Download Issue PDF - Platinum Metals Review

Download Issue PDF - Platinum Metals Review

Download Issue PDF - Platinum Metals Review

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

doi:10.1595/147106709X481660<br />

•<strong>Platinum</strong> <strong>Metals</strong> Rev., 2010, 54, (1)•<br />

Mass change at 400ºC, g<br />

0.5<br />

0<br />

-0.5<br />

-1<br />

-1.5<br />

-2<br />

Uncoated DPF<br />

No DOC<br />

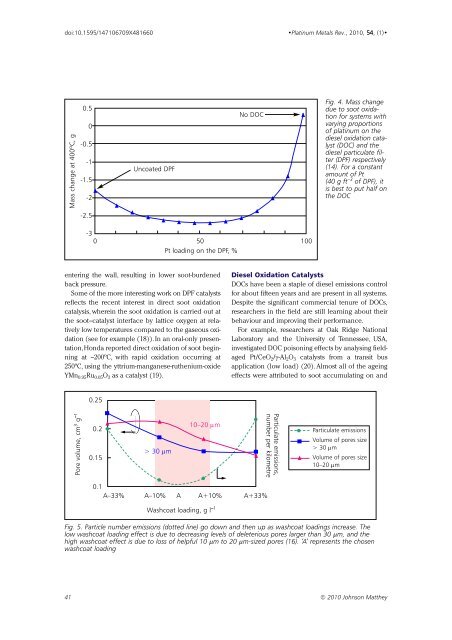

Fig. 4. Mass change<br />

due to soot oxidation<br />

for systems with<br />

varying proportions<br />

of platinum on the<br />

diesel oxidation catalyst<br />

(DOC) and the<br />

diesel particulate filter<br />

(DPF) respectively<br />

(14). For a constant<br />

amount of Pt<br />

(40gft –3 of DPF), it<br />

is best to put half on<br />

the DOC<br />

-2.5<br />

-3<br />

0 50 100<br />

Pt loading on the DPF, %<br />

entering the wall, resulting in lower soot-burdened<br />

back pressure.<br />

Some of the more interesting work on DPF catalysts<br />

reflects the recent interest in direct soot oxidation<br />

catalysis, wherein the soot oxidation is carried out at<br />

the soot–catalyst interface by lattice oxygen at relatively<br />

low temperatures compared to the gaseous oxidation<br />

(see for example (18)). In an oral-only presentation,Honda<br />

reported direct oxidation of soot beginning<br />

at ~200ºC, with rapid oxidation occurring at<br />

250ºC, using the yttrium-manganese-ruthenium-oxide<br />

YMn 0.95 Ru 0.05 O 3 as a catalyst (19).<br />

Diesel Oxidation Catalysts<br />

DOCs have been a staple of diesel emissions control<br />

for about fifteen years and are present in all systems.<br />

Despite the significant commercial tenure of DOCs,<br />

researchers in the field are still learning about their<br />

behaviour and improving their performance.<br />

For example, researchers at Oak Ridge National<br />

Laboratory and the University of Tennessee, USA,<br />

investigated DOC poisoning effects by analysing fieldaged<br />

Pt/CeO 2 /γ-Al 2 O 3 catalysts from a transit bus<br />

application (low load) (20). Almost all of the ageing<br />

effects were attributed to soot accumulating on and<br />

0.25<br />

Pore volume, cm 3 g –1<br />

0.2<br />

0.15<br />

> 30 μm<br />

10–20 μm<br />

0.1<br />

A–33% A–10% A A+10% A+33%<br />

Particulate emissions,<br />

number per kilometre<br />

Particulate emissions<br />

Volume of pores size<br />

> 30 μm<br />

Volume of pores size<br />

10–20 μm<br />

Washcoat loading, g l –1<br />

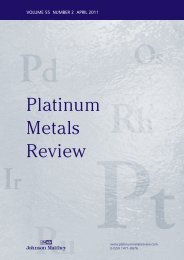

Fig. 5. Particle number emissions (dotted line) go down and then up as washcoat loadings increase. The<br />

low washcoat loading effect is due to decreasing levels of deleterious pores larger than 30 μm, and the<br />

high washcoat effect is due to loss of helpful 10 μm to 20 μm-sized pores (16). ‘A’ represents the chosen<br />

washcoat loading<br />

41 © 2010 Johnson Matthey