What does QMS look like in the Cloud? - Plex Systems

What does QMS look like in the Cloud? - Plex Systems

What does QMS look like in the Cloud? - Plex Systems

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Plex</strong> Onl<strong>in</strong>e<br />

Quality Management System (<strong>QMS</strong>)<br />

Quality Management System provides complete coverage for<br />

every department with<strong>in</strong> a manufacturer.<br />

<strong>Plex</strong> Onl<strong>in</strong>e’s Quality Management System (<strong>QMS</strong>) <strong>in</strong>cludes more than 40 <strong>in</strong>terconnected<br />

functions across eng<strong>in</strong>eer<strong>in</strong>g, quality and manufactur<strong>in</strong>g to imbed quality <strong>in</strong>to every part of<br />

manufacturers’ operations. Manufacturers benefit from <strong>in</strong>creased process repeatability,<br />

reduced variation, <strong>in</strong>creased production throughput and reduced defects.<br />

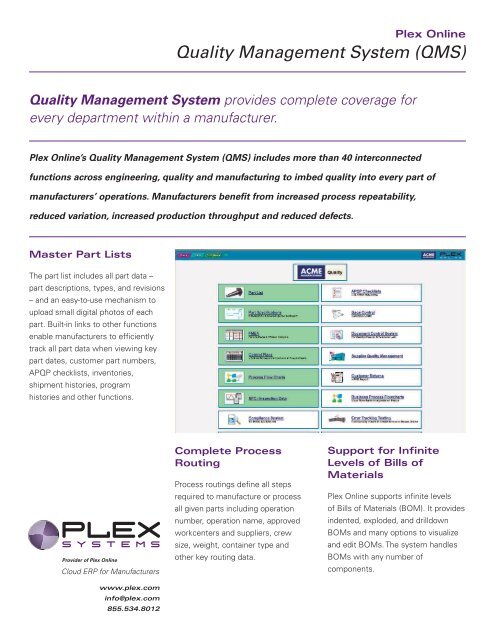

Master Part Lists<br />

The part list <strong>in</strong>cludes all part data –<br />

part descriptions, types, and revisions<br />

– and an easy-to-use mechanism to<br />

upload small digital photos of each<br />

part. Built-<strong>in</strong> l<strong>in</strong>ks to o<strong>the</strong>r functions<br />

enable manufacturers to efficiently<br />

track all part data when view<strong>in</strong>g key<br />

part dates, customer part numbers,<br />

APQP checklists, <strong>in</strong>ventories,<br />

shipment histories, program<br />

histories and o<strong>the</strong>r functions.<br />

Provider of <strong>Plex</strong> Onl<strong>in</strong>e<br />

<strong>Cloud</strong> ERP for Manufacturers<br />

www.plex.com<br />

<strong>in</strong>fo@plex.com<br />

855.534.8012<br />

Complete Process<br />

Rout<strong>in</strong>g<br />

Process rout<strong>in</strong>gs def<strong>in</strong>e all steps<br />

required to manufacture or process<br />

all given parts <strong>in</strong>clud<strong>in</strong>g operation<br />

number, operation name, approved<br />

workcenters and suppliers, crew<br />

size, weight, conta<strong>in</strong>er type and<br />

o<strong>the</strong>r key rout<strong>in</strong>g data.<br />

Support for Inf<strong>in</strong>ite<br />

Levels of Bills of<br />

Materials<br />

<strong>Plex</strong> Onl<strong>in</strong>e supports <strong>in</strong>f<strong>in</strong>ite levels<br />

of Bills of Materials (BOM). It provides<br />

<strong>in</strong>dented, exploded, and drilldown<br />

BOMs and many options to visualize<br />

and edit BOMs. The system handles<br />

BOMs with any number of<br />

components.

