Annual Report 2010 - Pfisterer

Annual Report 2010 - Pfisterer

Annual Report 2010 - Pfisterer

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

GROUP<br />

CoC Overhead Lines<br />

CoC Railway Catenary Systems<br />

High-speed project Ninghang<br />

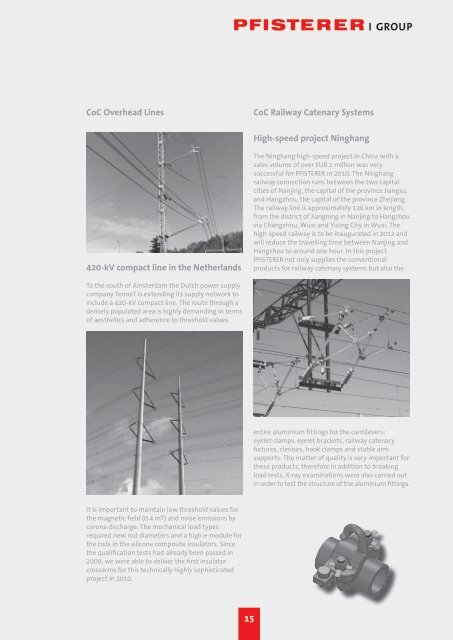

420-kV compact line in the Netherlands<br />

The Ninghang high-speed project in China with a<br />

sales volume of over EUR 1 million was very<br />

successful for PFISTERER in <strong>2010</strong>. The Ninghang<br />

railway connection runs between the two capital<br />

cities of Nanjing, the capital of the province Jiangsu,<br />

and Hangzhou, the capital of the province Zhejiang.<br />

The railway line is approximately 136 km in length,<br />

from the district of Jiangning in Nanjing to Hangzhou<br />

via Changzhou, Wuxi and Yixing City in Wuxi. The<br />

high-speed railway is to be inaugurated in 2012 and<br />

will reduce the travelling time between Nanjing and<br />

Hangzhou to around one hour. In this project<br />

PFISTERER not only supplies the conventional<br />

products for railway catenary systems but also the<br />

To the south of Amsterdam the Dutch power supply<br />

company TenneT is extending its supply network to<br />

include a 420-kV compact line. The route through a<br />

densely populated area is highly demanding in terms<br />

of aesthetics and adherence to threshold values.<br />

entire aluminium fittings for the cantilevers:<br />

eyelet clamps, eyelet brackets, railway catenary<br />

fixtures, clevises, hook clamps and stable arm<br />

supports. The matter of quality is very important for<br />

these products, therefore in addition to breaking<br />

load tests, X-ray examinations were also carried out<br />

in order to test the structure of the aluminium fittings.<br />

It is important to maintain low threshold values for<br />

the magnetic field (0.4 mT) and noise emissions by<br />

corona discharge. The mechanical load types<br />

required new rod diameters and a high e-module for<br />

the rods in the silicone composite insulators. Since<br />

the qualification tests had already been passed in<br />

2009, we were able to deliver the first insulator<br />

crossarms for this technically highly sophisticated<br />

project in <strong>2010</strong>.<br />

15