Download - Palfinger

Download - Palfinger

Download - Palfinger

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

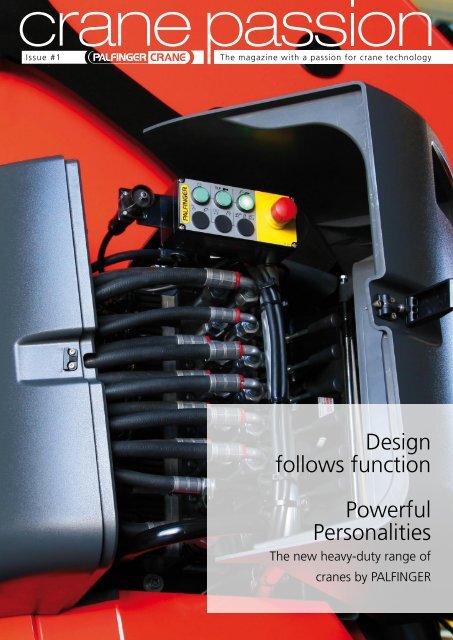

Issue #1<br />

The magazine with a passion for crane technology<br />

Design<br />

follows function<br />

Powerful<br />

Personalities<br />

The new heavy-duty range of<br />

cranes by PALFINGER

palfinger – passion – performance – power – perfection<br />

We proudly present "crane passion"<br />

Dear Partners and<br />

best loading crane" – that has been our<br />

Friends of PALFINGER,<br />

driving force for 50 years!<br />

With the creation of our new magazine<br />

crane passion, we have launched a on up to High Performance. With our<br />

In the meantime, PALFINGER has moved<br />

publication whose sole aim is to explore new High Performance line, successfully<br />

PALFINGER’s crane technology. It represents,<br />

in other words, a clear commit-<br />

plainly illustrated our leading role in<br />

launched in September, 2007, we have<br />

ment to our core competency. Cranes the loading crane sector. And now, as<br />

in all of their complexity – from the we follow up with the first model of<br />

development to the production phase – our new heavy-duty range, we clearly<br />

will be the focus of the magazine. confirm PALFINGER’s technological<br />

dominance in the market.<br />

With this publication we hope to give<br />

our customers an idea of the PALFINGER Get ready for some dynamic personalities,<br />

both hip and replete with inner<br />

world of crane technology and also<br />

convey a sense of PALFINGER’s unique qualities. Get ready for the new crane<br />

spirit – since there’s a lot more than generation by PALFINGER!<br />

just technology behind a PALFINGER<br />

crane. A "true PALFINGER" is the sum of<br />

passion, emotion, vision and individuals,<br />

plus a sound, global corporation with a Wolfgang Pilz<br />

sense of responsibility.<br />

CMO and managing director of the<br />

crane and hookloader divisions<br />

Passion has many facets. Passion for<br />

innovation, technology, aesthetics and<br />

perfection – with the understanding<br />

of being the leader in technology. For<br />

PALFINGER it is not enough to merely<br />

rank among the best: "To build the Enjoy reading!