<strong>Plex</strong> Onl<strong>in</strong>e<br />

Quality Management System (<strong>QMS</strong>)<br />

Comprehensive CAD<br />

Reduces Data Entry<br />

<strong>Plex</strong> Onl<strong>in</strong>e numbers and names<br />

each dimension on part draw<strong>in</strong>gs,<br />

<strong>the</strong>n synchronizes dimensions and<br />

<strong>the</strong>ir tolerances to part specification<br />

lists which <strong>in</strong> turn drive control plans,<br />

checksheets, and data collection. This<br />

saves manufacturers from hav<strong>in</strong>g to<br />

type <strong>in</strong> dimensional data and ensures<br />

complete coverage across Eng<strong>in</strong>eer<strong>in</strong>g,<br />

Quality and Manufactur<strong>in</strong>g. The<br />

system is used with AutoCAD 2004<br />

but will also work with most o<strong>the</strong>r<br />

CAD systems.<br />

Part Specifications<br />

Manufacturers establish and ma<strong>in</strong>ta<strong>in</strong><br />

detailed lists of dimensions and characteristics<br />

on specific parts, <strong>in</strong>clud<strong>in</strong>g<br />

target values and tolerances.<br />

Process Flow Charts<br />

<strong>Plex</strong> Onl<strong>in</strong>e enables manufacturers to<br />

create <strong>in</strong>dustry-standard, presentation<br />

quality process flow diagrams driven<br />

from <strong>the</strong> parts’ process rout<strong>in</strong>gs.<br />

FMEA Creation,<br />

Edit<strong>in</strong>g and View<strong>in</strong>g<br />

Manufacturers create, edit and view<br />

QS/ISO-9000-required Failure Mode &<br />

Effects Analyses (FMEAs) on screen.<br />

The system accommodates common<br />

and part-specific FMEAs.<br />

Flexible Control Plans<br />

Manufacturers create, edit and view<br />

QS/ISO-9000-required control plans<br />

and detailed <strong>in</strong>spection <strong>in</strong>structions<br />

on screen – <strong>in</strong>clud<strong>in</strong>g sample<br />

frequencies, gages, types of control<br />

charts, and o<strong>the</strong>r quality data. <strong>Plex</strong><br />

Onl<strong>in</strong>e accommodates common<br />

and detailed control plans, and<br />

automatically l<strong>in</strong>ks control plans<br />

with manufacturers’ part<br />

specification systems.<br />

Dynamic Control Plans<br />

<strong>Plex</strong> Onl<strong>in</strong>e enables manufacturers<br />

to comply with <strong>the</strong> AIAG/Ford Motors’<br />

<strong>in</strong>dustry quality standard that requires<br />

comb<strong>in</strong>ed specification-level control<br />

plans with process FMEA methodology,<br />

Gage R&Rs and Cp/Cpks.<br />

Checksheet and<br />

Process Instruction<br />

Author<strong>in</strong>g<br />

Manufacturers can author process<br />

<strong>in</strong>structions and checksheets that<br />

are fully <strong>in</strong>tegrated with, and driven<br />

from, control plans. Users can enter<br />

<strong>in</strong>spection data directly <strong>in</strong>to <strong>the</strong><br />

onscreen checksheet, validate it<br />

aga<strong>in</strong>st <strong>the</strong> specification limits, and<br />

store that data <strong>in</strong> <strong>the</strong> <strong>Plex</strong> Onl<strong>in</strong>e<br />

database.<br />

Statistical Process<br />

Controls (SPCs)<br />

<strong>Plex</strong> Onl<strong>in</strong>e’s Statistical Process<br />

Control (SPC) function collects<br />

<strong>in</strong>spection data and conducts<br />

<strong>in</strong>-process SPCs. It handles capability<br />

studies, dock audits, part layouts, f<strong>in</strong>al<br />

<strong>in</strong>spection sheets, PPAP <strong>in</strong>spections,<br />

and special user-def<strong>in</strong>ed checks. It<br />

performs all statistical calculations<br />

and pr<strong>in</strong>ts a variety of reports, such<br />

as histograms, averages and ranges,<br />

run charts and more. The SPC<br />

function is automatically l<strong>in</strong>ked<br />

with part specification, control<br />

plan and gage control functions.<br />

O<strong>the</strong>r Quality<br />

Functions for<br />

Complete Coverage<br />

<strong>Plex</strong> Onl<strong>in</strong>e’s complete <strong>QMS</strong> also<br />

<strong>in</strong>cludes <strong>the</strong> follow<strong>in</strong>g tools to help<br />

manufacturers analyze and solve<br />

quality issues, meet customer<br />

requirements, and comply with<br />

regulations and audits:<br />

• Problem control – also known as<br />

problem report<strong>in</strong>g and resolution,<br />

corrective action, or customer<br />

concern log<br />

• Cost recovery<br />

• Issue management<br />

• Five whys<br />

• Document control system<br />

• Specification/document<br />

management<br />

• TS-16949, ISO, and AS9100<br />

compliance<br />

• Visio <strong>in</strong>tegration<br />

• Internal and supplier audit<strong>in</strong>g<br />

• Gage control<br />

Provider of <strong>Plex</strong> Onl<strong>in</strong>e<br />

<strong>Cloud</strong> ERP for Manufacturers<br />

www.plex.com<br />

<strong>in</strong>fo@plex.com<br />

855.534.8012