April 2009 - Low Resolution - PAWPRINT PUBLISHING

April 2009 - Low Resolution - PAWPRINT PUBLISHING

April 2009 - Low Resolution - PAWPRINT PUBLISHING

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

NEWS<br />

Sign of the times: ArtCAM at CD&M<br />

IT TAKES a certain spirit to give<br />

up a lucrative career and dive<br />

headfirst into a new industry,<br />

but that’s exactly the scenario<br />

that gave birth to one of the top<br />

US sign companies.<br />

Classic Design and Manufacturing<br />

(CD&M) near downtown Pensacola<br />

(previously known as<br />

Classic Sign & Mirror), was opened<br />

22 years ago by Michael Sheehan.<br />

At the time, Mike was a licensed<br />

aircraft technician in Louisiana for<br />

a company that leased helicopters<br />

to the oil industry. However, Mike<br />

wanted to break free from his job<br />

and to take his hobby as a sign<br />

maker to a commercial level.<br />

Nevertheless, Mike’s background<br />

in aviation came in handy<br />

in the “everyday” inner workings of<br />

the business. It allowed CD&M to<br />

appreciate the newest, state-ofthe-art<br />

technology and this includes<br />

ArtCAM, artistic computer<br />

aided design and manufacturing<br />

software (CAD/CAM) from Delcam,<br />

based in Birmingham.<br />

“We were one of the first Art-<br />

CAM customers in the US because I knew straight away that it was so much more than just a design product. It’s the output to whatever you are going<br />

to make from the beginning to end. It’s the whole package.”<br />

Mike began changing the business’s focus towards manufacturing when a hurricane hit, leaving total devastation. However, Mike saved a lot of his own<br />

frequently used shapes, symbols and logos in ArtCAM by using the Relief<br />

& Vector Library, which allowed CD&M to continue producing quality designs<br />

quickly, even in a reduced capacity. “Good comes out of everything,”<br />

Mike said. “With ArtCAM we were able to expand upon the products and<br />

services we offered, as well as it being a big part of rebuilding our facility.”<br />

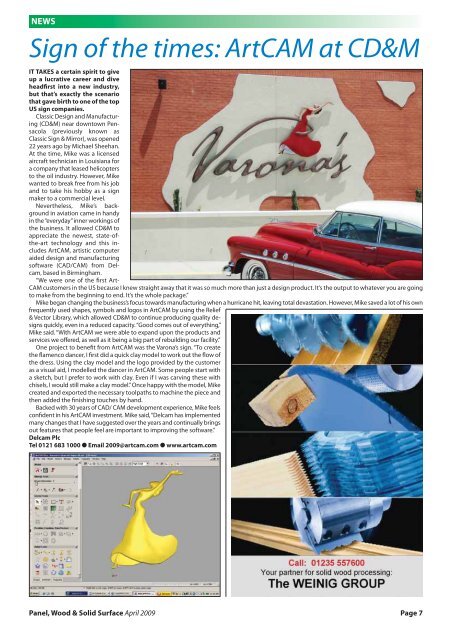

One project to benefit from ArtCAM was the Varona’s sign. “To create<br />

the flamenco dancer, I first did a quick clay model to work out the flow of<br />

the dress. Using the clay model and the logo provided by the customer<br />

as a visual aid, I modelled the dancer in ArtCAM. Some people start with<br />

a sketch, but I prefer to work with clay. Even if I was carving these with<br />

chisels, I would still make a clay model.” Once happy with the model, Mike<br />

created and exported the necessary toolpaths to machine the piece and<br />

then added the finishing touches by hand.<br />

Backed with 30 years of CAD/ CAM development experience, Mike feels<br />

confident in his ArtCAM investment. Mike said, “Delcam has implemented<br />

many changes that I have suggested over the years and continually brings<br />

out features that people feel are important to improving the software.”<br />

Delcam Plc<br />

Tel 0121 683 1000 ● Email <strong>2009</strong>@artcam.com ● www.artcam.com<br />

Panel, Wood & Solid Surface <strong>April</strong> <strong>2009</strong> Page 7