A Passion for<br />

Crane Technology<br />

crane passion | 3

Table of Contents<br />

Editorial 2–3<br />

Design follows function 6–7<br />

Powerful Personalities 8–9<br />

The Art of Finding the<br />

Right Material 10–11<br />

What Else You’ll Find in a<br />

PALFINGER High Performance<br />

Heavy-Duty Crane 12–13<br />

Protecting the Environment<br />

is Second Nature 14–15<br />

Cranes with a Profile 16–19<br />

crane passion | 5

follows function<br />

What you’ll find in a PALFINGER product<br />

is more than just the sum of its steel,<br />

hydraulic and electronic components.<br />

As compared to the competition, the<br />

added benefits of our products lie in the<br />

experience, stability, responsibility, and<br />

clearly defined areas of expertise that<br />

went into making them. The factors<br />

underlying our success include our<br />

readiness to meet the ever-changing<br />

demands of the market, our exceptional<br />

commitment to research and development,<br />

our state-of-the-art production<br />

facilities, as well as our permanent focus<br />

on design.<br />

Our passion for continual improvement<br />

in functionality, efficiency and safety is<br />

the mainspring for the innovative and<br />

on-going development of our products.<br />

Our cooperation with universities forms<br />

the basis for a wealth of patents and<br />

technical innovations.<br />

"Innovation results from our passion<br />

for the continual improvement of our<br />

products, processes and organization."<br />

Good design is not just a question of<br />

good taste. As a global player in the<br />

market, we simply owe our customers<br />

good design!<br />

These days, even hydraulic machinery<br />

and lifting systems are expected to<br />

meet ever-increasing demands regarding<br />

automation, comfort, ergonomics,<br />

and intelligent control technologies.<br />

PALFINGER meets these demands headon<br />

with its routine design studies and<br />

by intelligently implementing new ideas<br />

into its products.<br />

Functional design elements increase<br />

on-the-job comfort and facilitate service<br />

and maintenance. In addition to its<br />

functional advantages, a visually attractive<br />

product will also serve as a priceless<br />

advertising tool for its operators.<br />

The knowledge gained from over four<br />

years of development, the constructive<br />

feedback from numerous clients, as<br />

well as the know-how acquired from 50<br />

years in the crane business all went into<br />

the new High Performance crane generation.<br />

"The highest quality at competitive<br />

prices" has always been our goal. In<br />

order to meet these high standards, we<br />

have focused our attention on "quality"<br />

design.<br />

crane passion | 6

Quality design must first of all serve its<br />

purpose – that is, it has to be functional.<br />

But more than that, it also has to<br />

be simple, attractive and economically<br />

viable.<br />

The new design elements of the High<br />

Performance crane include attractive<br />

covers and casings out of premium<br />

synthetics that protect the crane from<br />

damage and weather, a newly designed<br />

control stand, along with many other<br />

clever details. Numerous tests and field<br />

studies contributed to the design of<br />

the new control stand, which is unique<br />

in terms of shape, appearance and<br />

comfort!<br />

A Dialogue on Design<br />

Development<br />

For PALFINGER design is evolutionary:<br />

innovation and development are truly an<br />

ongoing, fluid process. Acting on new<br />

ideas while improving old ones is a team<br />

effort, a dialogue among clients, dealers,<br />

product management, engineers, and<br />

sales and service staff.<br />

Realizing that "the customer is the best<br />

developer", we always have an open<br />

ear for customer demands and ideas.<br />

In the development phase, we attempt<br />

to incorporate features into our new<br />

machinery which will ultimately benefit<br />

the customer in terms of on-the-job<br />

comfort, technical advancements, safety,<br />

and assembly and service friendliness.<br />

Naturally, our service partners are also in<br />

close contact with our customers. Their<br />

demands, too, are incorporated into<br />

our products. In periodic quality circles<br />

comprised of service, development, and<br />

quality control departments, market<br />

needs and ideas are analyzed, forwarded<br />

and integrated into the future development<br />

of our products.<br />

"Direct contact with dealers and crane<br />

operators is very important to me. Starting<br />

with these initial contacts, our design<br />

process takes place 'from the inside<br />

out' with a team of engineers, product<br />

management and marketing staff,"<br />

states the industrial designer Heinrich<br />

Krug. He has been designing PALFINGER<br />

cranes for 15 years.<br />

crane passion | 7

Powerful<br />

Personalities:<br />

The new heavy-duty<br />

range of cranes by<br />

PALFINGER<br />

Innovative technology, functional<br />

and attractive design,<br />

comfortable equipment, and<br />

exceptional capacity have all<br />

joined together for the new<br />

PALFINGER High Performance<br />

heavy-duty crane.<br />

Finally! This is the crane the industry has<br />

been waiting for: "one class stronger"<br />

than its predecessor, unmatched in<br />

style, and outfitted, so to speak, in a<br />

tailor-made suit complete with clever<br />

design elements – the new PK 50002<br />

EH High Performance!<br />

Under the banner "Reduce to the max",<br />

our new stylistic vocabulary is with<br />

it. – In terms of design and selection<br />

of materials. Synthetic cover elements<br />

dominate the appearance. The synthetic<br />

covers over the control valve, slewing<br />

system and hydraulic hoses are all real<br />

eye-catchers.<br />

Synthetic covers protect sensitive crane<br />

components against dirt and impact.<br />

That reduces service and maintenance<br />

time and greatly extends the life of your<br />

loading crane.<br />

A crane that immediately stands out<br />

from the crowd with its new stylistic<br />

vocabulary. A crane in both concept and<br />

performance – just like a PALFINGER<br />

should be.<br />

PALFINGER. The most intelligent<br />

interpretation since the introduction<br />

of loading cranes.<br />

crane passion | 9

The Art of<br />

finding<br />

the rightMAterial<br />

At PALFINGER, nothing is left to chance. The synthetics, along with their manufacturing process,<br />

for all cover and functional design elements were specially developed in collaboration with<br />

