.3 Differences Between Forcing <strong>and</strong> Modifying Variables................................ 20-22<br />

21 Testing Using Program Status 21-1<br />

21.1 Program Status Display.................................................................................. 21-2<br />

21.2 What You Should Know About Testing in Single-Step Mode/Breakpoints..... 21-3<br />

21.3 What You Should Know About the HOLD Mode ............................................ 21-5<br />

21.4 Program Status of Data Blocks ...................................................................... 21-6<br />

21.5 Setting the Display for Program Status .......................................................... 21-7<br />

21.6 Setting the Mode for the Test ......................................................................... 21-8<br />

22 Testing using the Simulation Program (Optional Package) 22-1<br />

22.1 Testing using the Simulation Program S7-PLCSIM (Optional Package) ....... 22-1<br />

xiv<br />

<strong>Programming</strong> <strong>with</strong> STEP 7<br />

A5E00706944-01

Contents<br />

23 Diagnostics 23-1<br />

23.1 Hardware Diagnostics <strong>and</strong> Troubleshooting................................................... 23-1<br />

23.2 Diagnostics Symbols in the Online View ........................................................ 23-3<br />

23.3 Diagnosing Hardware: Quick View ................................................................. 23-5<br />

23.3.1 Calling the Quick View.................................................................................... 23-5<br />

23.3.2 Information Functions in the Quick View ........................................................ 23-5<br />

23.4 Diagnosing Hardware: Diagnostic View ......................................................... 23-6<br />

23.4.1 Calling the Diagnostic View ............................................................................ 23-6<br />

23.4.2 Information Functions in the Diagnostic View................................................. 23-8<br />

23.5 Module Information ......................................................................................... 23-9<br />

23.5.1 Options for Displaying the Module Information .............................................. 23-9<br />

23.5.2 Module Information Functions ...................................................................... 23-10<br />

23.5.3 Scope of the Module Type-Dependent Information...................................... 23-12<br />

23.5.4 Displaying the Module Status of PA Field Devices <strong>and</strong><br />

DP Slaves After a Y-Link .............................................................................. 23-13<br />

23.6 Diagnosing in STOP Mode ........................................................................... 23-15<br />

23.6.1 Basic Procedure for Determining the Cause of a STOP .............................. 23-15<br />

23.6.2 Stack Contents in STOP Mode..................................................................... 23-15<br />

23.7 Checking Scan Cycle Times to Avoid Time Errors....................................... 23-17<br />

23.8 Flow of Diagnostic Information ..................................................................... 23-18<br />

23.8.1 System Status List SSL ................................................................................ 23-19<br />

23.8.2 Sending Your Own Diagnostic Messages .................................................... 23-22<br />

23.8.3 Diagnostic Functions .................................................................................... 23-23<br />

23.9 Program Measures for H<strong>and</strong>ling Errors........................................................ 23-24<br />

23.9.1 Evaluating the Output Parameter RET_VAL ................................................ 23-25<br />

23.9.2 Error OBs as a Reaction to Detected Errors ................................................ 23-26<br />

23.9.3 Inserting Substitute Values for Error Detection ............................................ 23-31<br />

23.9.4 I/O Redundancy Error (OB70) ...................................................................... 23-33<br />

23.9.5 CPU Redundancy Error (OB72) ................................................................... 23-34<br />

23.9.6 Time Error (OB80) ........................................................................................ 23-35<br />

23.9.7 Power Supply Error (OB81).......................................................................... 23-36<br />

23.9.8 Diagnostic Interrupt (OB82).......................................................................... 23-37<br />

23.9.9 Insert/Remove Module Interrupt (OB83) ...................................................... 23-38<br />

23.9.10 CPU Hardware Fault (OB84)........................................................................ 23-39<br />

23.9.11 Program Sequence Error (OB85) ................................................................. 23-40<br />

23.9.12 Rack Failure (OB86)..................................................................................... 23-41<br />

23.9.13 Communication Error (OB87) ....................................................................... 23-42<br />

23.9.14 <strong>Programming</strong> Error (OB121) ........................................................................ 23-43<br />

23.9.15 I/O Access Error (OB122)............................................................................. 23-44<br />

24 Printing <strong>and</strong> Archiving 24-1<br />

24.1 Printing Project Documentation ...................................................................... 24-1<br />

24.1.1 Basic Procedure when Printing ...................................................................... 24-2<br />

24.1.2 Print Functions................................................................................................ 24-2<br />

24.1.3 Special Note on Printing the Object Tree ....................................................... 24-3<br />

24.2 Archiving Projects <strong>and</strong> Libraries ..................................................................... 24-4<br />

24.2.1 Uses for Saving/Archiving............................................................................... 24-5<br />

