Download Issue PDF - Platinum Metals Review

Download Issue PDF - Platinum Metals Review

Download Issue PDF - Platinum Metals Review

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

doi:10.1595/147106709X481372<br />

•<strong>Platinum</strong> <strong>Metals</strong> Rev., 2010, 54, (1)•<br />

with Ru-2 in 2 h at an S:C ratio of 100 and a temperature<br />

of 40ºC (73, 74). With the azeotropic HCOOH-<br />

NEt 3 mixture as the reductant, the same catalyst<br />

required about 60 h to complete the reduction (97%<br />

ee) at 28ºC and an S:C ratio of 200 (26). Likewise,<br />

1-acetonaphthone was reduced to (R)-1-(1-naphthyl)-<br />

ethanol with Ru-2 by aqueous HCOONa in 98% conversion<br />

and 87% ee in 6 h at 40ºC and an S:C ratio of<br />

100; but in the azeotropic HCOOH-NEt 3 mixture with<br />

Ru-1, a conversion of only 71% was achieved in 30 h<br />

at 50ºC (120). In the aqueous phase ATH, there<br />

appears to be no correlation between the electronic<br />

properties of substituents and the enantioselectivity,<br />

as shown by the reduction of para-OMe- and<br />

para-CF 3 -acetophenone with Ru-2, which both gave<br />

~95% ee in 2 h.<br />

For practical applications, easy separation of the<br />

catalyst and product is necessary. The Ru-1 catalyst<br />

allows for this, due to its hydrophilic PEG chain,<br />

which retains the catalyst in the water during<br />

product extraction with, for example, diethyl ether. In<br />

the case of acetophenone reduction, we measured<br />

the leached Ru; inductively coupled plasma (ICP)<br />

analysis showed that only 0.4 mol% of Ru leached<br />

into the organic phase. Remarkably, the PEG-immobilised<br />

catalyst could be reused fourteen times with<br />

no loss in enantioselectivity, demonstrating its excellent<br />

recyclability and lifetime under aqueous conditions.<br />

When HCOOH-NEt 3 was used without water,<br />

the recycle experiments could not be carried out for<br />

more than two runs without the rates and ees being<br />

eroded.<br />

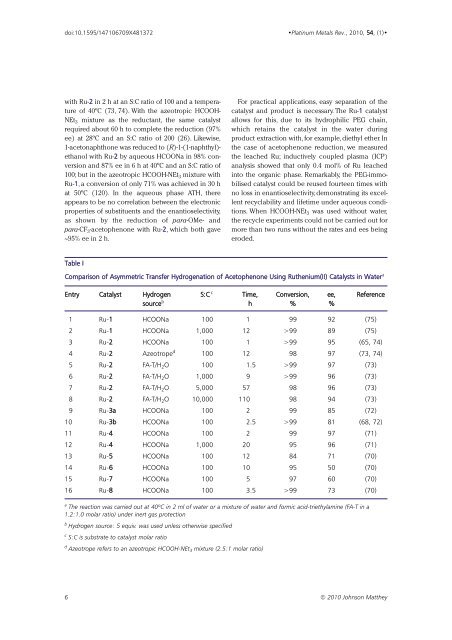

Table I<br />

Comparison of Asymmetric Transfer Hydrogenation of Acetophenone Using Ruthenium(II) Catalysts in Water a<br />

Entry Catalyst Hydrogen S:C c Time, Conversion, ee, Reference<br />

source b h % %<br />

1 Ru-1 HCOONa 100 1 99 92 (75)<br />

2 Ru-1 HCOONa 1,000 12 >99 89 (75)<br />

3 Ru-2 HCOONa 100 1 >99 95 (65, 74)<br />

4 Ru-2 Azeotrope d 100 12 98 97 (73, 74)<br />

5 Ru-2 FA-T/H 2 O 100 1.5 >99 97 (73)<br />

6 Ru-2 FA-T/H 2 O 1,000 9 >99 96 (73)<br />

7 Ru-2 FA-T/H 2 O 5,000 57 98 96 (73)<br />

8 Ru-2 FA-T/H 2 O 10,000 110 98 94 (73)<br />

9 Ru-3a HCOONa 100 2 99 85 (72)<br />

10 Ru-3b HCOONa 100 2.5 >99 81 (68, 72)<br />

11 Ru-4 HCOONa 100 2 99 97 (71)<br />

12 Ru-4 HCOONa 1,000 20 95 96 (71)<br />

13 Ru-5 HCOONa 100 12 84 71 (70)<br />

14 Ru-6 HCOONa 100 10 95 50 (70)<br />

15 Ru-7 HCOONa 100 5 97 60 (70)<br />

16 Ru-8 HCOONa 100 3.5 >99 73 (70)<br />

a The reaction was carried out at 40ºC in 2 ml of water or a mixture of water and formic acid-triethylamine (FA-T in a<br />

1.2:1.0 molar ratio) under inert gas protection<br />

b Hydrogen source: 5 equiv. was used unless otherwise specified<br />

c S:C is substrate to catalyst molar ratio<br />

d Azeotrope refers to an azeotropic HCOOH-NEt 3 mixture (2.5:1 molar ratio)<br />

6 © 2010 Johnson Matthey