universities and synthetics experts from the auto industry.<br />

The synthetics used in the crane column<br />

casings are manufactured by means of<br />

the R-RIM process (Reinforced Reaction<br />

Injection Molding).<br />

Wherever ergonomics, durability and<br />

shock-absorbent elements are called for,<br />

parts molded out of polyurethane foam<br />

are the ideal solution. Density, shore<br />

hardness, tensile strength, color and the<br />

fitting of fasteners and reinforcement<br />

elements can all be perfectly adjusted to<br />

each other. Surfaces can be designed in<br />

a wide array of options through the use<br />

of various structures and colors. The R-<br />

RIM production process makes optimal<br />

design and the robust, yet light-weight<br />

construction of crane casings possible.<br />

Another advantage of the R-RIM process<br />

is that small components can first<br />

be inserted into the tool form before<br />

the reaction takes place. This so-called<br />

"insertion technique" enables the small<br />

components to be integrated directly<br />

and stably into the design parts before<br />

being secured by foam.<br />

crane passion | 10

All crane column casings are applied<br />

with a pearl structure coating for longlasting<br />

UV protection.<br />

Qualities of synthetic casings<br />

at a glance:<br />

- Optimal light-weight construction<br />

- Ergonomic shapes<br />

- High resistance to temperature<br />

and UV rays<br />

- Premium appearance and surface feel<br />

- Impact-resistant, sturdy and robust<br />

Job-oriented stress tests confirm<br />

the durability of synthetic<br />

casings.<br />

The process: In R-RIM (Reinforced reaction<br />

injection molding) two components<br />

(polyol and isocyanate) and a flexibilizer<br />

are mixed in a so-called mix head to<br />

increase impact resistance and injected<br />

under high pressure into a molding<br />

tool. The exothermic reaction of the<br />

components produces the thermoset<br />

plastic polyurethane, which can then be<br />

removed from the tool.<br />

Treads designed to be both functional<br />

and highly resistant are produced with<br />

the aid of a polyamide plastic reinforced<br />

with fiber glass. These components<br />

are formed using the well-established<br />

injection molding process.<br />

ca. 80-90 kg<br />

ca. 30 kg<br />

crane passion | 11

Double slewing mechanism<br />

with two rotary drives<br />

Maintenance-free boom<br />

extension system<br />

Internally routed hose guide<br />

on the main boom<br />

The source of power. The double slewing<br />

mechanism with two rotary drives is<br />

absolutely unique in this performance<br />

class. Since the two gears are hydraulically<br />

oppositely prestressed, the crane’s<br />

slewing play is reduced to a minimum – a<br />

priceless advantage for jobs requiring a<br />

high outreach.<br />

PALFINGER’s maintenance-free boom<br />

extension system is a clear commitment<br />

to service-friendliness and environmental<br />

protection. The use of sliding elements<br />

made from special synthetic material<br />

and the well-established KTL cathotic<br />

dip painting means that the operator no<br />

longer needs to service the boom system.<br />

That not only saves time and money, but<br />

also protects the environment.<br />

The hydraulic hoses between the main<br />

and outer booms are internally routed.<br />

This invention, which is to be patented,<br />

provides protection against dirt and<br />

damage.

crane passion | 13<br />

Integrated oil tank<br />

Cable winch<br />

PALFINGER "inside"<br />

Integrating the oil tank on the base<br />

helps to save space. Additional room for<br />

installation on the chassis is no longer<br />