24.2.2 Requirements for Archiving ............................................................................ 24-5<br />

24.2.3 Procedure for Archiving/Retrieving................................................................. 24-6<br />

25 Working <strong>with</strong> M7 Programmable <strong>Control</strong> Systems 25-1<br />

25.1 Procedure for M7 Systems ............................................................................. 25-1<br />

25.2 Optional Software for M7 <strong>Programming</strong> ......................................................... 25-3<br />

25.3 M7-300/M7-400 Operating Systems............................................................... 25-6<br />

<strong>Programming</strong> <strong>with</strong> STEP 7<br />

A5E00706944-01<br />

xv

Contents<br />

26 Tips <strong>and</strong> Tricks 26-1<br />

26.1 Exchanging Modules in the Configuration Table............................................ 26-1<br />

26.2 Projects <strong>with</strong> a Large Number of Networked Stations.................................... 26-1<br />

26.3 Rearranging .................................................................................................... 26-2<br />

26.4 Editing Symbols Across Multiple Networks .................................................... 26-2<br />

26.5 Testing <strong>with</strong> the Variable Table ...................................................................... 26-3<br />

26.6 Modifying Variables With the Program Editor................................................. 26-4<br />

26.7 Virtual Work Memory ...................................................................................... 26-5<br />

A Appendix A-1<br />

A.1 Operating Modes ..............................................................................................A-1<br />

A.1.1 Operating Modes <strong>and</strong> Mode Transitions ..........................................................A-1<br />

A.1.2 STOP Mode ......................................................................................................A-4<br />

A.1.3 STARTUP Mode ...............................................................................................A-5<br />

A.1.4 RUN Mode ......................................................................................................A-13<br />

A.1.5 HOLD Mode....................................................................................................A-14<br />

A.2 Memory Areas of S7 CPUs.............................................................................A-15<br />

A.2.1 Distribution of the Memory Areas ...................................................................A-15<br />

A.2.2 Load Memory <strong>and</strong> Work Memory ...................................................................A-16<br />

A.2.3 System Memory..............................................................................................A-18<br />

A.2.3.1 Using the System Memory Areas ...................................................................A-18<br />

A.2.3.2 <strong>Process</strong>-Image Input/Output Tables...............................................................A-20<br />

A.2.3.3 Local Data Stack.............................................................................................A-24<br />

A.2.3.4 Interrupt Stack ................................................................................................A-25<br />

A.2.3.5 Block Stack .....................................................................................................A-26<br />

A.2.3.6 Diagnostic Buffer ............................................................................................A-27<br />

A.2.3.7 Evaluating the Diagnostic Buffer ....................................................................A-27<br />

A.2.3.8 Retentive Memory Areas on S7-300 CPUs....................................................A-29<br />

A.2.3.9 Retentive Memory Areas on S7-400 CPUs....................................................A-30<br />

A.2.3.10 Configurable Memory Objects in the Work Memory.......................................A-31<br />

A.3 Data Types <strong>and</strong> Parameter Types..................................................................A-32<br />

A.3.1 Introduction to Data Types <strong>and</strong> Parameter Types..........................................A-32<br />

A.3.2 Elementary Data Types ..................................................................................A-33<br />

A.3.2.1 Format of the Data Type INT (16-Bit Integers)...............................................A-34<br />

A.3.2.2 Format of the Data Type DINT (32-Bit Integers) ............................................A-34<br />

A.3.2.3 Format of the Data Type REAL (Floating-Point Numbers).............................A-35<br />

A.3.2.4 Format of the Data Types WORD <strong>and</strong> DWORD in<br />

Binary Coded Decimal Numbers ....................................................................A-39<br />

A.3.2.5 Format of the Data Type S5TIME (Time Duration) ........................................A-40<br />

A.3.3 Complex Data Types ......................................................................................A-41<br />

A.3.3.1 Format of the Data Type DATE_AND_TIME..................................................A-42<br />

A.3.3.2 Using Complex Data Types............................................................................A-44<br />

A.3.3.3 Using Arrays to Access Data..........................................................................A-45<br />

A.3.3.4 Using Structures to Access Data....................................................................A-48<br />

A.3.3.5 Using User-Defined Data Types to Access Data ...........................................A-50<br />

A.3.4 Parameter Types ............................................................................................A-52<br />

A.3.4.1 Format of the Parameter Types BLOCK, COUNTER, TIMER .......................A-53<br />

A.3.4.2 Format of the Parameter Type POINTER ......................................................A-53<br />

A.3.4.3 Using the Parameter Type POINTER.............................................................A-54<br />

A.3.4.4 Block for Changing the Pointer.......................................................................A-55<br />

A.3.4.5 Format of the Parameter Type ANY ...............................................................A-58<br />