necessary.<br />

The lateral cable guide of the cable<br />

winch on crane/fly jib combinations is<br />

the smart answer to questions of how<br />

to increase comfort, facilitate work and<br />

save time. The cable can be sheaved and<br />

remain in transport position, thus making<br />

unthreading of the cable, disassembly of<br />

the trolley head, and intermediate and<br />

reversing pulleys all things of the past.<br />

In addition to the perfect hardware, the<br />

new cranes are also distinguished by<br />

their numerous "soft skills" which make<br />

life easier for their operators:<br />

KTL, PAL 50, RRC, AOS, DPS, ISC<br />

Also available is a laterally tiltable cable<br />

winch, which minimizes the total height<br />

of the crane.

Protecting the Environment<br />

is Second Nature<br />

Innovation – Comfort – Safety –<br />

Environmental protection<br />

In addition to its passion for ongoing improvements in<br />

functionality, efficiency and safety, PALFINGER is also aware<br />

of its responsibility towards people (employees, dealers and<br />

customers) and the environment. Sustainability, careful management<br />

of resources, and product ecology are thus firmly<br />

anchored in its corporate philosophy. The use of environmentally<br />

compatible, recyclable and biodegradable substances<br />

and materials is second nature to PALFINGER.<br />

With the introduction of its new High Performance line,<br />

PALFINGER is not only paving the way towards intelligent<br />

consolidation – by "simply making the best even better" –<br />

but is also aiming for product ecology and recyclability. Steel<br />

components, hydraulic valves, brackets and pipes can all be<br />

completely recycled.

Maintenance-free boom extension system<br />

The sliding elements are molded from special synthetic material and have self-lubricating<br />

properties. No further servicing is required after the primary lubrication, in which the<br />

same grease is used as in the food industry. All other elements (slide rails, slide blocks,<br />

etc.) run without grease. They have only a secondary function as sliding elements; they<br />

are primarily adjustment and guiding elements. Special synthetic materials are also used<br />

for these elements in order to protect the boom against corrosion.<br />

Environmentally compatible coating technology<br />

PALFINGER High Performance cranes are coated by cathotic dip painting. In addition<br />

to the benefits of KTL coating, the environmental compatibility of both the paints and<br />

the painting process is also striking: the two-pack paints used in the process are watersoluble.<br />

Chromium VI-free surfaces of pipes, small parts and fittings<br />

All hydraulic pipes, fittings, small parts and brackets found on PALFINGER<br />

High Performance cranes are also coated using chromium VI-free methods.<br />

Biodegradable hydraulic oil<br />

On request, PALFINGER offers its customers a fully synthetic, environmentally sound hydraulic<br />

oil with rapid biodegradability for environmental crane operation. This oil guarantees<br />

smooth, year-round operation even under extreme conditions and when subjected to<br />

large changes in temperature.<br />

Lightweight construction saves resources<br />

A PALFINGER crane is a "lightweight" – that means, a higher payload and lower operating<br />

costs. The lightweight construction reduces the crane’s fuel consumption and thus<br />

makes a significant contribution towards reducing CO2 emissions.<br />

Load sensing – reduced fuel consumption<br />

By fitting the control unit with a proportional valve capable of load sensing, PALFINGER<br />

cranes are ready for efficient and economical variable displacement pump operation.<br />

The advantages are clear: less fuel consumption (fuel savings of up to 20%!), enhanced<br />

capacity for precision and multi-function control, and less stress on the entire hydraulic<br />

system since the oil remains cooler!<br />

Choosing a PALFINGER crane is a corporate decision that aims for value,<br />

reliability and sustainability.<br />

crane passion | 15

Cranes<br />

with a<br />

Profile

"Deluxe" Hexagonal<br />

Tube Production<br />

Hexagonal tubes are an essential component<br />

of a crane’s boom extension<br />

system. Naturally, the more precisely<br />

these parts can be produced, the more<br />

precisely the entire crane will be able to<br />

function.<br />

In recent years PALFINGER has been<br />

working at full tilt to increase the<br />

production capacity for all product areas<br />

and to heighten the efficiency of the<br />

production flow. The investments made<br />

focus on optimizing processes – which<br />

means, reducing lead time and inventory<br />

as well as maximizing quality and<br />

productivity. One component of the<br />

€ 80 million capital investment program<br />

is the new hexagonal tube production<br />

line at the Lengau plant in Austria.<br />

The basis of PALFINGER’s success is<br />

its technological superiority, driven by<br />

innovation, and its high level of product<br />

quality. A cornerstone of this success is<br />

its commitment to research & development<br />

and its implementation of the<br />

latest production technologies<br />

With its expansive quality campaign,<br />

based on ambitious and comprehensive<br />

investments in new production technologies<br />

at PALFINGER production sites,<br />

the PALFINGER Group has created the<br />

framework which will allow it to uphold<br />

its high quality standards of its products<br />

in the future.<br />

The modernization and expansion of<br />

the existing hexagonal tube production<br />

plant in Lengau firmly aims to achieve<br />

the following goals: to increase production<br />

capacity by approximately 40%,<br />

to increase efficiency by introducing a<br />

high level of automation, to improve<br />

product quality and process safety, to<br />

expand PALFINGER’s role as the leader in<br />

technology, and to secure the Austrian<br />

production site at Lengau for the longterm.<br />

Continued on page 18/19<br />

crane passion | 17

crane passion | 18<br />

Continues from page 16/17<br />

Hexagonal tubes<br />

Hexagonal tubes are an essential component<br />

of a crane’s boom extension system.<br />

The so-called extension and outer booms<br />

are based on hexagonal section tubes,<br />

which are manufactured out of highstrength<br />

steel with utmost precision. Workers<br />

attach additional steel components to<br />

these sections which are then welded by robots<br />

in perfect, reproducible quality. Thanks<br />

to the new technology, high-strength steel<br />

can be processed with utmost precision.<br />

Even the slightest production deviations can<br />

thereby be avoided, resulting in even more<br />

precise crane movements.<br />

The new plant<br />

The new plant is highly automated. It is<br />

comprised of the latest 4 and 5 KW laser<br />

cutting machines, new 800to and 1000to<br />

edging machines, new longitudinal welding<br />

and alignment machinery, as well as several<br />

new robotic welding systems. An edge-angle<br />

correction system and automatic alignment<br />

of the sections increase the sectional<br />

accuracy of the parts. The new longitudinal<br />

welding system, with its optimal clamping<br />

concept and optical locking of the welding<br />

gap, guarantees penetration welding and,<br />

thus, the best possible welding quality.<br />

The new small-parts edging machine, with<br />

edge-angle correction system for better use<br />

with robots, increases the precision of small<br />

parts.

KP-Cranep01+E<br />

PALFINGER AG · 5101 Bergheim/Salzburg, Austria · E-Mail info@palfinger.com · www.palfinger.com