A.3.4.6 Using the Parameter Type ANY .....................................................................A-61<br />

A.3.4.7 Assigning Data Types to Local Data of Logic Blocks .....................................A-64<br />

A.3.4.8 Permitted Data Types when Transferring Parameters ...................................A-66<br />

A.3.4.9 Transferring to IN_OUT Parameters of a Function Block...............................A-71<br />

xvi<br />

<strong>Programming</strong> <strong>with</strong> STEP 7<br />

A5E00706944-01

Contents<br />

Index<br />

A.4 Working <strong>with</strong> Older Projects ...........................................................................A-72<br />

A.4.1 Converting Version 1 Projects ........................................................................A-72<br />

A.4.2 Converting Version 2 Projects ........................................................................A-73<br />

A.4.3 Notes on STEP 7 V.2.1 Projects <strong>with</strong> GD Communication ............................A-74<br />

A.4.4 DP-Slaves <strong>with</strong> Missing or Faulty GSD Files..................................................A-74<br />

A.5 Sample Programs ...........................................................................................A-75<br />

A.5.1 Sample Projects <strong>and</strong> Sample Programs.........................................................A-75<br />

A.5.2 Sample Program for an Industrial Blending <strong>Process</strong>......................................A-77<br />

A.5.2.1 Defining Logic Blocks .....................................................................................A-79<br />

A.5.2.2 Assigning Symbolic Names ............................................................................A-81<br />

A.5.2.3 Creating the FB for the Motor .........................................................................A-83<br />

A.5.2.4 Creating the FC for the Valves .......................................................................A-88<br />

A.5.2.5 Creating OB1 ..................................................................................................A-90<br />

A.5.3 Example of H<strong>and</strong>ling Time-of-Day Interrupts .................................................A-96<br />

A.5.3.1 Structure of the User Program "Time-of-Day Interrupts"................................A-96<br />

A.5.3.2 FC12 ...............................................................................................................A-98<br />

A.5.3.3 OB10.............................................................................................................A-100<br />

A.5.3.4 OB1 <strong>and</strong> OB80 .............................................................................................A-102<br />

A.5.4 Example of H<strong>and</strong>ling Time-Delay Interrupts.................................................A-104<br />

A.5.4.1 Structure of the User Program "Time-Delay Interrupts" ...............................A-104<br />

A.5.4.2 OB20.............................................................................................................A-106<br />

A.5.4.3 OB1...............................................................................................................A-108<br />

A.5.4.4 Example of Masking <strong>and</strong> Unmasking Synchronous Errors ..........................A-110<br />

A.5.4.5 Example of Disabling <strong>and</strong> Enabling Interrupts <strong>and</strong><br />

Asynchronous Errors (SFC39 <strong>and</strong> SFC40) ..................................................A-115<br />

A.5.4.6 Example of the Delayed <strong>Process</strong>ing of Interrupts <strong>and</strong><br />

Asynchronous Errors (SFC41 <strong>and</strong> SFC42) ..................................................A-116<br />

A.6 Accessing <strong>Process</strong> <strong>and</strong> I/O Data Areas .......................................................A-117<br />

A.6.1 Accessing the <strong>Process</strong> Data Area ................................................................A-117<br />

A.6.2 Accessing the Peripheral Data Area.............................................................A-118<br />

A.7 Setting the Operating Behavior ....................................................................A-120<br />

A.7.1 Changing the Behavior <strong>and</strong> Properties of Modules......................................A-121<br />

A.7.2 Updating the Firmware (of the Operating System) in<br />

Modules <strong>and</strong> Submodules Offline.................................................................A-124<br />

A.7.3 Using the Clock Functions............................................................................A-126<br />

A.7.4 Using Clock Memory <strong>and</strong> Timers .................................................................A-128<br />

Index-1<br />

<strong>Programming</strong> <strong>with</strong> STEP 7<br />

A5E00706944-01<br />

xvii

Contents<br />

xviii<br />

<strong>Programming</strong> <strong>with</strong> STEP 7<br />

A5E00706944-01

1 Introducing the Product <strong>and</strong> Installing the<br />

Software<br />

1.1 Overview of STEP 7<br />

What is STEP 7?<br />

STEP 7 is the st<strong>and</strong>ard software package used for configuring <strong>and</strong> programming<br />

SIMATIC programmable logic controllers. It is part of the SIMATIC industry<br />

software. There are the following versions of the STEP 7 St<strong>and</strong>ard package:<br />

• STEP 7 Micro/DOS <strong>and</strong> STEP 7 Micro/Win for simpler st<strong>and</strong>-alone applications<br />

on the SIMATIC S7-200.<br />

• STEP 7 for applications on SIMATIC S7-300/S7-400, SIMATIC M7-300/M7-400,<br />